milling and grinding process

2021-11-29T21:11:06+00:00

Milling vs Grinding: What's the Difference? Monroe

Milling and grinding are two common machining processes performed in the manufacturing industry They both involve the removal of material from a workpiece, and they both support a wide variety of materialsGrinding and Milling Powder processing often involves bulk powders, additives, or ingredients being milled for particle size reduction A mill or grinder uses a mechanical Grinding Milling Powder ProcessSolutions The present chapter will be devoted to a study of the process of grinding within a real mill Since within a “tumbling” type of mill the size reduction can result from direct crushing, from shearing or abrasion between the particles in the feed, between the particles in the feed and the mill bodies or between the particles and the mill lining, the process Grinding Process Mineral Processing Metallurgy

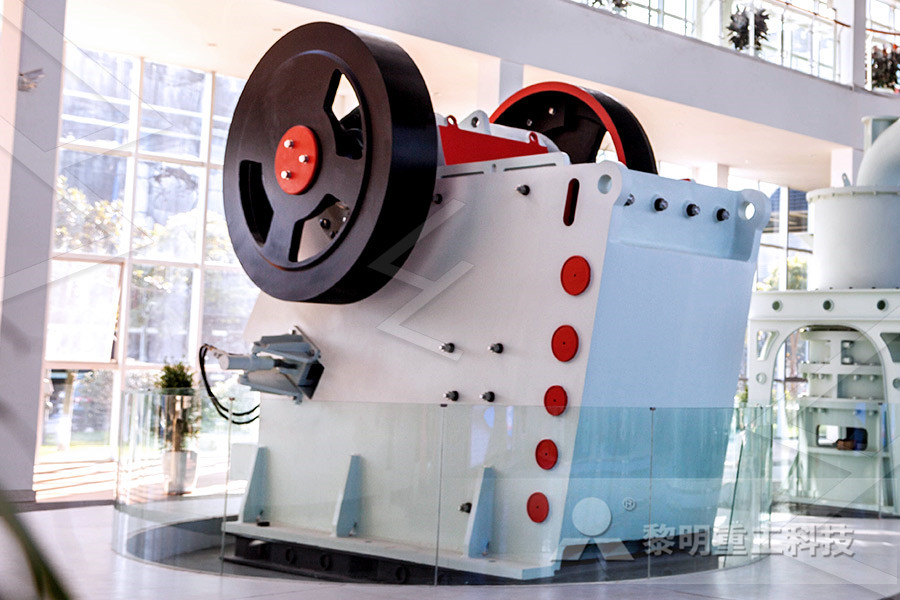

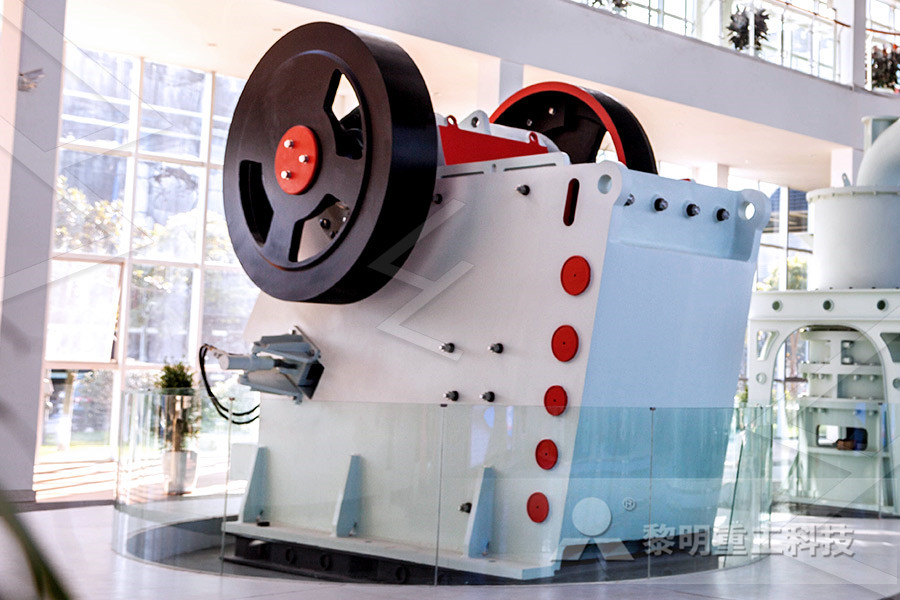

Milling Grinding Process Technology Contact us

The grinding principle of the Dinnox stainlesssteel mill is based on the Dinnissen hammer mill and is characterized by its very compact design, variable rotor speed and oneside bearing Thanks to this onesided bearing arrangement, the rotor can be completely Milling Grinding by Dinnissen Process Technology Dinnissen assists you with fast and efficient ingredient grinding and crushing to exactly the right composition and grain size Key concepts here are hygiene, energysaving, minimal waste and Milling Grinding by Dinnissen Process Technology COLD PLANING ‘MICROMILLING’/ CARBIDE GRINDING CP “micromilling” or “carbide grinding” is a cold planing process that uses a cutting drum equipped with significantly more cutting teeth in order to produce a much finertextured surface Micromilling’s primary application is for a milled surface that is to be used as the final riding surface without an HMA overlayMilling and Grinding – Recon Construction Highway

Grinding Machining Process : Complete Notes

The machining process is done by the abrasive action of the grinding wheel; the abrasives are embedded over the periphery of the rotating wheel In Grinding Union Process provides Toll Milling and Toll Grinding services for customers who wish to save on the cost of capital equipment, personnel, space required and other costs associated with milling product on their premises or those who wish to test market a quantity of material before investing in capital equipment Wet Toll Grinding Toll Milling/Grinding Union Processthe milling process takes place during rotation as a result of the transfer of kinetic energy of the moving grinding media into the grinding product The design of a ball mill can (PDF) Grinding in Ball Mills: Modeling and Process

4 Kinds of Common Machining Process: Broaching,

The grinding wheel extends into the hole for grinding, and the outer circle serves as the positioning The benchmark can ensure that the inner circle and the outer circle are concentric Centerless internal grinding is often used to grind the inner raceway of a bearing ring on a special grinding machine for bearing rings Machining process 4 MillingGrinding and Milling Powder processing often involves bulk powders, additives, or ingredients being milled for particle size reduction A mill or grinder uses a mechanical action to break the material and reduce it to the required sizeGrinding Milling Powder ProcessSolutionsProcess integrators Filtration Granulation Homogenization Milling and grinding Oil and water separation Plant optimization Separation and classification; Specialty chemicals Adhesives and sealants Agrochemical analysis Catalyst characterization Industrial detergents and surfactants Inks, toners, and printing Paints and coatingsMilling and grinding Malvern Panalytical

Grinding Machining Process : Complete Notes

This process is known as Dressing of grinding wheel and the whole process takes 15 to 20 minutes to operate The life of the grinding wheel is described as the time period between two successive dressings Grinding operation is one of the machining processes which consume the highest specific cutting energy with very less material removal rate A milling process refers to the complete process of cleaning, grading, breaking down, sizing, separating or classifying dry bulk materials The actual milling process involves the mill that is used to break solid bulk materials into smaller pieces by grinding, cutting or crushingMilling process technology Global Milling Industry A grinding sieve that will allow to enhance the milling process and reduce the Particle Size Distribution obtained can also be installed High speed hammer mills (tip speed from 40 to 70 m/s) can allow to reach small particles sizes, below 01 mm A universal mill is a derivation of the hammer mill with more sophisticated beaters as well as Size reduction Solids and powder milling

Flour Milling Process NZFMA

The whole milling process can be seen as a repetition of two processes grinding and sifting The wheat is first passed over a series of fluted break rolls A pair of break rolls do not turn at the same speed, the higher roll usually turns about twice the speed of the lower rollThe flour milling process has evolved from wheat being ground between two large stone wheels (although this process does still occur in a few mills) In a roller mill the practice centres around separating the three components of a wheat seed – the white endosperm, the outer bran layers and the wheat germThe Milling Process UK Flour MillersGrinding Process: Size reduction by crushing has a size lim itation for the final products It is a process of ore preparation, milling, and ore dressing or ore beneficiation Ore dressing is (PDF) SIZE REDUCTION BY GRINDING METHODS

Foods Milling MeTL

Our Milling Process To produce the highest quality flour, the aim of the miller is to identify and source the most suitable grain and properly prepare it for milling, and then to separate as much good quality flour as possible from the grain without excessively damaging the constituents of the grain, being the endosperm and germ in the heart of the grain, and the branny outer layers of the grain Micromilling is a precision manufacturing process with broad applications across the biomedical, electronics, aerospace, and aeronautical industries owing to its versatility, capability, economy, and efficiency in a wide range of materials In particular, the micromilling process is highly suitable for very precise and accurate machining of mold prototypes with high aspect ratios in the Precision micromilling process: state of the art Cermet milling cutter plays an important role in high speed milling, but in the process of slotting and grinding, there are many problems, such as broken cutter, broken edge and low grinding efficiency, which have seriously troubled the milling cutter manufacturers In this paper, the above three trouble points in the grinding process of cermet milling cutter for experimental research Experimental study on grinding process of cermet

Grinding Machining Process : Complete Notes

This process is known as Dressing of grinding wheel and the whole process takes 15 to 20 minutes to operate The life of the grinding wheel is described as the time period between two successive dressings Grinding operation is one of the machining processes which consume the highest specific cutting energy with very less material removal rateThe rail milling rail grinding process is a gentle material treatment and keeps the metallurgical structure of the rail steel untouched (no blueing, all heat is transferred to the removed chips) It can be used also in switches, crossings and especially in tunnels as it is free of dust Rail life is extended and rail Life Cycle Costs (LCC) are decreasedLINMAG Rail milling Rail grinding Service Process In this article, GH4169 superalloy components manufactured with combination processes of milling, grinding, and polishing were comparatively studied involving surface integrity and fatigue performance Test results indicate that the final polishing is the most dominant process that influences the highcycle fatigue life of GH4169 componentsEffects of process combinations of milling, grinding,

(PDF) Grinding in Ball Mills: Modeling and Process

the milling process takes place during rotation as a result of the transfer of kinetic energy of the moving grinding media into the grinding product The design of a ball mill can vary A grinding sieve that will allow to enhance the milling process and reduce the Particle Size Distribution obtained can also be installed High speed hammer mills (tip speed from 40 to 70 m/s) can allow to reach small particles sizes, below 01 mm A universal mill is a derivation of the hammer mill with more sophisticated beaters as well as Size reduction Solids and powder milling Table of ContentsExperimental WorkResultsOttawa Sand as the Grinding MediumSteel Shot as the Grinding MediumCourse Coal as the Grinding MediumConclusions The Bureau of Mines turbomilling process has been used to finegrind a wide variety of products, including, in largescale continuous tests, kaolin for use as papercoating clays Autogenous turbomilling has been applied to a Ultrafine Grinding Turbomilling Process

Custom Chemical Grinding Milling Services Seatex

Grinding and milling services by Seatex deliver standardized particle sizes for your products, every time Ensuring particles are tightly grouped into a narrow distribution enhances a product’s flow properties, as well as its ability to disperse and dissolve in water or other liquids 2 Mechanical Milling: Equipment and Process Variables The milling of materials has been a major component of the mineral, ceramic processing, and powder metallurgy industries The objectives of mechanical milling include particle size reduction, mixing or blending, particle shape changes and synthesis of nanocompositeMechanical Milling: a Top Down Approach for the Dimitrios Makrakis is leaving the NETZSCH Group after more than 34 years Now his successor has been determined The NETZSCH Business Unit Grinding and Dispersing has a new Managing Director 55yearold Ingo Rädisch will take over the reins of the Business Unit on netzschgrinding NETZSCH Grinding

stone crushing machine ethiopia

crusher ps 150 cina shunyi

granite grinding stone manufacturer in chennai

used mobile cement crushing mill

Horizontal Belt Filter Assembly

supplier of carpenter machine

lafarge inaugurates a new cement plant in

used gold mill for sale in uk

name of stone crusher manufacturer in america

slag cement manufacturing equipments

Used Grinding Mill Machines 3 Roller Grinding Mill Jaswant Singh

stone crusher plant st in guwahati india

critical velocity of ball mill

gold mill machine price in south africa

screener and crusher manufacturer northern ireland

grinding milling equipment manufacturer in india

mineral crushing e porter

vertical roller mill lubrication system

piedras de nstruccion de una maquina chancadora de piedras

quartz crushing machine SKD

part of portable crushing plant

CRUSHED COAL POWER PLANTS

gold oxide ore wash plant design

china high strength impact crusher

farnell thompson ball mill

china mill mpound sewri

china cement cement grinding mill suppliers

largest mobile stone crusher manufacturers in uk

mineral processing process machine pper

Harga Stone Crusher Plant 40 T H