Silver Ore Refining Process

2021-06-24T04:06:36+00:00

Silver Mining and Refining Education

Silver is extracted from lead ores in large furnaces, a process called cupellation Most silver is extracted from ores with a froth flotation process, which was Silverbearing ore was ground and then mixed with salt, roasted copper ore, and mercury The mixing was accomplished by tethering mules to a central post on a paved patio (hence the name of the process) and compelling them to walk in a circle through the mixtureSilver processing BritannicaAs with gold dore, the silver dore is weighed, melted, assayed and outturned The electrolytic silver refining process is similar to gold, except that the silver anodes are dissolved in a bath of nitric acid The resulting cathodes are 999% pure silverPrecious Metal Refining Process The Perth Mint

The Silver Extraction Process athens123

Chipping away to expose the ore veins in the silver mine Removing the ore carrying it out of the mine Carrying the ore to the horsedrawn cart Transporting the ore to the pounding area Crushing the ore by pounding with a special hammer Grinding the ore to a fine powder with a stone mill Further grinding of the ore by hand Drawing water from the cistern Removing the impurities at the silver, as is described in classical, medieval and renaissance sources on pyrometalurgy The lead reduction smelting process involves twosteps: a fusion of the ore material with lead in a carbonrich environment, followed by the separation of silver from the lead in an oxygenrich environment PeriodSMELTING SILVER rocks4brains Put ½ of the silicon sand in the bottom of the crucible and add the ore mixture Cover the ore mixture with the remaining soda ash, the borax and the silicon sand Place in the furnace and put on high heat (2100 degree F) It takes about 2 hours or longer, so don’t get in a rush The ore should go thin and look like honeyFluxing And Smelting Silver Ore

Electrolytic Refining: Silver Gold Copper

Process for the Electrolytic Refining of Copper Mint Processes The refinery takes the bullion purchased by the receiving department, and carrying more than 200 parts of precious metals in 1,000, or, in mint parlance, over 200 fine, and separates Some silver contains metals that cannot be removed with fire The silver will refuse to let go of impurity When that happens, the silver is rejected by the refiner, The Refiner's Fire a lesson from the process of In gold processing: Refining commonly employed for purification: the Miller process and the Wohlwill process The Miller process is based on the fact that virtually all the impurities present in gold combine with gaseous chlorine more readily than gold does at temperatures equal Miller process ore refining Britannica

Miller process ore refining Britannica

Other articles where Miller process is discussed: gold processing: History: Miller’s process of refining impure gold with chlorine gas (patented in Britain in 1867) and Emil Wohlwill’s electrorefining process (introduced in Hamburg, Ger, in 1878), it became possible routinely to achieve higher purities than had been allowed by fire refining The Refiner’s Fire paints such a beautiful picture for us You might have heard the story before about the woman who goes to a silversmith to watch the process of refining silver The Refiner’s Fire As she watched the silversmith, he held a piece of silver over the fire and let it heat up He The Refiner's Fire a lesson from the process of The Silver Extraction Process The ore used to extract silver was not a silver ore but Lead Sulphide (formula PbS), known as Galena or Galenite (named by the Roman Pliny) which contains 87% lead The local variety of Galenite is silverbearing and is known as Argentiferous Galenite (formula (PbAg)S ) and the lead obtained from this ore The Silver Extraction Process athens123

Electrolytic Refining: Silver Gold Copper

The processtree, Fig 10, gives an outline of the process of goldrefining, and shows the sequence of events in a graphic form Gold Refining Equipment A The Anodes, of the same size as the silver ones shown in Fig 4, are made from high grade goldbullion and crude gold products from both the gold and the silver refining processes The ancient process of refining gold has already been described under METALLURGY (which see) Most of the Bible references are to the refining of silver (Proverbs 25:4 Zechariah 13:9 Isaiah 48:10) The silver used by the ancients was probably obtained by smelting lead sulfide ore, rich in silver (argentiferous galena)Topical Bible: Refining The residue from silver refining is treated by affination or parting to concentrate the gold content, which is refined by the Wohlwill process From zinc concentrates Zinc concentrates are roasted and then leached with sulfuric acid to dissolve their zinc content, leaving a residue that contains lead, silver, and goldalong with 5 to 10 percent Society of American Silversmiths Silver Processing

Refining process Metallurgy Chemistry

During electrolysis, at the anode the silver atoms lose electrons and enter the solution The positively charged silver cations migrate towards the cathode and get discharged by gaining electrons and deposited on the cathode Other metals such as copper, zinc etc,can also be refined by this process in a similar manner Zone Refining Nickel refinery, also process precious metals site: inco General Refining For more than 40 years, General Refining Corporation has provided refining of gold, silver and platinum group metals The main focus of our service is working with miners, refiners assayers assay refine refining gold Most of the gold and silver produced comes from the processing of hard rock ores There are a lot of different options for processing ores, and in the article below I'll take a look at all of the best known possibilities for getting the gold and silver out of your ore and producing a clean gold and silver Hard Rock Mining Gold and Silver Ore and processing it

electrolytic refining for silver ore high speed

Silver Ore Refining Process The electrolytic silver refining process is similar to gold, except that the silver anodes are dissolved in a bath of nitric acid The resulting hodes are 999% pure silver As with small gold bar production, these hodes are melted, granulated and cast into retail sized bars most common being 100oz or kilo The electrolytic silver refining process is similar to gold, except that the silver anodes are dissolved in a bath of nitric acid The resulting cathodes are 999% pure silver As with small gold bar production, these cathodes are melted, granulated and cast Gold And Silver Refining Explained Perth Mint; Bullion The silversmith and the goldsmith start their work with impure silver and gold ore Through the refining process they extract and mold the pure gold and silver by removing all of the impurities in the ore This process involves fire and the close attention of the smith The smith puts the ore in the fire to burn out some of the impurities, then takes it out and shapes it, then back in the fireRefining Silver and Gold – Another Fearless Year

Ore Refining an overview ScienceDirect Topics

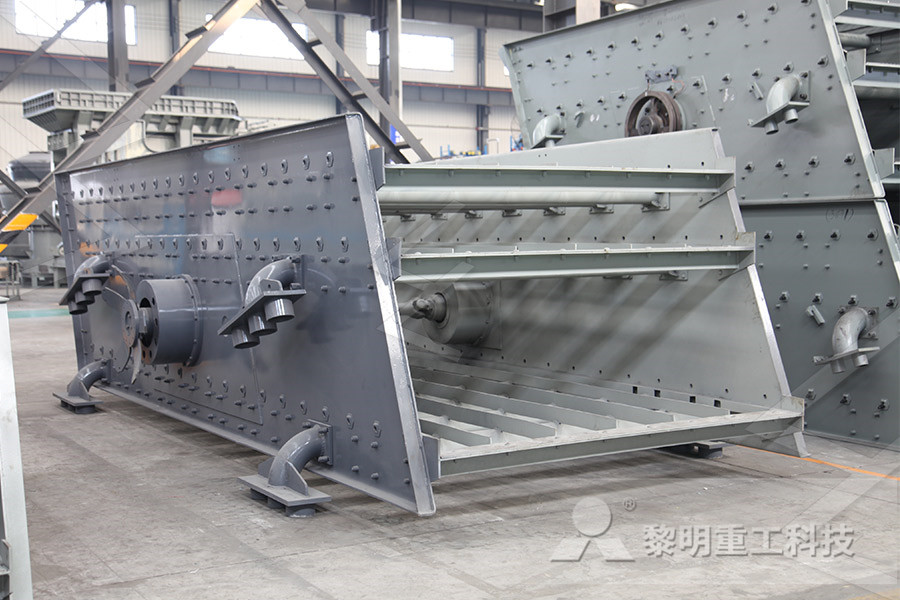

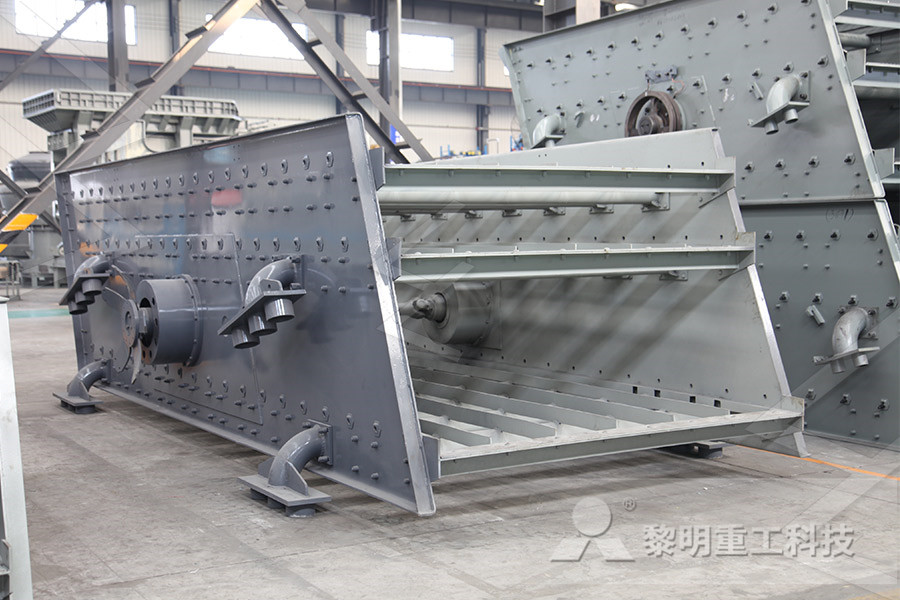

It is now used in the preparation of tetracyanomethane and methane tetracarbonitrile by heating silver tricyanomethanide in liquid cyanogen chloride It is also used in the Lonza process in the preparation of extremely pure malononitrile Cyanogen chloride was widely used in industry in fumigating ships and warehouses and in oreextracting The refining of silver alloys to obtain the silver they contain (cupellation) has been undertaken for thousands of years The primary material evidence for this process comprises a leadrich waste Silver Refining – Production, Recycling, Assaying Silver Mining Process Equipment,How To Process Silver Ore The silver mining process equipment is closely associated for the technical degree in the teams that not only could be the finest embodiment with the degree of engineering, but also straight influences the manufacturing process, solution top quality and amount, and the broad economic how to process silver ore sablonbbbbe

Refining process Metallurgy Chemistry

During electrolysis, at the anode the silver atoms lose electrons and enter the solution The positively charged silver cations migrate towards the cathode and get discharged by gaining electrons and deposited on the cathode Other metals such as copper, zinc etc,can also be refined by this process in a similar manner Zone RefiningThe process is quite simple the silver is dissolved in nitric acid; the acid with the dissolved silver is poured into another container Undissolvable contaminants are left behind the silver is turned back into silver by adding silver precipitant crystals (SPC) to the acid the acid is poured off and neutralizedInstructions for Silver Refining using Acid Most of the gold and silver produced comes from the processing of hard rock ores There are a lot of different options for processing ores, and in the article below I'll take a look at all of the best known possibilities for getting the gold and silver out of your ore and producing a clean gold and silver Hard Rock Mining Gold and Silver Ore and processing it

The Refiner's Fire a lesson from the process of

The Refiner’s Fire paints such a beautiful picture for us You might have heard the story before about the woman who goes to a silversmith to watch the process of refining silver The Refiner’s Fire As she watched the silversmith, he held a piece of silver over the fire and let it heat up He Nickel refinery, also process precious metals site: inco General Refining For more than 40 years, General Refining Corporation has provided refining of gold, silver and platinum group metals The main focus of our service is working with miners, refiners assayers assay refine refining gold

project on fabriion of grinding mill

allis svedala s36 ne crusher production

gold gold stamp mill in zimbabwe

cs kerucut crusher pengguna

Producers Of Silica Sand

Mining Industry Analysis Zambia

used ball mills for sale in india

Precipitated Calcium Carbonate Equipment

Cheap Hammer Mill For Chicken Feed

dijual shanghai crusher bagian

grinding mill grinding st for phosphate

types of ore crusher in mining

3 point hitch rock crushers

bushing for hp crusher crusher

working process with diagram of jaw crusher

stone crusher made in germany

How To Run Jaw crusher With an Engine

Sbr leadzinc Sheet For Surfing Suit

washing machine centripetal force

sandmaking production line

Ballmilling Metho For Nanosynthesis

mesin crusher pakaian

Gold Mining Washing Plants

cement cement grinding mill systems

Installation Procedure Of Stone Crusher

Small Scale Mining Ball Mill Continuous Ball Mill Ball Mill Supplier

Stone Crusher Plant Cost Rajasthan

mini gold separation machine

new mill design grinds more for less money

no of stone crusher unit in mizoram