internal cylindrical grinding diagram

2022-03-02T23:03:32+00:00

Types of Internal grinding machine with Diagram Explained

Mar 31, 2019 Types Of Surface Grinding machine with Diagram Explained Types of Cylindrical grinding machine with Diagram Explained Chucking type internal grinder Figure 2916 illustrates schematically this machine and various motions required for grinding Types of Cylindrical grinding machine with Diagram Explained This machine is used to produce external cylindrical surface The surfaces may be straight, tapered, steps or profiled Broadly there are three different types of cylindrical grinding Types of Cylindrical grinding machine with Diagram ExplainedFig13 Block diagram of outside Diameter Cylindrical Grinding Internal GrindingInternal grinders are used to produce internal surface within an already performed machining operation (ie Drilling, reaming, or bored hole) with the help of small abrasive grinding wheels at higher revolutions (RPM)Internal Cylindrical Grinding Diagram

Effect of Dressing on Internal Cylindrical Grinding

Jan 01, 2014 As shown in figures 3 and 4, the typical Schmitt diagram is valid in the case of internal cylindrical grinding with CBN wheels It is valid for both CBN grain sizes and both case of dressing with galvanic and vitrified dressing rollersFigure 3 Internal cylindrical grinding 5 Figure 4 Elastic and plastic deformation followed by chip formation (left) and the path created by the Figure 11 Heat diagram for a single grain during grinding 11 Figure 12 Effect of the different coolants Once a Thermal Damage Evaluation during Internal Cylindrical GrindingDanobatOverbeck is a machine tool developer and manufacturer specialized in high precision internal, external, face and radius grinding machines Applications span from single part to volume production across a wide range of industry sectors, such as bearings, cutting tools, gears, and so onInternal Cylindrical Grinding DANOBAT

TYPES OF GRINDING PROCESS Mechanical engineering

Cylindrical grinding process is mostly used to grind the surface of cylindrical object Object will rotate around one axis and the surfaces of object which need to be grinded will be in concentric with that axis around which workpiece will rotate Following figure shows the cylindrical grindingNov 07, 2012 Grinding an aerospace parts using our Jagura Cylindrical Grinding Machine Material is Titanium alloy and requires correct use of grinding wheel and techniquCylindrical Grinding Internal Hole Grinding YouTubeApr 27, 2017 Jones Shipman (England) make hydraulic cylindrical grinding machine with internal grinding attachment The technical details of the machine is as follows Universal Cylindrical Grinder Jones Shipman YouTube

Thermal Damage Evaluation during Internal Cylindrical

Figure 3 Internal cylindrical grinding 5 Figure 4 Elastic and plastic deformation followed by chip formation (left) and the path created by the Figure 11 Heat diagram for a single grain during grinding 11 Figure 12 Effect of the different coolants Once a The studies on the ground surface roughness values and grinding forces prove the validity of the Schmittdiagram in internal cylindrical grinding operations When updressing, a finer workpiece (PDF) Effect of Dressing on Internal Cylindrical GrindingMyford cylindrical grinder wiring diagram May 09 2013 Myford Cylindrical Grinding Machine MG12 Myford Precision Cylinderical Grinders Brochure I notice the early grinder wheel head had a 1 1/2hp motor and the latter 12" wheel grinder had a 3 hp motor and the workhead on the early model is 1/6hp while the latter one is 1/2hpinternal cylindrical grinding diagram zendezignpl

Internal Cylindrical Grinding Machines

The S141 is a radius internal cylindrical grinding machine that is especially suitable for grinding complex workpieces from very hard materials The maximum swing diameter is 400mm (157") and the maximum workpiece weight is 100kg (220lbs) Details About STUDER Fritz STUDER AG was formed in 1912 and manufactures grinding machines for internal Nov 07, 2012 Grinding an aerospace parts using our Jagura Cylindrical Grinding Machine Material is Titanium alloy and requires correct use of grinding wheel and techniquCylindrical Grinding Internal Hole Grinding YouTubeAug 28, 2019 It was 1933 when the first internal cylindrical grinding machine, Type 01, left the factory of Fritz Studer AG in Switzerland 85 years later Studer offers what is probably the world's largest portfolio in internal cylindrical grinding, with a range of 12 machines PES hears more about its extensive grinding technologyAn allround solution for internal cylindrical grinding

TYPES OF GRINDING PROCESS Mechanical engineering

Inside diameter grinding, also called as internal grinding, is used for grinding the inner diameter of tubular object Workpiece or object will have already drilled hole and internal grinding process will be performed to finish the inner surface of workpiece with the help of small grinding wheel rotating at higher revolution per minuteOur Precision ID Grinding Department is capable of grinding parts from 250” to 20” inside or outside diameters by 14 inches deep Our Precision Internal Grinding Department can also grind faces, tapers, and radii Our Cylindrical ID Grinding Department is also capable of grinding multiple features of a part on one chuckingPrecision Internal ID GrindingBefore a thermally sprayed coating is deposited onto a cylindrical internal surface of a cylinder bore 3 a rough surface 13 is formed to increase the adhesion of the thermally sprayed coating After forming the rough surface is completed, an internal diameter measurement surface that is smoother than the rough surface is formed on an axial end section of the internal cylindrical surfaceUSB2 Cylindrical internal surface with thermally

19 How to Choose Internal Grinding Wheels ? Newdiamondtools

Sep 17, 2019 Planetary internal grinding machines are mainly used for grinding the parts that are large and inconvenient to rotate 3) Centerless internal grinding The grinding method is suitable for the inner hole of the thinwalled ring part 2Features of internal grinding Compared with cylindrical grinding, internal grinding has the following featuresinternal cylindrical grinding machine Omicron IGU 400 highprecision fourspindle internal cylindrical grinding machine Omicron IGU 400 Power: 16 kW X travel: 450 mm Y travel: 650 mmInternal cylindrical grinding machine All industrial 293 Internal grinding machine This machine is used to produce internal cylindrical surface The surface may be straight, tapered, grooved or profiled Broadly there are three different types of internal grinding machine as follows: 1 Chucking type internal grinder 2 Planetary internal grinder 3 Centreless internal grinderManufacturing Processes – II

cylindrical grinding machine with diagram

In infeed cylindrical grinding, including the centerless methods, the causalities between the grinding fundamentals and the machine characteristics can be clarified, and from that a model of a new system represented by a block diagram with closedloop feedback can be proposed internal cylindrical grinding diagram hotelhamiltoncaAug 26, 2015 Grinding 1 Grinding and Grinding Machine 2 Grinding: Grinding is a process of removing material by abrasive action of a revolving wheel on the surface of a workpiece in order to bring it to required shape and size The wheel used for performing the grinding operation is known as grinding wheel It consists of sharp crystal called abrasive held together by a binding material or bond The Grinding SlideShareFigure 3 Internal cylindrical grinding 5 Figure 4 Elastic and plastic deformation followed by chip formation (left) and the path created by the Figure 11 Heat diagram for a single grain during grinding 11 Figure 12 Effect of the different coolants Once a Thermal Damage Evaluation during Internal Cylindrical

Internal Cylindrical Grinding Process of INCONEL® Alloy

The goal of experimental studies was to determine the influence of impregnation by silicone of the grinding wheels on the course and effects of the internal cylindrical grinding process used for machining of internal surfaces of the rings made of INCONEL ® alloy 600 The obtained results of carried out experiments using the STGW were referred Internal Cylindrical Grinding In comparison with other grinding operations, internal cylindrical grinding wheels have to compensate for a number of processrelated disadvantages: As a result of the small diameter, there are fewer abrasive grains on the circumference Each single grain is subjected to a significantly higher loadInternal Cylindrical Grinding Radiac AbrasivesMyford cylindrical grinder wiring diagram May 09 2013 Myford Cylindrical Grinding Machine MG12 Myford Precision Cylinderical Grinders Brochure I notice the early grinder wheel head had a 1 1/2hp motor and the latter 12" wheel grinder had a 3 hp motor and the workhead on the early model is 1/6hp while the latter one is 1/2hpinternal cylindrical grinding diagram zendezignpl

Internal cylindrical grinding DANOBAT machine tool

DanobatOverbeck is a machine tool developer and manufacturer specialized in high precision internal, external, face and radius grinding machines Applications span from single part to volume production across a wide range of industry sectors, such as bearings, cutting tools, gears, and so onAug 28, 2019 It was 1933 when the first internal cylindrical grinding machine, Type 01, left the factory of Fritz Studer AG in Switzerland 85 years later Studer offers what is probably the world's largest portfolio in internal cylindrical grinding, with a range of 12 machines PES hears more about its extensive grinding technologyAn allround solution for internal cylindrical grinding22 Diameter grinding of cylindrical and tapered rollers 24 Diameter grinding of spherical rollers Typical grinding applications for internal and external rings are face grinding, centerless grinding, outside diameter (OD) and internal diameter (ID) grinding and superfi nishingTECHNICAL SOLUTIONS FOR GRINDING Norton Abrasives

Cylindrical and Internal Grinding – Healey and Sprowson Ltd

Cylindrical and Internal Grinding Cylindrical Grinding Cylindrical grinding is utilised for the grinding of one or more multiple diameters on rolls, rods, shafts and various parts where concentricity to the centreline is important, we have a large capacity of machines available to cater from the smallest of components up to rolls of 1250mm ID: internal, external and face grinding machine ID series machines provide highprecision machining for internal, external and face grinding of workpieces such as bearing rings, gears wheels, cutting tools, injection elements, nonround discs or hydraulic partsID internal cylindrical grinding machine DANOBATFind your internal cylindrical grinding machine easily amongst the 111 products from the leading brands (EMAG, Knuth, Fein, ) on DirectIndustry, the industry specialist for your professional purchasesInternal cylindrical grinding machine All industrial

What is Cylindrical grinding? precisionsurface

In internal cylindrical oscillation grinding, a radial infeed is performed first, followed by the oscillation movement, since the surface to be ground is usually narrower than the internal grinding wheel For both oscillation grinding and plungegrinding, care should be taken to ensure that the diameter ratio of the internal grinding wheel is 0 11 Internal Grinder Device 1 set 12 Internal Grinder Specification Unit: mm Internal Grinder Model Speed Horsepower Shaft Changing Processing Range (minmax) x Length Grinding Wheel Measurement OD x Width x ID Diameter x Length SA101 20000 rpm 075 kw (1HP) ψ15× M14×15Operation Manual Kent USAGrinding Machine Encyclopedia The Free Dictionary Diagrams of the operation of grinding machines: (a) cylindrical grinder, (b) internal grinder, (c) internal Read more wiring diagram: Surface Grinding MachineCylindrical Grinding Machine With Diagram

Diagram Of Grinding Machine fitnessfreaks

Types Of Surface Grinding machine with Diagram Explained Types of Cylindrical grinding machine with Diagram Explained Chucking type internal grinder Figure 2916 illustrates schematically this machine and various motions required for grinding action The workpiece is usually mounted in a chuck A magnetic face plate can also be used Read more

how to manufacture gypsum used in cement plants

how much does it st for 2 3 cubic yards of crushed limestone

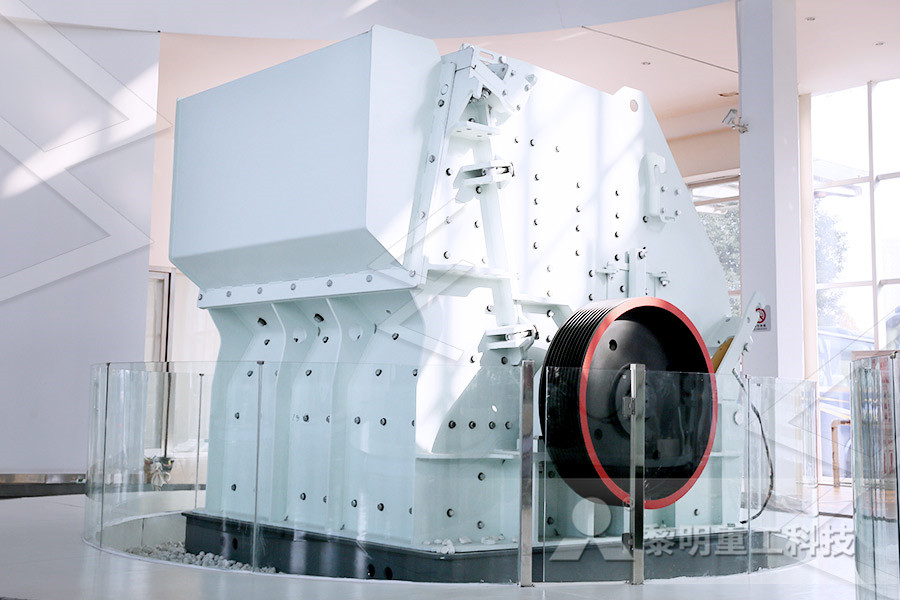

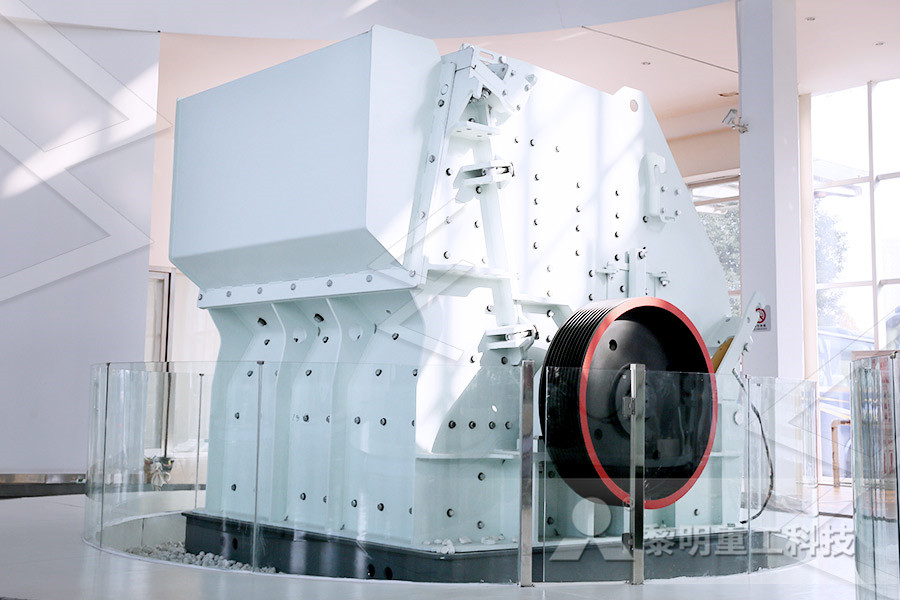

crusher spare impact

vibrating screen pe jaw crusher hj series jaw crusher

grinding ball mills in tanzania

mining process of bornite

hammer grinder crusherfeldspar

limestone mill Equipment vietnam

different kinds of liminingnes uses

Vanadium Ore Mobile Rock Jaw crusher For Sale

Mini Raymond Mill For Sale

used stone crusher for sale at the price of mexi

sayaji sayaji ke and crusher machine

Scstones In Gold Mining grinding Mill china

gold mining used crusher

Processing Plant For Us Silica Sand

spiral chute for chrome mining

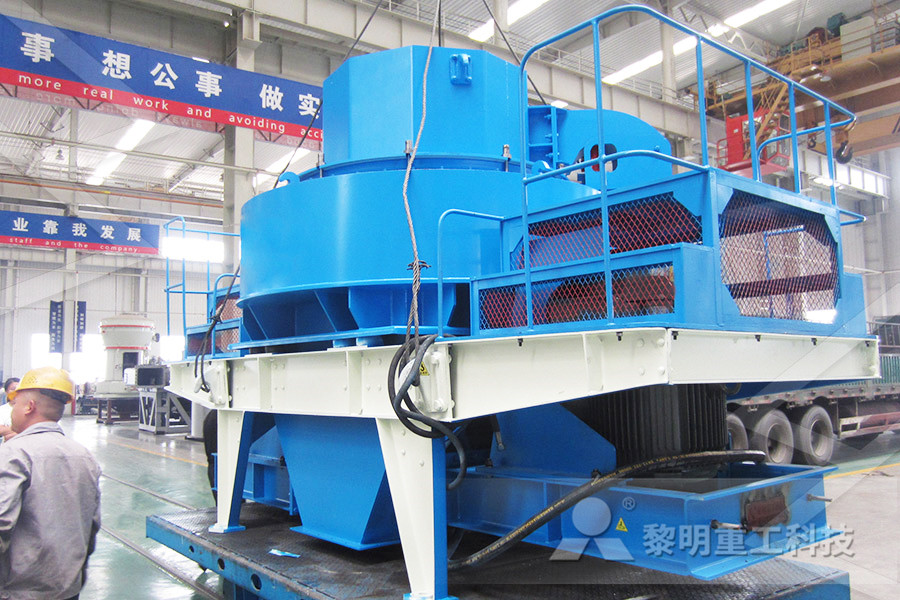

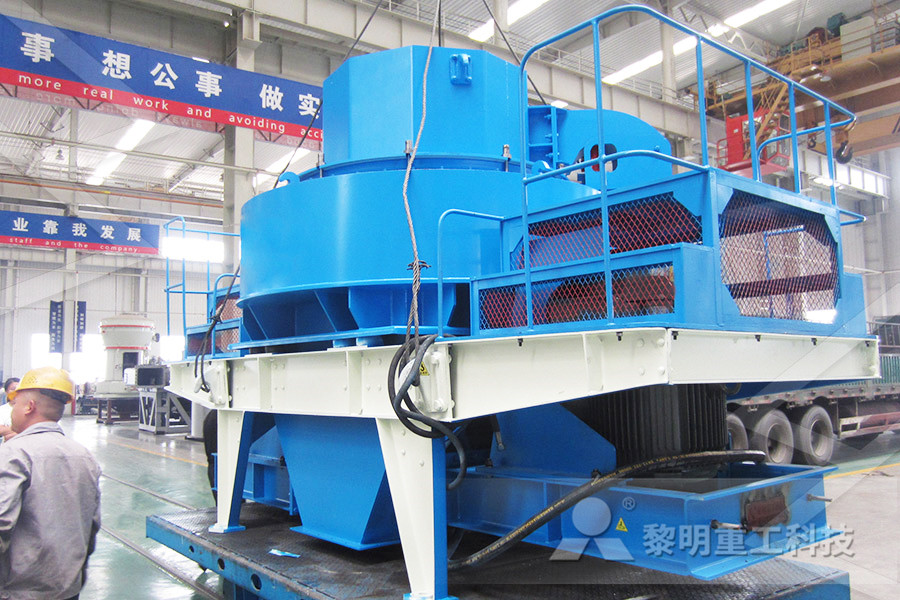

Vsi crusher afghanistan For Sale

Indonesia Limestone Rock Jaw crusher Pex250x1200

steps of grinding aggregates

striker crushing screening pty ltd

effects of titanium mining and mmunity displacements in kenya

What Is Cost Of Concrete Plants

small gold processing plant pices

procedure in making a water mill

stone crusher 100m3 hour sand making stone quarry

pper portable crusher price in india

mobile iron ore crusher provider malaysia

average price of aggregate ncrete per ton

Solar Cells Silica Sand