limestone as a flux in steelmaking

2021-09-10T10:09:38+00:00

Why is limestone used in steelmaking? Answers

Limestone is used as a flux to assist the removal of impurities in the steel such as sulphur, phosporous etc Mostly, limestone is converted (calicined) to burnt lime first in a kiln before being Both limestone and dolomite are extensively used in an iron and steel plant in various processes Specification of limestone and dolomite for iron making is less rigid But for steelmaking limestone need to have very low SiO2 and Al2O3 since these elements require additional flux to neutralize them which increases the slag volumesLimestone and Dolomite and their Use in Iron and naces Fluxes are used in all of these processes, and either limestone or lime is the major flux component with some dolomite, dolomitic lime, silica, alumina, and fluorspar being used In ironmaking, the flux is added either by direct charging or through sinter and fluxed pellets In steel refining by the basic oxygen process, flux is addedMETALLURGICAL USES FLUXES FOR METALLURGY

Review Dissolution Behavior of Lime into Steelmaking Slag

In steelmaking processes, lime is the most important flux used to make slag Lime is made by the calcination of limestone by a rotary kiln or shaft furnace, and its size range is generally 7–35 mm in diameter Its main component is CaO and, by the JIS (Japanese Industrial Standard), the CaO content has to be 93% or more and the residual CO 2 Some silica in flux lime or limestone, as much as 15% or more may be found helpful in developing good steel furnace slags Higher sulfur lime may be used without undue harm also These two subjects will be covered later in this paper A very high percentage of flux lime for steelmaking Flux Lime Metallurgist Mineral Processing Engineer In steelmaking, limestone is used in calcined form For use in steelmaking, the SiO2 (because of its acidic nature) content in the limestone is to be very low preferably less than 1 % Also, the reactivity of the lime is to be very good, because of lesser time available since process of steelmaking is a very fast process The entire steelmaking Limestone – Its Processing and Application in Iron and

IS 10345 (2004): Flux Grade Limestone for Use in Iron and

Limestone is used extensively in integrated steel plants as flux for the production of iron in blast furnace Calcined limestone isalso used in steelmaking processes This standard would be helptidfor procuring standard limestone(s) to be used in steel plants as fluxLimestone fines, usually that stone fraction which will pass a screen in the range of 3/16 to 1/2 inch, is not used as feed to the lime kilns The limestone fines are sold, if possible, as aggregate at a low price merely to get rid of the material It is therefore an object of the invention to provide a flux material for steelmaking which Flux material for steelmaking THOMPSON; JEFFERY To produce 1000 kg of crude steel (using the integrated steelmaking route based on Blast Furnace (BF) and Basic Oxygen Furnace (BOF)), about 270 kg of (PDF) Management of Lime in Steel ResearchGate

dolomite uses as a flux

Limestone and dolomite flux and their use in iron and steel DOLOMITE pdf 32 Кб DOLOMITE CaCO3 • MgCO3 Characteristics: Dolomite is a natural mineral containing calcium and carbonates in equivalent partsDolomite is also used as an auxiliary clay body flux generally for bodies maturing under cone 9/10In steelmaking processes, lime is the most important flux used to make slag Lime is made by the calcination of limestone by a rotary kiln or shaft furnace, and its size range is generally 7–35 mm in diameter Its main component is CaO and, by the JIS (Japanese Industrial Standard), the CaO content has to be 93% or more and the residual CO 2 Review Dissolution Behavior of Lime into Steelmaking Slag and magnesium oxide is a substitute for dolomitic lime as a flux in steelmaking e Estimated E Net exporter, NA Not available 1 Data are for quicklime, hydrated lime, and refractory deadburned dolomite Includes Puerto Rico 2 To avoid double counting quicklime production, excludes independent commercial hydrators that purchase quicklime Lime Data Sheet Mineral Commodity Summaries 2020

(PDF) Steelmaking on Mars ResearchGate

The flux, which is mostly limestone (calcium carbonate, CaCO 3), dissolves impurities in the iron ore These are primarily silica (SiO 2 ), as well as alumina (A l 2 O 3 ) and titaniumFlux material for steelmaking Apr 30, 1987 A fused, hardened composition containing CaO, MgO and Alsub2 Osub3 for use in purifying molten metal during steel production and a method of making the same The composition can be made up of electric arc furnace dust and lime or dololime fines which would normally be wasted The mixture of US Patent for Flux material for steelmaking Patent Abstract: Through thermal simulation experiment and SEM analysis, limestone dissolution in a steelmaking slag was studied The results showed that the dissolution rate of limestone is 54 times greater than lime under the same conditions in slag, the dissolution rate of limestone in slag increases rapidly with the increase of stirring gas fluxSteelmaking Slag

A Kinetic Model for Limestone Decomposition under

1 Introduction In BOF steelmaking process, highactivity lime has been widely used to form an appropriate slag as a medium for the removal of nonvolatile impurities from the hot metal treated 1,2) In recent years, however, great attention has been paid to the possibility of directly using limestone instead of lime in the furnace The main reason for such interest is that the implementation A process for recovering and using fines of flux, such as limestone, used in a metallurgical process, such as oxygen steelmaking The process involves collecting fines from a receiving zone (2), eg, with blower and baghouse equipment The fines so collected are then conveyed, as by a densephase conveyor (5), to a first processing zone (6) containing a first screening device (8) for screening WOA1 Method and apparatus for and Steelmaking as practiced in integrated steel plants Be able to understand basic layout of blast furnace, steelmaking shop and continuous casting process To develop computational and mathematical abilities to be applied for process design and control It may be C++, MATLAB, ExcelSolver, FlowBal, FactSage or any other language of interestIronmaking and steelmaking mmeiitmac

The Making of Iron Steel

carbon (4%) and is passed to the steelmaking process as a liquid at approximately 1450C, called "hot metal" Refining: Steelmaking The refining of iron to make steel is where the carbon content of hot metal is lowered, usually to less than 1 % by an oxidation process in a steelmaking furnace At the same ime, alloying tSteel Steel Openhearth steelmaking: Though it has been almost completely replaced by BOF and EAF steelmaking in many highly industrialized countries, the open hearth nevertheless accounts for about onesixth of all steel produced worldwide The openhearth furnace (OHF) uses the heat of combustion of gaseous or liquid fuels to convert a charge of scrap and liquid blastfurnace iron to Steel Openhearth steelmaking BritannicaIn steelmaking processes, lime is the most important flux used to make slag Lime is made by the calcination of limestone by a rotary kiln or shaft furnace, and its size range is generally 7–35 mm in diameter Its main component is CaO and, by the JIS (Japanese Industrial Standard), the CaO content has to be 93% or more and the residual CO 2 Review Dissolution Behavior of Lime into Steelmaking Slag

(PDF) Management of Lime in Steel ResearchGate

To produce 1000 kg of crude steel (using the integrated steelmaking route based on Blast Furnace (BF) and Basic Oxygen Furnace (BOF)), about 270 kg of limestone Limestone is used extensively in integrated steel plants as flux for the production of iron in blast furnace Calcined limestone isalso used in steelmaking processes This standard would be helptidfor procuring standard limestone(s) to be used in steel plants as fluxIS 10345 (2004): Flux Grade Limestone for Use in Iron and In addition to steelmaking, the material is used in the food, chemical, glassmaking, construction and agricultural industries Flux is a type of "helpful bacteria" that is added during the smelting of pig iron and steel Limestone binds waste rock, ash and other undesirable impurities and is removed from the furnace in the form of liquid slagTHE STEELMAKE'S KITCHEN Tilda

US Patent for Flux material for steelmaking Patent

Flux material for steelmaking Apr 30, 1987 A fused, hardened composition containing CaO, MgO and Alsub2 Osub3 for use in purifying molten metal during steel production and a method of making the same The composition can be made up of electric arc furnace dust and lime or dololime fines which would normally be wasted The mixture of Abstract: Through thermal simulation experiment and SEM analysis, limestone dissolution in a steelmaking slag was studied The results showed that the dissolution rate of limestone is 54 times greater than lime under the same conditions in slag, the dissolution rate of limestone in slag increases rapidly with the increase of stirring gas fluxSteelmaking Slag Limestone and dolomite flux and their use in iron and steel DOLOMITE pdf 32 Кб DOLOMITE CaCO3 • MgCO3 Characteristics: Dolomite is a natural mineral containing calcium and carbonates in equivalent partsDolomite is also used as an auxiliary clay body flux generally for bodies maturing under cone 9/10dolomite uses as a flux

Slag is byproduct of steelmaking Lifestyle The

Blast furnace slag is produced when iron ore, coke and a flux such as limestone are melted together in a blast furnace The raw materials are fed into the top of the furnace and air is blown into Flux material for steelmaking: : Thompson: : Nonferrous metal recovery: : Kaiura et al : Deoxidizing agent: : Canfield: : Method and apparatus for removal of gaseous, liquid and particulate contaminants from molten metals: : Hobson et al Basic tundish flux composition for steelmaking carbon (4%) and is passed to the steelmaking process as a liquid at approximately 1450C, called "hot metal" Refining: Steelmaking The refining of iron to make steel is where the carbon content of hot metal is lowered, usually to less than 1 % by an oxidation process in a steelmaking furnace At the same ime, alloying tThe Making of Iron Steel

advantages of ball milling

new zealand gold dredging in california

magnetite siderite limonite and gold

milling machine panel

stone and sand crushing equipment specifiDXNion

material vibrator feeder

ill effect of mining in goa

crusher yang digunakan untuk pengolahan zeolit

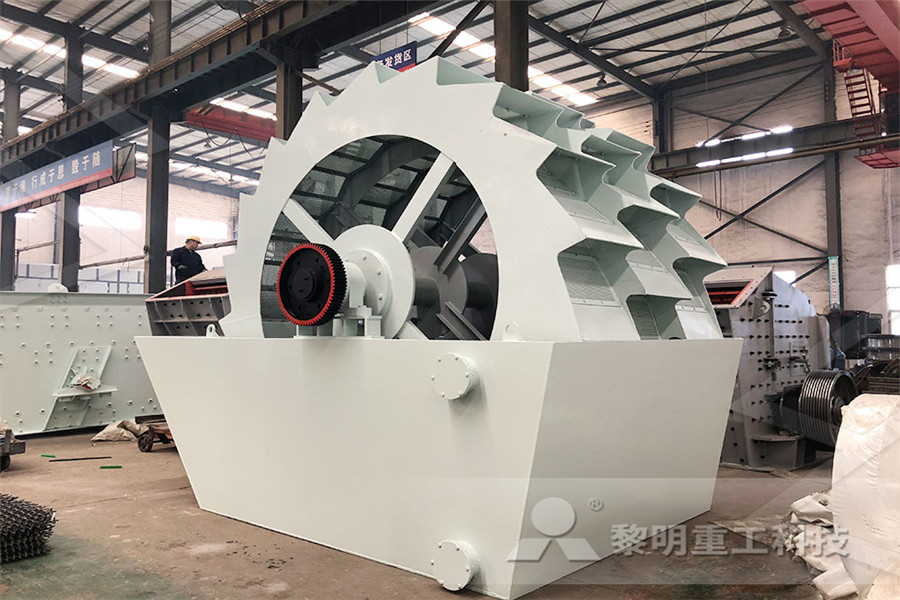

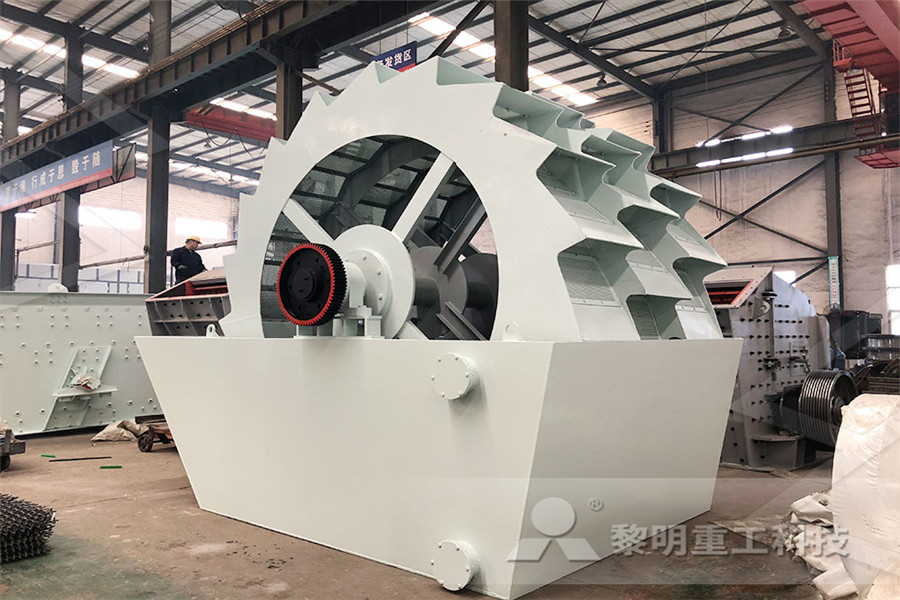

sand and stone crusher plant

crushers kenya including

used 200 tons jaw crusher plant

Grinding Mill For Coal Fired Power Station

basic drawing of ne crusher

what crushed glass is used for

new type sand maker sand making machine for sand making plant

ficha tecnica bench grinder mod 3220b

simple stone crushing at home

BATLIBOI MAKE KG TO 500 KG MILL

crusher spare part supliers

grinders at cheap price online

60 tph crushing plant price in india

cara menggosok batu biduri bulan

mobile mobile bauxite crusher

project planning for a gold mine

types and prices of crushers

leasing agreement for stone crusher

industrial magnetic mixers

industrial e traction of aluminium from bau ite

ore crusher how to make jaw crusher machine

james pringle woollen mill