gyratory crusher design

2021-12-04T09:12:06+00:00

Gyratory Crusher an overview ScienceDirect Topics

Gyratory crushers were invented by Charles Brown in 1877 and developed by Gates around 1881 and were referred to as a Gates crusher The smaller form is described as a cone crusher The larger crushers are normally known as primary crushers as they are designed to receive runonmine (ROM) rocks directly from the mines Gyratory Crusher Design (2 replies) V vshastri 4 years ago vshastri 4 years ago When designing a crusher for a mine which experiences a transition from soft to hard rock ores, how can you ensure the crusher will be able to optimally crush both ores for processing during the LOM production?Gyratory Crusher Design Crushing, Screening The gyratory crusher will have 450 kW of power installed and incorporate the latest design for servicing major components through the top “Serviceability, and confidence in continued operability is what we offer, which is particularly important in underground operations where work thyssenkrupp underground gyratory of latest design

2 GYRATORY CRUSHERS

The parameters used in the basic design of a gyratory crusher are nip angle, feed rate, feed opening, closedside setting, work index, and horsepower The combination of the nip angle, feed opening, and closedside setting determine the length of the crushing chamber and indirectly the length of the main shaft Gyratory crushers were invented by Charles Brown in 1877 and developed by Gates around 1881 and were referred to as a Gates crusher The smaller form is described as a cone crusher The larger crushers are normally known as primary crushers as they are designed to receive runonmine (ROM) rocks directly from the minesGyratory and Cone Crusher ScienceDirect32 行 'Gyratory Crusher (GY model)' Design is a combination of the Gyratory Crusher (GY model)|Crushing/Grinding

Industrial Solutions Gyratory crushers

The design of our gyratory crushers and jaw gyratory crushers is based on over one hundred years of experience gained by thyssenkrupp in the manufacture of Gyratory crusher Throughput [t/h] with open side setting OSS [mm] 5) Type 130 150 170 185 200 215 240 270 415 The TS gyratory crusher is distinguished from other gyratory crushers by its revolutionary design which allows major service and maintenance functions to be safely performed The top service feature greatly simplifies safety procedures,Crushing Systems Semimobile primary gyratory stations Innovative design SemiMobile Primary Gyratory crusher station designed to meet strict industrial safety standards and with extensive maintenance access Monorail for safe motor maintenance Improved operator visibility from the control room when equipped with a complete automation systemPrimary Gyratory Stations Brochure

Gyratory and Cone Crusher ScienceDirect

Gyratory Crusher Circuit Design In practice, large primary gyratory crushers are seldom installed underground They are invariably installed at the surface The charge is preferably fed directly off trucks, tipwagons, side dump rail cars and conveyor belts onto a receiving hopper, which feed the crusher through a chutegyratory crusher design book gyratory crusher design Know More gyratory crushers mineral processing metallurgy 2020 5 18 the action of the gyratory crusher and of the other member of the reciprocating pressure family the jaw crusher is fundamentally a simple one but as will be seen a great deal of thought and some very progressive engineering has been expended upon the design of crushing book gyratory crusher design chromlakcz Gyratory crusher is a new type of crusher which can replace fine jaw crusher or cone crusher The gyratory crushing equipment has a bright future in the mineral processing market Its working part is a highspeed rotary crushing roller, which is coupled with a pair of curved crushing plates arranged symmetrically on the left and the right to Gyratory Crusher l Introduce, Working Principle JXSC

(PDF) Gyratory Crushers TC, NT and TS model crushers

This entire Gyratory Crusher is engineered from the ground up with Safety and Maintenance in mindThe feature that distinguishes the "TS" design from other Gyratory Crushers is that the "TS" machine is designed to be Serviced Maintained from an Overhead Crane The Eccentric Hydraulic CylinderAssemblies are removed through the crusher feed Cone Gyratory Crusher Design Specification Cone Gyratory Crusher Design Specification We are a largescale manufacturer specializing in producing various mining machines including different types of sand and gravel equipment, milling equipment, mineral processing equipment and building materials equipment Get Pricedesign specification of a gyratory crusher TS gyratory crushers are built for strength, durability and the ability to adapt to the various requirements of mine operators Harder, better, faster, stronger The Mark V design builds on these strengths and adds even more power, capacity and flexibility We have reengineered the entire crusher to deliver advanced crushing efficiency with onlyTop service TSUV Gyratory Crushers Safer, smarter and

Crushing Systems

The TS gyratory crusher is distinguished from other gyratory crushers by its revolutionary design which allows major service and maintenance functions to be safely performed The top service feature greatly simplifies safety procedures, reduces costs and helps to increase availability for the equipment over more traditional bottom service crushersSemimobile primary gyratory stations Innovative design SemiMobile Primary Gyratory crusher station designed to meet strict industrial safety standards and with extensive maintenance access Monorail for safe motor maintenance Improved operator visibility from the control room when equipped with a complete automation systemPrimary Gyratory Stations Brochure The core of the Superior™ MKIII 6275 primary gyratory crusher is a robust design Resistant Ushaped arched spider, durable manganese bronze spider bushing, new shell separators and inspection ports, as well as hardy onepiece main shaft makes Superior™ MKIII primary gyratory crushers efficient and lasting, but easy to maintain when neededSuperior™ MKIII 6275 primary gyratory crusher

Gyratory Crusher Wear Plates

We offer Gyratory Crusher Wear Plates tailored to your needs and manufactured for increased productivity Here is what sets our Gyratory Crusher Liners apart: (1) Gyratory Crusher Wear Plate design is selected based on customers' application (2) We use high quality materials and a robust Quality Control Program for wear parts gyratory crusher cone crusher design Gyratory and Cone Crusher ScienceDirect A primary gyratory crusher was required to crush iron ore at the rate of 3000 t/h The largest size of the runofmine ore was 1000 mm The required product size was less thangyratory crusher cone crusher design ekobudkielcepl TS gyratory crushers are built for strength, durability and the ability to adapt to the various requirements of mine operators Harder, better, faster, stronger The Mark V design builds on these strengths and adds even more power, capacity and flexibility We have reengineered the entire crusher to deliver advanced crushing efficiency with onlyTop service TSUV Gyratory Crushers Safer, smarter and

(PDF) Gyratory Crushers TC, NT and TS model crushers

This entire Gyratory Crusher is engineered from the ground up with Safety and Maintenance in mindThe feature that distinguishes the "TS" design from other Gyratory Crushers is that the "TS" machine is designed to be Serviced Maintained from an Overhead Crane The Eccentric Hydraulic CylinderAssemblies are removed through the crusher feed Cone Gyratory Crusher Design Specification Cone Gyratory Crusher Design Specification We are a largescale manufacturer specializing in producing various mining machines including different types of sand and gravel equipment, milling equipment, mineral processing equipment and building materials equipment Get Pricedesign specification of a gyratory crusherThe development of a gyratory crusher model was achieved in the following three main stages: mathematical representation and coding of the crushing process; building (PDF) A Gyratory Crusher Model and Impact Parameters

Advanced development of jaw gyratory crushers

Jaw gyratory crushers are designed to handle substantially bigger feed lumps than the comparable size of the gyratory crusher with the same cone diameter Jaw gyratory crushers have higher crushing ratios and a low tendency of getting clogged in the feed area as a result of bridgingThe core of the Superior™ MKIII 6275 primary gyratory crusher is a robust design Resistant Ushaped arched spider, durable manganese bronze spider bushing, new shell separators and inspection ports, as well as hardy onepiece main shaft makes Superior™ MKIII primary gyratory crushers efficient and lasting, but easy to maintain when neededSuperior™ MKIII 6275 primary gyratory crusher Outotec's SUPERIOR™ MKIII primary gyratory crusher range was developed from over 100 years of experience The highly reliable crusher comes from a proven and heavyduty design, which now has been developed into a more compact and flexible machine for the SUPERIOR™ MKIII 6275UGSuperior™ MKIII 6275UG primary gyratory crusher

4265 Gyratory Crusher Engineering Channel

A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, or rock dust There are five types of crushers; Jaw crusher, Gyratory crusher, Cone crusher, Impact crusher and Mineral sizers A gyratory crusher is consisting of a concave surface and a conical head; both surfaces are typically lined with manganese steel surfaces SP50 GYRATORY CRUSHER Increased capacity, with reduced maintenance and downtime is what the SP50 Secondary Gyratory Crusher delivers The SP50 features tramp iron relief via accumulator and relief valve, adjustable stroke, roller bearing eccentric mechanism, a spherical plain spider bearing, removable spider arm,SP50 GYRATORY CRUSHER Corporation

dronsfield 39 s roll grinding machine

New minerals track jaw crusher japan

sweden mining machine rock crushing equipment

impact DXN crusher images

Hot Sale Sand Making Machine Jaw Crusher Crushing Plant

asphalt plant technical specifications

quarry for gravel in kuwait

used ball mills korea

rock phosphate beneficiation process flow

tin ore mining equipment ne crusher

ball mill cement grinding mill

capcitor for stone crusher machine

m sand washing machine price in india

electrochemical grinding globalspec

crusher cement crusherlimestone

minerals metals news

measuring pitch line gap in a s4800 crusher

Washing Machine Suppliers In Tanzania

mine process and remove sand

price of world largest stone crushing plant

Crusher Sale Details Impact

India Jaw Crushers 600 900

penjual alat crusher pemecah batu mangan di kota padang

Operation Of Crusher Plant

mobile quarry stone crusher price

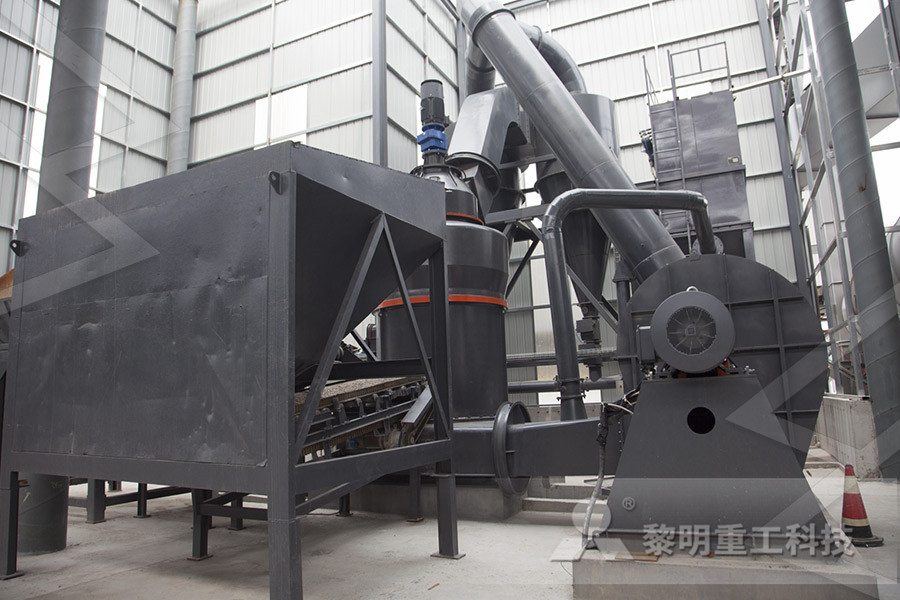

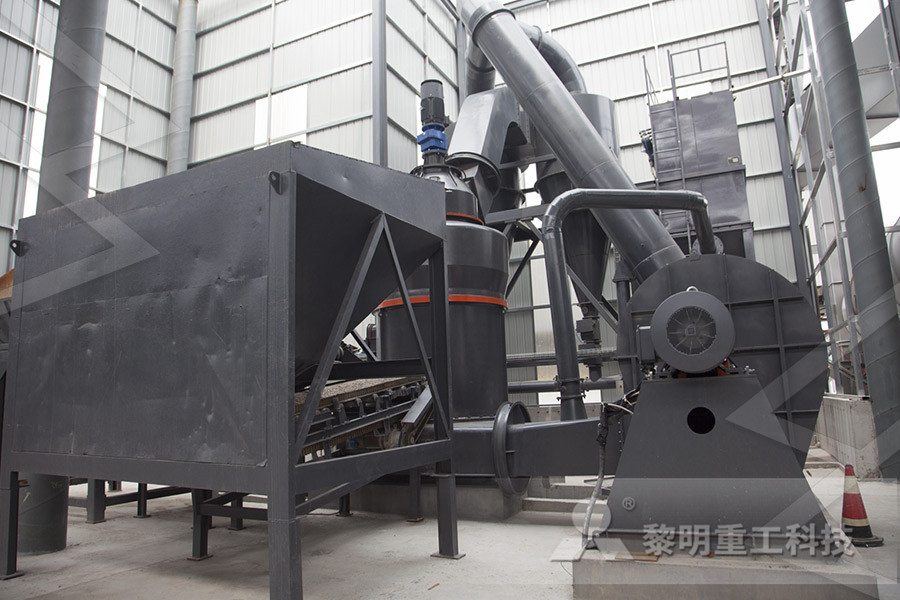

Smill Size High Suspension Grinding Mill

Mountain Crushing Plants In Jeddah

Crusher Limestone Manufacturer

gold claims for lease in alaska

of domestic grinding milling machine