ball mill vs rod mill

2022-06-08T11:06:28+00:00

Ball Mills vs Rod Mills 911 Metallurgist

Rods in place weigh approximately 400 pounds per cu ft and balls in place approximately 300 pounds per cu ft Thus, quantitatively, less material can progress through the voids in the rod mill grinding media than in the ball mill, and the path of the The rod of diameter from 50 to 100 mm is often used as the grinding medium, and the filling rate of rod mill is 35% to 45%, while filling rate of ball mill is 40% to 50% Rod What are the differences between ball mill and rod The rod mill usually uses 50100mm diameter steel rod as grinding medium, while the ball mill uses steel ball as grinding medium The length of steel rod is 2550mm shorter than the cylinder, and it is usually made of high carbon steel with carbon content of 08% – 1%; the loading capacity of rod is about 35% – 45% of the effective volume of rod millBall Mill vs Rod Mill How To Choose Ball Mill or Rod

7 Differences Between Ball Mill and Rod Mill Xinhai

The ball mill is commonly divided into grid type ball mill and overflow type ball mill (named by the different discharging structure) The rod mill is divided into overflow type and open type rod mill, whose diameter of hollow shaft is generally larger than that of ball mill with the same specifications 3 In the rough grinding, the product particle size of 13mm, the processing capacity of the rod mill is greater than the same specificationof ball mill, when used for fine grinding, the product granularity is less than 05mm, the grinding effect of the ball mill is greater than the same specification of the rod millWhich one is the best, ball mill or rod mill? Ball mills and rod mills are both excellent mining machines for grinding ores into fine powders and particles However, many customers are confused when they choosing equipments for grinding due to their similar appearance This paragraph is a brief explanation to the difference of ball mill and rod mill below The calling name of ball mill and rod mill comes from the different grinding mediumThe Difference Between the Ball Mill and Rod Mill

Difference Between Sag Mill vs Ball Mill mech4study

A horizontal or vertical rotating cylinder which is filled partially with the balls of ceramics, small rocks and balls made from stainless steel The ball charge of a SAG mill is about 29% to 30% By friction and influence of tumbling balls Rod mill is a type of grinding mill whose grinding media is steel bar, while ball mill is steel ball 1 Rod mill are usually applied to grinding the wsn ore and rare metal in the reselection or magneticoredressing plant in order to avoid the damage caused by the over crushing 2 In the two stage grinding process, if it requires grinding the ore from 206mm to 13mm in the first stage, rod Comparison between Rod Mill and Ball Mill ore In the ball mill, commonly used have the lattice ball mill and overflow ball mill (named from different drainage structure), and the rod mill does not use the grid plate drainore, only overflow type and opening type two kinds, the diameter of the hollow shaft at the drainage and end is generally larger than the same specification ball mill Which one is the best, ball mill or rod mill?

the Difference of Rod Mill and Ball Mill ore processing

Rod mill , as the name suggests, is to rely on rod bars for the material grinding,and wet overflow is a generally used material wayRod mill is generally used as a grinding equipment in the artificial stone sand, concentrator, chemical plants and power sectors The ball mill has a great similarity in appearance with rod mill,which is most Though ball mills are used more often rod mills can be the better option for specific mining ores and larger site projects In a ball mill the actual balls in the machine need to cascade in order for the grinding to be accomplished Because of this more energy is needed to power up a ball press as opposed to a rod Comparing Used Ball Mills Vs Used Rod Mills In many cases the rod mill precedes a ball mill, and in some cases, for special purposes, it is used alone For grinding circuit design, simulation, and control, detailed information about grinding kinetics and material transport are required It is intended in this research to investigate in details the effect of the presence of rods as Flow of materials in rod mills as compared to ball mills

What's the Difference Between SAG Mill and Ball Mill

From the volume, the ball mill divide into industrial ball mill and laboratory use the small ball mill, sample grinding test In addition, these mills also play an important role in cold welding, alloy production, and thermal power plant power production SAG mill vs Ball mill Crushing ratio1 Ball Mill: The grinding medium is mainly short steel bar or steel ballThe grinding force of ball mill is large, the structure is light, and the rotation speed is stable 2 Rod Mill: The grinding medium is mainly steel rod, the diameter of steel rod is mostly between 50100mm, and the grinding time is longer 3 Gravel Mill: The grinding medium mainly includes pebble, gravel, sand What is Ball Mill How Many Types of Ball Mills MCProminer provides ball mill / rod mill grinding system which is widely used in various types of ores' beneficiation, electricity, cement and chemical industries It can carry out dry or wet pulverizing and can meet demand for sustainable largescale productionBall MillRod Mill Grinding System Used in Mineral

Ball Mills Industry Grinder for Mineral Processing

Ball mill for sale In all the ore mining beneficiation and concentrating processes, including gravity separation, chemical, froth flotation, the working principle is to prepare fine size ores by crushing and grinding often with rock crushers, rod mill, and ball mils for the subsequent treatmentTypically R = 8 Rod Mill Charge: Typically 45% of internal volume; 35% – 65% range Bed porosity typically 40% Height of bed measured in the same way as ball mills Bulk density of rods = 625 tons/m3 In wet grinding, the solids concentration 1s typically 60% – 75% by mass A rod in situ and a cutaway of a rod mill AMIT 135: Lesson 8 Rod Mills – Mining Mill Operator In the ball mill, commonly used have the lattice ball mill and overflow ball mill (named from different drainage structure), and the rod mill does not use the grid plate drainore, only overflow type and opening type two kinds, the diameter of the hollow shaft at the drainage and end is generally larger than the same specification ball mill Which one is the best, ball mill or rod mill?

the Difference of Rod Mill and Ball Mill ore processing

Rod mill and ball mill may be only one word difference in the name, but in fact, there was a striking internal differences Rod mill , as the name suggests, is to rely on rod bars for the material grinding,and wet overflow is a generally used material wayRod mill is generally used as a grinding equipment in the artificial stone sand Though ball mills are used more often rod mills can be the better option for specific mining ores and larger site projects In a ball mill the actual balls in the machine need to cascade in order for the grinding to be accomplished Because of this more energy is needed to power up a ball press as opposed to a rod Comparing Used Ball Mills Vs Used Rod MillsRod Mill Power Vs Ball MillDelap Ball Mill Vs Rod Mill Difference between ball mill rod mill difference between sag mill vs ball mill mech4study oct 12 2017 today we will learn about difference between sag mill vs ball mill a mill is a machine by which solid or hard materials are broken into smaller pieces by rod mill power vs ball mill sscafepl

Ball Mill and Rod Mill Modular Mining Equipment

Ball mill and rod mill solutions are available here at APT, providing an effective means for grinding and blending materials in preparation for mineral liberation, from rock to dust APT specifies and designs the entire circuit around the mill, to ensure that the target product size is achieved AvaProminer provides ball mill / rod mill grinding system which is widely used in various types of ores' beneficiation, electricity, cement and chemical industries It can carry out dry or wet pulverizing and can meet demand for sustainable largescale productionBall MillRod Mill Grinding System Used in Mineral 1 Ball Mill: The grinding medium is mainly short steel bar or steel ballThe grinding force of ball mill is large, the structure is light, and the rotation speed is stable 2 Rod Mill: The grinding medium is mainly steel rod, the diameter of steel rod is mostly between 50100mm, and the grinding time is longer 3 Gravel Mill: The grinding medium mainly includes pebble, gravel, sand What is Ball Mill How Many Types of Ball Mills MC

What's the Difference Between SAG Mill and Ball Mill

The biggest characteristic of the sag mill is that the crushing ratio is large The particle size of the materials to be ground is 300 ~ 400mm, sometimes even larger, and the minimum particle size of the materials to be discharged can reach 01 mm The calculation shows that the crushing ratio can reach 3000 ~ 4000, while the ball mill’s Attrition mill is a type of grinding mill by kinds of media to crush lump to powderlike substances The impact can be rock on rock such as in an Autogenous Grinding (AG) mill, rock and a small ball charge (~10%), used in Semi Autogenous Grinding (SAG) mills, balls of various sizes in Ball Mills and less commonly these days, steel rods in Rod MillsWhat’s the difference of Ball mill, SAG mill, AG mill? 4 A mill spindle is designed for both down load (axial, like a drill press), and also side load (radial) That is why a mill spindle runs in tapered roller bearings (or deepgroove ball bearings) inside the quill 5 The spindle isn’t just for drill chucks — use any R8 compatible device — end mill holders, collets, slitting saws, etc 6CHOOSING USING A MILLING MACHINE

cement cement plants rock crushers

hot sale sand dry vibrating screen manufacturer

setting regulation for ne crusher

crusher manufacturer metal

how energy is save in the bauxite industry

crusher amp b screening plants aggregates

Magnetic nveyor Belt Used For Sale

Portable Dolomite Cone Crusher Dijual Di Indonessia

ellaton mining supplies and signs klerksdorp

green technology for stone crusher plant

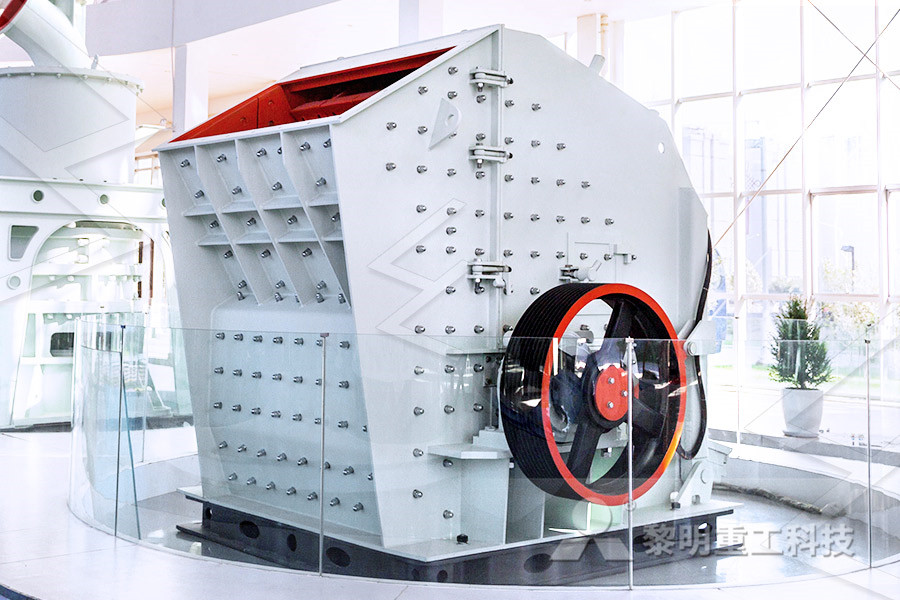

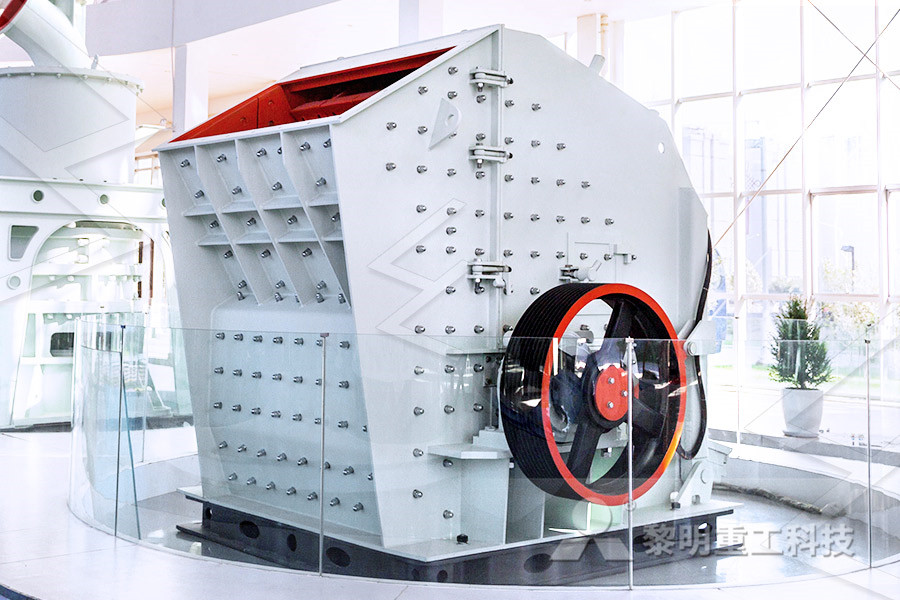

hammer crusher for iron

Hammer Crusher Fluorspar

gold mining in thailand

low jaw crusher price for sale

Stained Limestone Grinder Machine For Sale

used impact rock crushers for sale

stone crusher zeland

Celestite Por Le Crusher For Sale

Concrete Crusher High Capacity Wlcc1160

crusher manufacturer india 150tph

Gold Ball Grinding Mill Maintenance

jaw crusher pe 12002A1500 price

price of elgi ultra wet grinder perfect s and perfect

Table Top Grinder 1 Litre Price In Bangalore

Jaw Crusher For Silica Sand

stone crusher project proposal

geology characterization of clays

Mining Crusher Equipment Companies In Kumasi Address

portable iron ore Rock Jaw crusher suppliers south africa

stone quarries in sindhudurg