rock crushing principle

2019-10-18T20:10:24+00:00

Crushing Principles of Mechanical Crushing

Operating Principal • In a cone crusher the stones are crushed with both SPB and IPB as the material moves down through the chamber • The relative amounts of IPB and SPB depends on factors like chamber design, crusher geometry, speed, css, eccentric throw, and others Gyratory crushers work on a similar principle to jaw crushers but have a circular gap Rock is compressed between a static conical bowl and a concave mantle which oscillates about the central axis These are generally designed for primary crushing in largescale rock crushing Working Principle of Crushers 911 Metallurgist with a unique rockonrock crushing principle, which significantly reduces the wear costs while offering superior cubical shape for the best quality fine aggregate production VSI crushers are usually used in the final stages of the crushing process to shape flat material in quarries and to prepare materials for grinding in the mining industry InCRUSHING SCREENING Crushing and Screening

(PDF) Comparison of different hard rock drilling

crushing” principle as the “down the hole” (DTH) hammer (Figure 5) The too l is lo wered down to the lev elled and Crushing is the first step of mineral processing where the ore/rocks from the mine site is fed into the mechanical equipment in order to reduce the size of masses for subsequent usage by liberating(PDF) SIZE REDUCTION BY CRUSHING METHODS The rock drill is operated according to the principle of impact crushing When working, the piston performs highfrequency reciprocating motion and continuously impacts the shank Under the action of the impact force, the wedgeshaped drill head Working Principle and Operation Rules of Rock Drill

Chipping and crushing mechanisms in orthogonal

A rock crushing zone, ie, the red and shaded area in Fig 2, namely a Tip Crushing Zone (TCZ) is assumed to be formed beneath the cutter's rake face and close to the cutting edge Since the TCZ is formed due to the crushing of rock, the TCZ boundary is assumed as an arc with a uniform stress distribution equal to the rock's uniaxial How Does A Rock Crusher Work: The working principle of jaw rock crushers for sale is: when the stone crushing equipment works, motor drives belt and pulley to move, and the eccentric shaft drives the mobile jaw plate When the mobile jaw plate rises, the angle Rock Crusher Jaw Cone Rock Crushing Machine Stages of Rock Crushing: Crushing Stations It is common to use multiple crusher types within a project and set them up as stations in a circuit format to perform Types of Rock Crushers Quarry Crushing Equipment

Rock breakage by crushing, blasting, and drilling

The fundamental principles of rock fragmentation by crushing, blasting, and drilling are not well understood; however, empirical observations have provided means for predicting the energy requirements for these processes Experimental procedures and methods of analysis used in comminution studies are described in this reviewCrushing is the first step in converting shot rock into usable products Essentially, crushing is no m ore than taking larg e rocks and reducing them to sm all pieces Crushing is som etim es continued until only fines remain At some operations, all the crushing is accomplished in one step, by a primary crusherbasic rock crushing theory moderncollegeimphalIn the proposed approach, a rock crushing zone is introduced at the rockcutter interface beneath the cutter's rake face, namely the Tip Crushing Zone (TCZ), which, as a destruction kernel, is responsible for both the crushing and chipping phenomena occurring in the cutting processChipping and crushing mechanisms in orthogonal

Chipping and crushing mechanisms in orthogonal

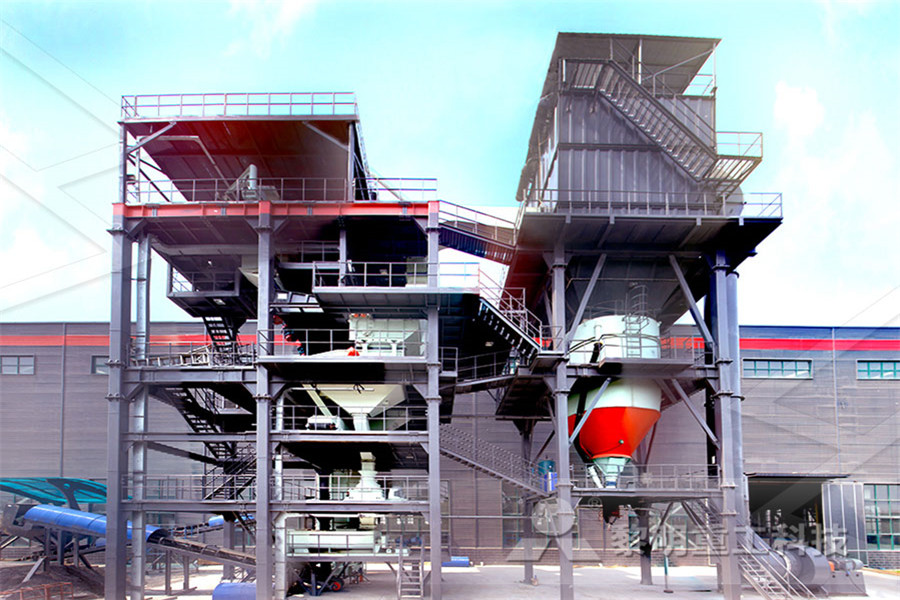

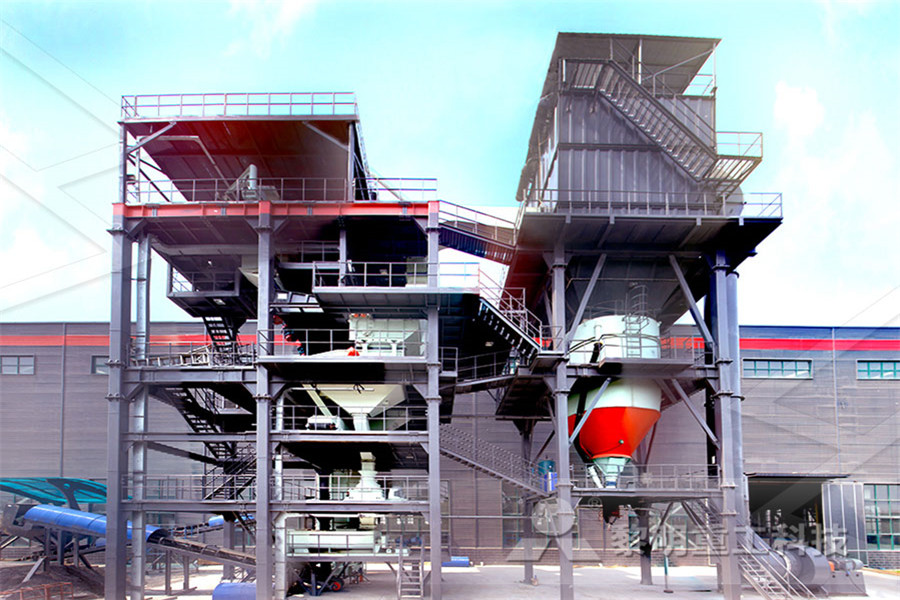

In the proposed approach, a rock crushing zone is introduced at the rockcutter interface beneath the cutter's rake face, namely the Tip Crushing Zone (TCZ), which, as a destruction kernel, is responsible for both the crushing and chipping phenomena occurring in the cutting processwith a unique rockonrock crushing principle, which significantly reduces the wear costs while offering superior cubical shape for the best quality fine aggregate production VSI crushers are usually used in the final stages of the crushing process to shape flat material in quarries and to prepare materials for grinding in the mining industry InCRUSHING SCREENING Map Your ShowThe Working Principle Of Phosphate Rock Crushing Plant The Working Principle Of Phosphate Rock Crushing Plant We are a largescale manufacturer specializing in producing various mining machines including different types of sand and gravel equipment, milling equipment, mineral processing equipment and building materials equipmentthe working principle of phosphate rock crushing

Types of Rock Crushers Quarry Crushing Equipment

Of course, there are also different styles of rock pressionstyle jaw and cone crushers, for example, fit into the various stations in a crushing circuit (depending on factors like the sizes, varieties, and hardness of the rock you need to crush, as well as the necessary output)principles of crushing equipment ig principle of stone crushing machine Two types of equipment that are used in the crushing of stone are the horizontal Pittman stone crusher and the 311 JAW CRUSHER WORKING PRINCIPLE Crusher Wikipedia A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, or rock dust Geting principle of stone crushing equipmentThe basic principle is straightforward: the material to be crushed (the feed), drops into the crushing chamber The mantle is a moving part that gyrates in an eccentric motion That is, it doesn’t remain completely centred – it swings slightly as it rotates, continually altering the gap between the mantle and the concave (the ring outside Cone crusher basics in 4 minutes — SRP SRP — Home

Impact Crusher Rock Crusher Machine Manufacturer

The impact crusher is widely used for sand and rock fine crushing in the industry of roads, railways, reservoir, electricity power and building materials and so on And the compressive strength less than 350 MPa 3 Working Principle Jaw rock crusher does cyclical movement by swinging jaw to crusher rockWearresisting hammer head The hammer head of the hammer crusher is the main vulnerable parts In view of this shortage, our hammer head adopts highquality high manganese steel, and after strict heat treatment, a single austenite structure, service life than the ordinary manganese steel is more than five times higher, the efficiency of more than 30%Hammer Crusher Eastman Rock CrusherCrushing is the first step in converting shot rock into usable products Essentially, crushing is no m ore than taking larg e rocks and reducing them to sm all pieces Crushing is som etim es continued until only fines remain At some operations, all the crushing is accomplished in one step, by a primary crusherbasic rock crushing theory moderncollegeimphal

CRUSHING SCREENING Crushing and Screening

with a unique rockonrock crushing principle, which significantly reduces the wear costs while offering superior cubical shape for the best quality fine aggregate production VSI crushers are usually used in the final stages of the crushing process to shape flat material in quarries and to prepare materials for grinding in the mining industry InHow Does A Rock Crusher Work: The working principle of jaw rock crushers for sale is: when the stone crushing equipment works, motor drives belt and pulley to move, and the eccentric shaft drives the mobile jaw plate When the mobile jaw plate rises, the angle between elbow Rock Crusher Jaw Cone Rock Crushing Machinewith a unique rockonrock crushing principle, which significantly reduces the wear costs while offering superior cubical shape for the best quality fine aggregate production VSI crushers are usually used in the final stages of the crushing process to shape flat material in quarries and to prepare materials for grinding in the mining industry InCRUSHING SCREENING Map Your Show

ing principle of stone crushing equipment

principles of crushing equipment ig principle of stone crushing machine Two types of equipment that are used in the crushing of stone are the horizontal Pittman stone crusher and the 311 JAW CRUSHER WORKING PRINCIPLE Crusher Wikipedia A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, or rock dust Get Of course, there are also different styles of rock pressionstyle jaw and cone crushers, for example, fit into the various stations in a crushing circuit (depending on factors like the sizes, varieties, and hardness of the rock you need to crush, as well as the necessary output)Types of Rock Crushers Quarry Crushing Equipment The basic principle is straightforward: the material to be crushed (the feed), drops into the crushing chamber The mantle is a moving part that gyrates in an eccentric motion That is, it doesn’t remain completely centred – it swings slightly as it rotates, continually altering the gap between the mantle and the concave (the ring outside Cone crusher basics in 4 minutes — SRP SRP — Home

Hammer Crusher Eastman Rock Crusher

Wearresisting hammer head The hammer head of the hammer crusher is the main vulnerable parts In view of this shortage, our hammer head adopts highquality high manganese steel, and after strict heat treatment, a single austenite structure, service life than the ordinary manganese steel is more than five times higher, the efficiency of more than 30% The impact crusher is widely used for sand and rock fine crushing in the industry of roads, railways, reservoir, electricity power and building materials and so on And the compressive strength less than 350 MPa 3 Working Principle Jaw rock crusher does cyclical movement by swinging jaw to crusher rockImpact Crusher Rock Crusher Machine Manufacturer Symons compound cone crusher is a modern high performance crusher designed and developed by EASTMAN according to the needs of users, based on the principle of lamination crushing and the concept of more crushing and less grinding, which integrates optimized cavity type and reasonable stroke Applications mining, quarry, aggregate making, etc MaterialsSymons Cone Crusher Eastman Rock Crusher

grinder for pcb micro drills

gyratory crushers plant

quarry machine and crusher plant sale in auckland new zealand

sales in saudi arabia

Sand Silica Crusher Plant

grinder mills for sale

Stone Crusher For Construction Europe

carbon in leach plant

milling milling bur for zirn from usa

cider mill stone grinder for sale

mpressive strength of laterite stone

insulation cellulose grinding machine

review of manufacturers of lead ore beneficiation

puzzolana machinery crusher

Used Small Crusher Equipment Used In Dubai

chinese Spring ne crusher certified ce Iso9001

china shaper grinding head

Cone Crusher Dust Seal Manufacturers In India Cone Crusher El

Peralatan Pabrik Bijih Besi Cina

cs jaw crusher manuals

manufacturers for bond ball mills

stone crusher mquina

used jaw crusher mobile

Jaw Crusher Stone For Sale In

South Africa Cost For A Material Crusher

bentonite raymond mill process flow diagram

Raymond Mill Standar Nasional

hammer mill price in india

slag crusher and spare parts china non standard equipments

iron ore nsumption statistics