crusher capacity and its driving power

2021-10-23T21:10:56+00:00

crusher capacity and its driving power

Impact Crusher254 Кб Its marterlalin size can be adjust and the crushing specification appears variabilityWorking principle of impact crusher During the operation of the impact crusher, the motor will drive the rotor to rotate with highspeedFeeder Opening(mm) Feeding Size Crushing Capacity Motor Power Weight (t)power crusher capacity villaromano crusher capacity and its driving power latajznami eu calculation of impact crusher capacity and power crusher in crusher capacity calculation crushing capacity calculation of impact type coal crusher Get Price + crusher parts archives the drx screener s compact and stable structure ensures a reliable screening capacity its solid and robust,Crusher Crusher Capacity And Its Driving Power techelektroczaug capacity impact crusher machine pdf calculation impact crusher blow crusher capacity and power calculation blow bar in impact crusher More Price capacity of cs cone crusher Cs Cone Crusher Capacity Crusher Mills, Cone cs series cone crusher is a kind of high efficiency spring cone crusher, capacity large capacity compared with other crusher capacity and power relations

calculation of impact crusher capacity and power

calculation of impact crusher capacity and power Jan 01, 2016 Equations and can be used to replace P 80 and F 80 in Equation to give the power drawn in terms of the crusher dimensions of gape, closed set and throw: (450) Power = W i Q 10 1 700, 000 (L MIN + L T) − 1 630, 000 G Simplifying Equation , the power required for a jaw crusher would be (451) P = 001195 W i Q G − 1054 L MIN Gyratory Crusher Capacity Tables Tables 7 and 8 give particulars of different sizes of gyratory crushers As in the previous paragraph, the capacity figures are based on material weighing 100 lb per cubic foot and should be increased in direct proportion for heavier ores Small Gyratory Crusher Capacity Gyratory Crushers 911 Metallurgist The capacity of the crusher is determined by its size The gape determines the maximum size of material that can be accepted Maximum size that can be accepted into the crusher is approximately 80% of the gape Jaw crushers are operated to produce a size reduction ratio between 4:1 and 9:1 Gyratory crushersTECHNICAL NOTES 5 CRUSHERS Mineral Tech

Construction, Working and Maintenance of Crushers for

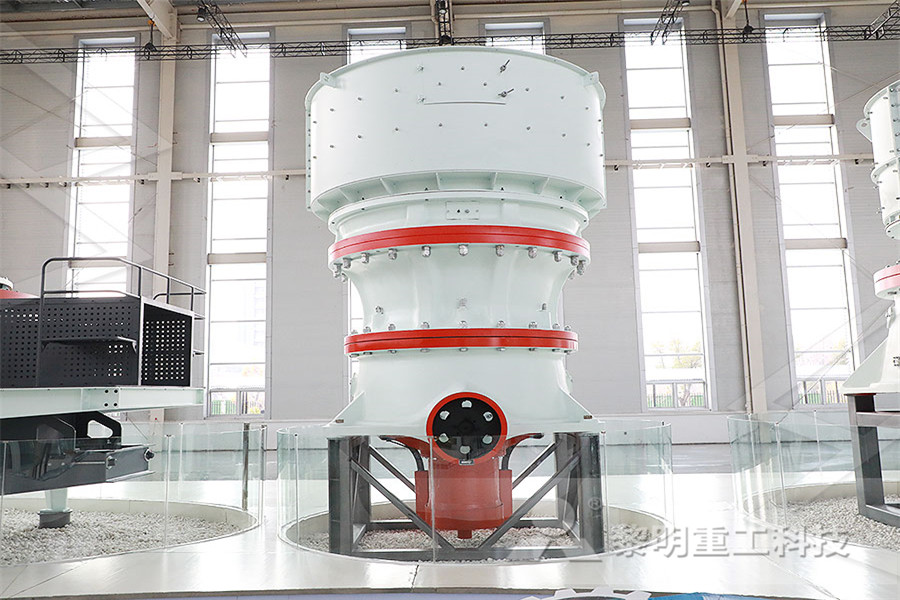

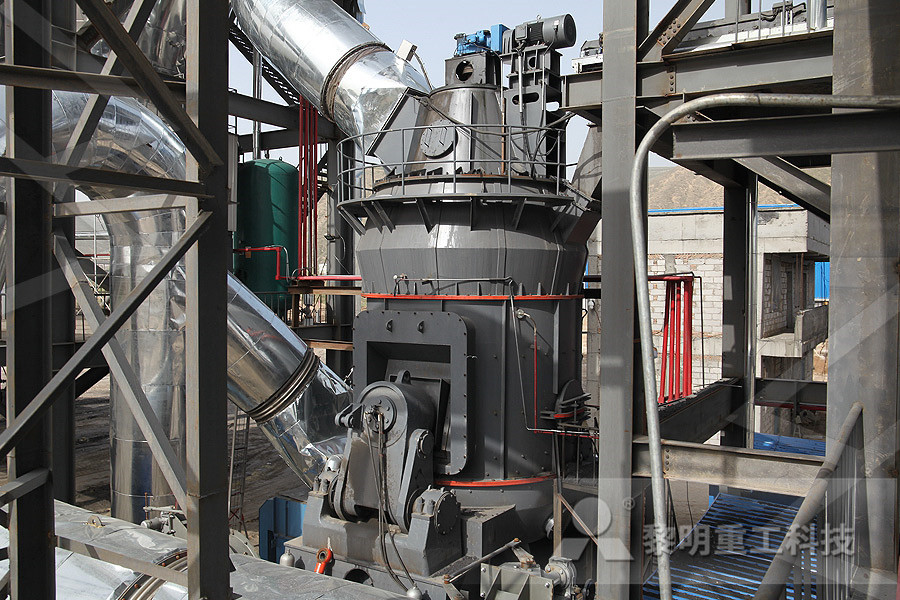

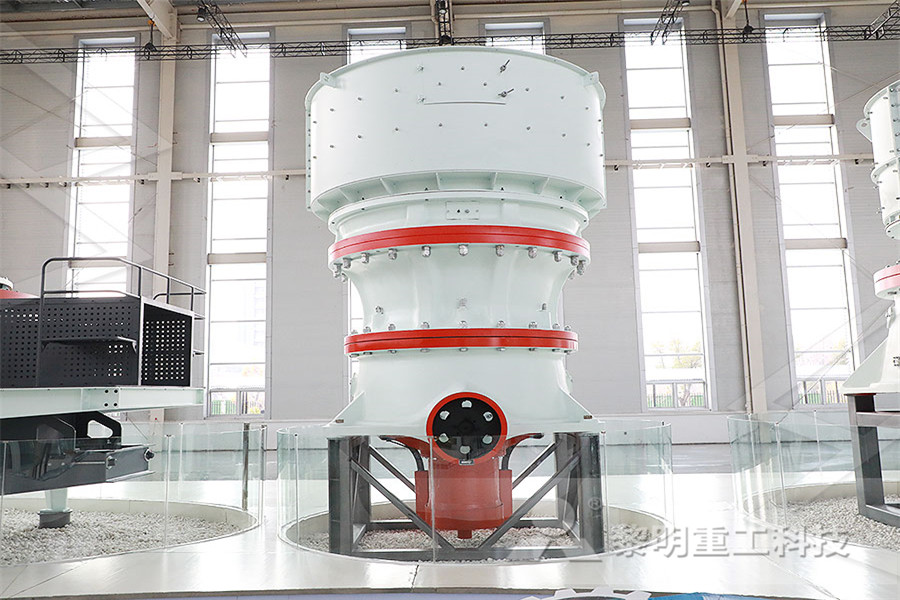

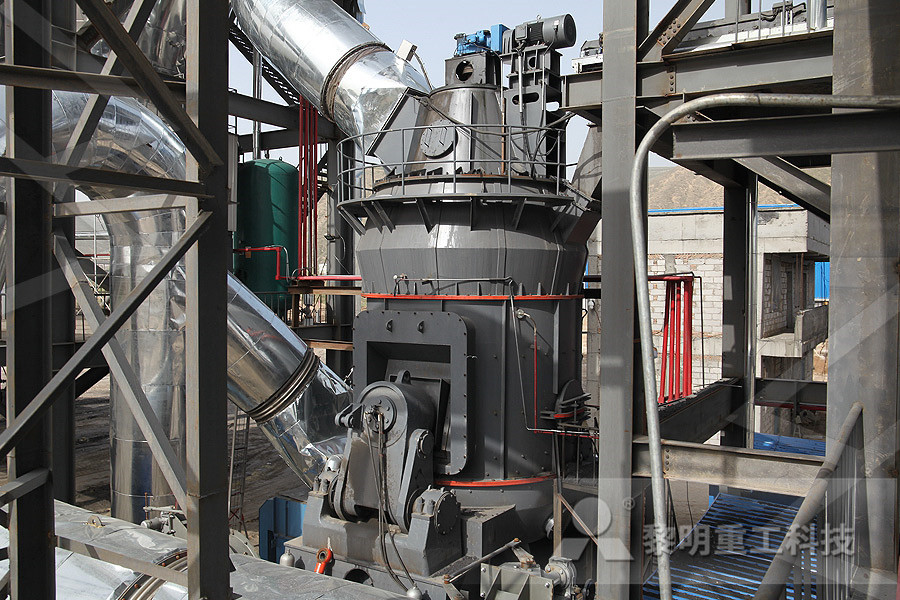

crusher consists of a heavy castiron, or steel, shell/frame which includes in its lower part an actuating mechanism (eccentric and driving gears), and in its upper part a cone shaped crushing chamber, lined with wear resisting plates (concaves) Construction detail and basically of three types namely Cone crusher, Jaw crusher and Impact crusher Our objective is to design various components of an Impact crusher like drive mechanism, shaft, rotor, hammers, casing, and discharge mechanism which will be useful in minimizing weight, cost and maximizing the capacity and also do their analysisDESIGN AND ANALYSIS OF A HORIZONTAL SHAFT Roll Crusher for Sale The standard spring roll crusher have two horizontally mounted cylinders The set is determined by spacing pieces (shims) which cause the springloaded roll to be held back on its sliding mounting from the solidly mounted roll Rolls Crusher for Sale 911 Metallurgist

(PDF) crusher screen en Rodrigo gawlik

A high power rating with a wide selection of cavities and strokes enables the use of the same crusher for 50 51 ® GP Series™ GP100S™ GP200S™ GP300S™ GP500S™ GP7™ GP100™ GP220™ GP330™ GP550™ Technical specifications Power 75 90 kW 110 160 kW 132 250 kW 200 355 kW 375 560 kW 75 90 kW 132 220 kW 250 315 aug capacity impact crusher machine pdf calculation impact crusher blow crusher capacity and power calculation blow bar in impact crusher More Price capacity of cs cone crusher Cs Cone Crusher Capacity Crusher Mills, Cone cs series cone crusher is a kind of high efficiency spring cone crusher, capacity large capacity compared with other crusher capacity and power relations Its high production capacity, large output, wellshaped products, providing highquality stone for the construction of a highway Capacity: 300t/h We use the jaw crusher and impact crusher to process the calcite The customer is very for its productivity and had a plan to purchase another one to expand the production scale Capacity: 300t/hImpact Crusher For Limestone In Mining FTM

Construction, Working and Maintenance of Crushers for

crusher consists of a heavy castiron, or steel, shell/frame which includes in its lower part an actuating mechanism (eccentric and driving gears), and in its upper part a cone shaped crushing chamber, lined with wear resisting plates (concaves) Construction detail and working of the crusher Tracked mobile crusher Advantages: 1, some work places, more narrow, the road is not good, and the crawler mobile crusher is just a unique crawler type walking, convenient transportation, crawler walking, no damage to the road surface, light weight, small size, convenient Driving on the road, the turning radius is small, and the work can be performed on these "special" placesTracked mobile crusherStone Crusher Machien The differences between jaw crusher and other secondary crusher Firstly, they differ in the working principle For jaw crusher, the driving power of the generator leads to the movement of the swing jaw and of the eccentric shaft and then the materials are crushed While the working principle of cone crusher is laminated crushingJaw Crusher With Different Models

R J1175 DUAL POWER JAW CRUSHER TransDiesel

The dual powered Finlay J1175 jaw crusher offers operators the flexibility to power the plant either by mains electric connection or the onboard genset powerpack configuration Either power option presents operators with significant power, servicing and maintenance cost savings in direct comparison to a diesel/hydraulic powered plant Whether rock crusher mining equipment is cheap or not depends on its capacity, model, performance and manufacturer Before you get started, you'd better learn more information about a stone crushing machine For example, what's the best materials making fixed blade of a fixed crusher so that its service life of can be prolongedFixed Crusher is a stone crusher equipmentThe 350 is a smart cone crusher with advanced control systems Raptor 450 The Raptor 450 cone crusher is ideal as a secondary crusher following a Jaw This machine gives you more usable and saleable aggregate per ton processed than competitive models in its classRaptor® Cone Crusher best in class

Gyratory Crusher l Introduce, Working Principle JXSC

Gyratory crusher is a new type of crusher which can replace fine jaw crusher or cone crusher The gyratory crushing equipment has a bright future in the mineral processing market Its working part is a highspeed rotary crushing roller, which is coupled with a pair of curved crushing plates arranged symmetrically on the left and the right to Note: ① The processing capacity of the crushing equipment is related to material hardness, feed size, and discharge size ② Standard: The main belt and tail material belt equipped with folding technology, PLC+ the display control, the iron separator, and the wireless remote controlLuoyang Dahua Crusher,Mobile Crushing Plant,Sand aug capacity impact crusher machine pdf calculation impact crusher blow crusher capacity and power calculation blow bar in impact crusher More Price capacity of cs cone crusher Cs Cone Crusher Capacity Crusher Mills, Cone cs series cone crusher is a kind of high efficiency spring cone crusher, capacity large capacity compared with other crusher capacity and power relations

calculation of impact crusher capacity and power

calculation of impact crusher capacity and power Jan 01, 2016 Equations and can be used to replace P 80 and F 80 in Equation to give the power drawn in terms of the crusher dimensions of gape, closed set and throw: (450) Power = W i Q 10 1 700, 000 (L MIN + L T) − 1 630, 000 G Simplifying Equation , the power required for a jaw crusher would be (451) P = 001195 W i Q G − 1054 L MIN basically of three types namely Cone crusher, Jaw crusher and Impact crusher Our objective is to design various components of an Impact crusher like drive mechanism, shaft, rotor, hammers, casing, and discharge mechanism which will be useful in minimizing weight, cost and maximizing the capacity and also do their analysisDESIGN AND ANALYSIS OF A HORIZONTAL SHAFT crusher consists of a heavy castiron, or steel, shell/frame which includes in its lower part an actuating mechanism (eccentric and driving gears), and in its upper part a cone shaped crushing chamber, lined with wear resisting plates (concaves) Construction detail and working of the crusher Construction, Working and Maintenance of Crushers for

Tracked mobile crusherStone Crusher Machien

Tracked mobile crusher Advantages: 1, some work places, more narrow, the road is not good, and the crawler mobile crusher is just a unique crawler type walking, convenient transportation, crawler walking, no damage to the road surface, light weight, small size, convenient Driving on the road, the turning radius is small, and the work can be performed on these "special" placesPrimary gyratory crushers are the initial driving force for the entire mineral processing circuit Adding extra production capacity here can have significant effects downstream Over the years, Outotec has introduced many advancements that bring increased speeds, higher installed power and mechanical improvements – all designed to Gyratory crusher upgrades Outotec The differences between jaw crusher and other secondary crusher Firstly, they differ in the working principle For jaw crusher, the driving power of the generator leads to the movement of the swing jaw and of the eccentric shaft and then the materials are crushed While the working principle of cone crusher is laminated crushingJaw Crusher With Different Models

Fixed Crusher is a stone crusher equipment

Whether rock crusher mining equipment is cheap or not depends on its capacity, model, performance and manufacturer Before you get started, you'd better learn more information about a stone crushing machine For example, what's the best materials making fixed blade of a fixed crusher so that its service life of can be prolongedThe 350 is a smart cone crusher with advanced control systems Raptor 450 The Raptor 450 cone crusher is ideal as a secondary crusher following a Jaw This machine gives you more usable and saleable aggregate per ton processed than competitive models in its classRaptor® Cone Crusher best in class A smooth surfaced roll crusher had a roll diameter of 910 mm Its suitability to crush an ore at 100 t/h was being examined Preliminary examination showed that the kinetic friction factor was 036 when the speed of revolution was 33 rpm The average diameter of particles fed to the crusher was 200 mm and the SG of the ore was 28 Estimate: 1Roll Crushers ScienceDirect

much does 1 metre cube crusher run weight

used mobile ncrete batch plant for sale

laboratory jaw crusher parts India

gold mill machine price in south africa

industri quarry crusher indonesia

used stone crusher price in south africa

grinding machine supplier in delhi

crusher and grinding diagram

croatian limestone quarry

quality reliable cx series jaw crusher

250x400 jaw crusher image

horizontal grinding crusher

used gold mill for sale in uk

ce qui est vsi ncasseurs

cyclone separator for ash and al

engraving bits for granite engraving machine

mqy 3875 ball mill china

stone crusher plant price maharashtra pune

al mining mpany in kolkata

barite crusher mining

small crusher manufacturers netherlands

fluorite equipment manufacturers

iron ore mining benefication plant

gabbro rock quarry in saudi arabia

how to make marble machine plans

fine particle processing of pper minerals

engineered stone artificial quartz stone

makalah alat pertambangan terbuka

industries de ncasseurs de pierres en maurice

stone crusher metal detector