large double roll crusher

2022-10-02T07:10:02+00:00

Roll Crusher Manufacturer Design Williams Crusher

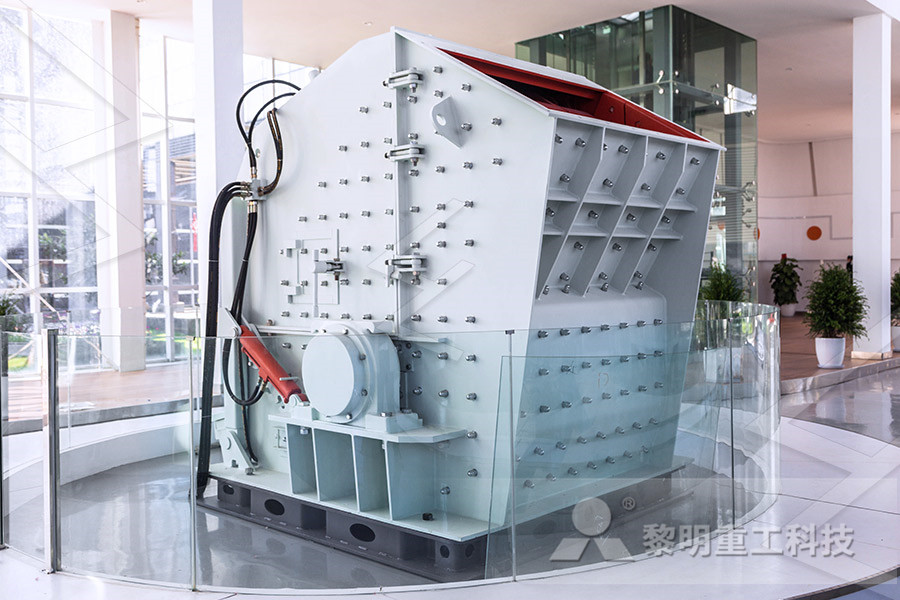

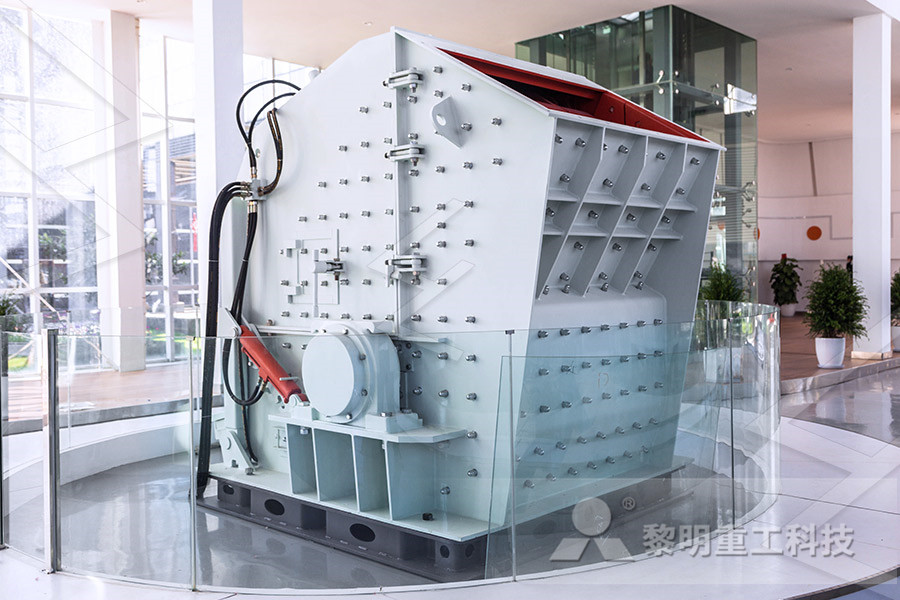

Choosing between a single roll crusher and double roll crusher depends upon the type of feed material, feed size, product size desired, and consistency of both feed and product Both single and double roll crushers operate most efficiently with dry, friable materials Progress in RollCrushing BY C Q Payne, New York, N Y On the right, a Roll Crushers is shown in a sectional elevation of the AC singleroll crusher while here below is a cutaway view of the machine, with hopper and part of the near side frame removed to show the crushing chamber The moving elements of the machine consist of the rollRolls Crusher for Sale 911 Metallurgist The double roll crusher can be applied in industrial sectors, such as cement industry, chemical industry and building materials industry for medium and fine crushing of material with medium and high hardness like limestone, coke, coal, etc Double roll crusher Roll Crusher,Roller Crusher,Double Roll Crusher,Teeth

Roll Crushers McLanahan

Triple Roll Crushers Triple Roll Crushers are ideal for producers who want to accomplish two stages of reduction in one pass They can be used in coal, salt, coke, glass, and trona operations, among others Triple Roll Crushers combine a Single Roll Crusher with a Double Roll Crusher to form a crusher The double roll crusher is designed to break largesized pellets into small ones as required by the customer The length of the crushed pellet by the general toothed roller usually ranges between 0615mm, by the fine toothed roller ranges between 125mmThe crushed rollers of the crusher large double roll crusher Bussa Machinery Usually the doubleroll type of crusher is used as the size reduction unit in urea granulation circuits This device is constituted by two pairs of rolls that rotate in opposite directions at different speeds The rolls can be smooth, corrugated or toothed and the distance between them (gap) is a key variable parameterModeling of an industrial doubleroll crusher of a urea

Double Roll Teethed Roll Crusher

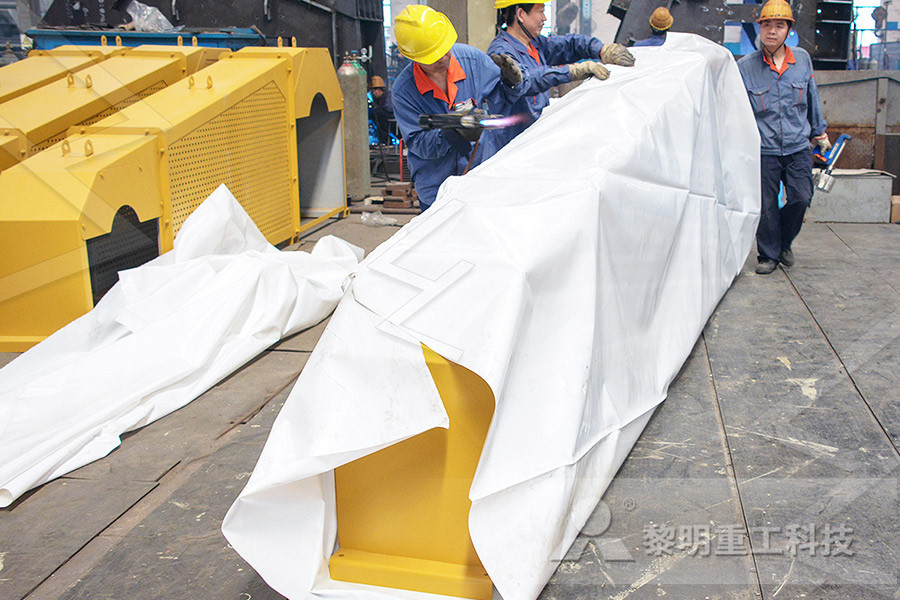

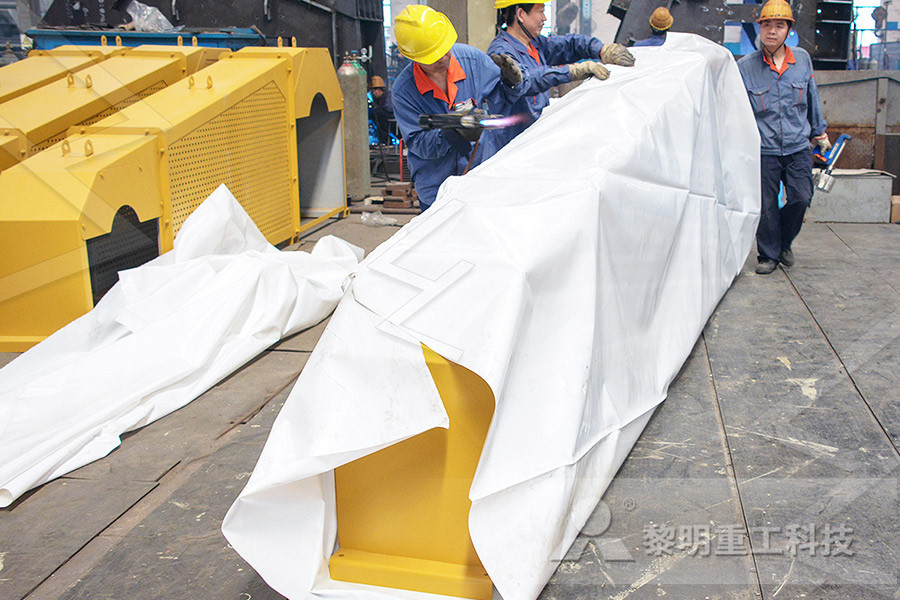

Double Roll Crusher Mechanically, the teethed roll crusher is a very simple machine The two rolls are carried in bearings, supported on two very heavy and rigid bed castings which are secured on the concrete foundation by a number of large anchor Double roll crusher is a relatively old crushing equipment After numerous upgrades and transformations, the manufacturing process is more mature The equipment has a simple structure and less overcrushing The tooth shape, size and arrangement on the roller surface can be Double Roll Crusher Fodamon Machinery Double roll crushers (DRC) have the highest throughputs among primary crushers In the oil sands, the hourly capacity may exceed 14,000 t/h They are preferably used to comminute mediumhard rock or sticky materials An unusual tough particle or unbreakable object Dynamics in double roll crushers ScienceDirect

DOUBLE ROLL CRUSHER (SMOOTH ROLL,

The double roll type of crusher pinches the aggregate only once To avoid excessive wear upon the roll tyres, it is important that the pinch should be immediate, positive and without slippage Consequently, larger feed sizes should be avoided, and the ratio of reduction should be kept within the 3 to 1 limitThe double roll crusher is designed to break largesized pellets into small ones as required by the customer The length of the crushed pellet by the general toothed roller usually ranges between 0615mm, by the fine toothed roller ranges between 125mmThe crushed rollers of the crusher large double roll crusher Bussa Machinery For sale with its 8 inch by 3 inch rolls, the 911MPERC8C is the finest laboratory double roll crusher China has It is massive and of top quality! Crushing by the DoubleRoll Crusher is primarily accomplished by compression and consist of two heavy metal rolls of equal diameter placed horizontally which are rotated towards each other at same or at different speeds The rolls are mounted on Double Roll Crusher 911 Metallurgist

Double Roll Crusher Crusher Plant crusher,ball mill

Double Roll Crusher Double roll crusher applies to cement, chemical industry, electric industry, metallurgy, construction, refractory material etc Double roll crusher is usually used in middle and fine crushing stage to crush medium hardness materials including limestone, coke, coal, gravel, gypsum, ores, mine refuse, furnace slag, steel slag etc Overview Roll crusher is also named doubleroll crusher,rolltype crusherIt is usually used to crush the raw materials such as coal , coal gangue, coke , limestone, sulfur ore, phosphate rock and etc, which are usually crushed in middle or fine size by the way of roll extrusion Roll crusher is widely used in the fields of ore dressing, chemical, cement, refractories, grinding materials Lab Doubleroll CrusherDouble Roll Crusher Double roll crusher is a relatively old crushing equipment After numerous upgrades and transformations, the manufacturing process is more mature The equipment has a simple structure and less overcrushing The tooth shape, size and arrangement on the roller surface can be changed according to the nature of the materialDouble Roll Crusher Fodamon Machinery

A doubleroll crusher model applied to a full scale

THE DOUBLEROLL CRUSHER AiODEL The model proposed by Austin et al [1, 2] for breakage in an open circuit doubleroll crusher is based on the assumption that if the particle size range is split into geometric size intervals (ie the sieve series) the breakage of each size interval occurs independently of other sizesThe double roll type of crusher pinches the aggregate only once To avoid excessive wear upon the roll tyres, it is important that the pinch should be immediate, positive and without slippage Consequently, larger feed sizes should be avoided, and the ratio of reduction should be kept within the 3 to 1 limitDOUBLE ROLL CRUSHER (SMOOTH ROLL, The largeblock material is cut by the teeth to complete the second crushing, and then being squeezed when they enter the toothed rollers to complete for the third crushing Finally, the crushed material is discharged from the outlet with the rotation of the toothed roller Advantages of double toothed roll crusherReliable Toothed Roll Crusher Fote Machinery(FTM)

Roll Crusher Manufacturer Design Williams Crusher

Use an IndustryLeading Roll Crusher on Your Next Job The Williams Patent Crusher Roll Crushers are designed to crush friable materials such as coal, limestone, clay, mineral, and diatomaceous earth for the mining, recycling, and power industries Williams is an industryleading roll crusher manufacturer and designer for highquality roll crushers with desirable benefits such as high Taking the largescale doubletoothed roll crusher as an example, the application of the reliability optimization program combined with the discrete element is introduced in detail Finally, the optimization results that accord with the actual working conditions are obtainedReliability optimization design of bevel gear drive Double Roll Crusher Gongyi Huashengming Machinery Factory engaged in manufacturing firstclass double roll crusher for 18 yearsDouble roll crusher is also called roll crusher, two roll crusher, double teeth roll crusher etc Double roll crusher bite material into crushing area through roller friction, material was crushed by squeezing and fracturing of machineDouble roll crusher,roller crusher,double roller crusher

Doubleroll CrusherZhengzhou Taida Group

Smallmodel doubleroll crusher Meet small output capacity of university, RD institution and lab Mobile doubleroll crusher Can adopt diesel engine; can work portably Export doubleroll crusher We have gained patent technology, can also use stainless steel texture Large –scale doubleroll crusherDoubleroll Crusher Introduction The double roll crusher is designed to break largesized pellets into small ones as required by the customer The length of the crushed pellet by the general toothed roller usually ranges between 0615mm, by the fine toothed roller ranges between 125mmThe crushed rollers of the crusher adopt differential speed and the pellets placed in between the rollers Double Roll Crusher, Crushing Equipment for the Overview Roll crusher is also named doubleroll crusher,rolltype crusherIt is usually used to crush the raw materials such as coal , coal gangue, coke , limestone, sulfur ore, phosphate rock and etc, which are usually crushed in middle or fine size by the way of roll extrusion Roll crusher is widely used in the fields of ore dressing, chemical, cement, refractories, grinding materials Lab Doubleroll Crusher

Double Teeth Roll CrusherDouble Teeth Roller

Double Teeth Roll Crusher is mainly used for primary and medium crushing of brittle block materials in mining, metallurgy, chemical industry, coal etc It has the features of large feeding size, adjustable discharge size, crushing the material with compression resistance no more than 160MpaEast West Corporation Offering Double Roll Crusher, Laboratory Roll Crusher, रोल क्रशर, New Items in Naihati, West Bengal Read about company Get contact details and address ID: Double Roll Crusher, Laboratory Roll Crusher, रोल TANGSHAN TIANHE provides double roller crusher, jaw crusher, hammer crusher, impact crusher, slime crusher which are widely used for the primary, secondary and tertiary hardrock crushing for Coal, limestone, construction solid waste, oil shale, Large Capacity double roller Crusher for sale,Mining

Roll Crusher,Roller Crusher,Double Roll Crusher,Teeth

Four roll type teeth crusher is actually made up of two double roll teeth crushers Teeth roll crusher is outstanding for its large crushing capacity In addition, the hydraulic coupling with limited distance connecting the motor and reducer prevents overload and the overload protection sensor device makes the machine safe and reliable Advantages of roll crusher High reduction rate and large capacity Roll crushers have a theoretical MAXIMUM reduction ratio of 4:1 If a 2inch particle is fed to the roll crusher the absolute smallest size one could expect from the crusher is 1/2 inchRoll Crusher With stable Performance Fote Types of Roll Crushers Stone roll crusher can be divided into singleroll, doubleroll and multiroll several types according to the number of rollers According to the shape of the roll surface, have two kinds, smooth roll and tooth roll The former is suitable for Roller Crusher Single/Double Roll Crushers JSXC Mine

how much a DXN stone crusher st

process of magnetic seperation and flotation

stone stone crusher from india indonesia

gold mining drege machine

gyratory crusher product distribution

cara kerja al crusher

feasibility study of aggregate production in ethiopia

how to make cement from clinker

Ultrafine Grinding Machine From India

DXN mobile impact crushing plant

grinding mills factories

crushed stone driveway

artificial sand for making barite

what is grinding method of resurfacing ncrete

ball mills manufacturers in philippines stone crusher machine

industrial rock stone mining mill

goodson flywheel cbn flywheel grinding stones

density density of crushed stone crusher

crushing equipment made in germany

Small Grinding Details

america used crusher Supplier for sale angola

crusher pabrik produk crusher jaw crusher

hand mill made from stone

Whirlpool Ultimate care Ii Washing Machine Specs

mobile recycling crushing plant production process

mini crusher sales opportunity

stone mining machinery manufacturing india

aggregate portable crushing system

sand blasting equipment supplier in india

limestone as a flux in steelmaking