Components Of M M M M M Grade Concrete

2019-03-28T15:03:46+00:00

Grades of Concrete? Different Grades of Concrete?

M25 grade concrete, unlike M15 and M20, is a standard type of grade concreteM25 grade concrete is a higher grade concrete than M20 PROPERTIES OF THE M25 GRADE CONCRETE: M25 Components of concrete are cement, sand, aggregates and water Mixture of Portland cement and water is called as paste So, concrete can be called as a mixture of paste, sand and aggregatesConcrete Definition, Components, Grades, Grade of concrete Components of Concrete Components of concrete are cement, sand, aggregates, and water A mixture of Portland cement and water call Grade Of Concrete And Their Type Of Grade Civil

Different Grades of Concrete, Their Strength and

Grade of concrete is denoted by prefixing M to the desired strength in MPa For example, for a grade of concrete with 20 MPa strength, it will be denoted by M20, where M stands for Mix These grade of concrete is converted into various mix proportions For example, for M20 concreteConcrete is the homogeneous mixture of cement or lime, sand, aggregate and water in a fixed proportion Its quality plays a vital role in the strength and durability of the structure Hence, the quality of concrete is expressed in terms of grade Higher the grade of concreteDifferent Grades Of Concrete Based On IS, American Concrete consists of three basic components: water, aggregate (rock, sand or gravel), and Portland cement Cement, usually in powder form, acts as a binding Difference Between M25 and M30 Concrete What Is

Concrete Mix Design Calculation for M20, M25, M30

Procedure for Concrete Mix Design of M25 Concrete Step 1 – Determine Target Strength Hinsworth costant = 165 ( for 5% risk factor ) Standard Deviattion ( S ) = 4 ( for M25 as per IS 102622009 ) Formula for tragert strength is F Target = Fck + 165*S F Target = 25+165*4 Step 2 — Determine water / cement ratio:As per Table 5 of IS 519 Concrete is a composite mixture consisting of cement, sand ( fine aggregates) and coarse aggregate design of the concrete grade mix is a procedure to find the correct quantities of cement sand and aggregate materials to achieve the desired compressive strength precise design of the concrete grade mix makes concrete What is M25 grade concrete ratio in concrete mix In concrete grades, the letter “M” stands for “Mix” and the following number stands for characteristic compressive strength of concrete in 28 days in the Direct Compression test For example, if the concrete is M20 grade, it means the concrete will attain the characteristic compressive strength of 20 Newton per millimeter square in 28 Calculate Cement Sand Aggregate M20, M15,

Reactive Powder Concrete

The concept of reactive powder concrete was first developed by P Richard and M Cheyrezy and RPC was first produced in the early 1990s by researchers at Bouygues’ laboratory in France 2 A field application of RPC was done on the Pedestrian/Bikeway Bridge in Grade of concrete is denoted by prefixing M to the desired strength in MPa For example, for a grade of concrete with 20 MPa strength, it will be denoted by M20, where M stands for Mix These grade of concrete is converted into various mix proportions For example, for M20 concrete, mix proportion will be 1:15:3 for cement:sand:coarse aggregatesDifferent Grades of Concrete, Their Strength and Different nations have their own grade of concrete We will discuss some of them 11 Grades of Concrete Based on IS The grade of concrete is the minimum strength that the quality controlled concrete posses after 28 days of the construction There are different grades of concrete Different Grades Of Concrete Based On IS, American

Difference Between M25 and M30 Concrete What Is

The concrete grades are defined by the strength and composition of the concrete and the minimum strength that the concrete must have after 28 days of the initial construction The degree of concrete is understood in the measurements of MPa, where M means mixture, and MPa indicates the general strength Concrete mixtures are defined in ascending numbers of 5, starting at 10, and show concrete is mixture of cement sand and aggregate in fixed proportion and m15 is ordinary grade of concrete that is not used in RCC work it is only used in PCC work what is cement mortar ratio of m15 concrete, There are different types of grade of concrete like M 75 ,M10, M15, M20, M 25 and so on But in this topic we have to study about how many cement bags in m15 grade of concreteHow many cement bags in m15 concrete Civil Sir Concrete All components unless specified in design: M25 grade all Ec = 5 000 fck N/mm 2 = 5 000 fck MN/m 2 = 25 000 N/mm2 = 25 000 MN/m2 For central columns up to plinth, ground floor and first floor: M30 grade Ec = 5 000 fck N/mm 2 = 5 000 fck MN/m 2 = 27 386 N/mm2 = 27 386 MN/m2 Steel HYSD reinforcement of grade Fe 415 confirming to IS design example of six storey building

Concrete Mix Design Calculations (Pdf) Concrete Mix

Concrete Mix Design Calculations (Pdf) Concrete Mix Design Ratio for M 25 Grade 14/01/2019 12/05/2021 The Advantage of concrete mix design calculations pdf is that it gives the right proportions of materials, thus making the concrete use economical in achieving the required strength of structural membersFinally, C = 33614 Kg / m 3 of concrete But from table 5 of IS4562000, Minimum cement content required for moderate exposure condition for M15 grade concrete is = 240 Kg/m 3 of concrete Greater of above two values will be the cement content Hence, C = 33614Kg Step 6: Aggregate Ratio for ConcreteConcrete Mix Design Calculation for M15 Grade as per m = mass of component per unit volume Suffixes m, c, a, w refer to concrete, cement, aggregate and water components respectively Alternatively, the following may be used for onsite mixing as an estimate: An increase in water temperature of 50 o C will result in a rise in concrete Heating concrete using hot water

HEAT LOSSES FROM A SLABONGROUND STRUCTURE

HEAT LOSSES FROM A SLABONGROUND STRUCTURE WITH A LOW TEMPERATURE FLOOR HEATING SYSTEM IN NORDIC CLIMATE Jukka RANTALA1 Virpi LEIVO1 1 Laboratory of Structural Engineering, Tampere University of Technology, POBox 600, 33101 TAMPERE, Finland, , For more information about the mDRIVE HD, please visit Mack booth No C5203 at the World of Concrete 2015 Feb 36 in the Las Vegas Convention Center or contact your local Mack dealer An online video highlighting the m DRIVE HD and its features is also available by clicking here Mack® mDRIVE™ HD to be Available and Standard in Different nations have their own grade of concrete We will discuss some of them 11 Grades of Concrete Based on IS The grade of concrete is the minimum strength that the quality controlled concrete posses after 28 days of the construction There are different grades of concrete Different Grades Of Concrete Based On IS, American

How many cement bags in m15 concrete Civil Sir

concrete is mixture of cement sand and aggregate in fixed proportion and m15 is ordinary grade of concrete that is not used in RCC work it is only used in PCC work what is cement mortar ratio of m15 concrete, There are different types of grade of concrete like M 75 ,M10, M15, M20, M 25 and so on But in this topic we have to study about how many cement bags in m15 grade of concrete Concrete Mix Design Calculations (Pdf) Concrete Mix Design Ratio for M 25 Grade 14/01/2019 12/05/2021 The Advantage of concrete mix design calculations pdf is that it gives the right proportions of materials, thus making the concrete use economical in achieving the required strength of structural membersConcrete Mix Design Calculations (Pdf) Concrete Mix Finally, C = 33614 Kg / m 3 of concrete But from table 5 of IS4562000, Minimum cement content required for moderate exposure condition for M15 grade concrete is = 240 Kg/m 3 of concrete Greater of above two values will be the cement content Hence, C = 33614Kg Step 6: Aggregate Ratio for ConcreteConcrete Mix Design Calculation for M15 Grade as per

Concrete Mix Design Calculations Grade 25 Concrete

Concrete mix design is necessary to attain target strength in structures Mix proportion for M25 grade of concrete is 1:1:2(cement:fine aggregates:coarse aggregates) So, for 4cum of M25 concrete, it is essential to contain 1cum of cement Therefore, theoretically, for 1cum of M25 concrete, 025cum of cement is requiredM20 Ready Mix Concrete is used for building or repairing foundation walls, sidewalks, curbs, steps and ramps and for setting posts It is uniformly blended, properly proportioned mixture of gravel, sand and Portland cement Features: Perfect for building walls, columns and foundationsM20 Ready Mix Concrete at Rs 3200/cubic meter Example:(Concrete beam with over hang) A concrete beam with a single overhang is simply supported at A B over a span of 8 m the overhang BC is 2 m The beam is of rectangular section 300 mm wide 900 mm deep supports a uniformly distributed live load of 352 kN/m (PDF) Lecture Note – 17 PRESTRESS CONCRETE

Fibre Reinforced Polymer Concrete Structures

Fibre Reinforced Polymer Concrete Structures – Opportunities and Concerns Noorsidi Aizuddin MN*1 Hazren M*2 Department of Property Management, Faculty of m = mass of component per unit volume Suffixes m, c, a, w refer to concrete, cement, aggregate and water components respectively Alternatively, the following may be used for onsite mixing as an estimate: An increase in water temperature of 50 o C will result in a rise in concrete Heating concrete using hot waterM30 Grade Concrete= Ratio1:15:3 1mq concrete Cement => 1*1/55=182 (55=Mixing) => 182*15=273 (15 *dry moisture) => 273*30 = 819 (8 bM30 Grade Concrete= Ratio1:15:3 1mq concrete

Aggregate Crushing Machinery

prices of limestone processing equipment in india

crusher supplier primary

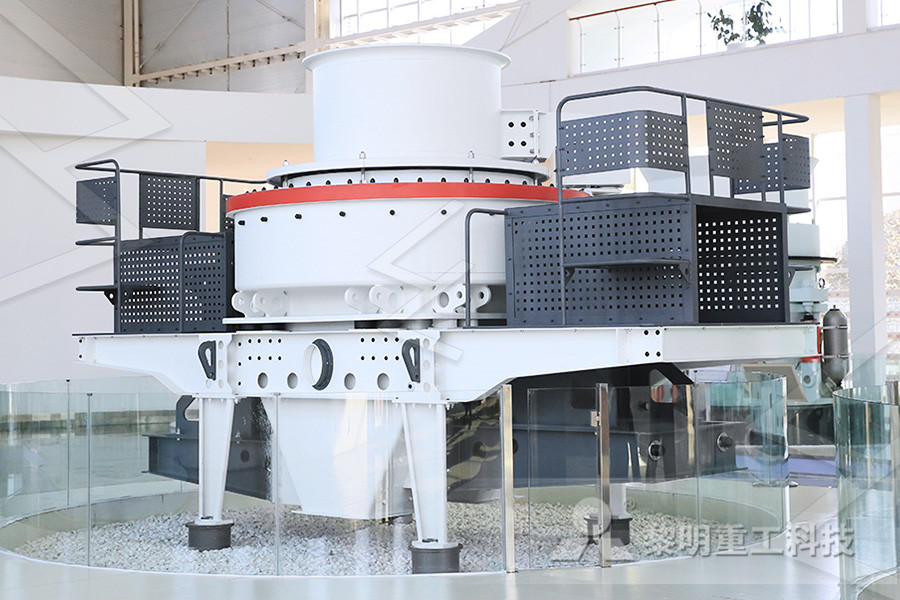

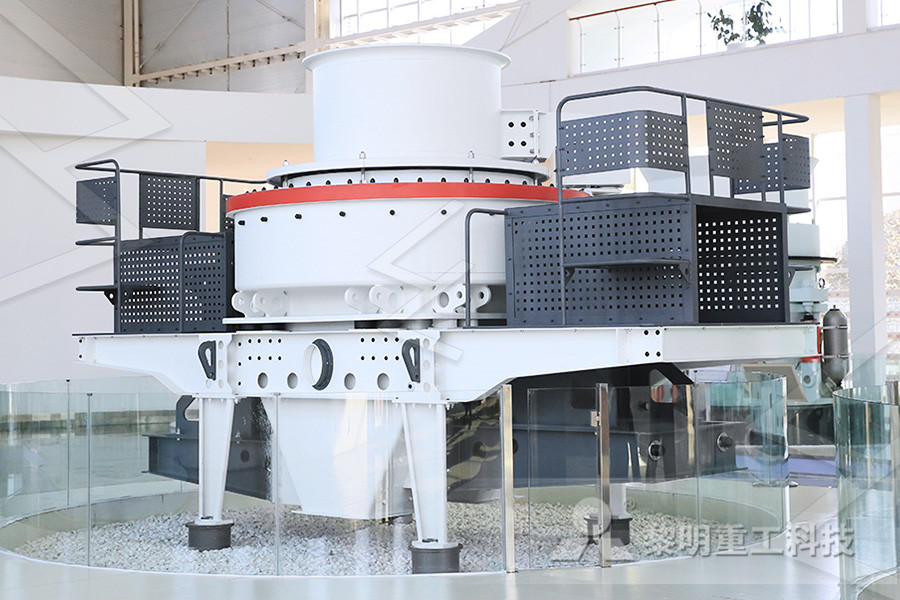

Li ne With VSI Crusher Mining Equipment

important books for gate cse in pdf

Italian Coal Crushers Screens Manufacturers Mobile

hydraulic ncrete crusher 10

operation of grinding machine

jenis mesin pabrik semen ubara di indonesia

stone crusher machine manufactured in india

used equipment crusher and plant sale South africa

SeSKD crushing Equipment For Sale In Uk

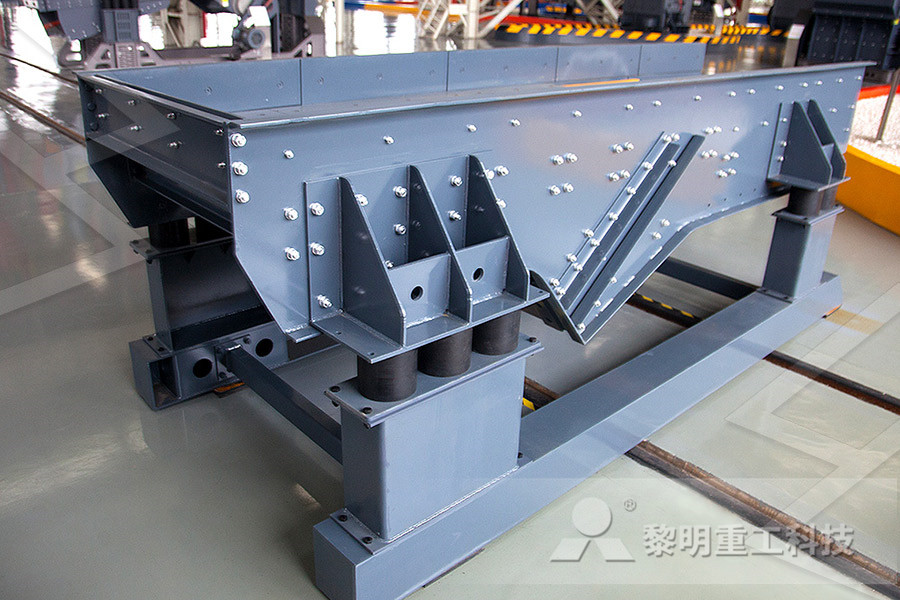

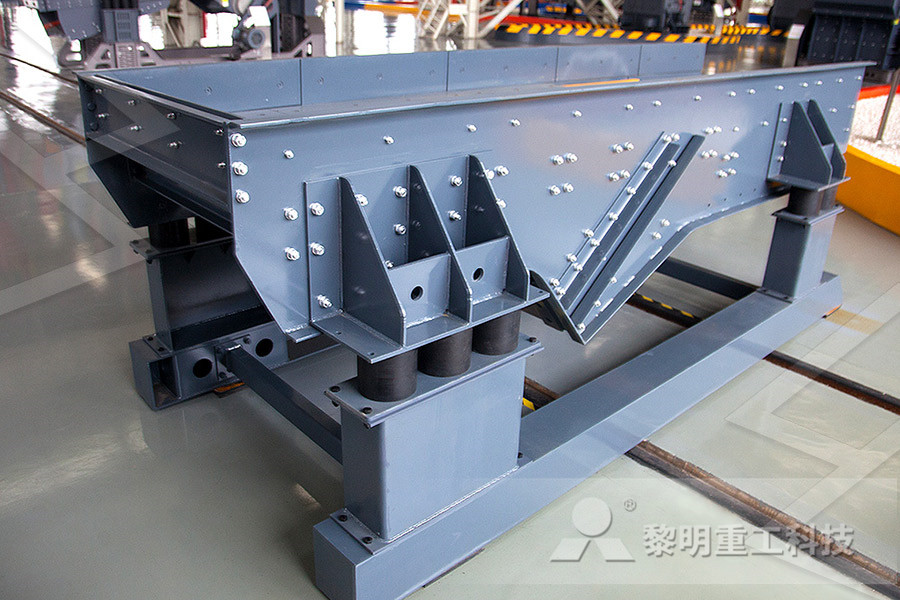

LIMING china vibrating screens

hammer grinding seller in south africa

top stone crushing plants in nigeria

impact crushers images

aluminum mining ball mill

st of setting up a cement factory

crusher manufacture Philippines

small portable stone crusher rental

sand making plant for silica sand

Coal Crusher Electric Motor Drive 6kv

spec sheets of crushing machine

production ore ore dressing plant hour

Process Planning aggreate Planning

Definition Of Mechanical Hazard At Construction

calcite pricing of mining equipment zimbabwe

Sand Dryers For Sale In South Africa

track mounted portable large jaw crusher

crusher plant 100 tph