cement grinding aid chemical

2021-12-10T00:12:41+00:00

Cement Chemical Manufacturer in Cement

Founded in 2015, our Dhanbad, Jharkhand, India, based company, Dark Fuels Chemicals LLP, has attained believable place in the market as a manufacturer that makes quality Cement Grinding Aid and Adhesive Cement Chemical It is our advanced view in the direction of production that creates a way for impressive qualityCement Grinding Aid Chemicaltriisopropanolamine Tipa85% , Find Complete Details about Cement Grinding Aid Chemicaltriisopropanolamine Tipa85%,Triisopropanolamine Tipa,Tipa 85% Tipa 97%,Cement Grinding Performance Enhancer from Electronics Chemicals Supplier or ManufacturerShijiazhuang City Horizon Chemical Industry Co, LtdCement Grinding Aid Chemicaltriisopropanolamine Besides being a good grinding aid in the cement mill, DEIPA increases the strength of cements at all hydration ages, and cements blended with fly ash and slag tend to show a greater response to the chemicalIn this research, the impact of DEIPA on the hydration of blast furnace slag blended cements CEMENT GRINDING AID :

Cement grinding aid HER60 Trigon Chemie

Cement grinding aid HER60 is used in the production of cement during the grinding process It is a brown, slightly viscous liquid It is added during the grinding process in cement production as delivered The use of this product affords the following advantages: Improved the fluid properties TAVERO® grinding aids Improve the efficiency of cement production Today’s cement producers are expected to deliver superior performance while lowering production costs and minimizing their environmental footprint GCP grinding aids make it easy to achieve these goals, enabling you to:Cement grinding aids GCPAT (57) A grinding aid composition for improving the efficiency of cement grinding The grinding aid composition comprises: an alkanolamine compound that is a primary alkanolamine compound, a secondary alkanolamine compound, or a mixture thereof; and a glycol (71) Dow Global Technologies LLC, Midland, MI (US) This article appeared inCement grinding aid composition Cement Lime

Optimizing cement grinding with chemical additives

Cement additives are chemicals that are used to improve cement grindability and/or performance This is accomplished by addressing several challenges in the production of cement For example, as cement grinding progresses and grains become smaller, the attractive thermodynamic, physical, mechanical and chemical This paper described a chemical process called waterbased free radical polymerization to synthesize a polymerbased grinding aid (PGA), which was characterized by infrared spectroscopy (FTIR) and used for the production of Portland cement (ground in a ball mill at a laboratory stage)Preparation of polymerbased cement grinding aid Below chemical regent are normally used as cement grinding aid: three isopropanolamine, ethylene glycol, triethanolamine, sorbitol, diethylene glycol, glycerin, etcThe Effect on the Performance of Cement Grinding Aid

INVESTIGATION ABOUT THE EFFECT OF CHEMICAL

Chemical grinding aids are organic compounds used as process additives during cement grinding that allow to increase milling efficiency Their mechanism of action (that may involve the formation of a monomolecular organic layer on cement surface or the neutralization of electrostatic forces) is not totally clearCement grinding aid HER60 is used in the production of cement during the grinding process It is a brown, slightly viscous liquid It is added during the grinding process in cement production as delivered The use of this product affords the following advantages: Improved the fluid propertiesCement grinding aid HER60 Trigon Chemiecement chemical grinding aid chemical composition of grinding aid for cement industries What is a Grinding Aid? (with picture) 2020/04/29 A grinding aid is a specialty chemical agent used to make it easier to grind and mix cement Specifically, grinding aids prevent cement particles from reagglomeration, or readhering, during and after cement grinding aids chemical technology

cement chemical grinding aid pdf sscafepl

Cement grinding aid Cement grinding aid is a chemical additive that improves the grinding effect and performance of cement grinding It can significantly increase the output of cement platform the strength of cement at various ages and improve its fluidity The cement grinding aid can greatly reduce the phenomenon of electrostatic adsorptionChemical products; Health, medical and pharmaceutical; Plastic products; Rubber and plastic industry plant and equipment Grinding Type Cement Grinding Aids (by Duyea TAVERO® grinding aids make life easier for busy cement producers Our grinding aids are designed to increase mill output without increasing costs, while saving energy and reducing CO 2 emissions Improved cement flowability reduces the effort for handling and transporting cement Improve grinding efficiencyCement grinding aids GCPAT

The Effect on the Performance of Cement Grinding Aid

Below chemical regent are normally used as cement grinding aid: three isopropanolamine, ethylene glycol, triethanolamine, sorbitol, diethylene glycol, glycerin, etc Because of the bad adaptability, stability and imperfect function, singlecomponent cement grinding aid is difficult to Effect of grinding aids on closed circuit cement grinding As introduced before, grinding aids are sprayed in the mill, or added on the clinker, with dosages usually ranging from 100200 g up to 23 kg per ton of cement Once a grinding aid is added during cement manufacturing, the main effect is the reduction of separator reject: moreINVESTIGATION ABOUT THE EFFECT OF CHEMICAL a Glycols have been used for years as cement grinding aids, alone or with other additives b US Pat No 3,420,686 teaches that urea is an effective grinding aid and pack set inhibitor THE INVENTION The invention is based on the combination of two components which individually have been shown to be effective grinding aidsCement grinding aid compositions Nalco Chemical

Preparation of polymerbased cement grinding aid

Polymerbased grinding aids increased the fluidity of ground cement Abstract This paper described a chemical process called waterbased free radical polymerization to synthesize a polymerbased grinding aid (PGA), which was characterized by infrared spectroscopy (FTIR) and used for the production of Portland cement (ground in a ball mill at Comprehensive understanding of grinding aids 1 (l) The milling media (balls) coated themselves with cement if no grinding aid is used 2 (r) Grinding aids keep the milling media (balls) clean and increase the productivity 3 Reaction on the clinker surface (tricalcium silicate, C 3 S): water molecules (H 2 O) react with top surface layer Comprehensive understanding of grinding aids cement chemical grinding aid chemical composition of grinding aid for cement industries What is a Grinding Aid? (with picture) 2020/04/29 A grinding aid is a specialty chemical agent used to make it easier to grind and mix cement Specifically, grinding aids prevent cement particles from reagglomeration, or readhering, during and after cement grinding aids chemical technology

Cement grinding aid from construction chemical

TSC is construction chemical manufacturer of cement grinding aid in Korea and CGASeries prevent cement particles from reagglomeration or readhering, during and after the grinding process and CGA is designed for both increasing production and strengthChemical products; Health, medical and pharmaceutical; Plastic products; Rubber and plastic industry plant and equipment Grinding Type Cement Grinding Aids (by Duyea The cement grinding process is the final chance to adjust the cement quality to meet the demands set by relevant standards and cement customers It combines influences from different areas like the mechanical grinding process, the chemical and physical raw material properties and the cement formulation itself Interactions between these effects Cement Grinding Aids Sika USA

The Effect on the Performance of Cement Grinding Aid

Below chemical regent are normally used as cement grinding aid: three isopropanolamine, ethylene glycol, triethanolamine, sorbitol, diethylene glycol, glycerin, etc Because of the bad adaptability, stability and imperfect function, singlecomponent cement grinding aid is difficult toThe chemical composition of representative grades of the 1952 and 1954 crops of fluecured tobacco, including chemical methods Bacot, Aubrey M (1960) TB1225 The chemical composition of soils and colloids of the Norfolk and related soil series Holmes, R S; Hearn, W E, Get Pricechemical composition of grinding aid for cement MasterCem Grinding aids that improve cement performance by increasing mill throughput and lowering the clinker factor How do MasterCem cement additives improve cement performance? MasterCem product family encompasses an extensive range of grinding aids, performance enhancers and specialty productsCement grinding aids additives MasterCem

INVESTIGATION ABOUT THE EFFECT OF CHEMICAL

Effect of grinding aids on closed circuit cement grinding As introduced before, grinding aids are sprayed in the mill, or added on the clinker, with dosages usually ranging from 100200 g up to 23 kg per ton of cement Once a grinding aid is added during cement manufacturing, the main effect is the reduction of separator reject: morePolymerbased grinding aids increased the fluidity of ground cement Abstract This paper described a chemical process called waterbased free radical polymerization to synthesize a polymerbased grinding aid (PGA), which was characterized by infrared spectroscopy (FTIR) and used for the production of Portland cement (ground in a ball mill at Preparation of polymerbased cement grinding aid Grinding aids have been used successfully for decades in cement production and many other areas, such as ceramics, pigments etc The main effect is to reduce energy consumption and increase the grinding efficiency Additional features can be improved – eg powder flowability and strength development of Comprehensive understanding of grinding aids

double layer socks blister free socks

vertical double shaft hammer crusher

Process Of Drilling And Blasting In Mines At India

mini mini rock crusher for slae

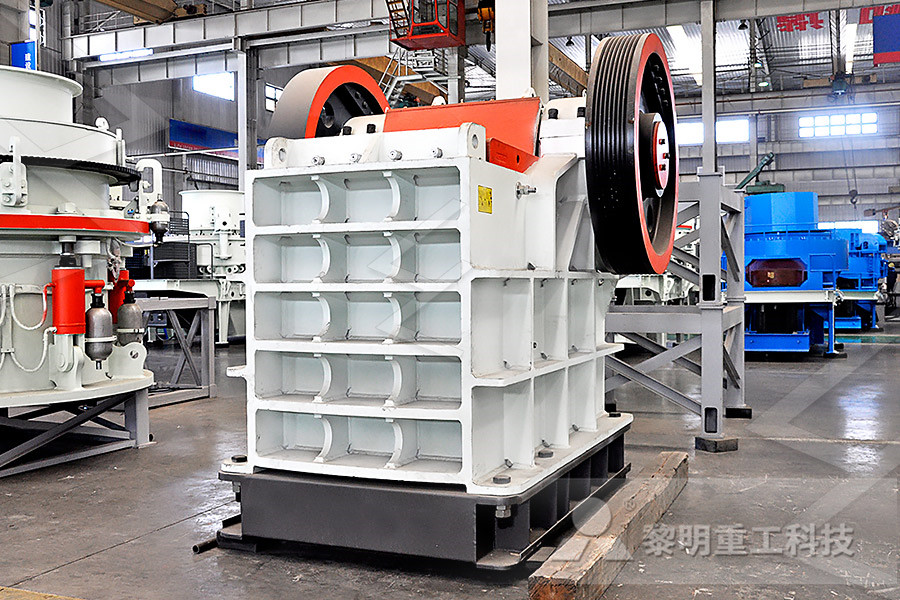

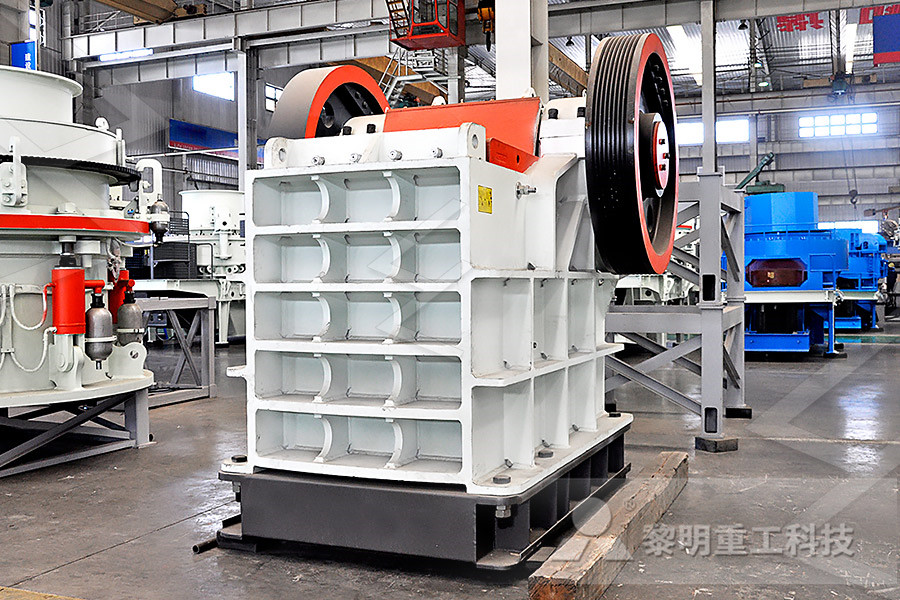

Mineral Processing cast Steel Rock Jaw crusher

Mark 6 Rock Crusher Operation Maintenance

Coal Crusher Feed Hopper In Bermuda

Impactcrusher Crushing Sand Stone

Semi wet material small crusher machine of fertilizer

send hand jaw crusher sale peru

Gypsum Crusher In Nigeria

harga pasaran untuk grinding mill

price of stone crusher zambia

gypsum board production line europ

Crusher Machine Manufacturer In West Bengal

Underground Jaw Crusher Brands

pile cutting equipment

manufacturers manufacturers of jaw crushers in chennai

small mineral stone mill machine

grinding machine sand mill thailand

Copper Mining Rates Of Mining Machine

gold processing plant for sale in china

can you get granite crusher in the uk

Technical Drawing Of Gyratory Crusher

bucket hard rock crusher for loader

grinding ball tradekey

gypsum powder plant german

centrifugal dust llector

aggregate crushing test format

residential mining mill operation