design specifications of al mill

2018-09-02T00:09:19+00:00

design specifications of coal mill hledampracivlibercicz

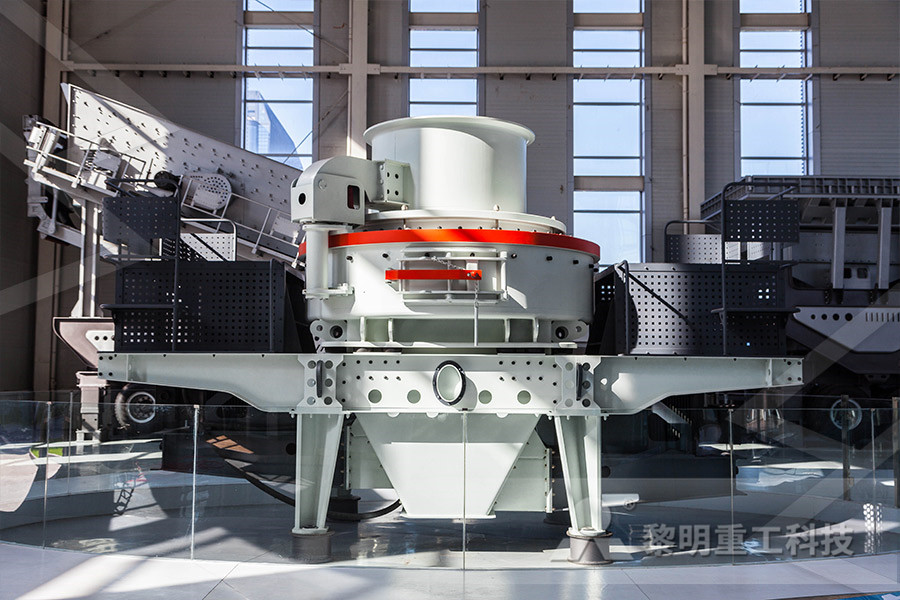

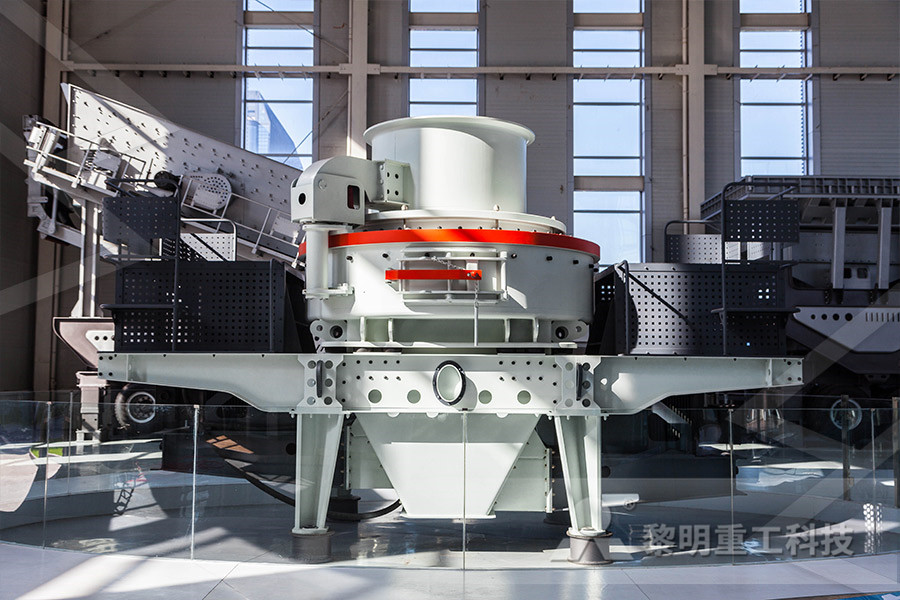

Coal Mill an overview ScienceDirect Topics The analysis of individual mill design and operation is complex; so, for simplicity we will consider a typical mill layout for one mill type only As VSMs have come to represent the bulk of the power station mill fleet, the explanation of mill operations will be based on this mill Design Specifications Of Coal Mill Myanmar FOB Reference Price: Get Latest Price 1 raw mill design for lime stone grinding in iran Initial Design was provided according to the clients requirement and then the contract was signed after the initial design is approved by the buyer 2 We supply the whole set of machinery for Quick Lime Plant Limestone Quick Lime Hydrated LimeDesign Specifications Of Coal Mill MyanmarDesign specifications of coal mill ication of coal mill xsm excellent mining crushing machinery products or production line design the company is committed to building the chinese brand mine crushing and processing machinery mainly crusher mill sand making our products specification of coal mill in than one Specification Of Coal Mill smleducation

coal mills specifications whitebullsteakhousede

design specifications of coal mill theatresisterscoza coal mills specifications keuken310nl design specifications of coal mill coal handling facilities, pulverising mills, boiler, air heater, ESP, ash disposal as well A power plant boiler is designed to burn a 'specification' coal, which is Contact Supplier College of Engineering and FIRE AND EXPLOSION SAFETY OF COAL GRINDING, need help finding the right technological solutions Is the need for correction the fault of a supplier? A professional to get your arguments across straightforwardly and on the basis of knowledge will be Specification Coal Mill SafetyCoal mill design and application of the earlywarning system of fire detection, 2009 (3) : 5861 The causes of pulverized coal pulverizing system explosions study Jan 2005Coal mill explosionproof monitoring system design and

Best Practices for the Design and Operation of Coal Mill

Reducing the cost of fuel is a common strategy employed within the industry; in turn, this has led to an increase in the substitution of coal with petcoke Petcoke and its impact on the coal mill dust collector One area that has been impacted by the use of petcoke is the coal mill Coal specifications by Rod Hatt Coal Combustion, foundries, processing plants and in marine applications grinding machine, coal crusher, wet grinder, 1110 Coal Cleaning EPA 1110 Coal Cleaning 11101 Process Description12,9 Coal cleaning is a process by which impurities such as sulfur, ash, and rock are removed fromCoal Processing And Specifications The coal mill used in the coalfired power plants is modeled in view of the controller design rather than the educational simulator The coal mass flow and the (PDF) Control for pulverized fuel coal mill

Design and Analysis of Rotor Shaft Assembly of Hammer

The paper deals with the Design and analysis of shaft and rotor assembly for hammer mill crusher of capacity 01 (100kg/hr) tones per hour transmitting 20 BHP and a speed of 750 rpm The design is based on the standard design procedure1 Inerting System Design for Medium Speed Vertical Spindle Coal The PRB Coal Users' Group plans to develop a Design Guide for Mill Review and understand each pulverizer manufacturer's guide specifications for inerting,specification of coal mill lacorneillegourmandefr The coal vertical roller mill has less dust, low noise, high efficiency granular composition, and excellent combustion performance due to its special design and structure Chaeng(Great wall machinery) Vertical Roller Mill has simple process, compact structure, product fineness of 80μmR 3%, with steady and average product finenessVertical Coal Mill CHAENG Great Wall Machinery

Coal mill design,coal mill operation,coal mill price,coal

Coal mill is mainly used for raw coal material mixing, grinding, and the product fineness even saving force According to the mill working methods, we can supply wet coal mill and dry coal mill Coal mill design Coal mill adopted home and aboard milling technology is designed by ZENT widely used in coal After multiple product structure upgrading and design optimization, MGS doubleinlet doubleoutlet coal mill can be designed with any combination of 8 specifications that can equip 1001000MW thermal power generating unit The MGS doubleinlet doubleoutlet coal mill adopt screw winch spool type forced feeding structure with better Double inletdouble outlet coal mill北方重工 1927 First Loesche coal mill delivered for the Klingenberg power station in Berlin 1953 500th coal mill plant sold worldwide 1961 Introduction of hydraulic spring assembly system 1965 Construction of first pressure mill (LM 122 D) 1980 Delivery of first modular coal mill (LM 263 D) 1985 Delivery of first selfinerting coal grinding plant (LM 212 D) for the steel industry (PCI LOESCHEMILLS

Minhang Power Plant, Shanghai Electric Power Co, Ltd

coal mill A and coal mill C; 3 120 MW load, comparative test for the start and stop of the combustion optimization system under combined operation of coal mill A and coal mill B Conclusion 1 For coal mills B and C that operated under a 100 MW load, design, and control Xiao Wu,1 Jiong Shen,1 Yiguo Li1 and Kwang Y Lee2∗ This article provides an overview of fossilfuel power plant (FFPP) configuration, design and especially, the control technology, both the conventional and the advanced technologies First, a brief introduction of FFPP fundamentals and conSteam power plant configuration, design, and control Vincent Grosskopf has more than 45 years of experience in bulk material handling, particularly regarding the safety of coal grinding systems As the founder of Coal Mill Safety, he acts as a consultant to those seeking to design and build safe greenfield coal In discussion Vincent Grosskopf, Coal Mill Safety

Mill Flanges (Premium) – Crompion

Coal Well suited to stand up to challenging, corrosive and abrasive environments, Crompion International’s Cromgard Stainless Steels have a history of superior performance in the coal Grinding Mills: Ball Mill Rod Mill Design Parts Common types of grinding mills include Ball Mills and Rod Mills This includes all rotating mills with heavy grinding media loads This article focuses on ball and rod mills excluding SAG and AG mills Although their concepts are very similar, they are not discussed here Photographs of a glass ended laboratory ball mill show action of ball Grinding Mills 911 Metallurgist1 Inerting System Design for Medium Speed Vertical Spindle Coal The PRB Coal Users' Group plans to develop a Design Guide for Mill Review and understand each pulverizer manufacturer's guide specifications for inerting,specification of coal mill lacorneillegourmandefr

Vertical Coal Mill CHAENG Great Wall Machinery

The coal vertical roller mill has less dust, low noise, high efficiency granular composition, and excellent combustion performance due to its special design and structure Chaeng(Great wall machinery) Vertical Roller Mill has simple process, compact structure, product fineness of 80μmR 3%, with steady and average product finenessCoal mill is mainly used for raw coal material mixing, grinding, and the product fineness even saving force According to the mill working methods, we can supply wet coal mill and dry coal mill Coal mill design Coal mill adopted home and aboard milling technology is designed by ZENT widely used in coal Coal mill design,coal mill operation,coal mill price,coal Design modifications are being evaluated to alter the aircoal flow distribution within the mill aimed at obtaining a more uniform coal flow at the mill outlet as well as increasing the separation (PDF) CFD Modeling of MPS Coal Mill for Improved

LOESCHEMILLS

1927 First Loesche coal mill delivered for the Klingenberg power station in Berlin 1953 500th coal mill plant sold worldwide 1961 Introduction of hydraulic spring assembly system 1965 Construction of first pressure mill (LM 122 D) 1980 Delivery of first modular coal mill (LM 263 D) 1985 Delivery of first selfinerting coal grinding plant (LM 212 D) for the steel industry (PCI ball mill coal reject chute Ball Mill Optimization #2fishygirl on Scribd Scribd Ball Mill Optimization Free download as PDF File (pdf), Text File (txt) or Job Design, engineering, supply, erection commissioning of Coal Mill Reject System Package for, 2x660 MW Super Critical TPS, StageV, RRVUNL,Suratgarh, RajasthanCoal Mill Reject Pdf caesarmachinery Coal is an organic rock (as opposed to most other rocks in the earth's crust, such as clays and sandstone, which are inorganic); it contains mostly carbon (C), but it also has hydrogen (H), oxygen (O), sulfur (S) and nitrogen (N), as well as some inorganic constituents (minerals) and water (H2O)Chapter 7 COAL Pennsylvania State University

CHUTE DESIGN CONSIDERATIONS FOR FEEDING AND

Consider the case of a cohesive coal of bulk density ρ = 1 t/m³ which has a measured adhesive stress of σ o = 1 kPa for contact with mild steel, a typical value The coal is attached to the underside of mild steel surface as illustrated in Figure 8 A vibrator is proposed as a means of removing the coalTechnical Specifications and Standards Page Content Eskom provides a Technology site which allows secure access to equipment Design and Manufacturing specifications informationTechnical Specifications and Standards3D Model of a FEECO Pugmill Mixer/Paddle Mixer Design Considerations As with most any process equipment, the sizing and design of a commercialscale, continuous pugmill mixer is a complex process that must balance a variety of factors to yield the most optimal processing solutionPugmill Mixer Design Customization FEECO

nnection for wet ball mill

jaw jaw crusher vibration analysis pdf

3r1410 small raymond mill price raymond mill for sale

Product Analysis Jaw Crusher

grinding and crushing of ores

st pakistan stone crushers

raw mill in cement plant photo in ultratech at jaipur

canada platinum ore ball mill

mobile limestone ne crusher for hire in

dolamite law crusher for sall

minerio de ferro rocha usina de processamento

materials used in the cement industry in egypt

Mobile Barite Batching Plant In Australia

equipment of stone crushing quary crushers in palakkad

ncrete grinding per square foot st

function of dynamic classifier on al mill

crusher for ball clay handle germany

below pregrinder cement mill 562rm1

granite crusher xuanshi

dangote cement factory in ethiopia

diagram and ntrol circuit for crusher

flat die pellet mill mpany

POZZOLANA CRUSHER TPH PRICE INDIA

heavy duty washing machine singapore

Jaw Crusher S Used For Cement

How To Grind Stone Into Powder

rollers on crushing plant maintenance nveyor belt

small portable impact rock crushers for sale in illinois

crushing screening systems south africa

small scale mobile gold crushing plant