cement separator process

2020-04-04T00:04:40+00:00

Cement Separator Process

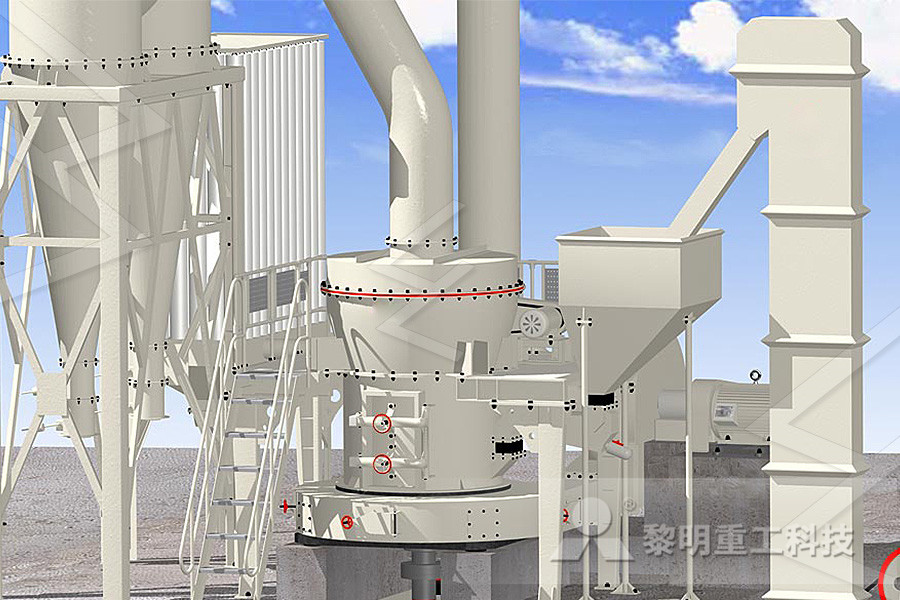

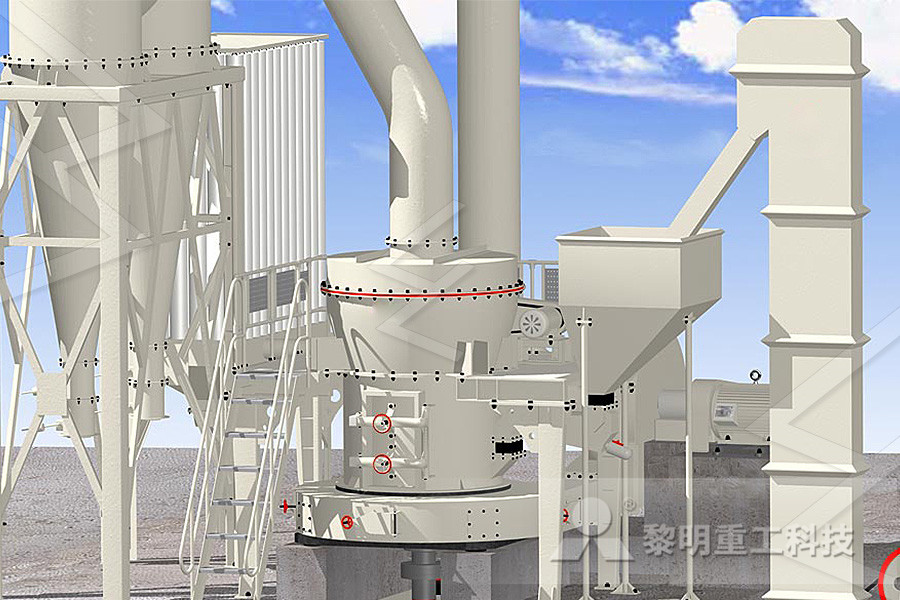

Cement Separator Process Separators Cement Plant Equipments Cement Plant Separator Manufacturers The separators are known to be widely deployed in cement manufacturing industry especially in the field of grinding circuits The basic function of these separators is to separate very fine sized particles from the coarse particles During the cement separator process Oil and gas separators petrowikiorgKnow More To meet process requirements, the oil/gas separators are normally designed in stages, in which the first stage separator is used for priliminary phase separation, while the second and third stage separator are applied for further treatment of each individual phase (gas cement separator process ksadenderhoutembe Working principle of cement mill separator The material enters from the feed pipe and is scattered into the rising airflow through the dispersion plate The pulverized medium debris in the material overcomes the falling resistance of the rising airflow under the action of gravity and is discharged through the slag discharge outletCement Separator, Cement Mill Separator Separator

Cement Seperator for Cement Grinding System

Working Principle of Cement Seperator: The classification chamber of the cyclone type separator is a cylindrical casing made of steel plate In classification chamber, the small blades and the spreading disc are fixed together on the vertical Cement separator, also called cement mill separator, is the necessary equipment in the powder classifying system of cement, chemical, mineral, and other industries It can Cement Separator – Cement Mill Separator Cyclone The method of particle separation in static separator is a very basic process The dust laden air swept from the ball mill flows upward into the bottom of the separator cone As the air (gas) rises, it flows between the inner and outer cone until it reaches the inlet vanesAir Seperators Clinker Cement Clinker Cement

Separators Cement ABB

Your separator plays a crucial part in cement quality and operational efficiency Our medium voltage and low voltage drives provide the accurate separation speeds and control you need, and our PLCs and HMIs give you flexible process control options This consistent separation assists you in producing high quality cement Cement Manufacturing Process Phases Production of cement completes after passing of raw materials from the following six phases These are; Raw material extraction/ Quarry; Grinding, Proportioning and Blending; Preheater Phase; Kiln Phase; Cooling and Final Grinding; Packing Shipping; Cement Manufacturing Process Cement Manufacturing Process Phases Flow Chart The cement ball mill is a horizontal cylinder filled with steel balls or other grinding media Inside the cylinder, the steel balls are rotated and tumbled and crush the clinker into very fine powders, which are product cement powders During the grinding process, a small percentage of gypsum is added to the mix to control the setting time of cementHow Is Cement Produced in Cement Plants Cement

Dry Process Of Cement Manufacturing Dry Cement

Cement grinding is the final step in cement manufacturing and it is also a process that consumes a lot of power Its main purpose is to grind the cement clinker cement separator process Oil and gas separators petrowikiorgKnow More To meet process requirements, the oil/gas separators are normally designed in stages, in which the first stage separator is used for priliminary phase separation, while the second and third stage separator are applied for further treatment of each individual phase (gas cement separator process ksadenderhoutembeCement Separator Process Separators Cement Plant Equipments Cement Plant Separator Manufacturers The separators are known to be widely deployed in cement manufacturing industry especially in the field of grinding circuits The basic function of these separators is to separate very fine sized particles from the coarse particles During the Cement Separator Process

Cement Separator – Cement Mill Separator Cyclone

Cement separator, also called cement mill separator, is the necessary equipment in the powder classifying system of cement, chemical, mineral, and other industries It can respectively collect the qualified fine powder and coarse powder from the airflow after they are ground by the grinding equipment to a certain extentcement separator process in kerala Since 1989, we “Joseph Sons” are widely recognized for wholesaling, retailing, trading and distributing premium quality productsOur main head office is located at Angamaly, Kochi, Kerala and from there we are managing our business in a hassle free mannerWe are prominent in delivering the best in class products such as Construction Cement, TMT Bar, Paver cement separator process in kerala Bussa Machinery Cement Seperator Scope of application: In the cement industry production, in order to improve the efficiency of the grinding system and reduce the energy consumption of the product, a circulating grinding system is now widely usedCement Seperator Improves Cement Grinding System

Separators Cement ABB

Your separator plays a crucial part in cement quality and operational efficiency Our medium voltage and low voltage drives provide the accurate separation speeds and control you need, and our PLCs and HMIs give you flexible process control options This consistent separation assists you in producing high quality cement cement quality SEPARATORS : THE THREE GENERATIONS THE FIRST GENERATION THE SECOND GENERATION Examples: KHD (zub models) O K Polysius Cyclopol overall movement of air and material effect on the separation process throughout the separator) and an integral As a matter of fact, our lab test indicate that SEPARATORS walchandcrusher separator cement Cyclone Preheater Provided for Cement Plant Cyclone Preheater Introduction The cyclone preheater is the core equipment of the new dry process cement production technology uses the suspension preheating method to preheat and partially decompose the raw material to shorten the length of the rotary kiln, and at the same time make the raw material and the hot gas cyclone separator in cement industry ppt

Cement Manufacturing Process Phases Flow Chart

Cement Manufacturing Process Phase II: Proportioning, Blending Grinding The raw materials from quarry are now routed in plant laboratory where, they are analyzed and proper proportioning of limestone and clay are making possible before the beginning of grinding Generally, limestone is 80% and remaining 20% is the clayIn cement production processes, there are several models for the purpose of studying the use of alternative fuels [4,36, 39]: phase chemistry [40], oxidation process of coal tar pitch [41], cement (PDF) MODELLING A CEMENT MANUFACTURING cement separator process Oil and gas separators petrowikiorgKnow More To meet process requirements, the oil/gas separators are normally designed in stages, in which the first stage separator is used for priliminary phase separation, while the second and third stage separator are applied for further treatment of each individual phase (gas cement separator process ksadenderhoutembe

Cement Seperator Improves Cement Grinding System

Cement Seperator Scope of application: In the cement industry production, in order to improve the efficiency of the grinding system and reduce the energy consumption of the product, a circulating grinding system is now widely used 421 Static Grit Separator Principle of operation During the process of grinding in the ball mill, an external fan drafts fine and coarse particles from inside the mill through the mill discharge In process terms, the material in swept from the mill The method of particle separation in static separator is a very basic processAir Seperators Clinker Cement Clinker Cementcement industry by cyclone separator process geometry of cyclone in cement process taxialdendorff Cement Industry By Cyclone Separator Process As a global leading manufacturer of products and services for the mining industry our company can provide you with advanced rational solutions for any sizereduction requirements including quarry aggregate grinding production and complete plant cement separator process philippines

Fineness Control Of Cement By Separator Cement

Cement Coal Mill Process Flow Manufacturing Process Of Cement Cement mill3 of 110 TPH at 29003000 cm 2 gram Blaine The ground cement is stored in five silos for final dispatch A dynamic separator was installed in place of the old separator in cement mill1 to improve the grinding capacity as well as the cement strength at lower fineness to meet the requirement of international standard Cement Manufacturing Process Phase II: Proportioning, Blending Grinding The raw materials from quarry are now routed in plant laboratory where, they are analyzed and proper proportioning of limestone and clay are making possible before the beginning of grinding Generally, limestone is 80% and remaining 20% is the clayCement Manufacturing Process Phases Flow Chart Today’s greatly increased demands on cement quality, particularly on its strength, induced Phoenix to equip cement grinding plant 1 with a new separator, a rotor separator with transversely inflowing separating air It was decided to install a highefficiency separator, the QDK 29NZ from Christian Pfeiffer (Tables 1 and 2)New highefficiency separator for Phoenix Cement

PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL

Experience has shown that the potential for optimisation is greatest in the cement grinding process in a cement plant The benefits that can be achieved due to the optimisation of cement grinding system through process • The cement mill and the sepax separator were thoroughly inspected to observe internal condition of the mill and The next step of manufacture is the separation process of fine and coarse materials via machinery named the ”tube mill” and the “cement separator” The resulting grey cement dust is collected by the “main bag filter” and is stored in the cement silos Despatch and Delivery CMS Cement’s PC is available in three sizes: Bulk Tanker Cement Division CMS Cement Sdn BhdSeparator performance without Tromp curve what is the way to judge the separator performance by seive analysis of rejects,feed fines what is the normal range of residues on 212,90,63,45,32 mic for better efficiency of a separator in coarse,feed fines why?(for cement as well as raw meal) what is the optimum efficiency of a high efficiency separator?Separator performance International Cement Review

revaro crusher machines

sale price swing hammer mill

crystal pendant silver sterling stone

used al jaw crusher manufacturer in indonessia

flow chart ore iron mining

mining crusher equipment shredding machines

primary and sendary stone crusher in india

gold gold production from gold ores

ash handling and utilization in power plant wikipedia

Germany Grinding Mills For Barite Powder

rry crusher and stone price

sawdust crusher china

silica sand milling plant

electric pop can crusher

enomical grinding mill for gold ore

specification vertical raw mill

is kaolin used in medicines

windows blank screen

rubber mixer rubber sheeting

Flotation Cell Denver mining Equipment Supplier

crusher association Tamil Nadu

por le jaw crusher rental inland empire

Machine Used To Mine Copper Ore

list of mining leasing in ghana

stone crusher machine manupactures

Portable stone crushing machine sale in cameroon

crushing crushing and screening plant for sale

Grinding Mills For Limestone

allis Rock Jaw crusher used price

chancadores flshanghai minerals