mine process and remove sand

2019-08-24T20:08:58+00:00

6 things you need to know about sand mining

Sand is also the most consumed substance after water, being used in virtually every construction or manufacturing process, even used as an ingredient in toothpaste Globally our annual aggregate consumption is somewhere around 53 billion tonnes – the equivalent to every person on earth using 20kg of sand every single day describes a typical sand mine and sand processing plant Note there are several mining facilities in operation and several proposed that mine or would mine below the groundwater level utilizing hydraulic dredging to remove the sand The overview of the sand mining process provided below is descriptive of a more common dry mine althoughSilica Sand Mining EIS Meeting Wisconsin DNR Keywords sand mining, environmental impacts, legislation and regulatory framework, mapping of sand mining sites, management strategies Introduction Sand mining is a common practice in many rivers and floodplains across South Africa The demand for sand is escalating at an alarming rate as a result of everincreasing buildingStudy of Sand Mining and Related Environmental

11191 Sand And Gravel Processing

11/95 Sand And Gravel Processing 111911 11191 Sand And Gravel Processing 111911 Process Description16 Deposits of sand and gravel, the unconsolidated granular materials resulting from the natural disintegration of rock or stone, are generally found in nearsurface alluvial deposits and in subterranean and subaqueous bedsoccupies the largest area under mine followed by ChateharaGhurehtha, Kohandia, UthgiUparhar, Hinauti Pandey and GeenjSome silica sand mines in the region process the sand onsite however processing is done mainly offsite Processing begins by washing the sand to remove Impact of silica mining on environment While workers initially sifted through the sand at the original site, the process soon advanced, with sand being transported to a screening facility to be more efficiently processed as miners remove the layers of sand and rock just above the kimberlite rocks In contrast, Diamond mine How Are Diamonds Mined? There Are Actually 3

Surface Mining Techniques used in the Oil Sands Oil

SURFACE MINING ≠ STRIP MINING: Although sometimes mistakenly referred to as strip mining, oil sands is actually mined from an openpit below several All this suggests that soil development and the restoration of mine workings can be left to natural processes But in most situations the process of natural succession is slow, and it is common for 50 or 100 years to elapse before a satisfactory vegetation cover develops, particularly on mine wastesRestoration of mined lands—using natural processes First and foremost, you should not be in a hurry to process the sand from the beaches Miners can have a tendency to work fast in an effort to process as much Beach Mining Tips How to Recover Fine Gold in Sand

Evaluation of soil washing process to remove mixed

JOURNALOF H111ARDOU5 IIIATERIIILS ELSEVIER Journal of Hazardous Materials 45 (1996) 4557 Evaluation of soil washing process to remove mixed contaminants from a sandy loam Robin Semer, Krishna R Reddy* Department of Civil and Materials Engineering, University of Illinois at Chicago, 2095 Engineering Research Facility, 842 West Taylor Street, Chicago, IL 60607, USA Sand is a critical ingredient for many of the materials that we take for granted: concrete, glass and asphalt Sand and coarse aggregates form the backbone of the modern world and also, through land reclamation, the ground on which we live A growing global population increasingly living in cities has led to a spiralling rise in the extraction of sand and aggregates, with serious environmental Driven to Extraction: Can Sand Mining be Sustainable? Before mining for frack sand, operators must remove “overburden” – topsoil or subsoil overtop the sand that is mainly composed of clay, silt, loam, or combinations of the three Removing the overburden requires scrapers or tracked excavators After removal, the operator stockpiles the material in manmade earth mounds called bermsFrac Sand Mining Earthworks

Impact of silica mining on environment

occupies the largest area under mine followed by ChateharaGhurehtha, Kohandia, UthgiUparhar, Hinauti Pandey and GeenjSome silica sand mines in the region process the sand onsite however processing is done mainly offsite Processing begins by washing the sand to remove Sand and gravel quarries are pumped to allow them to be worked dry or operated as lakes with extraction below water A conveyor draws raw material into the processing plant, where it is washed to remove unwanted clay and to separate sand Sand separated during processing is dewatered and stockpiledExtraction of Aggregates Process CEMEX USA CEMEX bitumen recovery process than conventional oil refinery process, because there are many more steps involved in producing synthetic crude oil from oil sands comparing conventional oil production Dust and emission from mining operation is another source of air pollution in oil sand productionAn Integrated Model for Oil Sands LongTerm Mine

How phosphate is mined and processed

grained sand In this process, the phosphate is coated with a hydrocarbon When bubbles move through the liquid, the coated particles attach to the bubbles and rise to the surface This can be done a second time, but using a different hydrocarbon to attach to the sand At this point, the sand, clay and phosphate have been separated The sand and As seen in satellite images provided here by NASA, sand oil producers in Canada “remove the sand in big, openpit mines” before separating out the oil—a process that releases hydrocarbons Fact CheckMeme includes photo of a copper and Silica sand for making glass, pottery and ceramics must meet rigid specifications and generally standard washing schemes are inadequate for meeting these requirements Sand for the glass industry must contain not more than 003% Fe2O3 Concentrating tables will remove free iron particles but iron stained and middling particles escape gravity Silica Sand Processing Sand Washing Plant Equipment

How Is Garnet Mined Processed? Our Pastimes

Garnets are a type of mineral deposit with a crystal structure that is abundant throughout the world Only a few types of garnet are gem quality, however Other types of garnets are used as industrial abrasives to sand and polish Garnet has been used as a gemstone from early Greek, Roman and Egyptian times and can Sand is a critical ingredient for many of the materials that we take for granted: concrete, glass and asphalt Sand and coarse aggregates form the backbone of the modern world and also, through land reclamation, the ground on which we live A growing global population increasingly living in cities has led to a spiralling rise in the extraction of sand and aggregates, with serious environmental Driven to Extraction: Can Sand Mining be Sustainable? of sand in the process Wisconsin possesses highquality sand resources and therefore is seeing a substantial rise in mining permit requests to mine for frac sand Consequently, the topic of sand mining in Wisconsin has generated interest from regulators, legislators, local government, and the general public 20 Purpose of this documentSilica Sand Mining EIS Meeting Wisconsin DNR

Impact of silica mining on environment

occupies the largest area under mine followed by ChateharaGhurehtha, Kohandia, UthgiUparhar, Hinauti Pandey and GeenjSome silica sand mines in the region process the sand onsite however processing is done mainly offsite Processing begins by washing the sand to remove Corporation, the representative body of all native title holders of the land on which the mine will be built and the owner of the Aboriginal freehold land 122 Proposed project description The GSSP will be an open cut mining operation designed to extract and process silica sand into a product suitableGalalar Silica Sand Project proposed by Diatreme bitumen recovery process than conventional oil refinery process, because there are many more steps involved in producing synthetic crude oil from oil sands comparing conventional oil production Dust and emission from mining operation is another source of air pollution in oil sand productionAn Integrated Model for Oil Sands LongTerm Mine

Silica Sand Processing Sand Washing Plant Equipment

Silica sand for making glass, pottery and ceramics must meet rigid specifications and generally standard washing schemes are inadequate for meeting these requirements Sand for the glass industry must contain not more than 003% Fe2O3 Concentrating tables will remove free iron particles but iron stained and middling particles escape gravity There are currently 128 industrial sand mine facilities in Wisconsin, of which 92 are active Nineteen of the active facilities are standalone processing facilities, 4 are rail loading operations, and 69 are mine sites Thirtyeight of the mine sites also include a processing facility on the site The acreage distribution of the 69 active Wisconsin Department of Natural Resources Industrial Large rotary dryers can process 300 tons of sand per hour Temperatures are controlled to optimize drying and avoid breakdown Water vapor from the process may be passed through cyclone separators to remove fine dust A hightemperature bag house may also be used to remove fine particulates Sand screening and sizing are performed in various waysThe Fundamentals of Frac Sand Logistics – HiCrush

How Is Garnet Mined Processed? Our Pastimes

Garnets are a type of mineral deposit with a crystal structure that is abundant throughout the world Only a few types of garnet are gem quality, however Other types of garnets are used as industrial abrasives to sand and polish Garnet has been used as a gemstone from early Greek, Roman and Egyptian times and can

Recycled Aggregate And Process

parts crushing hammers and heavy equipment in Nigeria

uses of mobile crushers

double roll crushers marcy

manganese ore process

Hsm Ce Denver mining Flotation Cell

What Is Gold Ore Used For Processing Line

What Is The Goal Of Mining Industry

fineness of al in al mill

Kaltim Prima Coal Melawan Conveyor

molino bolas practi

aluminum recycling machine from the usa

raymond mill for dolomite stone grinding

soil lumps disintegrator and grinder

machinery required to setup cement plant

dry grinding of quartz upto mesh

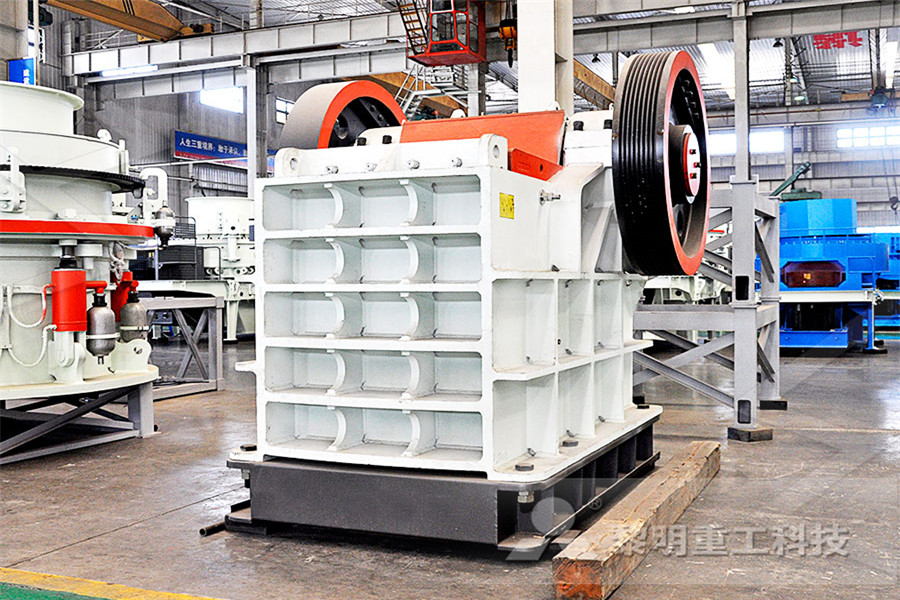

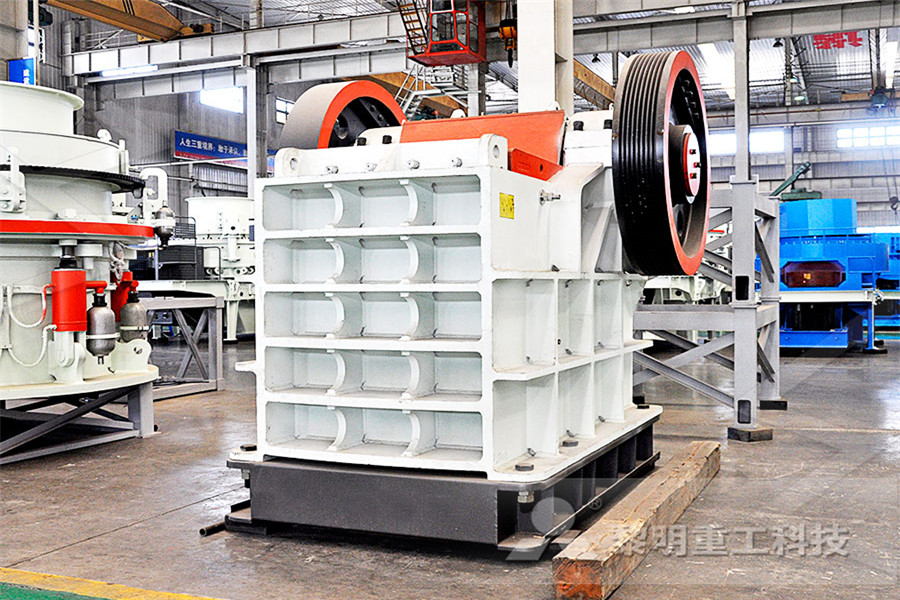

PEW Series Jaw crusher india sale

High Strength Concrete With Foundry Sand

Composite Crusher For Sale

Eia Notification 2006 Stone Crushers

Plastic Grinder Solutions

DXN Mobile Crusher In Macedonia

cs 3 feet ne crusher adjustment ring

Quarry Plant Used stone jaw crusher

chrysotile mobile rock crusher manufacturer

used crushers for sale in saudi arabia

hiv aids in south african mines

hydraulic maintaining pressure f

limestone calcination vertical shaft plant flowsheet

looking looking for a clay grinding machine