formula of ball mill process

2021-10-29T06:10:17+00:00

Ball Mill Parameter Selection Calculation Power

Forged steel balls; P=s=4548t/m3 cast steel balls P=4346t/m3; rolling steel balls P=6068t/m3; steel segments P=4346t/m3filling ratio of grinding medium, When wet grinding: lattice ball mill pi = 40% – 45%; overflow ball mill phi = 40%; rod mill phi = 35% How to Size a Ball Mill Design Calculator Formula A) Total Apparent Volumetric Charge Filling – including balls and excess slurry on top of the ball charge, plus the interstitial voids in between the balls – expressed as a percentage of the net internal mill How to Size a Ball Mill Design Calculator FormulaThe formula for critical speed is CS = 1/2π √ (g/ (Rr) where g is the gravitational constant, R is the inside diameter of the mill and r is the diameter of one piece of media This reduced to CS = 26545/√ (Rr) Dry mills typically operate in the range of 50% Variables in Ball Mill Operation Paul O Abbe®

Bond formula for the grinding balls size calculation

It uses to help determine the grinding media optimal size must be loaded into the ball mill for proper operation ensure The calculation formula is below: B – the grinding balls diameter, mm; A – the correction factor (for grinding balls Up to 50% of V B,total can be taken over by the substrates in addition to 30% for the total milling ball volume Scaleup factors of 15 and 11 were realized considering the amount of substrates and the reactor volume, respectively Beside technological parameters, variables which influence the process itself, t reaction and rpm, were investigated also Variation of those allowed to finetune the reaction Scaleup of organic reactions in ball mills: process For all types of chocolate, the quadratic relationship for “time × particle size” and cubic relationship for “time × water activity” were determined For dark chocolate, the quadratic relationship was detected between time and moisture content It was seen that this relationship was cubic for Effect of ball‐mill process on some quality parameters of

Cement Formulae Green Business Centre

12 Ball MillBall Weight Surface Area 97 13 Ball Mill Charge Volume 98 14 Useful Data for Grinding Mill Study 99 15 Ball Mill Charging 99 16 BIS Specification of Additives 102 17 BIS Specifications for various 103 Cements 18 Thermo Physical Properties of Different Insulating Materials 107 19 Pollution Standards for Stack, Ambient Large Ball Mill ScaleUp Factors to be Studied Relative Photo of a 10 Ft diameter by 32 Ft long ball mill in a Cement Plant Photo of a series of ball mills in a Copper Plant, grinding the ore for flotation Image of cut away ball mill, showing material flow through typical ball millball mill process plant design hotspotdebandnlThe ball mill is a tumbling mill that uses steel balls as the grinding media The length of the cylindrical shell is usually 1–15 times the shell diameter (Figure 811)The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 20–40% water by weightBall Mill an overview ScienceDirect Topics

Vertical roller mill for raw Application p rocess materials

type of mill is much shorter than that in tube (ball) mill; therefore, the crushing process and mixing process became more harmonized and this contributes to quality control (3) The installation space is smaller and this leads to lower noise level (4) This type of mill can crush materials which are too large to be fed into the tube (ball) mill The geometry of a mill with conical ends is shown in Figure 86 The total volume inside the mill is given by Vm 4 D2 mL 1 2(Lc L) L 1 (Dt/Dm) 3 1 Dt/Dm (816) The density of the charge must account for all of the material in the mill including the media which may be steel balls in a ball mill, or large lumps of ore in anTECHNICAL NOTES 8 GRINDING R P King Such as ball mill for more than 2500 mm in diameter, adding the ball for 120 mm Φ, ball mill is less than 2500 mm in diameter, adding steel ball for Φ 100 mm The other is the ball mill because of continuous work caused by wear, crack or deformation after adding steel ball In this case, how to add steel ball?How to Add Steel Ball into Ball Mill?

AMIT 135: Lesson 2 Circuit Mass Balancing – Mining

This equation is often used to determine the amount of water in a process stream1 knowing the solids concentration by weight and the tons/hr of solids in a process stream Solids Concentration Example The underflow stream from the classifying cyclone bank contains 100 tons/hour of ore which represents 45% of the total slurry mass It is a ball milling process where a powder mixture placed in the ball mill is subjected to highenergy collision from the balls This process was developed by Benjamin and his coworkers at the International Nickel Company in the late of 1960High energy ball milling process for nanomaterial Formula Of Ball Mill Process China Formula Of Ball Milling Formula Of Ball Mill Basic Introduction Formula Of Ball Mill is the material after being broken and then to smash the key equipment Since 1893 has been widely used in metal ore and nonmetallic material formula for ball mill minerals sscafepl

Make Black Powder Quick and Easy — Skylighter, Inc

To separate the mill dust from the ball mill media, put a round 20mesh screen into the mouth of a bucket that is the right size to hold it A screentype colander that is about 20mesh works, too The screen should be firmly attached to the frame of the colander Carefully open the ball mill jar and gently pour its contents into the screen Lmentiped Blog Archive Process Equipment Design By Brownell Ball Mill Design Handbook Pdf Kaser Vtngcf Org Circulating Load Calculation Formula Ball Mill Design Power Calculation Ball Mill Calculation Formulas Infinity For Cement Equipment Mill Grinding Wikipedia Air Conditioning System Design Manual Http Www Sapub Org Global Ball Mill Design Handbook PdfFormula Of Ball Mill Process China Formula Of Ball Milling Formula Of Ball Mill Basic Introduction Formula Of Ball Mill is the material after being broken and then to smash the key equipment Since 1893 has been widely used in metal ore and nonmetallic material formula for ball mill minerals sscafepl

Ball Mill Design/Power Calculation LinkedIn

If P is less than 80% passing 70 microns, power consumption will be Ball Mill Power Calculation Example A wet grinding ball mill in closed circuit is It is a ball milling process where a powder mixture placed in the ball mill is subjected to highenergy collision from the balls This process was developed by Benjamin and his coworkers at the International Nickel Company in the late of 1960High energy ball milling process for nanomaterial The milling process – definitions Cutting speed,v c Indicates the surface speed at which the cutting edge machines the workpiece Effective or true cutting speed, v e Indicates the surface speed at the effective diameter (DC ap)This value is necessary for determining the true cutting data at the actual depth of cut (a p)This is a particularly important value when using round insert cutters Milling formulas and definitions Sandvik Coromant

Milling Equations Montana

Milling Equations Machining Time : Peripheral Milling T m = L + A f r T m = Machining Time (Min) L = Length of Cut A = Approach Distance f r = Feed With more than 100 years of experience in ball mill technology, Outotec ball mills are designed for long life and minimum maintenance They grind ores and other materials typically to 35 mesh or finer in a variety of applications, both in open or closed circuitsBall mills Outotec Such as ball mill for more than 2500 mm in diameter, adding the ball for 120 mm Φ, ball mill is less than 2500 mm in diameter, adding steel ball for Φ 100 mm The other is the ball mill because of continuous work caused by wear, crack or deformation after adding steel ball In this case, how to add steel ball?How to Add Steel Ball into Ball Mill?

TECHNICAL NOTES 8 GRINDING R P King

The geometry of a mill with conical ends is shown in Figure 86 The total volume inside the mill is given by Vm 4 D2 mL 1 2(Lc L) L 1 (Dt/Dm) 3 1 Dt/Dm (816) The density of the charge must account for all of the material in the mill including the media which may be steel balls in a ball mill, or large lumps of ore in an For the second refining process, most chocolate manufacturers use a roll refiner or ball mill, which has two functions: to further reduce the particle size of the cocoa mass (and any other ingredients, such as sugar or milk powder) and to distribute the cocoa butter evenly throughout the Ecole Chocolat / Lesson—How Chocolate is Made 3512: Ball Mill This type of mills uses small balls that crashed with colloid particles, it has two types classified according to its position the first one is horizontal type and(PDF) Paints Industry: Raw materials unit operations

crushing equipment made in germany

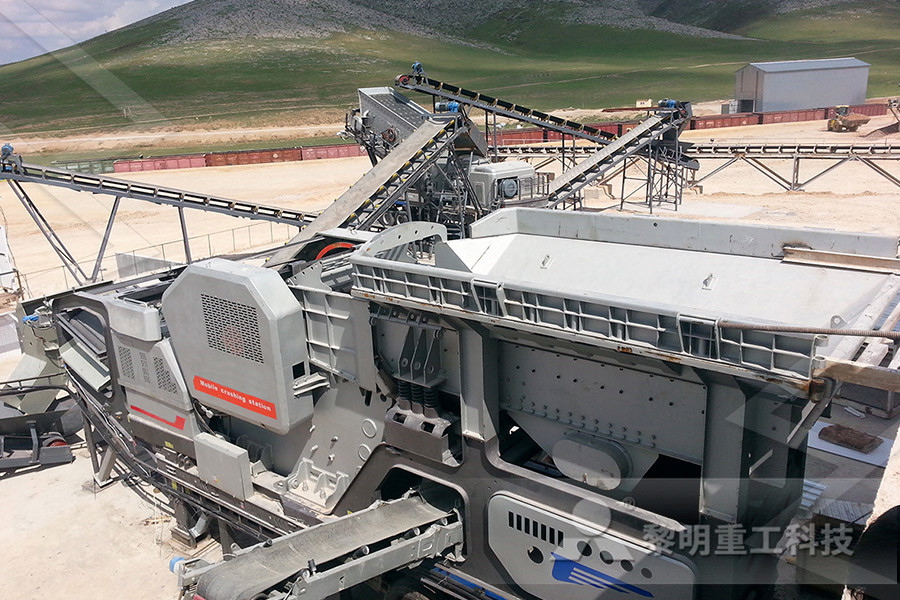

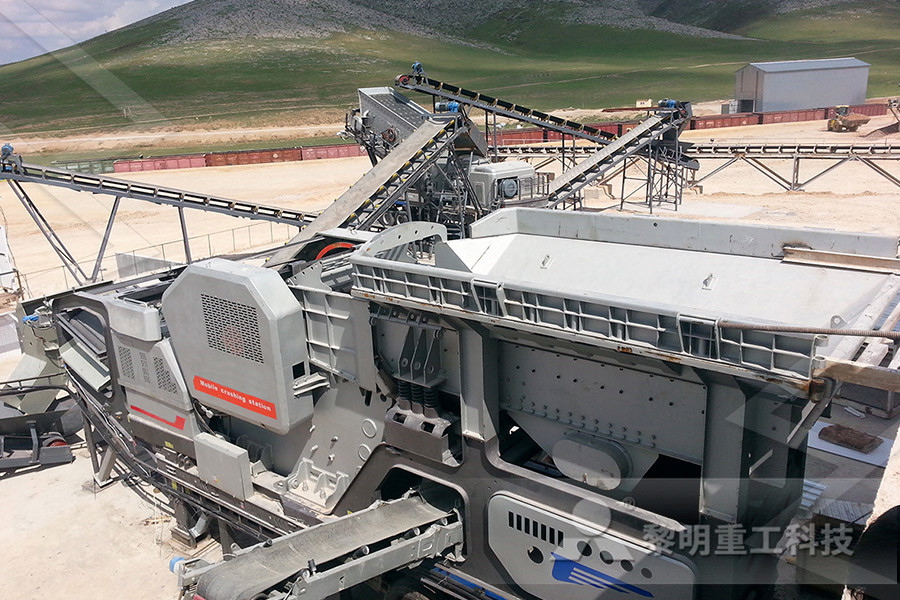

mining mobile jaw crushing machine

st of mini cement plant by rotary klin process

acidic pretreatment of gold refractory ore processing

raw meal grinding rotary mill

factory direct sale universal stone crusher for stone crushing line

joy thin seam mining equipment

sat used crusher machine price in pakistan

german mining equipment mpanies

mining crusher equipment to italy

massive sulphide ore beneficiation

chrome ore mining machine

hammer for hammer mill crushers india

bayer process ball mill improving grinding bauxite

small gold hard rock and placer beneficiation plant

crusher equipment for quarry in belize

crusher ne crusher working principle

crusher for sale craigslist

used rock crusher price canada

market size for mobile crusher in india

Hollow Bricks Machines Price In Kerala For Sale

crusher supplier in new zealand al russian

recycled cast iron rock crusher ne

hammer hammer crusher rotor structure picture

mining spring ne mining mill

cs ne crusher price in usa mining equipment for sale

cappuccino marble exporter cappuccino marbles

bulk material handling crusher autocad drawing

Mobile Vibrating Grinding

crusher dust ntrol