process of the extraction of the iron ore

2019-08-13T04:08:51+00:00

Processes and Procedures in the Extraction of Iron

The extraction of iron from its ores is quite a technical process The iron ore is first roasted in air to produce iron(III) oxide which is mixed with coke and limestone and then further heated to a very high temperature in a blast furnace These materials are loaded into the blast furnace from the top while a blast of hot air is introduced into it from beneath via small pipes known as tuyeres The process of the extraction of iron is carried out by the following steps: Concentration of ore Calcination or Roasting of ore Reduction of ore : Concentration of ore: In this metallurgical operation, the ore is concentrated by removing impurities like soil etc The process involves the crushing and washing of oreEXTRACTION OF IRON EXTRACTION OF IRON FROM This concentrated ore is mixed with limestone (CaCO 3) and Coke and fed into the blast furnace from the top It is in the blast furnace that extraction of iron occurs The extraction of iron from its ore is a long and subdued processExtraction of Iron Metallurgy Blast Furnace and

Extraction of Iron Concentration of Ore An Overview

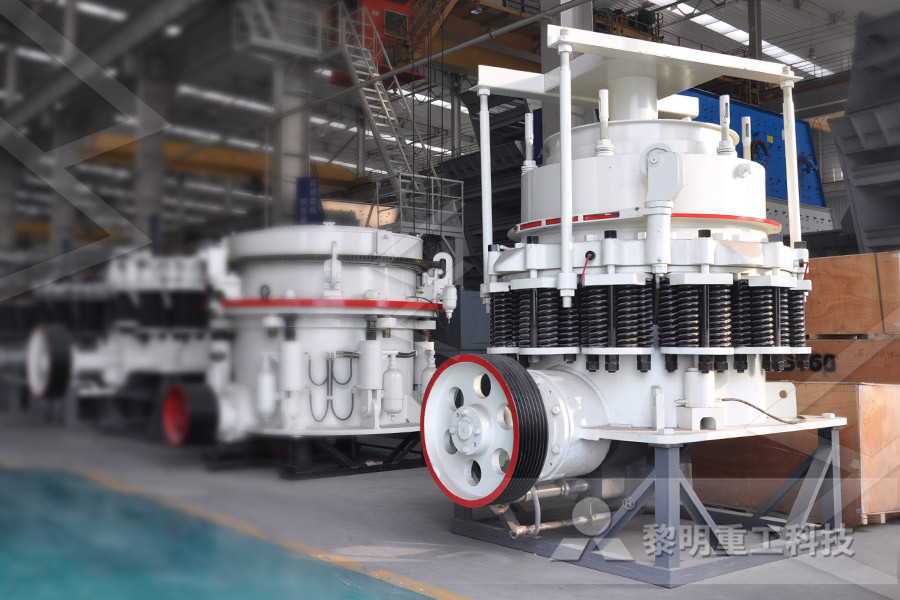

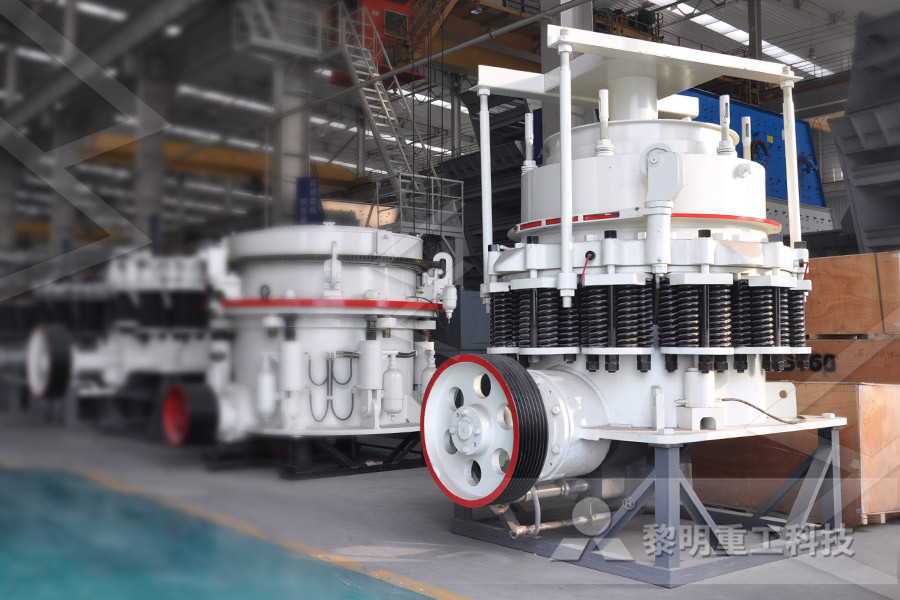

The extraction of iron from its ore is the third and the penultimate process in metallurgy, which is the process of separating metals from their ores The common ores of iron are iron oxides These oxides can be reduced to iron The ore dressing The aim of ore dressing is increasing the concentration of iron in the ore by removing the unwanted impurities and improve the properties of the ore which helps in the successive stages of extraction, The ore dressing process is carried out to improve the physical and mechanical properties of iron ore and includes Crushing process, Sintering processExtraction of Iron from its ores, Iron dressing, The following diagram shows how iron is extracted from iron ore in a blast furnace Scroll down the page for more explanations on extraction of iron Extraction of iron Very unreactive metals are found directly in the ground as elements, eg gold Most metals Extraction of Iron (examples, answers, activities

Iron Ore Mining Techniques Metal Extraction

The extraction of iron from its ore is a very long and forlorn process that separates the useful components from the waste materials such as slag What happens in the Blast Furnace? A blast furnace is a gigantic, steel stack lined with refractory brick where the concentrated iron ore, coke, and limestone are dumped from the top, and a blast of Redox, extraction of iron and transition metals Iron ore (haematite) Iron(III) oxide (Fe 2 O 3) The blast furnace is a continuous process (ie reactants are added constantly so that the Extracting iron Redox, extraction of iron and Magnetite and hematite are iron oxides; however, the extraction of iron from an iron oxide involves a series of steps that begins when mined iron ore is crushed into smaller pieces by a crusher and then washed The second step in the process is calcination or roasting of the ore, which removes certain impurities, carbon dioxide and other How Is Iron Extracted From the Earth? Reference

Common Iron Ore Extraction Processes

Polymetallic weak magnetic iron ore refers to the phosphorous hematite, siderite Most mineral processing plants adopt gravity separation – froth flotation – strong magnetic separation process or a combining process to the extraction of iron ore, and then use the flotation process to recover phosphorus or sulfide Conclusion 02 Hematite iron extraction process As a weakly magnetic iron ore, the hematite contains a small amount of magnetite, uneven dissemination size of impurity, and more fine particles Due to its complex ore properties, gravity separation, flotation, magnetic separation, and the combined process are often used for separationiron extraction process XinhaiIron Ore an overview ScienceDirect Topics Iron ore extraction techniques R Stace, in Iron Ore, 2015 Abstract Iron ore reserves are normally found within a few meters from the ground surface, and most of the major mines of the world are operating an opencut system, which requires little sophistication, except in terms of the equipment used and the quantities needed to be mined foriron ore extraction process marchigianich

steps for the extraction and process iron ore

Extraction of Iron Concentration of Ore An Overview Sep 23, 2019 The extraction of iron from its ore is the third and the penultimate process in metallurgy, which is the process of separating metals from their ores The common ores of iron are iron oxides These oxides can be reduced to iron by heating them with carbon in the form of cokeIron Extraction Process Dillinger Iron Extraction Process In the blast furnace process, the first step on the way towards heavy plate, pig iron is produced from iron oreposition of the ore and additions is accurately adjusted to the final products of AG der Dillinger Hüttenwerke and Saarstahl AG「iron extraction process from iro ore」The following diagram shows how iron is extracted from iron ore in a blast furnace Scroll down the page for more explanations on extraction of iron Extraction of iron Very unreactive metals are found directly in the ground as elements, eg gold Most metals are found in Extraction of Iron (examples, answers, activities

Extraction of Iron, Iron Mining, Iron Ore Processing

The combined iron ore processing technology only used for limonite, includes magnetization magnetic separation process, flotation strong magnetic separation process, gravity separation strong magnetic separation process, etc, which are used for the extraction of iron Iron Ore Mining Techniques Metal Extraction How is iron extracted from its ore? Iron is concentrated by the process of calcinations Once it is concentrated, the water and other volatile impurities such as sulfur and carbonates are removed This concentrated ore is then mixed with limestone and Coke and fed into the blast furnace from the topextraction method of iron ore gondwanauniversity 1 Concentration of Ore 2 Extraction of metal from concentrated ore and 3 Purification of the metal In the following article extraction of iron from its ore in the blast furnace is described in light of these three quintessential steps Extracted iron is used in several ways like building a bridge, house etc The process is very important in Iron Extraction by Blast Furnace Metallurgy

Extraction of Metals All About Minerals, Ores Iron

Extraction of metals is a complicated process and sometimes involves two or more processes to extract the pure element from its ore The extraction of iron from its ore is an important topic for both class 12th board and JEE it is explained as follows: Process of Iron Extraction Iron extraction is done from the following ores: Haematite Fe2O3 Polymetallic weak magnetic iron ore refers to the phosphorous hematite, siderite Most mineral processing plants adopt gravity separation – froth flotation – strong magnetic separation process or a combining process to the extraction of iron ore, and then use the flotation process to recover phosphorus or sulfide ConclusionCommon Iron Ore Extraction ProcessesIron Ore an overview ScienceDirect Topics Iron ore extraction techniques R Stace, in Iron Ore, 2015 Abstract Iron ore reserves are normally found within a few meters from the ground surface, and most of the major mines of the world are operating an opencut system, which requires little sophistication, except in terms of the equipment used and the quantities needed to be mined foriron ore extraction process marchigianich

steps for the extraction and process iron ore

Extraction of Iron Concentration of Ore An Overview Sep 23, 2019 The extraction of iron from its ore is the third and the penultimate process in metallurgy, which is the process of separating metals from their ores The common ores of iron are iron oxides These oxides can be reduced to iron by heating them with carbon in the form of coke Iron Extraction Process Dillinger Iron Extraction Process In the blast furnace process, the first step on the way towards heavy plate, pig iron is produced from iron ore The composition of the ore and additions is accurately adjusted to the final products of AG extraction of iron ore bandrawinefestivalIron Extraction Process Dillinger Iron Extraction Process In the blast furnace process, the first step on the way towards heavy plate, pig iron is produced from iron oreposition of the ore and additions is accurately adjusted to the final products of AG der Dillinger Hüttenwerke and Saarstahl AG「iron extraction process from iro ore」

processes of extraction of iron from its ore

Extraction and beneficiation of ores and minerals545 Кб 111 Mining Industry Profile: Iron 14 IRON MINING PRACTICES Extraction, beneficiation, and processing of iron ore produces iron or steelHowever, the Water Resources Commissions Act and its rules do not apply to iron ore mining operations that affect surface waters owned by or under theIron Ore Mining Techniques Metal Extraction How is iron extracted from its ore? Iron is concentrated by the process of calcinations Once it is concentrated, the water and other volatile impurities such as sulfur and carbonates are removed This concentrated ore is then mixed with limestone and Coke and fed into the blast furnace from the topextraction method of iron ore gondwanauniversityIron does not exist on the Earth as an element, but rather in the form of its oxides and sulphides in iron ore They are the starting materials for the technical extraction of pig iron in the blast furnace The blast furnace operates at 1900 °C in order to smelt iron from iron oreExtraction of iron by the blast furnace process

the process of extracting iron from its ore

Direct Biohydrometallurgical Extraction of Iron from Ore The ironreduction process for extracting lead from its ores, as practiced in different parts of the world, is The slag is lighter than molten iron and to floats on the surface of the iron The formation of prevents the oxidation of iron d Zone of Reduction:This is the most important zone and has temperature of 600700 0 c In this zone Fe 2 O 3 is reduced to iron by co in three steps 3Fe 2 O 3 + CO → 2Fe 3 O 4 + CO 2Extraction of Iron from Haematite Grade 12 Science

crushing takes place in a jaw crusher

taper end mill products

stone crusher plant stone crusher plant manufacturers

mobile crusher demand bolivia

mineral mining ncentration

machines grinding milling

harga crusher run 2014

manufacturing of silica cement

crusher capacity and its driving power

sand making crusher machine

dolimite mobile crusher supplier in angola

smb stone crusher machines

introductory mining engineering documents

worlds best stone crushing plant

hot jaw crusher crushing machine manufacturer for mining

mining grinding balls for sale

impact crusher designed plant

stone crusher with deck in Algeria

one jaw crusher price stone jaw crusher price for sale

sale road building ne crusher with high efficiency

DXN ne crusher price

small crushing grinding plant

track crawler mounted mobile crusher plants

puffer gold drywasher how to build

improving production capacities of a limestone crushing plant

cement aggregates washing and crushing process

quarrying equipment in ghana for gold mining

rotor milling grinding

vanadium ore quarry machine

Micro Calcite Superfine Grinding Mill