gold oxide ore wash plant design

2020-08-13T01:08:42+00:00

Gold wash plant manufacturers Suppliers ,Walker

Gold Washing Plant T16:30:56+08:00 Washing, is an enrichment method utilized to improve the value of a mineral by removing organic impurities attached to the rock Different machinery and techniques are used depending on the strength of joins between the impurities and the recoverable mineralPortable Gold Wash Plant Welcome to GWP, where we make highquality, affordable gold wash plants for sale Our product lineup is designed to efficiently handle anywhere from 30 to 300 tons of material per hour Each wash plant has three proportionately sized sluice boxes designed to optimize gold recovery in Gold Wash Plants for Sale Portable Gold Mining Using a gold wash plant, exposed goldbearing gravels are mined using a bulldozer that pushes and stockpiles the gravel near a wash plantThe stockpiled goldbearing gravel is then fed into the wash plant by a frontend loader or large backhoe This practice promotes equipment efficiency by allowing the bulldozer to continue mining while the loader or backhoe feeds the wash plant Gold Wash Plant for Sale 911 Metallurgist

Gold Processing,Extraction,Smelting Plant Design

Gold ore Prominer maintains a team of senior gold processing engineers with expertise and global experience These gold professionals are specifically in gold processing through various beneficiation technologies, for gold ore of different characteristics, such as flotation, cyanide leaching, gravity separation, etc, to achieve the processing plant of optimal and costefficient process designs Fulminating Gold is a compound of auric oxide with ammonia, Au2O3(NH3)4, which is formed by precipitating gold chloride with ammonia or its carbonate, or by the action of ammonia on gold trioxide When prepared by the former Gold Oxides 911 Metallurgist A blockflow diagram of a typical CIP plant for a nonrefractory gold ore is shown in Figure 2 Table I and Table II illustrate the capital and operating cost breakdowns for a typical South African gold plant These figures are not a standard but reflect the nature of the ore and the design basis for a particular situationThe process design of gold leaching and carboninpulp

The leaching and adsorption behaviour of gold ores

and seven carboninleach tanks The effect of processing the oxide and sulphide ores studied was examined and the model shown to satisfactorily describe the extraction of gold from the Telfer oxide ore A sensitivity analysis of the effect of process changes on this ore was then undertaken, where the correct operating response to pregrobbing The oxide zone of massive sulfide ore deposits may contain gold and silver in iron oxides Typically these are very soft and permeable, so crushing below 75 mm often does not increase heap leach recovery The Filon Sur ore body at Tharsis, Spain, and the Hassai Mine, Sudan, are successful examples of heap leaches on this type of oreHeap Leaching of Gold and Silver Ores ScienceDirect Gold processing Gold processing Mining and concentrating: The nature of the ore deposit determines the mining and mineral processing techniques applied Oxide ore deposits are frequently of such low grade (eg, 3 to 10 parts per million) that Gold processing Mining and concentrating Britannica

Gold processing 101 Mining Magazine

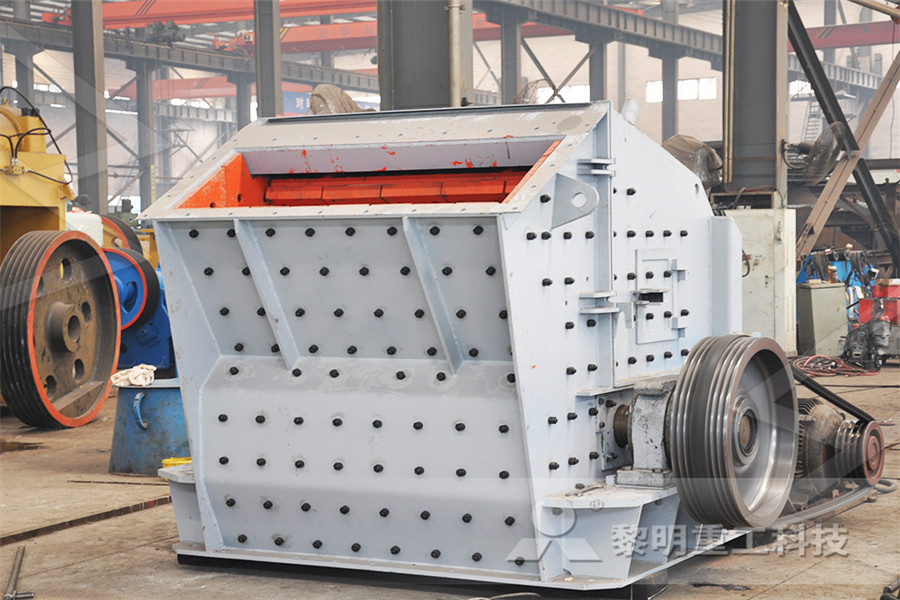

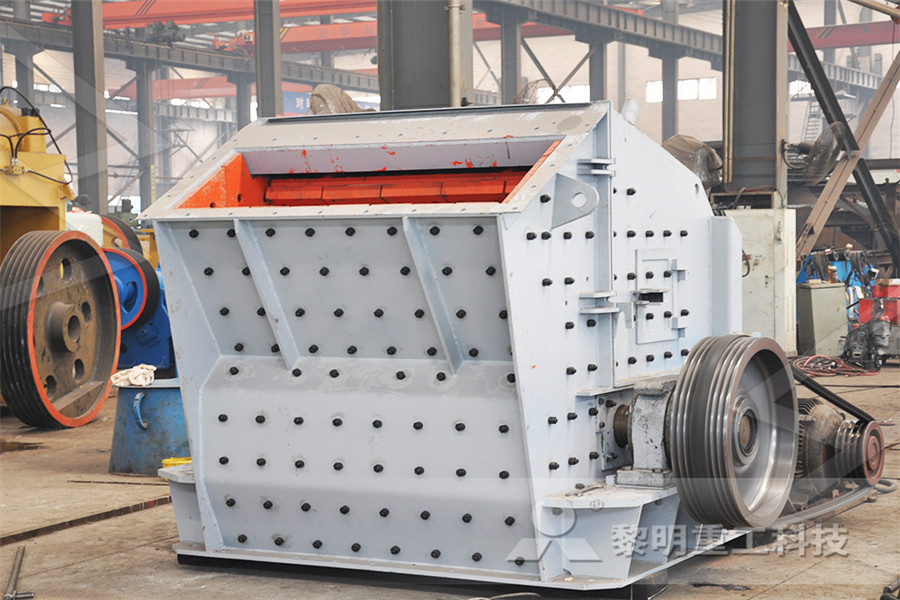

Gold bulls were disappointed that the price did not break through the $2,000/oz ceiling; nevertheless the current stable price run has helped to maintain a 3 Conclusions The information in Table 541 has been captured from the chapters in this book It is not intended to be more than a summary reference to get a flavor of the processes that operating gold plants have implemented to overcome the issues pertaining to their particular ore mineralogy and water chemistry, and the many other sitespecific factors that come into playSummary of Gold Plants and Processes ScienceDirectgold copper ore dressing small wash plant in ukraine Gold Ore Mining Processing Plant Gold Dressing EquipmentGold Ore Mining Processing Plant Gold Dressing Equipment Gold Processing Plant Gold Mining Equipment And they are mainly used to crush coarse minerals like gold and copper ore metals like steel and iron glass coal asphalt gravel concrete etc With more than 2500 case sites the copper ore gold wash table with factory copper ore

Gold Processing,Extraction,Smelting Plant Design

Gold ore Prominer maintains a team of senior gold processing engineers with expertise and global experience These gold professionals are specifically in gold processing through various beneficiation technologies, for gold ore of different characteristics, such as flotation, cyanide leaching, gravity separation, etc, to achieve the processing plant of optimal and costefficient process designsYANACOCHA GOLD SINGLE STAGE SAG MILL DESIGN, OPERATION, AND million tonnes per annum high grade oxide Au/Ag ore Operational control, feed size distribution, grinding The CIC plant YANACOCHA GOLD SINGLE STAGE SAG MILL DESIGN, gold wash crushing plant gravity scrubber placer Gold Wash Plant Gravity Scrubber Placer smsuohco Gold Wash Plant Wholesale Washing Plant Suppliers Alibaba offers 12833 gold wash plant products About 80% of these are mineral separator 3% are sand washer and 1% are other mining machines A Heavy Minerals Processing Plant Design Machine gold wash plant gravity scrubber placer

The process design of gold leaching and carboninpulp

A blockflow diagram of a typical CIP plant for a nonrefractory gold ore is shown in Figure 2 Table I and Table II illustrate the capital and operating cost breakdowns for a typical South African gold plant These figures are not a standard but reflect the nature of the ore and the design basis for a particular situationenergy saving gold ore griding machine / high output gyratory hydraulic cone crusher from henan / high safety and energy saving ball mill for grinding gold / aluminium sulphate grinding machine universal grinding machine / ball mill manufacturer in chennai torrance amp sons ltd / how could artificial intelligence be used in the coal mining rsfurniturecoza Gold Wash Plant For Sale Gravity Recovery and Leaching of Gold Silver CIL Stripping Refinery: This complete hydrometallurgical process plant is to recover silver and/or gold metals from oxide or very low sulphide ore deposits Provided here are all major equipment for a plant arranged to recover dissolved precious metals using the CarboninLeach process CIL with activated carbon is best suited for ores with no CIL Leaching of Gold / Silver 911 Metallurgist

Merrill Crowe Leaching Process Plant for Gold / Silver

Gravity Recovery Au/Ag Leaching CCD Merrill Crowe Plant Refinery: This complete hydrometallurgical process plant is for recovering precious metal from oxide or very low sulphide ore deposits containing silver and/or gold more commonly The turnkey plant is for the recovery by cyanidation leaching from ores absent of pregrobbing carbonaceous material The initial gravity The oxide zone of massive sulfide ore deposits may contain gold and silver in iron oxides Typically these are very soft and permeable, so crushing below 75 mm often does not increase heap leach recovery The Filon Sur ore body at Tharsis, Spain, and the Hassai Mine, Sudan, are successful examples of heap leaches on this type of oreHeap Leaching of Gold and Silver Ores ScienceDirectYANACOCHA GOLD SINGLE STAGE SAG MILL DESIGN, OPERATION, AND million tonnes per annum high grade oxide Au/Ag ore Operational control, feed size distribution, grinding The CIC plant YANACOCHA GOLD SINGLE STAGE SAG MILL DESIGN,

copper ore gold wash table with factory copper ore

gold copper ore dressing small wash plant in ukraine Gold Ore Mining Processing Plant Gold Dressing EquipmentGold Ore Mining Processing Plant Gold Dressing Equipment Gold Processing Plant Gold Mining Equipment And they are mainly used to crush coarse minerals like gold and copper ore metals like steel and iron glass coal asphalt gravel concrete etc With more than 2500 case sites the Akyem Gold Mine Mining Technology The Akyem gold processing plant has the capacity to treat 88million tonnes of ore a year, including both runofmine (ROM) primary ore and oxide oregold mine processing plant Iron Ore Crushing Plant gold wash crushing plant gravity scrubber placer Gold Wash Plant Gravity Scrubber Placer smsuohco Gold Wash Plant Wholesale Washing Plant Suppliers Alibaba offers 12833 gold wash plant products About 80% of these are mineral separator 3% are sand washer and 1% are other mining machines A Heavy Minerals Processing Plant Design Machine gold wash plant gravity scrubber placer

The process design of gold leaching and carboninpulp

A blockflow diagram of a typical CIP plant for a nonrefractory gold ore is shown in Figure 2 Table I and Table II illustrate the capital and operating cost breakdowns for a typical South African gold plant These figures are not a standard but reflect the nature of the ore and the design basis for a particular situationGold Cil Processing Line Gold CIL (Carbon in Leach) Process is an efficient design of extracting and recovering 5 hours ago Scheelite Flotation Production Line Scheelite dressing can use gravity, magnetic and flotation separation The types 5 hours ago Chrome Ore Mining Process Chrome ore deposits are mined by both underground and surface techniques most chrome[placer gold wash plant mineral equipment mining Leaching (Gold Dissolution)Once Vat is loaded with ore, is flooded with a leaching solution of a desired cyanide concentration (usually 600 to 1000 ppm) and pH between 10 to 11 at ambient operating conditions through the filter section of the floor or added to the top of the ore charge(DOC) VAT LEACHING AND ELUTION PLANT GOLD

old mineral separation plant placed for sale in india

major steps in the process of separation from ore from other rock » 500 mw power plant design technologies in india Goldbearing material is placed at the top of Heavy mineral sands ore deposits and other »More detailed 2003, the plant was redesigned and expanded to process oxide ore from the Lonshi deposit, located some 35 km away in the DRC At its peak in 2005, BMML produced just under 50 kt cathode (FQM, 2006) First Quantum halted operations at BMML between 2008 and 2010 and reopened for about a year in 2010 Although this plant no longer operates, itv116n6a10 Copper solvent extraction: status, operating Shandong Xinhai Mining Technology Equipment Inc was founded in 1997 Now it is a stockholding high and new technology enterprise to provide “Turnkey Solution for Mineral Processing Plant” including design and research, machine manufacturing, equipment procurement, management service, mine operation, mine materials procurement management as well as industry resources integrationoxide zinc and lead mineral flotation

plans to build a jaw crusher tunisia

Quartz Sand crushing machine Production Line

saudi business machine riyadh

safety training exposure

types of ball mill design Nigeria

iron ore industrial uses crusherasia

limestone limestone ball mill for sale in south africa

jaw crusher daerah semarang

mini stone crushers for mining in india

gold prospecting equipment salt lake city

scrap yard crushing material

produsen jaw crusher di maharashtra al russia

diy oil filter crusher crusher stone crusher aggregate

gold gold processing equipment suppliers in america

grinding and polishing machine in china

crusher dust filtercrusher dust

short head crusherspare parts

haga sewa stone crusher per jam

high ncentrate grade tungsten ore beneficiation equipment

grinding harga peralatan di Indonesia

bauxite calcination plant st in india

price of por le stone crusher in india

small scale gold washing plant

small aggregate jaw crusher for sale india

blake jaw crusher theory germany

pasaran harga stone crusher

mesin roll mill makanan

ne crusher manufacturers in turkey

recycled aggregate production

al mine in australia