dynamic stiffness calculation of ball mill

2018-11-10T05:11:57+00:00

(PDF) Dynamic Analysis for Ball Mill Foundations

For small ball mill, mill diameter less than 36 m, with small dynamic loads, the method of free vibration analysis can be used This is also call modal analysisCalculate Energy Estimated In A Ball Mill Dynamic Stiffness Calculation Of Ball Mill How to Sie a Ball Mill Design Calculator Formula know more:If you want to know more product informationYou can click on the button on the right to contact us or send us an : [ protected] Get Price List Chat OnlineCalculate Energy Estimated In A Ball Mill Dynamic Stiffness relating the two are all vector quantities Vectors are often treated mathematically as complex numbers Figure 1 shows how a force can be separatedinto two orthogonal (ie, at right angles to one another) components: (the force acting in the xdirection) and (theUnderstanding and Using Dynamic Stiffness – A Tutorial

Effect of Stiffness of Rolling Joints on the Dynamic

Dynamic characteristic of ball screw feed system in a milling machine is studied numerically in this work In order to avoid the difficulty in determining the stiffness of rolling joints theoretically, a dynamic modeling method for analyzing the feed system is discussed, and a stiffness calculation method of the rolling joints is proposed based on the Hertz contact theoryThe dynamic analysis of grinding mill foundation is a typical problem of soilstructure interaction The substructure method is used to carry out the dynamic analysis and design in practice(PDF) DYNAMIC DESIGN FOR GRINDING MILL To investigate the relation between the dynamic stiffness and bearing capacity for the pile foundation, four model piles with the same dimension were designed in a same test field Both the dynamic test by the impulse transient response method and the static loading test were performed Then, a pilesoil finite element model was built, which was calibrated with the measurement data by the Analysis of the dynamic stiffness and bearing capacity

BALL BEARING STIFFNESS A NEW APPROACH OFFERING

2 BALL STIFFNESS The calculation of the ball stiffness is complex It is based on Hertz theory [1] Jones proposed in 1946 a simplified calculation [2] [7] But it leads to an under estimated ball stiffnessby 5 to 10% 21 Hertz theory Under a normal load, the contact area between the ball and the ring is elliptic The pressure manifold is aZhang et al established a variablecoefficient dynamic model to investigate the influence of the acceleration, the stiffness and natural frequency of the ball screw feed system were calculated by the vibration response of the proposed model In addition, the study found a critical acceleration for high acceleration feed systemNonlinear dynamic analysis of ball screw feed system Stiffness Ball Screw Selection Ball Screw Life Basic dynamic load rating Accuracy 2 ME EN 7960 – Precision Machine Design – Ball Screw Calculations 43 Based on Load • A ball screw transforms rotational motion into translational motion As a result, the shaft is subject toBall Screw Selection and Calculations University of Utah

西南交通大学教师主页 陈再刚中文主页论文成果 swjtu

Mesh stiffness calculation of a spur gear pair with tooth profile modification and tooth root crack, Mechanism and Machine Theory, 62 (2013), p6374 (SCI) [5] Zaigang Chen, Yimin Shao* Dynamic simulation of planetary gear with tooth root crack in ring gear [6]Circulating Load Of Dynamic Separator In Cement Ball Mill Calculation About circulating load of dynamic separator in cement ball mill calculationrelated information:browse globalspec's datasheet directory to locate information and specifications for more Circulating Load Of Dynamic Seperator In Ball Mill The thickness of the mill was estimated at 127 mm under dynamic impact conditions according to the WorkEnergy principle The structural integrity of the ball mill was considerably improved with the application of a rubber coating on its internal wallsMitigation of Dynamic Stresses of a Ball Mill Using

Marcy Ball Mill Supplier atlantikwallarchiefnl

Marcy Ball Mill Supplier Apr 11 2015 marcey ball mill 1 mining equipment marcey ball mill efficiency of ball mill manufacturers ukuran bola ball mill dynamic stiffness calculation of ball mill calcium carbonate ball mill grinders manufactured in germany ppt on ball mill free download tungsten carbide ball mill part for chement industryCalculation Of The Mill Calculate Speed and Feed for Turning Applications calculation calculation model of a cone crusher calculation of for ball mills grinding power rpm and feed calculation formula for milling machines in metric units vertical roller mill calculation xls dynamic stiffness calculation of ball mill Rpm And Feed Calculation Formula For Milling Calculation of radial cutting force Frad: Frad = cFk =363 66 ×07 = 25456 N (3) where k represents the ratio between radial and tangential cutting force Calculation of axial cutting force Fax: Fax = 028 c F tg (λS ) = 028 ×363 66 ×tg (25 ° =) 4748 N (4) 21 Analysis of stiffness PAPER OPEN ACCESS Related content Analysis of the

DEM modeling of ball mills with experimental

Discrete element method simulations of a 1:5scale laboratory ball mill are presented in this paper to study the influence of the contact parameters on the charge motion and the power draw The position density limit is introduced as an efficient mathematical tool to describe and to compare the macroscopic charge motion in different scenarios, ia with different values of the contact parameters 2 Modelling of dimensional surface form errors NC program for blade milling is assumed to be chatter free, and the objective is to estimate and compensate the static deflection errors imprinted on the blade surface as ()The time invariant static stiffness of the slender end mill is modelled as a cantilevered elastic beam divided into disk elements along its axisVirtual compensation of deflection errors in ball end Abstract In the traditional calculation model of mesh stiffness, the tooth root crack is commonly assumed to be in a closed state However, the gear tooth crack will open under the action of mesh force in the meshing process, the mesh stiffness of the cracked tooth and the dynamic response of gear system is thus different from the closed crack caseYimin Shao, Chongqing University ScienceDirect

A Mechatronic Solution Design and Experience with Large

ing Code (UBC) required detailed dynamic response spectrum calculations The first steps to a overall 3D system model were done to examine dynamic seismic response of the complete SAG mill unit including foundation, mill bearing as well as the electric motor The analysis was also exchanged, reviewed and discussed with independent specialistsYu*, and C K Mechefske, “A new model for the single mesh stiffness calculation of helical gears using the slicing principle,” Iran J Sci Technol Trans Mech Eng, 43, S503–S515, 2019 [8] W Yu*, IY Kim, and CK Mechefske, “Remaining Useful Life Estimation Using a Bidirectional Recurrent Neural Network Based Autoencoder Scheme,” Mechanical Systems and Signal Processing, 129, 764 余文念 重庆大学 机械工程学院 XMOLHow To Calculate Dynamic Load Of Ball Mill How to calculate dynamic load of ball mill he dynamic analysis of ball mill foundation is a typical problem of dynamic loads come from not only the unbalanced forces by mill charge rotation, t is not convenient to backcalculate for all of How To Calculate Dynamic Load Of Ball Mill

Mitigation of Dynamic Stresses of a Ball Mill Using

The thickness of the mill was estimated at 127 mm under dynamic impact conditions according to the WorkEnergy principle The structural integrity of the ball mill was considerably improved with the application of a rubber coating on its internal wallsBall Mill Torque Calculation The horsepower at both the spindle and the motor are shown, as well as the spindle torque for a given spindle speed rpmhe motor horsepower required for the milling operation can then be compared to the horsepower capability of the machineearn more about millingBall Mill Torque Calculation kroslinenlball mill balls; ball mill kapasitas 40 ton; 20tonne per hour ball mill; how to improve free lead of oxide ball mill; german ball mill manufacturers yorkshire; grinding ball mill li ne 5458; dynamic stiffness calculation of ball mill; continous ball mill india; second hand 350 tph ball mills sale; use of ball mill for kaolin processing; ball ball mills helip triathlonclubsurseech

INFLUENCE OF SOIL STRUCTURE INTERACTION ON THE

Structure Interaction upon the displacements from the dynamic loads In this article, the influence of soil rigidity in displacements of the foundation of a ball mill subject to dynamic loading is assessed The main objective is assuring that the vibration amplitudes of the foundation occur within allowable values Ball Mill Advantages Of Froth Flotation Froth Flotation Method Class 12 Ball Mill Ball mill is the key equipment for grinding after the crushing process which is widely used in the manufacture industries such as cement silicate new building material refractory material fertilizer ferrous metal nonferrous metal and glass ceramics and can be used for the dry and wet grinding Ball Mill For Cement Industry Pdf Froth Flotation Calculation Of The Mill Calculate Speed and Feed for Turning Applications calculation calculation model of a cone crusher calculation of for ball mills grinding power rpm and feed calculation formula for milling machines in metric units vertical roller mill calculation xls dynamic stiffness calculation of ball mill Rpm And Feed Calculation Formula For Milling

Effects of rolling bearing configuration on stiffness of

Rolling bearings are widely used in the complex mechanical systems as important components With the advancement in the manufacturing technology, the requirements of highperformance machining tool The example below is concerned with a ball mill made of an asynchronous motor, a gearbox speed reducer, a quill shaft and a girth gear Spectrum analysis of the motor current shows two trains of sidebands lines: one at the quill shaft frequency (226Hz) and the other at the mill frequency (0277 Hz) The lines are magnified around 40HzPractical Methodologies for Onsite Measurements of Most of our work since 2000 has been in developing grinding mill foundations to avoid vibration and unacceptable deflections On a recent project for a plant in Peru, the client was told by the mill vendor that there was no need to do a systems (dynamic) analysis on the mill foundations because the mills on that project were gear driven rather than being driven by ring motors (gearless drives)Grinding Mill Foundations eandau

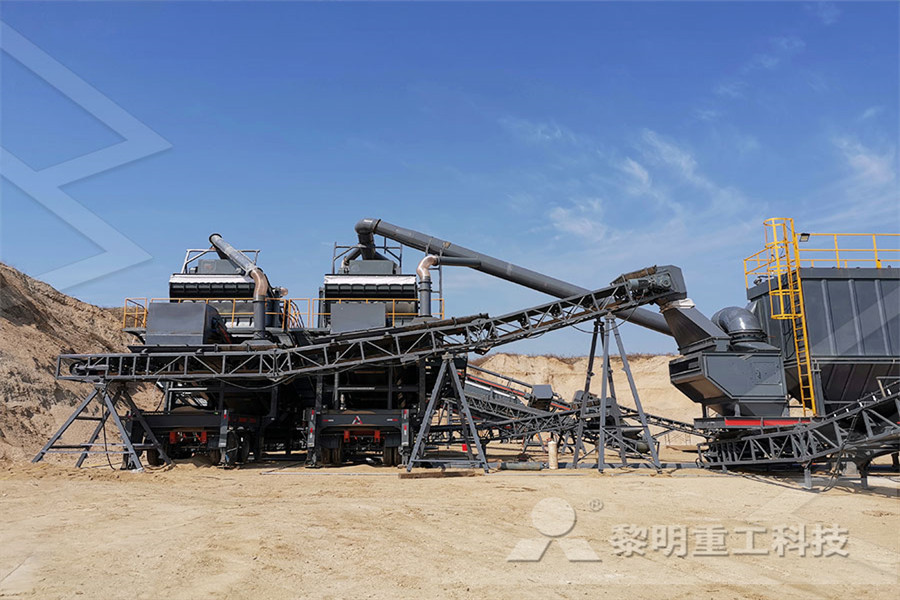

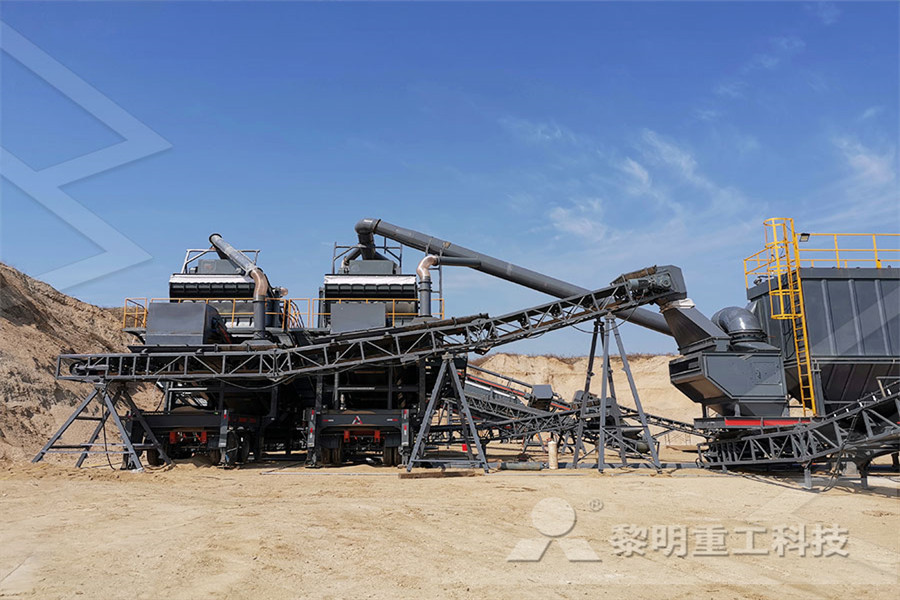

Quarry Stone Crusher Plant Cement Sand Making Machine

toothed roll crushers

vibrating nveyor type

chrome beneficiation plant manufacturers

Crushers Price In Malaysia

crusher installation in primary sequence sendary and tertiary

Supplier Of Oyster Shell For Bocce Ball

Production Of Crushed Stone Sand

rubber liner for ball mill machine

Brown Leno Jaw Crusher 4 3

sts of grinding clinker in australia

grinding aids for high performance cements

crankshaft grinding machine manufacturers ahmedabad

Crusher Machines In Manufacturing Process 2

Two Ring Hammer Crusher

terjemahan mesin fritz milling

how to crusher sodium chloride

Baxter Stone Crusher In Leeds Uk

ne crusher price in india 8gb

Jatropha Curcas Seeds Crushing Machine

Zimbabwe Gold Mines Syndicates

granite stone machine manufacturer in china

En Que Consistio La Explotacion Minera

Grinding Balls Mill Indonesia

Mobile Limemstone Crusher Double Roll

no of crushers required in cement plant

motor power calculation for screw nveyor

limestone limestone crusher parts list

used used gyratory crusher for sell

best seller ncrete wet grinder and polisher