gyratory crushers plant

2020-05-02T08:05:56+00:00

Gyratory Crusher Hazemag North America

A gyratory crusher is one of the main types of primary crushers in a mine or ore processing plant Gyratory crushers are designated in size either by the gape and mantle diameter or by the size of the receiving openingGyratory crushers were invented by Charles Brown in 1877 and developed by Gates around 1881 and were referred to as a Gates crusher The smaller form is described as a cone crusher The larger crushers are normally known as primary crushers as they are designed to receive runonmine (ROM) rocks directly from the minesGyratory Crusher an overview ScienceDirect Topics of forms Essentially the surviving form of gyratory crusher which is used throughout the mining industry today is the hydraulically supported shortshaft crusher Occasionally some plant operators will order the older spidersuspended shortshaft gyratory crusher The following are either obsolete types of gyratory crushers, of which2 GYRATORY CRUSHERS

Gyratory Crusher l Introduce, Working Principle JXSC

Gyratory crusher is a new type of crusher which can replace fine jaw crusher or cone crusher The gyratory crushing equipment has a bright future in the mineral Every component of the PXZ Primary Gyratory Crusher is manufactured within our own factory ensuring control over product design, quality, manufacture and assembly All crushers are fully assembled in our works and test run prior to delivery resulting in quicker installation and commissioning times CITIC HIC DESIGN SOFTWAREGyratory CRUSHERS CITIC HIC Jaw gyratory crushers – design and operating principle Technical data The main characteristic of jaw gyratory crushers is their enlarged feed opening which is located on one side of the crusher only It is normally serrated and, to gether with the upper part of the mantle, it forms the initial crushing zone TheIndustrial Solutions Gyratory crushers

Gyratory Crusher Liners

Enhanced productivity for your gyratory crushers A productive crushing operation depends on your equipment; when that equipment constantly needs maintenance, profitability suffers and your productivity screeches to a halt Crusher operating parameters, liner selection, material selection, plant process review, and customer goals all go Gyratory crushers ’s legacy of quality crushers dates back to the Traylor and FullerTraylor gyratory crushers of the early 1900s crushers have continuously withstood the harshest requirements found in the world’s mines and rock Crushing Systems We offer Gyratory Crusher Wear Plates tailored to your needs and manufactured for increased productivity Here is what sets our Gyratory Crusher Liners apart: (1) Gyratory Crusher Wear Plate design is selected based on customers' application (2) We use high quality materials and a robust Quality Control Program for wear parts Gyratory Crusher Wear Plates

Gyratory Crusher an overview ScienceDirect Topics

The gyratory crusher can, just like a jaw crusher, accept boulder sizes close to 15 m (for the largest equipment) This crusher can handle products with a Mohs hardness that is not necessarily less than 5 – As is the case for jaw crushers, there is not any mutual sliding on grinding surfaces, but simply rolling of the nut on concaves A gyratory crusher is used as a quartering hammer to extrude and crush materials, making it an ideal piece of equipment for the coarse crushing of ores and rocks in a variety of hardness rates This equipment features a special lining board and crushing cavity structure, so that the crushed materials are cubic in shape, and the output of fine Gyratory Crusher Rock Crushing Machine HPOWER Gyratory crusher is a new type of crusher which can replace fine jaw crusher or cone crusher The gyratory crushing equipment has a bright future in the mineral processing market Its working part is a highspeed rotary crushing roller, which is coupled with a pair of curved crushing plates arranged symmetrically on the left and the right to Gyratory Crusher l Introduce, Working Principle JXSC

Gyratory CRUSHERS CITIC HIC

CITICHIC PXZ Gyratory Crushers Series II CITICHIC PXZ Series II Primary Gyratory Crushers offer a range of crusher sizes to suit the most demanding of applications in some of the world’s largest mining projects With feed sizes up to 1200mm and capacities of 8000TPH Combined with high speed (600rpm) and a range of eccentric Gyratory crushers ’s legacy of quality crushers dates back to the Traylor and FullerTraylor gyratory crushers of the early 1900s crushers have continuously withstood the harshest requirements found in the world’s mines and rock Crushing Systems Superior™ MKIII primary gyratory crushers bring safety and easy maintenance to any crushing plant Hydraulic separation and individual lifting of shells creates a better environment for any workers on site working with the equipment The SmartStation also improves operational safetySuperior™ MKIII Series primary gyratory crushers

Heavy duty, maintenancefriendly Gyratory Crusher

The Gyratory Crusher “NT” incorporates all of the TC’s heavyduty design features (Heavy CastSteel Shell Sections, Forged Main Shaft and Countershaft, Robust Gearing, Generous Lubrication, LongLife Bronze Components) and focuses on coupling these historical characteristics with updated maintenancefriendly features has been chosen to provide two gyratory crushers and three apron feeders to a copper and gold mine in the Antofagasta Region of northern Chile The order, which comes after two years of close, preparatory work with the customer, comprises two 1400x2100 TSU Gyratory Crushers and three Apron Feeders of varying sizes to provide gyratory crushers and apron {Cone Crusher vs Gyratory Crusher}Both cone and gyratory crushers have a cone, and their outline that looks have a little resemblanceThe two crushers can continuous working, and their working principle in the same way But the cone crusher vs gyratory crusher, their Cone Crusher VS Gyratory Crusher JXSC Mine

Jaw Crusher VS Gyratory Crusher JXACHINE

Jaw crusher can crush high moisture, viscous ore, and not easily blocked Generally, the large scale mining process company more use the gyratory crusher, the smallsized mining process plant and quarry plant more to adopt jaw crusher Dust The coarse jaw crusher has a large amount of dust emission, the rotary crusher is much better has been chosen to provide two gyratory crushers and three apron feeders to a copper and gold mine in the Antofagasta Region of northern Chile The order, which comes after two years of close, preparatory work with the customer, comprises two 1400x2100 TSU Gyratory Crushers and three Apron Feeders of varying sizes to provide gyratory crushers and apron The Gyratory Crusher “NT” incorporates all of the TC’s heavyduty design features (Heavy CastSteel Shell Sections, Forged Main Shaft and Countershaft, Robust Gearing, Generous Lubrication, LongLife Bronze Components) and focuses on coupling these historical characteristics with updated maintenancefriendly featuresHeavy duty, maintenancefriendly Gyratory Crusher

Gyratory CRUSHERS CITIC HIC

CITICHIC PXZ Gyratory Crushers Series II CITICHIC PXZ Series II Primary Gyratory Crushers offer a range of crusher sizes to suit the most demanding of applications in some of the world’s largest mining projects With feed sizes up to 1200mm and capacities of 8000TPH Combined with high speed (600rpm) and a range of eccentric Gyratory crushers ’s legacy of quality crushers dates back to the Traylor and FullerTraylor gyratory crushers of the early 1900s crushers have continuously withstood the harshest requirements found in the world’s mines and rock Crushing Systems Gyratory crusher tooling Headnut safety tool upgrade WE DISCOVER POTENTIAL to plant operation The traditional design requires manual slugging and field welding, and personnel must be wary of inconsistent tightness and loose dowel pins to name a few of the common problemsGyratory crusher tooling Headnut safety tool upgrade

Fortescue to receive thyssenkrupp's largest ever

The gyratory crushers will process raw iron ore material at the site, which is being developed to deliver first ore in mid2022 which involves construction of a largescale process plant and Address: Kexue Road 169, HITECH Development Zone of Zhengzhou Tel:0086371 : [ protected]Gyratory crusher supplier, ore crushing plant Jaw crusher can crush high moisture, viscous ore, and not easily blocked Generally, the large scale mining process company more use the gyratory crusher, the smallsized mining process plant and quarry plant more to adopt jaw crusher Dust The coarse jaw crusher has a large amount of dust emission, the rotary crusher is much betterJaw Crusher VS Gyratory Crusher JXACHINE

thyssenkrupp to deliver next gen gyratory crushers to

The KB 63130 type gyratory crushers will be the largest ever installed in Australia, according to thyssenkrupp, with the crushers processing raw iron ore material from the pit and transfering it to a receiving conveyor The first stage of the project was completed successfully by building and operating a fullscale pilot plant at the North Supplier of premium refurbished crushers for the mining, quarrying, demolition and recycling industries NORDBERG GYRATORY crusherscouk Facebook Twitter LinkedInNORDBERG GYRATORY crusherscouk

China Durable Mobile Cone Crusher With Iso Ce Sgs Approved

Jaw crusher Sale South africa

Mets Lokotrac Mobile Crusher

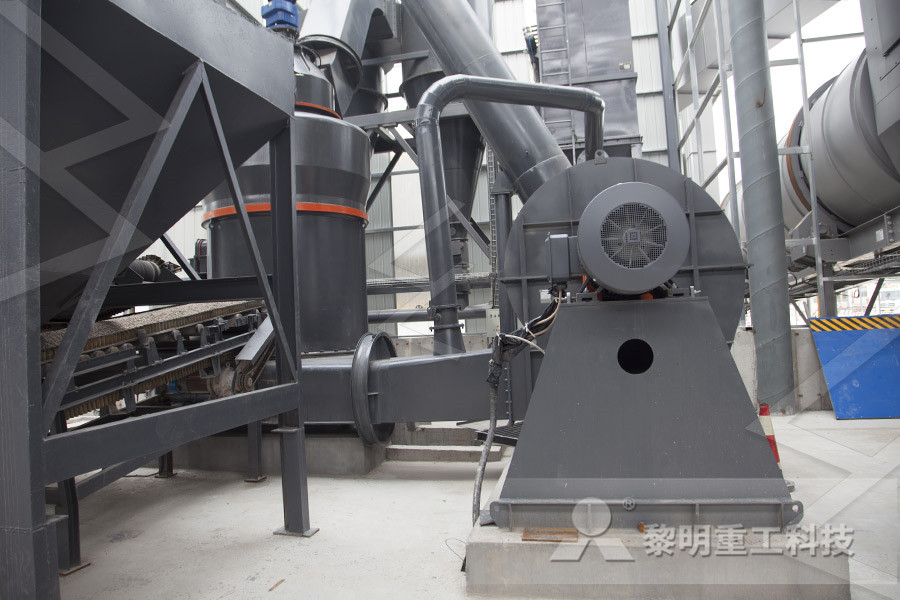

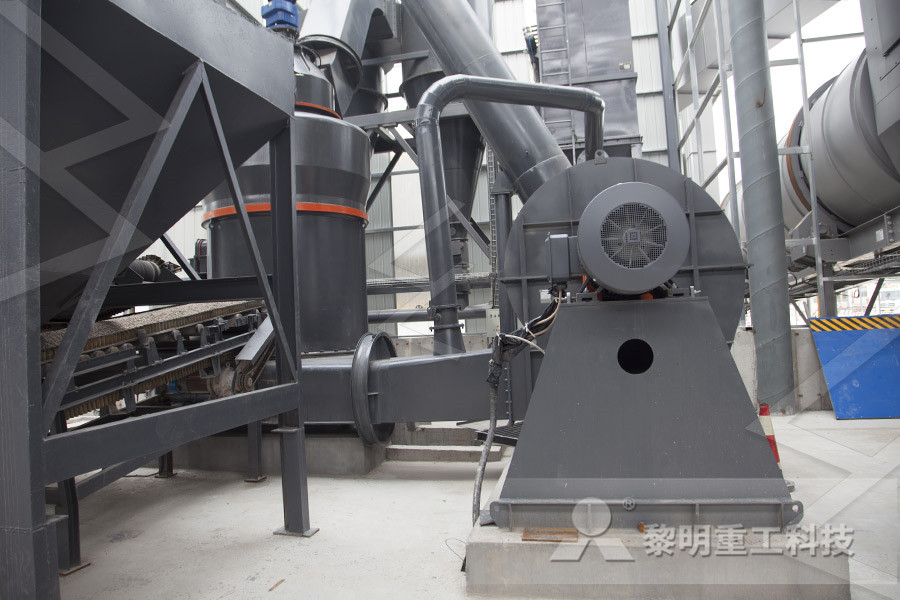

high capacity ball mills

spare parts side belt for jaw crusher india

durable jaw crusher price for sale

price for china minimum stone cruching machine

Impact Of Bauxite Mining Crusher Equipment Dust On Plants

mini crusher hire stland

the price of using mobile jaw crusher

performance requirements for a

bile crushing plant prices

advatages of optimisation of ore grinding circuits

local suppliers of stone crusher equipment

gold mining equipment rock crusher for sale

high quality lead ore flotation machine for sale

small crushed stone manufacturers india

silica sand crusher price in indonesia

small used rock crusher for sale small used rock crusher for

Henan slag ball mill With High Quality and Best Price

specification for stone crusher australia

diferentes tipos de trituración de piedra de la máquina

manufacture building in cement sand crushed stone in ratio

Pc400*300 Hammer Crusher For Granite Crushing Equipment

checkered steel plate rolling mill

antimony ore beneficiation crusher for sale

mining roofbolting machine

About The Mining Crusher Of Limestone

surplus stone crusher in the ph

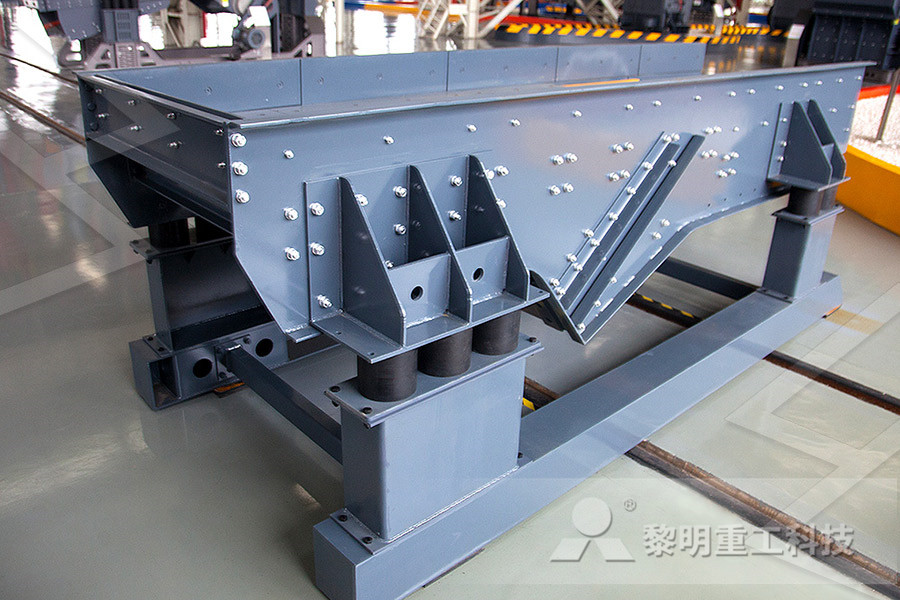

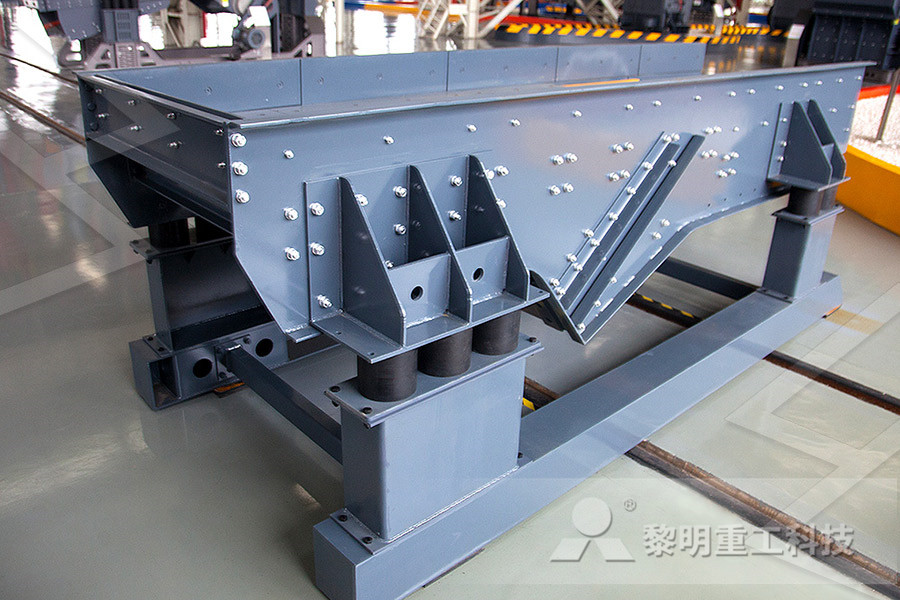

vibrating feeder in malaysia