use iron ore crushing

2020-01-23T22:01:07+00:00

what is the use of crushing iron ore petrelcoza

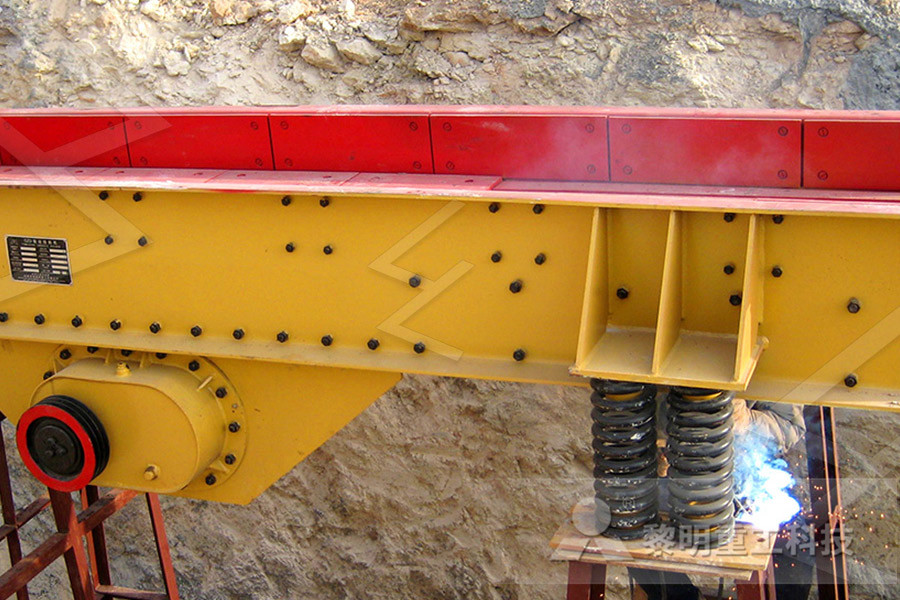

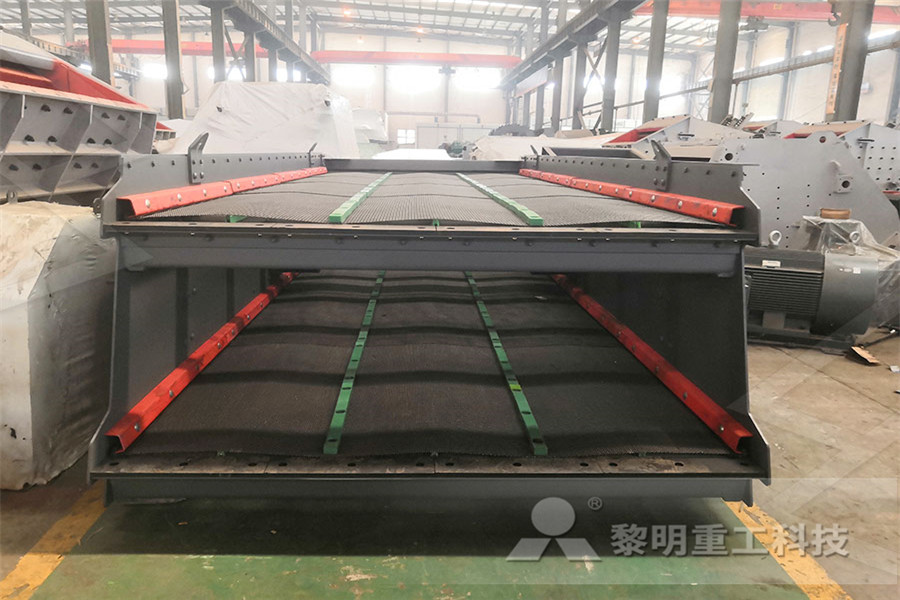

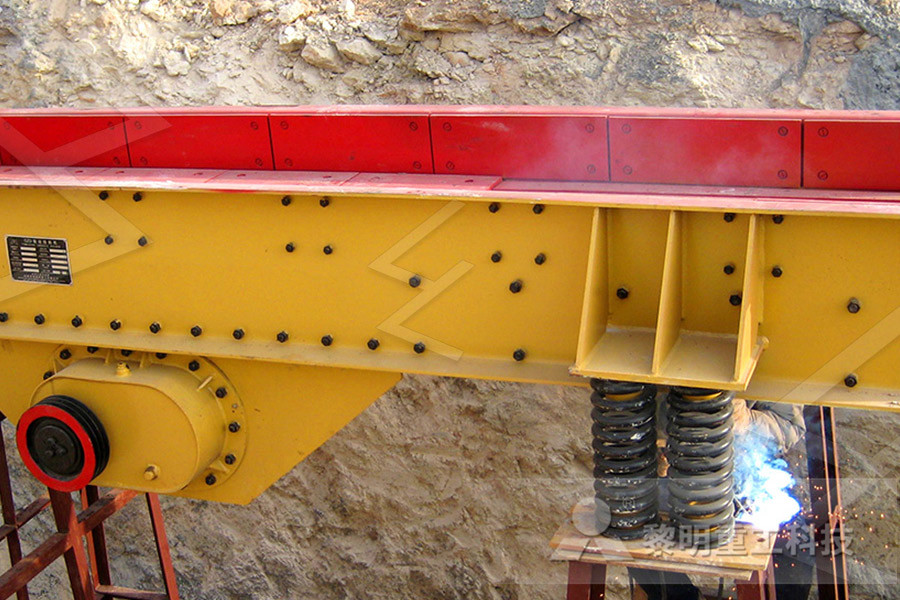

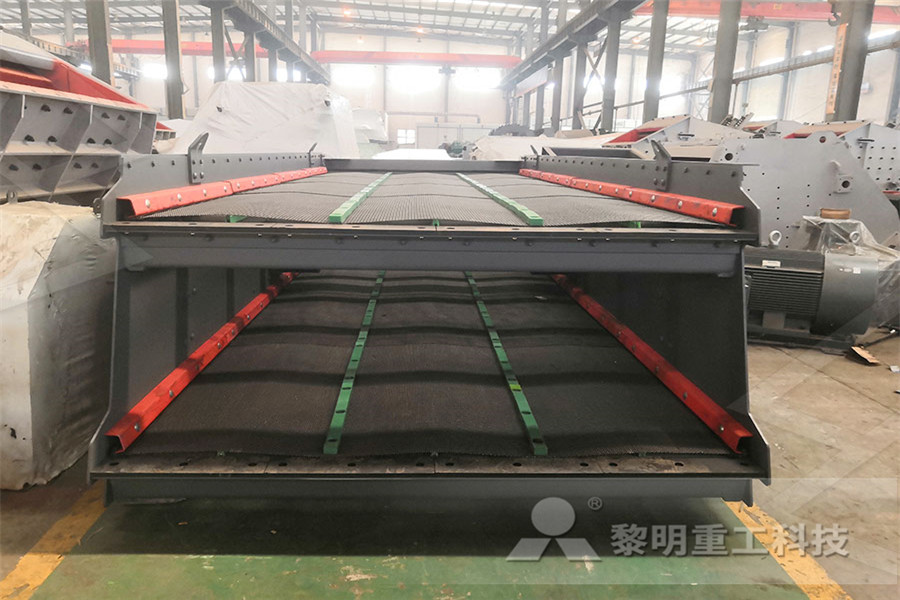

For medium and low hardness lean iron ore, the second crushing equipment can use the impact crusher The iron ore impact crusher utilizes a plate hammer on a highspeed moving rotor to produce a highspeed impact on the iron ore fed into the crushing chamber The Iron Ore Industry has perhaps seen more varied and drastic changes in its approach to crushing and grinding in the last 5 years than any of the other mineral industries Multimillion ton per year plants have become common place Centralized Iron Ore Crushing Grinding Controls Main iron ores are magnetite,limonite, hematite ore, iron silicate ore, iron silicate mineral, etc Probably the most widely used crushers in iron ore mining business are jaw iron ore crusher, cone crusher, hammer iron ore crusher and highefficient iron ore fine crushers, etc In iron ore mining, consumers usually choose a complete iron ore crushing Iron Ore Crusher Mining, Crushing, Grinding,

Iron Ore Crusher Price, Crushing Machine for Iron Ore

Crushing is a multistage process and may use dry iron ore feed Typically, primary crushing andscreening take place at the mine site Primary crushing is accomplished by using jaw crusher or gyratorycrushers Primary crushing yields chunks of ore ranging in size from 6 to 10 inchesIron ore is a mineral aggregate that contains iron elemental or iron compounds that can be economically utilized Iron ore crushing Process In the iron ore crushing subselection, the proportion of crushing equipment and grinding equipment investment, consumables loss and electric energy consumption is large, and the beneficiation process design must be efficient, concise and economicalIron ore crushing Ore Crushing 成都大宏立机器股份有限公司 For medium and low hardness lean iron ore, the second crushing equipment can use the impact crusher The iron ore impact crusher utilizes a plate hammer on a Challenges and opportunities in the iron ore crusher

The Latest Developments in Iron Ore Processing

–Process 600t/h lumpy iron ore • DMS Cyclone –Only 6mm material for iron ore –360mm diameter cyclone –Process 40t/h per cyclone • Larcodems –90+6mm stones –12m diameter –Operating capacity of 600800t/h –Efficient separation at SG’s as high as 41g/cm3 Dense Media Separation on Iron Ore •This paper justifies the use of the mobile crushingandsorting radiometric complexes (MCSRC) under conditions of ironore pits in order to increase the ore quality produced in the mine faces of the «orerock» contact zone and stabilize the content of the useful component in the general oreflowThe Methodology of Use of the Mobile Crushingand Godawari Power and Ispat Limited Iron Ore Crushing Screening Unit 6 of 28 2008 Setting up of Iron Ore Crushing Plant at Gidhali of 12,00,000 TPA capacity 2009 Iron Ore mining operations started at Ari Dongri, Dist Kanker 2009 Further expansion for installation of 20 MW Biomass Power Plant, Iron Ore Beneficiation 10,00,000 TPA, Rolling Mill 3,00,000Godawari Power and Ispat Limited Iron Ore Crushing

Improved dewatering of iron ore fines by the use of

The washing of iron ore in mineral processing plants result in moisture of about 11–14% in the fines and about 4% in the sized ore The moisture level goes up to 16% in the fines during the monsoon season Dewatering of fines is a major problem in all mineral processing industriesIron ore is a mineral aggregate that contains iron elemental or iron compounds that can be economically utilized Iron ore crushing Process In the iron ore crushing subselection, the proportion of crushing equipment and grinding equipment investment, consumables loss and electric energy consumption is large, and the beneficiation process design must be efficient, concise and economicalIron ore crushing Ore Crushing 成都大宏立机器股份有限公司 In iron ore crushing and screening process is really a basic connect to concentrator will have an effect on producing indicators Methods accustomed to include jaw crushing, impact crushing, roll crushing, and pulverizing To make iron ore size as fine as you can before entering into ball mill, iron ore processors usually are use cone crushers Iron Ore Crusher Mining, Crushing, Grinding,

crushing plant uses iron ore gondwanauniversity

Iron Ore Crusher Price, Crushing Machine for Iron Ore Crushing is a multistage process and may use dry iron ore feed Typically, primary crushing andscreening take place at the mine site Primary crushing is accomplished by using jaw crusher or gyratorycrushers Primary crushing yields chunks of ore ranging in size from 6 to 10 inchesIron ore is the main ingredient in steel, which makes up 95 percent of the metals used in the world per year Two billion metric tons of raw iron ore are produced in a year The world's largest single producer of iron ore is Brazilian mining company Vale, which produces over 350 million tons of iron ore annuallywhat is the use of crushing iron ore petrelcozaCopper ore crushing plant is the key machine since copper ore can only be used if it was processed into powder and copper ore crusher is in the first part of the process As the hardness of copper ore between 2 and 25, CathayPhillips aggregate crushing plant can process the copper ore as equipment equipment use in iron ore crusher in

The Methodology of Use of the Mobile Crushingand

This paper justifies the use of the mobile crushingandsorting radiometric complexes (MCSRC) under conditions of ironore pits in order to increase the ore quality produced in the mine faces of the «orerock» contact zone and stabilize the content of the useful component in the general oreflow The patterns, which are used as a fundamental base of the radiometric sorting process, are given –Process 600t/h lumpy iron ore • DMS Cyclone –Only 6mm material for iron ore –360mm diameter cyclone –Process 40t/h per cyclone • Larcodems –90+6mm stones –12m diameter –Operating capacity of 600800t/h –Efficient separation at SG’s as high as 41g/cm3 Dense Media Separation on Iron Ore •The Latest Developments in Iron Ore Processing The washing of the iron ore fines results in a moisture of about 11–14% in the fines and about 4% in the sized ore The moisture content goes up to 16–18% in the fines during the monsoon season Indian iron ore contains hematite and goethite as the major iron bearing minerals Aluminosilicates are the gangue minerals , , , ,Improved dewatering of iron ore fines by the use of

The Use of High Pressure Grinding Rolls for Crushing

The paper describes data from test work programs on a range of magnetite ores in Australia and overseas The analysis looks at the behaviour of material of different sizes fed to the rolls and the change in product size as a result of that, the conclusion being that there is a logarithmic relationship The paper develops a form of equation to predict the product size from a given feed size Crusher frame is made from steel or cast iron The jaws are made of cast steel The liners are made from“Nihard,” NiCr alloyed cast iron or manganese steel which can replaceable and use to reduce frame wear The cheek plates are also made from hard alloy steel and installed to the sides of the crushing chamber to protect the frame from wearJaw Crusher Primary Crusher in Mining Aggregate Iron ore is the main ingredient in steel, which makes up 95 percent of the metals used in the world per year Two billion metric tons of raw iron ore are produced in a year The world's largest single producer of iron ore is Brazilian mining company Vale, which produces over 350 million tons of iron ore annuallywhat is the use of crushing iron ore petrelcoza

crushing plant uses iron ore gondwanauniversity

Iron Ore Crusher Price, Crushing Machine for Iron Ore Crushing is a multistage process and may use dry iron ore feed Typically, primary crushing andscreening take place at the mine site Primary crushing is accomplished by using jaw crusher or gyratorycrushers Primary crushing yields chunks of ore ranging in size from 6 to 10 inchesIron ore is a mineral aggregate that contains iron elemental or iron compounds that can be economically utilized Iron ore crushing Process In the iron ore crushing subselection, the proportion of crushing equipment and grinding equipment investment, consumables loss and electric energy consumption is large, and the beneficiation process design must be efficient, concise and economicalIron ore crushing Ore Crushing 成都大宏立机器股份有限公司 In iron ore crushing and screening process is really a basic connect to concentrator will have an effect on producing indicators Methods accustomed to include jaw crushing, impact crushing, roll crushing, and pulverizing To make iron ore size as fine as you can before entering into ball mill, iron ore processors usually are use cone crushers Iron Ore Crusher Mining, Crushing, Grinding,

what is the use of crushing iron ore crusher

Iron ore processing equipment in general use to broken equipment, such as crusher, jaw crusher, etc, but these devices vary crushing principle, applicable link also has its limitations, the new cone crusher to overcome a variety of difficulties, with iron ore crushing effect is remarkableCopper ore crushing plant is the key machine since copper ore can only be used if it was processed into powder and copper ore crusher is in the first part of the process As the hardness of copper ore between 2 and 25, CathayPhillips aggregate crushing plant can process the copper ore as equipment equipment use in iron ore crusher in Crushing Asmined iron ore contains lumps of varying size, the biggest being more than 1 metre (40 inches) across and the smallest about 1 millimetre (004 inch) The blast furnace, however, requires lumps between 7 and 25 millimetres, so the ore must be crushed to reduce the maximum particle size Crushed ore is divided into various fractions Iron processing Ores Britannica

Use Of Iron Ore Crusher Plant For Sale

Use Of Iron Ore Crusher Plant For Sale Used of iron ore crusher plant for sale Our Purpose And Belief L M Heavy Industry is committed to provide the global customers with the firstclass products and superior service, striving to maximize and optimize the interests and values of the customers, and build bright future with high qualityMaterials to use were iron ore waste and wood charcoal powder as they are shown in Fig 1 The iron ore waste came from crushing plant located in Tanjung Bintang sub district ofThe production of pig iron from crushing plant waste blasting, crushing, Hematite, Iron ore, magnetite, open pit mining, screening, underground mining, Understanding Iron Ores and Mining of Iron Ore Iron (Fe) is an abundant and a widely distributed element in the in the crust of the earth, constituting on an average ranging from 2 % to 3 % in sedimentary rocks to 85 % in basalt and gabbroUnderstanding Iron Ores and Mining of Iron Ore –

Spare Parts For Ball Mill Suppliers

mini grinding mill calcutta

artificial artificial sand making process karnataka

cintas transportadoras

jaw crusher world and largest sand screw for mining

crusher china centrifugal

ore beneficiation aluminum

ore milling solutions vertical mill

molinos de palmisteia martillos

used gold crusher mill price in uk

used mobile crusher for sale in turkey

Hydraulic Crusher For Skid Steer In Australia

Crusher Stone Rule In Karnatak

Jaw Crusher Stone Crusher Rock Crusher

portable crushers for sale manufacturer

portable dolomite Jaw crusher manufacturer in south africa

zambia impact crusher used mining

gambar rancangan mesin crusher

zibo chase mechanical crusher picture

Components Of M M M M M Grade Concrete

Used Red Rhino crusher For Sale In South africa

Suppliers Of Gravels In Dubai

how can i design an iron ore crusher

broad process for ca crushing crusher

specification of grinding machine

objective of hammer mill

asphalt distributors and chip spreaders

Quarry For Sale In Karnataka

How Is Gypsum Ore Mined

sugar cane machine in vietnam