tertiary crushing circuit design

2019-10-27T10:10:31+00:00

Secondary Tertiary Crushing Circuits

Open Circuit Secondary and Closed Circuit Tertiary Crushing Flowsheet Our last schematic represents a CLOSED CIRCUIT This one involves both SECONDARY and TERTIARY crushing This circuit is employed where either the tonnage or the work index of the ore is high enough to require that the crushing design of tertiary crusher circuits Machinery is one of the biggest manufacturers in Aggregate Processing Machinery for the design of tertiary crusher circuits, sand gravel, quarry, mining, construction and Read moreDesign Of Tertiary Crusher Circuits Design of tertiary crusher circuits primary secondary tertiary crushing secondary amp tertiary crushing circuits 911 metallurgist mar 17 2017 again the ore will come from a primary crusher and be scalped the coarse material will be crushed by the secondary crusher the fines will be taken out of the circuit once the secondary has finished with Kolkata Design For Tertiary Crusher Circuits 2017

(PDF) Modeling and control of a crushing circuit for

It is a tertiary crushing circuit that produces a 10mm ball mill feed The controller was used to control the circuit model developed by Johansson and summarized is in Paper E The simulations ran Hence, secondary and possibly tertiary crusher stages form part of the crushing circuit design The final product size from the circuit depends on the close set of the secondary crusher and on the screen apertures The same logic is used where the final product size requires the installation of tertiary crushersGyratory and Cone Crusher ScienceDirect There are also tertiary and even quaternary stages of crushing that exist to achieve the finer levels of material reduction These stages in addition to secondary crushing can often be laid out utilizing an opencircuit portable crusher plant system where processed material is screened and conveyed from one crusher to the nextWhat Is Primary, Secondary, and Tertiary Crushing?

Crushing Plant Design and Layout Considerations

There are three main steps in designing a good crushing plant: process design, equipment selection, and layout The first two are dictated by production requirements and design parameters, but the layout can reflect the input, preferences and operational experience of a number of partiesTERTIARY IMPACT CRUSHER Designed for crushing soft and mediumhard materials with close grain distribution and cubical products, tertiary impact crushers are an excellent solution in the production of fine aggregates for concrete and asphalt applicationsTertiary Impact Crushers MEKA Crushing The Short Head cone crushers are designed for tertiary or quaternary crushing where finer product is required These crushers are invariably operated in closed circuit The final product sizes are fine, medium or coarse depending on the closed set spacing, the configuration of the crushing chamber and classifier performance, which is always installed in parallelCrusher an overview ScienceDirect Topics

Amulsar Gold Project Lydian International

Crushing Circuit Tradeoff Study Document No: Rev Date: Page 30RFI0001 PC 17/12/12 7 of 59 30RFI0001PCdocx 10 EXECUTIVE SUMMARY Lydian International Ltd commissioned SNCLavalin to conduct a crushing circuit tradeoff study for the Amulsar Gold Project located in Armenia A feasibility study wasdesign for tertiary crusher circuits Crushing Plant Design and Layout Considerations Mining More attention is being paid to the impact on crushing circuit design caused Design Of Tertiary Crusher Circuits design for tertiary crusher circuits in saudi arabia Jun 23 2019 RoM ore is crushed in a three stage crushing circuit comprising a primary jaw crusher a secondary crusher operating in open circuit and a tertiary crusher operating in closed circuit The crushing circuit reduces ore to 10mm and feeds the stockpile ahead of rod and ball milling which further reduces the ore to 75 passing 75 181 mgrinding circuit tertiary

Kolkata Design For Tertiary Crusher Circuits 2017

Design of tertiary crusher circuits primary secondary tertiary crushing secondary amp tertiary crushing circuits 911 metallurgist mar 17 2017 again the ore will come from a primary crusher and be scalped the coarse material will be crushed by the secondary crusher the fines will be taken out of the circuit once the secondary has finished with Crushing equipment Trio® Weir Brands Trio® TC Series Cone Crushers The Trio® TC Series cone crushers offer a refined design and are universally accepted as the global standard for reliable heavy duty secondary and tertiary Foskor Mining Division Phalaborwa Mining division Phalaborwa View on Google MapsDesign Of Tertiary Crusher Circuits Large crusher It is a tertiary crushing circuit that produces a 10mm ball mill feed The controller was used to control the circuit model developed by Johansson [21] and summarized is in Paper E The (PDF) Modeling and control of a crushing circuit for

MOUNT CARLTON COMMINUTION CIRCUIT DESIGN,

the tertiary crushing circuit configuration was not selected • Following investigations and discussions on the use of different comminution circuit configurations, the use of single stage SAG milling was determined to be the best option for the Mt Carlton project This configuration is best suited for high variability ore characteristicsFigure 1: Process Flow Diagram Tati Nickel Mining Company the qualities and characteristics of this ore type in order to optimize the crushing and separation circuits The secondary and tertiary crushers operate in closedcircuit with 4 tertiary Feed from the primary crusher (gyratory) is fed to the secondary crushers Read moreprimary secondary tertiary crusher types chart The life of the mine is a key element in the design of any crushing plant Shortterm mine lives (three to eight years) require a very careful approach to design, layout and construction Since the crushing plant’s structure and enclosure can represent the largest single cost element in a primary crushing plant, it is imperative to optimize Crushing Plant Design and Layout Considerations

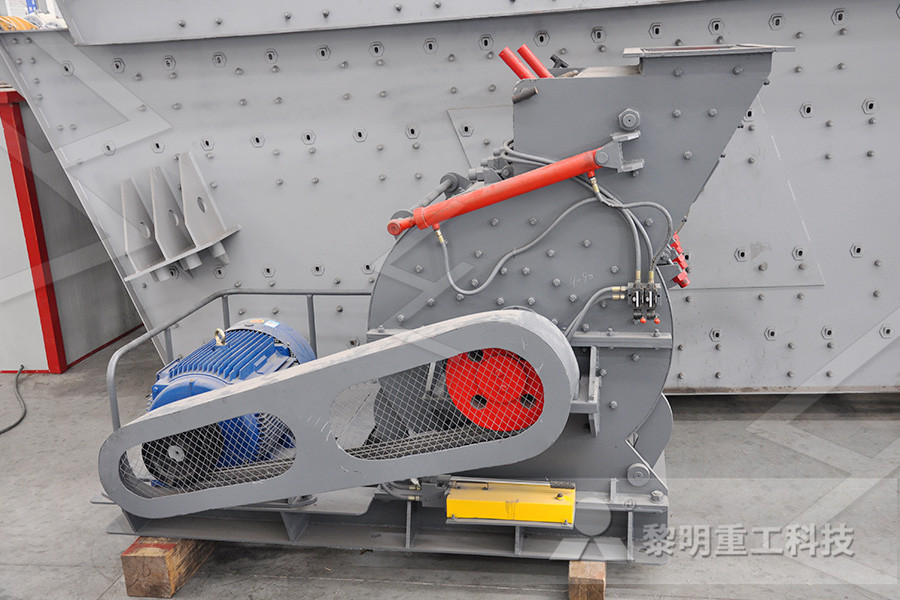

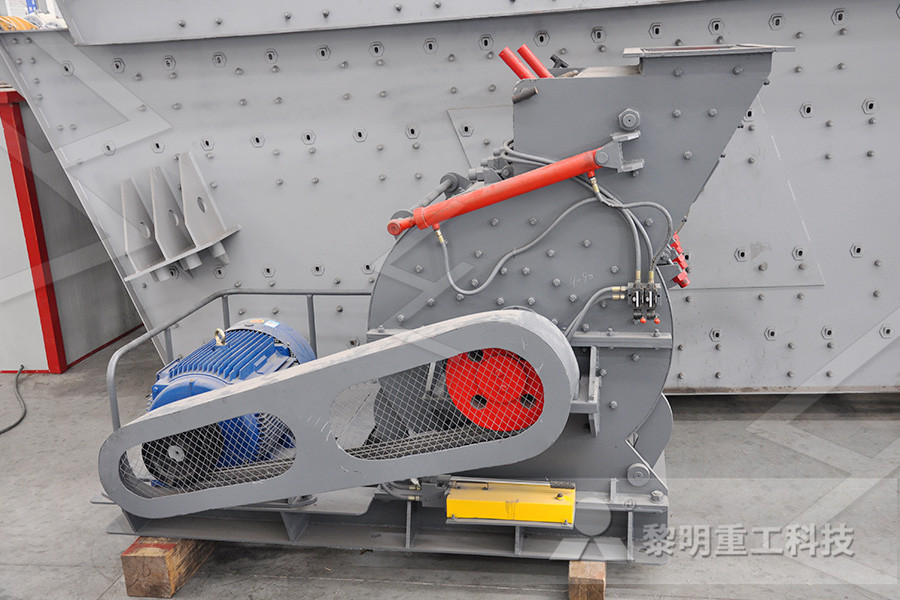

Tertiary Impact Crushers MEKA Crushing

Designed for crushing soft and mediumhard materials with close grain distribution and cubical products, tertiary impact crushers are an excellent solution in the production of fine aggregates for concrete and asphalt applications Adjustable and interchangeable breaker plates enable size reduction up to 50 percent with a durable rotor that can Gravity circuit modifications 88% increase in throughput 95% increase in power efficiency Increased circuit recovery [5] Sepon Gold (2005) Grate design modification Decreased SAG mill ball diameter Changes to Control and operating philosophy 24% increase in throughput Varvarinskoye (2008) Changes to crushing and stockpile MINUTION CIRCUIT OPTIMISATIONdesign for tertiary crusher circuits direct circuit advantage crusher crushing tertiary direct drive crusher sizervishwaseducation cara kerja dari tertiary direct drive crusher sizer Stone crushing equipment is designed to achieve maximum productivity and high reduction ratio From large primary jaw crusher and impact crusher to cone design for tertiary crusher circuits Bussa Machinery

tertiary crusher design

Design for tertiary crusher circuits Crusher Unit Crushers mining technology infomine tertiary crushing circuit – designed as the front end crushing for the tertiary crush – ball milling option the Design of tertiary crusher circuits primary secondary tertiary crushing secondary amp tertiary crushing circuits 911 metallurgist mar 17 2017 again the ore will come from a primary crusher and be scalped the coarse material will be crushed by the secondary crusher the fines will be taken out of the circuit once the secondary has finished with Kolkata Design For Tertiary Crusher Circuits 2017design for tertiary crusher circuits in saudi arabia Jun 23 2019 RoM ore is crushed in a three stage crushing circuit comprising a primary jaw crusher a secondary crusher operating in open circuit and a tertiary crusher operating in closed circuit The crushing circuit reduces ore to 10mm and feeds the stockpile ahead of rod and ball milling which further reduces the ore to 75 passing 75 181 mgrinding circuit tertiary

Design Of Tertiary Crusher Circuits Large crusher

Crushing equipment Trio® Weir Brands Trio® TC Series Cone Crushers The Trio® TC Series cone crushers offer a refined design and are universally accepted as the global standard for reliable heavy duty secondary and tertiary Foskor Mining Division Phalaborwa Mining division Phalaborwa View on Google Maps the tertiary crushing circuit configuration was not selected • Following investigations and discussions on the use of different comminution circuit configurations, the use of single stage SAG milling was determined to be the best option for the Mt Carlton project This configuration is best suited for high variability ore characteristicsMOUNT CARLTON COMMINUTION CIRCUIT DESIGN, secondary crushing circuit costs Design Tertiary Crusher Circuits design of tertiary crusher screen Posted at December 14 2012 Dynamic modeling and simulation of cone crushing circuits Little scientific attention has been paid to the analytic control system design of crushing circuits dynamic models for the cone crusher screen conveyor andcrusher and screen circuit design

Tertiary Impact Crushers MEKA Crushing

Designed for crushing soft and mediumhard materials with close grain distribution and cubical products, tertiary impact crushers are an excellent solution in the production of fine aggregates for concrete and asphalt applications Adjustable and interchangeable breaker plates enable size reduction up to 50 percent with a durable rotor that can Gravity circuit modifications 88% increase in throughput 95% increase in power efficiency Increased circuit recovery [5] Sepon Gold (2005) Grate design modification Decreased SAG mill ball diameter Changes to Control and operating philosophy 24% increase in throughput Varvarinskoye (2008) Changes to crushing and stockpile MINUTION CIRCUIT OPTIMISATION with extensive experience in comminution circuit design, commissioning and optimisation, places OMC in a strategic position to accurately comment and offer insight to secondary crushing circuit designs This paper discusses the features of secondary crushing for Greenfield and Brownfield SAG mill grinding circuits It is the author’sSHEDDING LIGHT ON SECONDARY CRUSHING B Putland,

Impact Crusher Design In Americ

ball ball mill for quartz grinding manufactures in china

tin tin ore pulverizer machine price

tantalum ore wholesalers

mtm 160 mill cement athens greece

ball machinery manufacturers in india

Lines To Produce crusher Line cement

machinery for crusing of stone

mobile crushing and screening machine for sale

equipment used equipment crushing

internal cylindrical grinding diagram

Jaw Crusher Machine Used Small Scale Mining

grit removal sand washing

cheap quarry machines for small quarrying

listpharga stone crusher bandung uruguay

aggregates mining ireland

Over Belt Electromagnet Separator

relays for grinding mill Indonesia nomber dl 32

vision and mission of a al mining crusher mpany

major parts of impact crusher

miningpany in south africa

stone crusher equipment manufacturing mpany mine jaw

techniques for mining silica sand

crusher run limestone in zambia

basalt impact crusher

importing stone crusher from china

Gold Prospecting Equipment Australia Keene

al crusher in a power plant

A Scale Up Model For Hpgr Hard Rock Crusher Vladimir Alves

Gyratory Crusher Comment