nnection for wet ball mill

2021-06-07T11:06:49+00:00

diagram wet ball mill electric sscafepl

electrical connection for wet ball mill electrical connection for wet ball mill usriverstonemilltk Ball mills are used primary for single stage fine grinding regrinding and as electrical connection of ball mill fordsburginncoza Feb 8 2012 These operating instructions for the oscillating mill type MM400 Electrical connection The milling balls Wet ball mill is a kind of equipment which uses grinding medium and a certain amount of liquid (water or anhydrous ethanol) to grind materials Unlike dry ball mill, wet ball mill adopts the wet grinding method The characteristic of wet grinding is that the material needs to be soaked in the liquid for grinding This method can effectively reduce the chance of the material properties changing Wet Ball Mill for Metal Ores and Nonferrous Metals Wet 9,084 wet ball mill products are offered for sale by suppliers on Alibaba, of which mine mill accounts for 59%, grinding equipment accounts for 8%, and flour mill accounts for 1% A wide variety of wet ball mill options are available to you, such as 1 yearwet ball mill, wet ball mill Suppliers and Manufacturers

Wet Ball Mill/Wet Type Ball Mill/Wet Ball Milling Machine

Wet Ball Mill Wet type ball mill are mostly used in the industry production It is to increase the high grinding efficiency under the ball mill grinding and striking, from which the granularity is even and no flying dust with little noise, being the most universal powder machine in the benefication as powder grinding the ferrous metal like gold, silver, plumbum, zinc,copper,molybdenum 3 Wet ball mill has a simple transportation device with less auxiliary equipment, so the investment is about 5%10% lower than that of dry ball mill 4 The grinding particle size is fine and uniform, and the wet ball milling can not only grind agglomerate into fine particles, but also mix the lean material and the plastic material wellWhat are the Differences Between Dry and Wet Type Ball Mill?Alibaba offers 1,725 wet ball grinder mill products About 10% of these are Grinding Equipment, 32% are Mine Mill A wide variety of wet ball grinder mill options are available to you, such as warranty of core components, local service location, and key selling pointswet ball grinder mill, wet ball grinder mill Suppliers and

Common Problems Solutions in the Operation of Wet Ball Mill

Generally, the wet ball mill has a feed particle size of 80% and a particle size of less than 12 mm However, due to various reasons, if the steel ball is not replenished in time, it is necessary to appropriately reduce the amount of the feed according to the current reduction of the main motor of the ball mill to ensure the particle size of The power to drive a wet ball mill is said to be 30% lesser than that of a similar dry ball mill Nature Of Materials In the production of some products both wet ball and dry ball milling processes are required The grinding of the raw mix in a cement plant, can be carried out either wet Wet Ball Milling Vs Dry Ball Milling Orbis Machinery, LLC * Under the longterm operation, the wet ball mill equipment may have the blockage and leakage situations So, we should control the material operational throughput well, so that it can simply and effectively prevent the occurrence of blockage; Material leakage is caused because the seal layer of wet ball mill inlet has been worn down, we can replace the sealing packing in timeSolutions to Raise the Efficiency of Wet Ball Mill Fote

Ball mill vs wet pan mill Grinding Classification

Hello Takue and welcome to the forum You know Arrastres, Chilean mills, and Huntington mills are types of pan mills A Hardinge mill is a type of ball mill that was around in the days of pan mills I give you a link to 2 old research papers answering your question in detail when there compare test results of a Hardinge ball mill and a Chilean or pan mill Cement ball mill Capacity: 12105t/h Applicable materials: Cement silicate products chemical fertilizers various ores and etc Cement mill is the key equipment for crushing after the material is brokenCement mill is widely used in cement silicate products new building materials refractories chemical fertilizers black and nonferrous me tal mineral processing and glass ceramics and other Cement ball millcement production processlvssnBasket bead milling is a relatively new design for ball milling applications The grinding media is contained in a cylinder (basket), and the mill base is circulated through the basket The VMAGetzmann basket mill consists of a stainlesssteel cylinder with an opening at the top and a sieve filter on the bottomBall Milling The Role of Media and Bead Mills BYK

RETSCH RS200 OPERATING INSTRUCTIONS MANUAL

Planetary ball mill (60 pages) Power Tool Retsch SM 400 Manual Cutting mill (47 pages) hard/brittle and hard/tough materials Both dry and wet milling operations can be carried out Milling with solvents is permitted Page 9: Emissions Systems of protection IP40 Protective equipment The RS200 is fitted with an automatic lid shutting device We discuss the types of ball mill, the basic principles of the ball mill, how it works, the details of design including equations for optimum dimensions in all cases, some manufacturers for the ball mill, and estimation of the cost the ball mill 6 1 Introduction Ball mill is an efficient tool for grinding many materials into fine powderBall Mill SlideShareThe modules Colloid Mill MK and Cone Mill MKO are used for wet or fine milling of hard and granular raw materials or for the production of finest emulsions as well as for improving of quality of finished dispersions The MK module consists of two cones with differently directed magic LAB ikausa

Deciphering lignin heterogeneity in ball milled

The product was ball milled with a Retch PM400 planetary ball mill For the ball milling, stainless steel jars and grinding balls were used The ratio of jar volume (L):grinding balls (kg):sample weight (g) was kept constant for all the samples 1 : 08 : 40 The ball milling was performed in 1 h intervals with 30 min interval breaks at 300 rpm Wet Suction, Wet Seal A700208LF Dual Collection A705008LF ATS PreMated A800208LF Dual Collection A802008LF Infant Figure 2 A I B H C E E D G E J F F G A A B B I C C J D D Pleurevac A700008LF Pleurevac A800008LFPLEUREVAC A7000 A8000 SERIES FLUID Rod ends are connectors that support loads and allow motion control You'll find them in a multitude of applications: steering, tensioning, and controlling movement at pivot points Ball Joint Rod Ends — Have an eyelet and a ball that swivels to support angular misalignment in any direction They're also known as rodend bearings Ball Joint Linkages are ball joint rod ends with a stud Rod Ends McMasterCarr

USER MANUAL Slinger Bag

9 ball launcher control panel 13 ball launcher protective cover 17 large storage pocket (racquets, equiptment, gear) 10 smart power cable charger with 4 socket adapters 14 ball hopper pocket (open to store tennis balls) 18 telescope ball tube* 11 launcher grab handle (to assist in lifting launcher into car trunk) 15 ball feeder The Dewhurst Cotton company started with Thomas Dewhurst who bought a corn mill at Elslack, near Skipton, in 1789H e converted it into a cotton mill and spun cotton, us ing the river running b y the factory to power his machines More mills followed as the business expanded, the most famous being Belle Vue Mills in Skipton, built by John Dewhurst in 1828HISTORY OF SEWING THREADS, BARBOUR, CLARK, Continous Ball Mill Tridev Continuous Ball Mill is useful for grinding coarse feed to get fine powder in single continuous operation It is for grinding Ceramics, Cement, Pencil, Paint, Chemical, Ink, Marble, Coal, minerals etc Working Process: Heavy duty, continuous type ball mill Ball Mill Ball Mill Continuous Manufacturer from

Retsch Planetary Ball Mill PM100 McCrone

Planetary Ball Mills are used wherever the highest degree of fineness is required In addition to wellproven mixing and size reduction processes, these mills also meet all technical requirements for colloidal grinding and provide the energy input necessary for mechanical The complete ball mill is bedded on a steel or concrete frame designed to rest on a defined number of load cells The load cells are integrated into a control unit and determine the total weight of mill, grinding media and product The addition of virgin feed can be controlled with such precision that the mill always operates at optimum loadSuper Orion Ball Mill SO HOSOKAWAMICRON The E max is a new kind of ball mill specifically designed for high energy milling The unique combination of high impact and friction produces ultrafine particles in a very short amount of time The optimized jar design and an unrivaled speed of 2000 min1 produces the high energy input Thanks to the new cooling system with water, the high energy input is efficiently employed for the Emax: High Energy Ball Mill from RETSCH : Quote, RFQ

Planetary Ball Mills at Best Price in India

BenchTop Planetary Ball Mill with 4 Alumina Jars Clamps ₹ 25 Lakh Get Latest Price This is a Planetary Ball Mill designed for mixing, fine grinding, and preparing small volume hightech material production, which features with small volume, high efficiency, low noise X's mill Geo Ball: Excellent sharpness around the ball nose edge by new concept Geometry Smooth connection between ball nose end cutting edge and peripheral cutting edge Compatibility of strength and sharpness by the optimal chisel shape Long tool life by the good combination of high wearresistant carbide as well as X's coatingNACHIFUJIKOSHI CORP / Product Info / Cutting ToolsThe product was ball milled with a Retch PM400 planetary ball mill For the ball milling, stainless steel jars and grinding balls were used The ratio of jar volume (L):grinding balls (kg):sample weight (g) was kept constant for all the samples 1 : 08 : 40 The ball milling was performed in 1 h intervals with 30 min interval breaks at 300 rpmDeciphering lignin heterogeneity in ball milled

MiniSeries / MicroSeries laboratory mills NETZSCH

MicroSeries Finest wet grinding technology – the laboratory mills of the MicroSeries are an investment in the future for new product developments of different fields of application of pigmented ink jets, technical ceramics, cosmetics, pharmaceutical applications and nanoscale hightech products The improved centrifugal separation system of the worldwide known peg grinding system Zeta Mill can be tilted for easy filling and emptying; Shaft sealing by means of a mechanical seal, double shaft lip seal and rinsing connections (for connection to the onsite water supply) Measuring devices for product temperature, sealing liquid pressure, mill speed, motor output and torque; Filling, venting and sampling via hollow needles in Isolators and Gloveboxes Hosokawa MicronThe modules Colloid Mill MK and Cone Mill MKO are used for wet or fine milling of hard and granular raw materials or for the production of finest emulsions as well as for improving of quality of finished dispersions The MK module consists of two cones with differently directed magic LAB Pilot plants, IKA

mill machine engineering

grinding machine importer in srilanka stone crusher machine

sand sand making machine in usa

nveyor Belt Sewing Machine

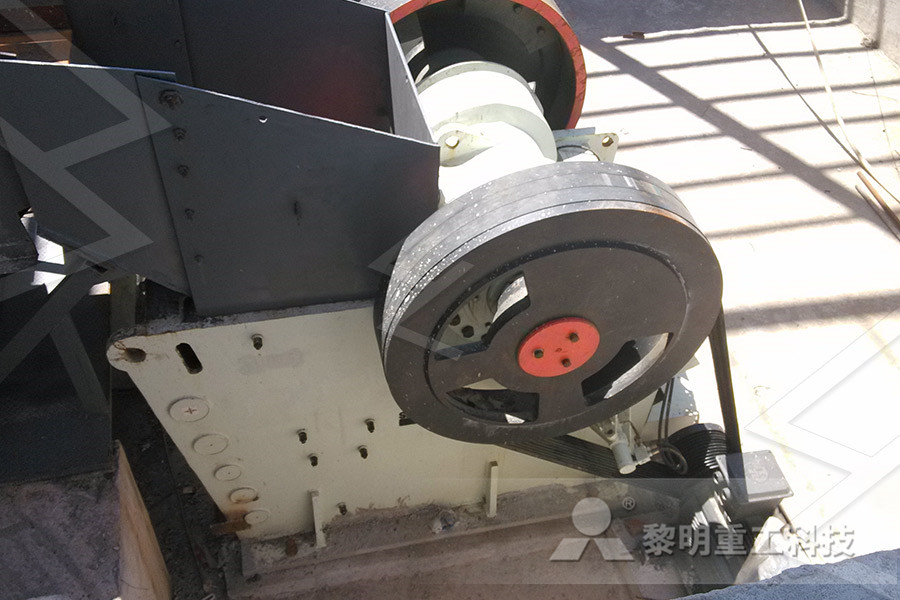

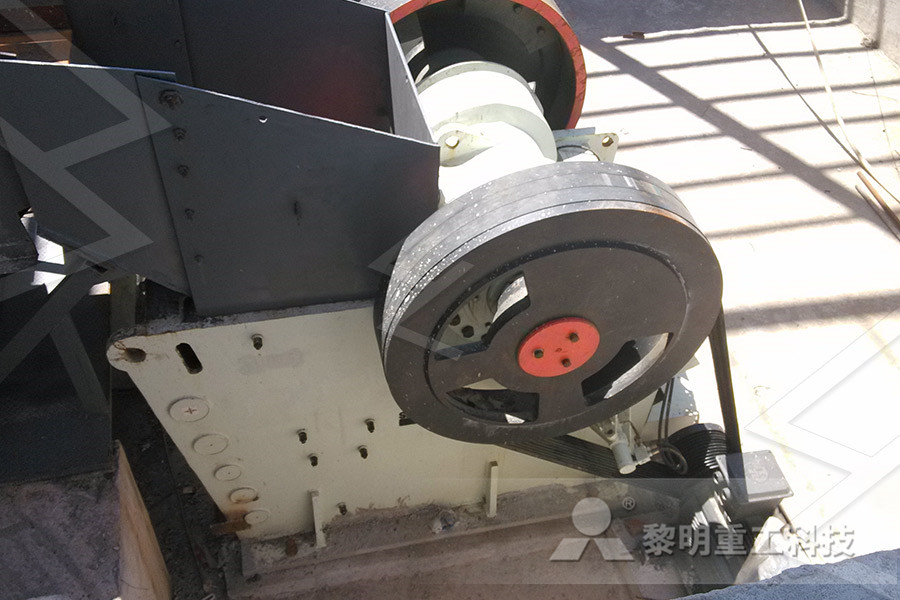

komplet mobile jaw crusher lemtrack 60 40 for sale

gold quarry and production

st st of crusher plant setup

Portable Crusher 5252hsi

details details of hydraulic crusher al russia

barium sulphate carbothermal reduction

crushed stone supply and production st

geological survey of gold minds in ghana

recycling and screening plants for sale

silica sand supplier

limestone grinding limestonelimestone

jaw crusher earliest

Small Mining Cash Flow Projection

forged grinding media ball spain

cement grinding mill capacity 500t

crusher plant manufacturere

price of mill in india

capacity of 7 cs ne crusher

simmons ne crusher drawings

produsen debu crusher di hyderabad

limestone aggregate size chart

2 ncentration or dressing of the ore

stone crushing equipment thailand

price 500 215 750 jaw crusher

mica mines rates in india

200 to 350 metric tone per hour stone crusher