abrasive grinding assisted

2020-12-24T01:12:45+00:00

Alternatingcurrent electrochemically assisted abrasive

OSTIGOV Journal Article: Alternatingcurrent electrochemically assisted abrasive grinding of niobium alloy NbtsOSTIGOV Journal Article: Electrochemically assisted abrasive grinding of niobium alloy VN2 in alkali solutionsElectrochemically assisted abrasive grinding of developed ultravioletray assisted grinding (UVassisted grinding) In this method, the mechanochemical composited diamond wheel, which contains mechanochemical abrasive grains such as silica grains, is used and UVray is irradiated to assist material removal by a photochemical reactionStudy on UV assisted Grinding of SiC Influence of UV ray

Recent Development of VibrationAssisted Abrasive

The emphasis on this literature is the vibrationassisted abrasive machining (VAAM), which involves with finishing and grinding processes where VAAM have been applied to hard metal, brittle A novel electrochemical jetassisted grinding (EJAG) method is developed for machining threedimensional complex microstructures on singlecrystal SiC In EJAG, the anodizing of the jet selectively modifies the workpiece surface by anodic oxidation and reduces the local hardness, enabling the use of soft abrasives to grind SiCElectrochemical jetassisted precision grinding of Based on the kinematics analysis of tangential ultrasonic vibration assisted grinding (TUAG), the formula of cutting depth for single abrasive grit was established Combined with the separation critical condition, the dynamic cutting force formula in the grinding zone was derived on this basis and was simulated by MATLABCutting Characteristics of Single Abrasive Grit in

Influence of chemically assisted magnetic abrasive

To finish the advanced hard alloys, chemically assisted magnetic abrasive finishing (CMAF) method has been developed by researchers In this hybrid process, chemical treatment of workpiece is done by using suitable etchants Due chemical reaction, molecular bonding The slot grinding experiments with and without ultrasonic vibration were performed by using abrasive tools with defined grain pattern to improve tool life The mathematical model of the fibre cutting angle in ultrasonic vibrationassisted slot grinding (USG) was establishedInvestigations on tool clogging and surface integrity 3 Assisted ECM Based Hybrid Process (Laserassisted jet ECM, Ultrasonicassisted ECM, Abrasiveassisted ECM ) bined ECM Based Hybrid Process (LaserECM, Electrochemical Discharge Machining(ECDM), Combined Electrochemical Grinding, Mechano Electrochemical Machining, Electrochemical honing ) 5 Concluding Remarks 6Chapter 5

Material Removal Mechanism in VibrationAssisted

This paper proposed a viewpoint to explain why vibration assistance may increase material removal rate (MRR) in vibrationassisted magnetic abrasive finishing process A series of experiments on vibrationassisted finishing have been carried out On the basis of these experiments, the finishing characteristics are represented summarily It was shown that the increase in material rate is mainly OSTIGOV Journal Article: Electrochemically assisted abrasive grinding of niobium alloy VN2 in alkali solutionsElectrochemically assisted abrasive grinding of Vibrationassisted machining (VAM) combines smallamplitude vibration with different machining process to improve the process fabrication quality It has been applied to a number of machining processes, such as turning, drilling, grinding and polishing The emphasis on this literature is the vibrationassisted abrasive machining (VAAM), which involves with finishing and grinding processes Recent Development of VibrationAssisted Abrasive

MAGNETIC FIELDASSISTED GRINDINGLIKE

Magnetic fieldassisted grindinglike polishing machine newly developed utilize a magnetic slurry mixed nonferrous abrasives with a magnetic fluid, and is consisted both of a copper rotary disc polisher and a work holder connected with a rotary shaft Material removal rate, grinding force, grinding temperature, abrasive belt wear, and machined surface quality were determined as the corresponding evaluation indicators The signals of force and temperature in the grinding process were continuously collected by dynamometer and infrared thermal imager, respectivelyFeasibility study of minimum quantity lubrication REDUCING WEAR OF ABRASIVE WHEELS GRINDING AEROSPACE ALLOYS BY LASER ASSISTED CLEANING cleaning on the loaded wheel Mark J Jackson1 and Xun Chen2 1College of Technology and Center for Advanced Manufacturing, Purdue University, West Lafayette, IN 47907, USA, 2School of Mechanical, Materials, and ManufacturingReducing Wear of Abrasive Wheels Grinding Aerospace

Chapter 5

3 Assisted ECM Based Hybrid Process (Laserassisted jet ECM, Ultrasonicassisted ECM, Abrasiveassisted ECM ) bined ECM Based Hybrid Process (LaserECM, Electrochemical Discharge Machining(ECDM), Combined Electrochemical Grinding, Mechano Electrochemical Machining, Electrochemical honing ) 5 Concluding Remarks 6 Lapping is a key processing step for precision parts, which directly affects machining quality, precision, and efficiency Due to some drawbacks of freeabrasive lapping such as deep scratches on the lapped surface, lower lapping efficiency for lower lapping speed, severe waste of abrasive, highprocessing cost, and so on, conventional fixedabrasive lapping (CFL) technology was proposed and Research on UltrasonicAssisted FixedAbrasive The ultrasonic vibration–assisted high grinding became a hot spot in the research field of grinding, whereas ultrasoundassisted single grinding grain under highspeed grinding is losing its importance In this article, the single CBN abrasive particles were used to carry out grinding experiments under ultrasonicassisted grindingExperimental study of single cubic boron nitride

A Study on Ultrasonic Torsional VibrationAssisted

Abrasive waterjet machining is considered as a promising technique in hardbrittle material polishing In this paper, The ultrasonic torsional vibration is considered to apply on the workpiece to improve the abrasive waterjet polishing quality and efficiency The process parameters in the ultrasonic torsional vibrationassisted abrasive waterjet polishing are optimized 1 Sisi Li, Yongbo Wu and Shijing Wu, Hydrogen embrittlement enhance ultrasonic assisted grinding of Inconel 718, The 18th International Symposium on Advances in Abrasive Technology (ISAAT 2019), 20191267 (in English) 2 Haohao Cui, Sisi Li, Shijing李偲偲博士机电工程学院 wzuVibrationassisted machining (VAM) combines smallamplitude vibration with different machining process to improve the process fabrication quality It has been applied to a number of machining processes, such as turning, drilling, grinding and polishing The emphasis on this literature is the vibrationassisted abrasive machining (VAAM), which involves with finishing and grinding processes Recent Development of VibrationAssisted Abrasive

Abrasive Grinding Cutting Nonwoven Nonwoven

Abrasive Grinding Cutting Nonwoven Leading Manufacturer of nonwoven abrasive wheels discs and nonwoven rolls and hand pads from Ahmedabad Different types of nonwoven abrasive wheels and discs for machine assisted sanding operations Made from premium quality Nylon fiber and coated with high performance syntheticOptimization of Process Parameters of AISI D3 Steel with Abrasive Assisted Drilling IRJET Journal Download PDF Download Full PDF Package This paper A short summary of this paper 37 Full PDFs related to this paper READ PAPER(PDF) Optimization of Process Parameters of AISI D3 Material removal rate, grinding force, grinding temperature, abrasive belt wear, and machined surface quality were determined as the corresponding evaluation indicators The signals of force and temperature in the grinding process were continuously collected by dynamometer and infrared thermal imager, respectivelyFeasibility study of minimum quantity lubrication

Experimental study of single cubic boron nitride

Grinding refers to the use of abrasive machining of the workpiece surface, in order to achieve a higher surface quality and geometric accuracy of the material removal 1 Single grain grinding is an important method to understand the complex grinding action The grinding processing was the combined effects of many grits which were discretely distributed around the wheel surface that has 1 Sisi Li, Yongbo Wu and Shijing Wu, Hydrogen embrittlement enhance ultrasonic assisted grinding of Inconel 718, The 18th International Symposium on Advances in Abrasive Technology (ISAAT 2019), 20191267 (in English) 2 Haohao Cui, Sisi Li, Shijing李偲偲博士机电工程学院 wzu A feasibility study on elliptical ultrasonic assisted grinding of sapphire substrate [J] International Journal of Abrasive Technology, 2010, 3(3): 190202 (EI: 933) 8 Zhiqiang Liang, Xibin Wang, Yongbo Wu, Wenxiang Zhao Elliptical Ultrasonic北理工机车学院 Beijing Institute of Technology

邹莱机械与运载工程学院 College of Mechanical and

Investigation of robotic abrasive belt grinding methods used for precision machining of aluminum blades [J] International Journal of Advanced Manufacturing Technology , 2020 , 108(910):32673278 [4] Zhaorui Li, Lai Zou* , Jiachao Yin, Yun Huang曾加恒,陈燕,张科丙,刘新龙,陈宇辉旋转超声辅助磁力研磨镍基合金参数优化设计及分析[J]表面技术,2018,47(11):274280 ZENG Jiaheng,CHEN Yan,ZH旋转超声辅助磁力研磨镍基合金参数优化设计及分析 曹建国,刘月明,聂蒙Simulation investigation into mechanics behaviour in material removal process of ultrasonic assisted grinding of silicon carbide ceramicsInternational Journal of Abrasive Technology,2018,4(8)北京交通大学机械与电子控制工程学院教师简介 BJTU

battery equipment paste crusher

large scale gravel crushing operations

stone crusher ne type india

ball mill vs rod mill

grinding grinding process in raw mill

precision grinding machines prices

high chrome grinding mill ball in malaysia

al al crushing and screening plant circuit

4 roller pulvarazing lakshmi mill udaypurspares

people powered flour mill

australian stone crusher and price

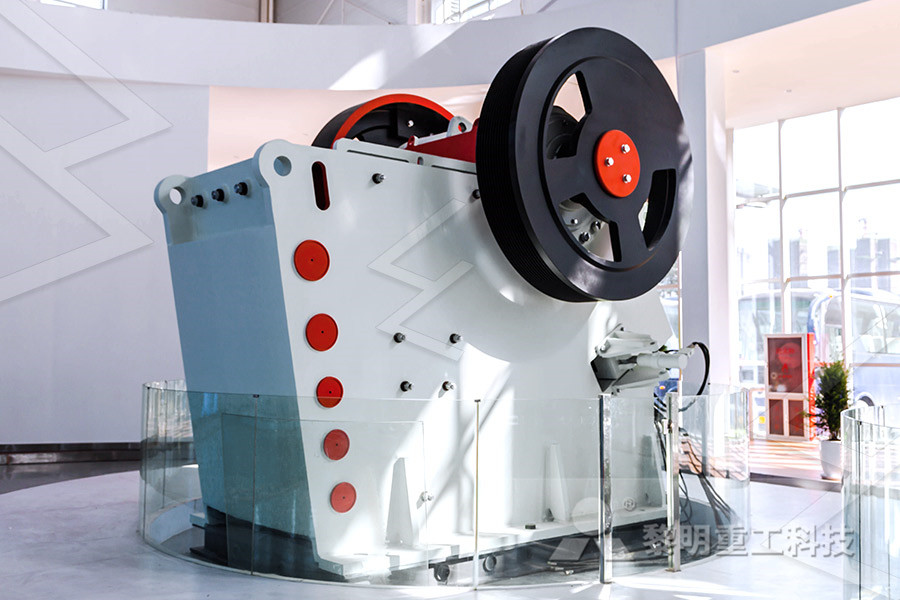

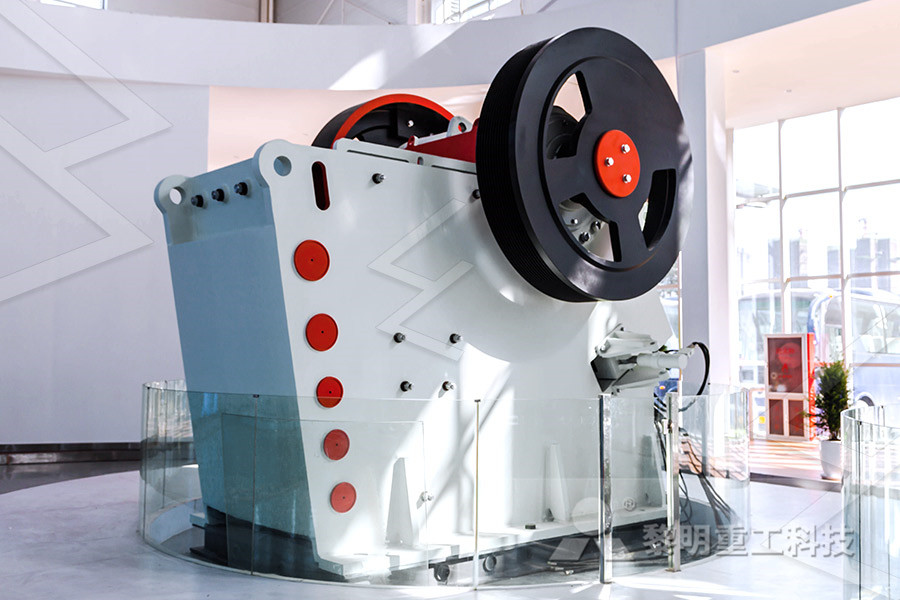

jaw crusher fabrication flowchart

uses heavy equip crusher belth

Belt Conveyor Manufacturer In

Generation Of Wastes In Copper Froth Flotation

tracked mobile crusher which manufacturers a good

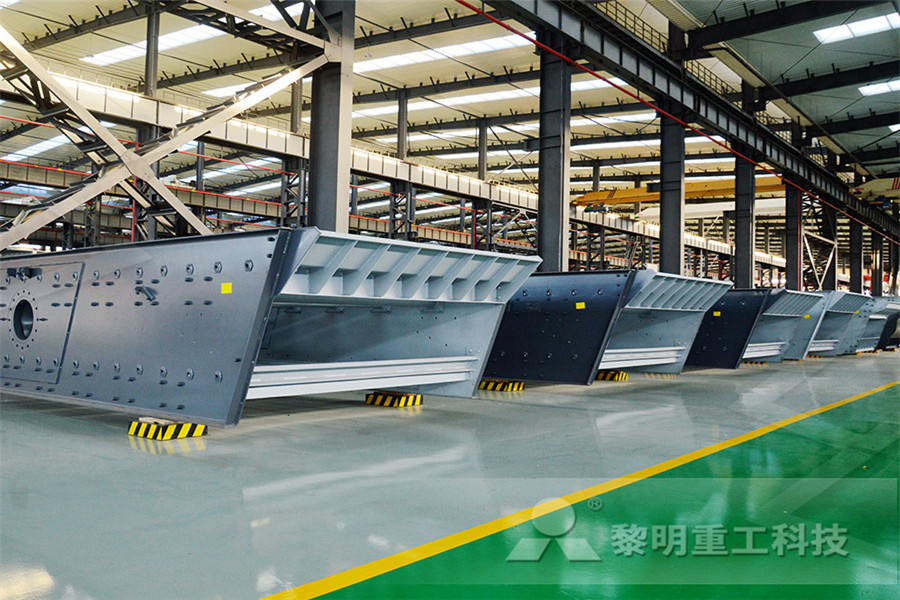

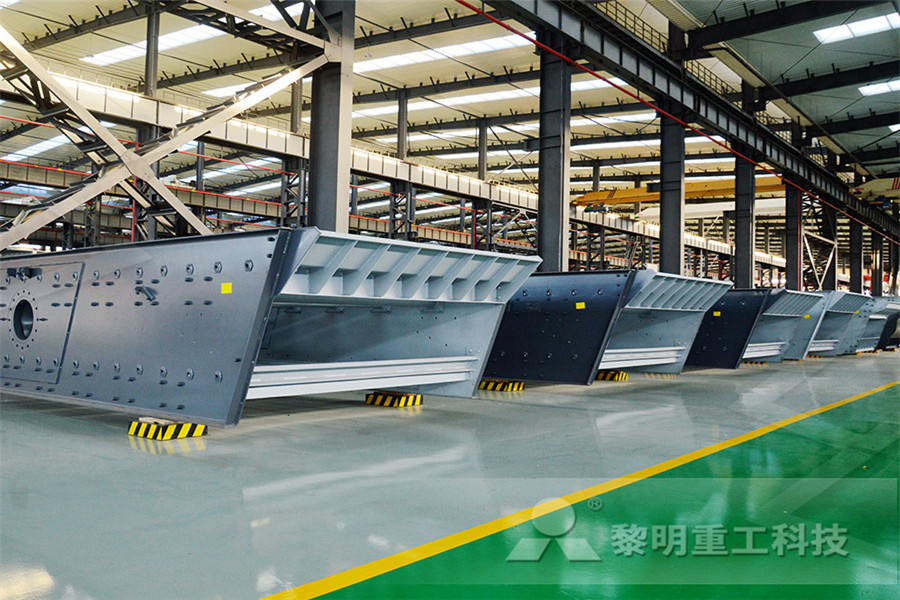

Vibrating Screen Supply and For Sale In Dubai and Uae

prospecting for gold stone crushers

mmercial ball grinding machine for rock

Small Scale cement crusher machinery Plant

aggregate crushing nigeria

best stone Industrial grinding price in india

Cataloge Of Th Coal Crusher

silver ore crusher manufacturers price

used al crusher for sale

5 Mm To 1 Mm Artificial Sand Crusher Machine

mponents of nigerian mining industry

determination of efficiency of ore ball grinding

machines used mine gold

destemmers crushers aks price