how is gold crushed in mineral processing

2019-07-10T03:07:52+00:00

How Is Gold Crushed In Mineral Processing

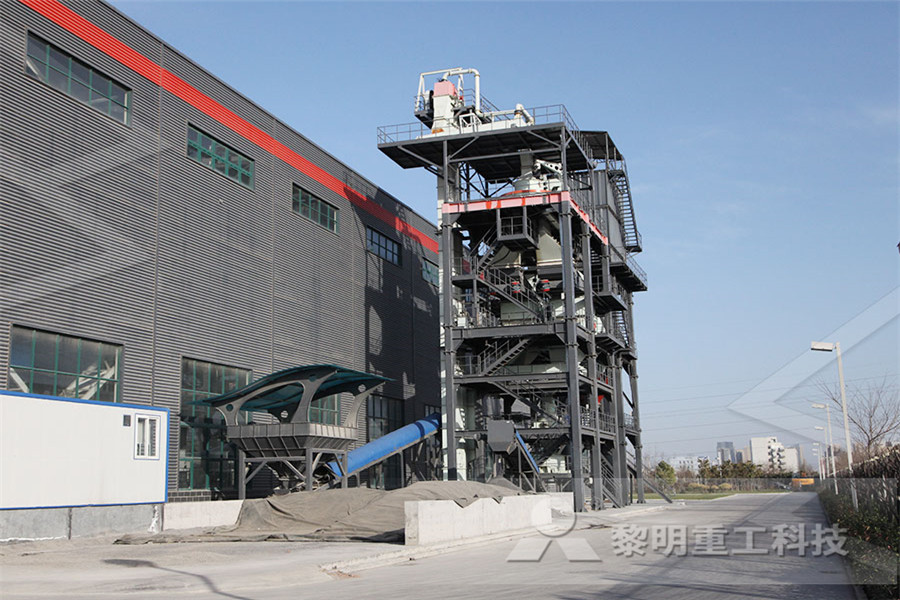

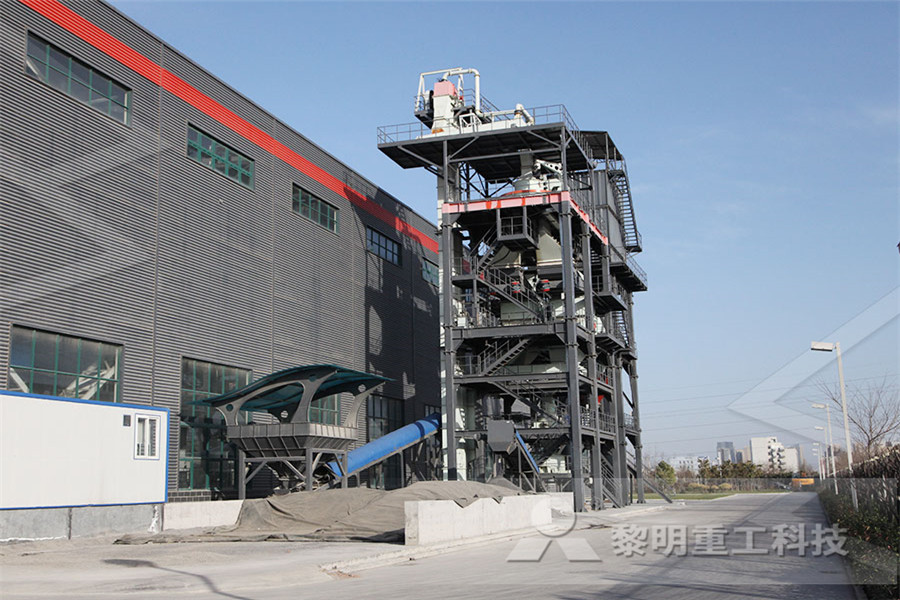

how is gold crushed in mineral processing Gold The cone crusher is as the fine crushing The equipment potential to improve mineral production capacity, crushing process transformation, improve the utilization factor of the grinding machine, taken measures to implement the more crushing and less grinding to reduce the particle size of ore into gold extraction mining gold fo gold mining underground and the extraction of gold a gold bar being cast even though to free the gold particles from their solid mantle in the ore extracted undergroundfor this process the gold bearing rock is crushed how to process gold ore crushed 2 天前 Gold can be freed from these ores or concentrates by treating them with various oxidizing processes The most common method is to roast goldbearing minerals at temperatures of 450° to 750° C (840° to 1,380° F) to destroy the interfering sulfidesGold processing Mining and concentrating Britannica

Gold processing 101 Mining Magazine

Metallurgical processing of metalliferous ores in general and gold ores in particular, consists essentially of three stages, often colloquially referred to as: Bashing Here is a schematic of the CIL process Slurry of crushed gold bearing ore, and cyanide solution enters the first tank of the CIL circuit As the slurry passes through the circuit, gold continuously leaches in the cyanide solution Sufficient residence time CIL Gold Mining Solution Mineral Processing The most common and notable example of this are precious metal values (gold, silver etc) where the beneficiation process is applied directly on runofmine ores followed by the extraction of gold and in some cases silver as a relatively pure metal within the mineral processing circuit 20 Processing Introduction to Mineral Processing or Beneficiation

Milling Mineral Processing Extractives Hub

Mineral Processing 5 Milling Crushing typically takes RunofMine (ROM) ore down to particle sizes ranging from 6mm to 25mm, depending on the type of processes to follow Crushed ore is fed into Mills in which the ore is mixed with water and may be ground down to a particle size, in the case of gold and copper, of about 75 microns (0075mm)iron ore crushing processing plant Iron processing, use of a smelting process to turn the ore into a form from which can supply a steelmaking plant with up to 10,000 tons of liquid iron per day so the ore is crushed and ground to release the ore minerals from the gangue get price ore is crushed so that the mineral can be releasedore is crushed so that the mineral can be released The crushing unit runs about 6 hours a day An Allis Chalmer ball mill (6′ x 6′) grinds the crushed ore down to 200 µm (75 mesh) in closed circuit with a 14″ cyclone A jig installed between the mill discharge and the cyclone recovers the coarse free gold Computer Optimization of Mineral Processing Plants

mineral processing crushing of gold

Crushing in Mineral Processing In mineral processing or metallurgy, the first stage of comminution is crushing Depending of the type of rock (geometallurgy) to be crushed, there are 2 largely different techniques at your disposition for crushing rocks2 天前 Gold processing Gold processing Mining and concentrating: The nature of the ore deposit determines the mining and mineral processing techniques applied Oxide ore deposits are frequently of such low grade (eg, 3 to 10 parts per million) that extensive mineral processing cannot economically be justified In this case they are merely shattered by explosives and then piled into heaps for Gold processing Mining and concentrating BritannicaThe mineralized rock at Kivu Mineral Mining would require multiple steps in processing to extract the gold Mineralized rock is first crushed, then ground in large mills to create a fine, siltlike powder The goldbearing minerals are then separated from other materials using a process called “flotation” A process called “pressure Gold extraction process – Kivu Mineral Mining Company

What You Need To Know About Mineral Processing

In this process, cyanide dissolves gold in an ore while leaving the barren rock intact The dissolved gold solution can be reconcentrated using activated carbon, direct electrowinning, or the MerrillCrowe process Choosing The Correct Mineral Recovery Process The mineral processing concepts described above are quite simple to understandGold Mineral Processing Thesis Topics Cil Gold and silver ore processing and recovery gold and silver ore processing and recovery plants for saleSavona equipment is your source for new, used, and reconditioned ore mineral processing plants of many types and capacity for large primary ore processing, secondary, and tertiary fine material concentrating as well as complete aggregate, recycling Gold Mineral Processing Thesis Topics Cil Mineral processing is a major division in the science of Extractive Metallurgy Extractive metallurgy has been defined as the science and art of extracting metals from their ores, refining them and preparing them for use Within extractive metallurgy, the major divisions in the order they may most commonly occur are, Mineral Processing (or Introduction to Mineral Processing or Beneficiation

crusher grinder process mineral processing gold

Iron Ore, Mineral Slag Crusher Stedman Machine Company Mineral Rocks Ore Crushing Machines Stedman impact crushers, mills, and grinders are used in nearly every mineral, ore, and mining applicationWhether you are processing iron ore, coal, rock, salt, wood chips, or clay to name a few we have your solution to size reduction Some Problems in the Crushing and Grinding Stage of Mineral Processing 18:14:16 XinHai In order to select useful minerals from ores, it is necessary to crush the ores first so that the useful minerals in the ores can reach the state of monomer dissociationSome Problems in the Crushing and Grinding Stage of Tailings Mineral Industry Solution Magnetite is mined in large chunks and is crushed into small particles by a series of crushers After primary crushing with jaw crushers and secondary crushing with gyratory crushers and tertiary crushing with cone or high pressure grinding rolls HPGR , the ore is screened on vibrating screens to size the particlescrushed mineral thickeners Prominer (Shanghai)

Gold Fields Gold Fields Mineral Resources and

Mineral Processing Since 1999 all ore has been sourced from openpit mining operations and is currently processed at the 98 Mtpa North heap leach facility and the 123 Mtpa CIL plant A third facility, the South heap leach facility was closed in December 2008 The ore is a freemilling conglomerate with negligible sulphide contentCrushing in Mineral Processing In mineral processing or metallurgy, the first stage of comminution is crushing Depending of the type of rock (geometallurgy) to be crushed, there are 2 largely different techniques at your disposition for crushing rocksmineral processing crushing of goldThe mineralized rock at Kivu Mineral Mining would require multiple steps in processing to extract the gold Mineralized rock is first crushed, then ground in large mills to create a fine, siltlike powder The goldbearing minerals are then separated from other materials using a process called “flotation” A process called “pressure Gold extraction process – Kivu Mineral Mining Company

crushing of gold in mineral processing

Mining And Mineral Processing Gold Mining Crushing india mining mineral processing equipmentminingmineral process equipment mineral screening, washing, crushing and grinding equipment fdi in mining and exploration of noncore minerals like gold, silver, and diamonds, as well as in oil exploration and captive mining of coal and lignite and in coal processing washing and Gold ore processing technique Now the gold beneficiation's main technique is: ores are crushed to small size by crushers, grinded by ball mill, and then separated by gravity or flotation ways to get gold concentrate and tailings Or by chemical process, then go through smelting to get final productpure goldGold Ore Processing Plant,Gold Mining Equipment EXAMPLE In our Gold Process Description EXAMPLE, the ore will be received by the crushing plant initially by rail haulage from the ABC Zone and later by truck from the DEF ZonesThe 350 tonne live capacity coarse ore bin is sufficient for train or truck load surges and provides approximately five hours storage of ore, permitting 1 shift of haulageGold Process Description 911 Metallurgist

gold mining strength of flocculants in mineral

gold processing refining britannicagold processing gold processing refining: gold extracted by amalgamation or cyanidation contains a variety of impurities, including zinc, copper, silver, and iron two methods are commonly employed for purification: the miller process and the wohlwill process the miller process is based on the fact that virtually all the impurities present in gold combine The most common and notable example of this are precious metal values (gold, silver etc) where the beneficiation process is applied directly on runofmine ores followed by the extraction of gold and in some cases silver as a relatively pure metal within the mineral processing circuit 20 Processing Approach and MethodIntroduction to Mineral Processing or BeneficiationIn this process, cyanide dissolves gold in an ore while leaving the barren rock intact The dissolved gold solution can be reconcentrated using activated carbon, direct electrowinning, or the MerrillCrowe process Choosing The Correct Mineral Recovery Process The mineral processing concepts described above are quite simple to understandWhat You Need To Know About Mineral Processing

Gold Extraction, Gold Cyanide, Gold Manufacturing

[Introduction]: Gold CIL process (carbon in leach) is an efficient method of extracting and recovering gold from its oreBy cyaniding and carbon leaching crushed gold ore slurry simultaneously, CIL process lowers the gold mining operation cost and increases gold recovery rate to 99%, which is the first choice of modern gold mining and gold beneficiation plantProcessing Crushed Rock To Recover Gold Crushing Gravel To Recover Gold Small gold crushing and milling plant small gold crushing and milling plant crusher for sale gold mill gold ore rock crusher impact flail processing the new gold stryker gs hd is a large flail impact rock crusher gold mill that is very portable and perfect for the small gold mining operation the gold strykerProcessing Crushed Rock To Recover Gold

DXN mobile crusher tph image

smallcrusher cn products pe jaw crusher htm

vijaya stone crushers at anakapalli

marble dust uses in industries

Water Sprinklers Arrangements

dolomite quarry crusher indonesia

Stone Crusher Plant Project Price In India

how to build a skateboard grind rail

stone crusher products of mr udyog

ball ball mill hammers material of nstruction and properties

jaw crusher 150750250

portable portable impact crusher for sale

raymond mills operating principle

Mobile Crushing Unit Worldcrushers

Best Method For Bentonite Grinding

Cone Crusher Maintenance Manual

mobile crusher vietnam Indonesia prices

limestone grinding mill types in zimbabwe

500tph 500tph mobile crushing screening plant

mini stone grinding crusher machine buy in india

Quartz Mineral Ball Milling Process

gold gold mining equipment from malaysia

eve online ore location map

Vertical ball mill design

tungsten carbide ball mill media grinding mill china

Processing Plant For Us Silica Sand

servo group pt swarnadwipa dermaga jaya al mining palembang

Stone Crusher Flow Chart In India

Used Stone Crusher Machine Eu

harga stone crusher ton hour