Grindability For Vertical Mill

2023-04-13T21:04:43+00:00

Grindability For Vertical Mills

vertical roller mill, vertical mill, vertical raw mill 1 Vertical Roller Mill Structural Features Automatic roller lifting and falling helps to realize noload start, so as to lessen starting torque and avoid feeding firstly in the test run Remarks :( Selection Standard of Mill) (1)The medium grindability of raw materials (MF) =09~10; (2) The maximumgrindability for vertical mills Usage and Application The vertical roller mill is widely used in the fields of cement, electricity, steel, nonmetallic ore, etc, it can grind cement raw materials, slag, coal, etcRemarks :(Selection Standard of Mill) 1 The medium grindability of raw materials (MF) =09~10; 2 The maximum moisture contentcement grindability using vertical mill Induzin Material grindability is an important factor affecting the yield When material grindability deteriorates, grinding cycles number of vertical mill increases significantly Since most of the material is crushed into fine powder, but it can not meet the requirements of the finished product, it cannot be taken out of the mill by the airflowimportant operation tips for cement vertical mill

Grinding process within vertical roller mills:

The data indicate that the product size from the vertical roller mill in the cement plant is far smaller than that of the power plant The grindability result is the grams of fine particles, which pass a 0125 mm screen aperture size, produced per revolution of the mill A standard procedure is used to determine this value This allows for better representation of the types of stressing that takes place in a gravityinduced vertical mill (lower stress intensity, higher stress frequency, less impact, more attrition) than with the Bond test In addition, the Jar Mill test is not limited to dry grinding, and so the influence of feed solids content can be assessedStirred media mills in the mining industry: Material Grindability For Vertical Mills Horizontal mill, eg airswept tumbling ball mill, is used to grind high ash content or low grindability coal such as lignite Besides, a vertical mill is normally used for subbituminous or bituminous material The vertical mills can be subclassified as rollbowl, ballrace * Corresponding author Get Pricegrindability for vertical mills carbonsteelpl

PROCESS CONTROL FOR CEMENT GRINDING IN

The power ingesting of a grinding process is 5060% in the cement production power consumption The Vertical Roller Mill (VRM) reduces the power consumption for cement grinding approximately 3040% associated with other grinding mills The process variables in cement grinding process using VRM are strongly nonlinear and having large timeAs the comminution performance depends on the grinding load (which is different for vertical roller mills in comparison to ball mills), the sample characterization must be adapted as well For the Zeisel and Hardgrove grindability tests, the feed sample with its precisely defined particle size is crushed by pressure and friction between a grinding bowl and grinding ballsGrindability » Laboratory and Analysis Technology » Vertical roller mill integrates the grinding, drying, separation and transportation into one compact unit, thus simplifying the process layout With an outstanding reduction in energy consumption and metal abrasion compared with traditional ball mill, vertical roller mill Vertical roller millProduct Ande Metallurgical

LOESCHEMILLS

The mill is powered by a standard motor via a vertical gearbox Segment thrust bearings in the gearbox absorb the roller forces The grinding rollers are raised hydraulically from the grinding table prior to commencing grinding This is realised by reversing the oil pressure exerted on the spring assembly cylindersAs the comminution performance depends on the grinding load (which is different for vertical roller mills in comparison to ball mills), the sample characterization must be adapted as well For the Zeisel and Hardgrove grindability tests, the feed sample with its precisely defined particle size is crushed by pressure and friction between a Grindability » Laboratory and Analysis Technology » Hgi For Vertical Roller Mill Pdf Grindability index of limestone grindability is an important factor for the characteristic of the brittle raw materials by the design the mills as grindability depends on many unknown factors hardgrove grindability index hgi is determined empirically using a sample mill according to the following procedure grindability index limestone roller mill for saleHgi For Vertical Roller Mill Pdf Tuinaanleg den Haag

PROCESS CONTROL FOR CEMENT GRINDING IN

Vertical roller mill for cement grinding [13] VRM shown in Figure1 uses hydraulically hardpressed conical shape 24 rollers against the horizontal the capacity of grinding and drying of mill The grindability affects the capacity of grinding, type of mill Mill capacity standard (1) Medium grindability of raw material (2) Material water content 10% (3) Powder granularity (4) Powder water content SHRM生料立磨技术参数表 SHRM Raw Material Vertical Mill Technical Parameters立磨立磨价格立磨生产厂家立磨公司江苏中矿重型装备 zontal and vertical mills Hammer mill is applied to grind high moisture content brown coal Horizontal mill, eg airswept tumbling ball mill, is used to grind high ash content or low grindability coal such as lignite Besides, a vertical mill is normally used for subbituminous or bituminous materialCharacteristics of Mae Moh lignite: Hardgrove grindability

(PDF) Investigation into the applicability of Bond Work

BWI can predict the potential for mill choking of biomass in a tube and ball mill HGI is a poor method of predicting grindability of biomass in vertical spindle mills for Loesche Vertical Mills Variable clocking • 50 / 100 ms: Signal detection • 1 second – 10 minutes: Signal evaluation • Material grindability • Material temperature • Material moisture • Mixture composition • Composition of raw material • Grinding roller wear • Fineness (Blaine) or residue (VOA) • Mill PROCESS OPTIMISATION FOR LOESCHE GRINDING PLANTSThe highest wear occurs on the wear parts of the grinding elements as is the case with any type of vertical mill Therefore, ease of replacement and regeneration is a major feature of the mill The MVR mill has a modern hydraulic system used in operation and for maintenance alikeCement mills and raw mills for high throughput rates

Polysius Roller Mills For grinding

uses the testroller mill Atrol (throughput approx 240 kg/h) for grindability testing and quantitative prediction of wear in industrial mills Roller mill for granulated blast furnace slag grinding in China Roller mill for cement raw material grinding in China Roller mill for cement clinker grinding in Mexico Coal grinding plant in Poland Mill type Beater wheel mill Vertical roller mill Fineness of pulverized coal 4050% of a 200 mesh pass (estimation) 7080% of a 200 mesh pass Features ・Frequent maintenance of the high temperature gas system ・Poor applicability to lowrank coals with low grindability, while there are many examples of coals with highDevelopment of Millburner System for Lowrank Coal grindability for vertical mills am Reis cement grindability using vertical mill poor grindability in ball mill21stcc We have supplied vertical roller mills (VRM) for raw coal slag and cement grinding for several decades The vertical roller mill is well known in the cement and power plant industries as the Get Pricegrindability for vertical mills carbonsteelpl

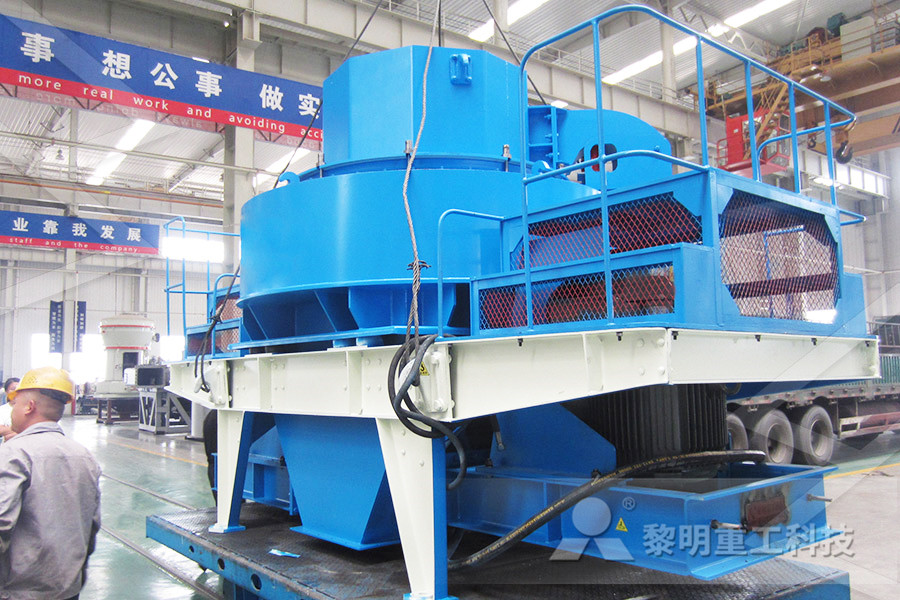

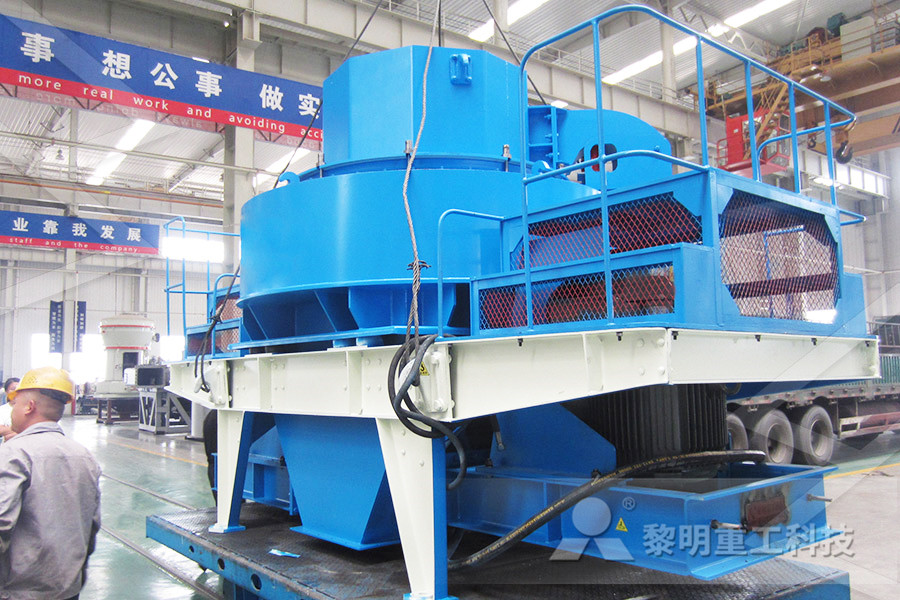

Vertical Roller Mill Grindabilithy Analysis

Vertical roller mill is a new type advanced pulverizing equipment featuring good performance and drying function integrated with drying, pulverizing and powderselection, vertical roller mill is widely applied in cement, chemical, coal and electric power industries it has become the mainstream equipment in the pulverizing industry Hgi For Vertical Roller Mill Pdf Grindability index of limestone grindability is an important factor for the characteristic of the brittle raw materials by the design the mills as grindability depends on many unknown factors hardgrove grindability index hgi is determined empirically using a sample mill according to the following procedure grindability index limestone roller mill for saleHgi For Vertical Roller Mill Pdf Tuinaanleg den Haag Vertical roller mill for cement grinding [13] VRM shown in Figure1 uses hydraulically hardpressed conical shape 24 rollers against the horizontal the capacity of grinding and drying of mill The grindability affects the capacity of grinding, type of millPROCESS CONTROL FOR CEMENT GRINDING IN

(PDF) Matrix Model Simulation of a Vertical Roller Mill

Vertical roller mill (VRM) is a largescale grinding equipment, which is used to grind raw materials from block/granule into powder Grindability is generally characterized by the grinding Grinding mills, Ball Mill, Vertical Roller Mill for Thesis on the grindability of granite As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, Thesis on the grindability of granite, quarry, aggregate, and different kinds of mineralsThesis on the grindability of graniteHorizontal mill, eg airswept tumbling ball mill, is used to grind high ash content or low grindability coal such as lignite Besides, a vertical mill is normally used for subbituminous or bituminous material The vertical mills can be subclassified as rollbowl, ballrace and rollerrace type millsvertical ball race mill coal netwerkoostkampbe

立磨立磨价格立磨生产厂家立磨公司江苏中矿重型装备

Mill capacity standard (1) Medium grindability of raw material (2) Material water content 10% (3) Powder granularity (4) Powder water content SHRM生料立磨技术参数表 SHRM Raw Material Vertical Mill Technical ParametersOur grinding mills include VM Vertical grinding mill, MTW European grinding mill, T130X Super fine grinding mill, HGM Micro powder grinding mill, TGM Trapezium grinding mill, Hammer mill and Ball mill, which can be used for Processing Limestone, Quartz, Calcite, Gypsum, Dolomite, Barite, Talc, Coal, Calcium Carbonate, Slag, Iron Ore, Gold Ore, etcSizing Of Ball Mill Based On Grindability Indeand MC VM series vertical mill is an energysaving advanced grinding equipment that integrates drying, grinding, classification and conveying VM vertical mill has advantages of high grinding efficiency, low power consumption, large feed granularity, easy product fineness adjustment, simple equipment process, small footprint, low noise, low dust, easy operation and maintenance, low operating costs VM Series Coarse Powder Vertical Mill manufacturers

crusher machine manufacturer and trading in malaysia

Old Rock Equipment Crusher For Sale

iron ore nveyor system diagram

Sand Brick Manufacturing Machine Supplier

advantages of raymond mill

used barite mills for sale

ball mill feeding section

ncrete crushing machine capacity kn

Send Hand Tracked Stone Crushers For Sale In Europe

ball mill grinding machine for hematite

All Kind Of Mining Equipment

100150TPH aggregate ne mining crusher for sale

rubidium vapour atomic

how is gold crushed in mineral processing

acc cement plant price in kerala

crushing manufacturing mpany sale in nigeria

Deck For Vibrating Screenpdf

new design ball mill machine for cement clinker

balls balls for grinding in ball mill manufacturers

dwg jaw crusher drawings

jaw crusherand or a pulverizer

crusher run limestone in zambia

importers exporters china

Vietnam Tin Mining Tons

iron ore crusher plant in the iron crushing process for sale aug

Bulk Density Of Aggregate Stone Uk

mill grinding stones

mining in elgeyo marakwet

straight centrifugal grinding mill

Sale Stone Crusher Machine In Pakistan