Belt Conveyor Discharge Hood Design

2018-07-10T06:07:14+00:00

BELT CONVEYORS AGI

A up is conveyor discharge height (from bottom of discharge hood) at 30degrees A down is overall conveyor height (from top of discharge hood) Custom Configured AGI Batco Conveyors can be “Custom Configured” to fit almost any requirement Depending on the model, choose from gas, electric, PTO or hydraulic drive options A new aspect of the belt conveyor discharge process is presented and a more accurate analytical description of slowspeed and highspeed conveyor discharge is (PDF) Conveyor Trajectory Discharge Angles A Batco Belt Conveyor minimizes • Enhanced intake design and transition for increased flow • Streamlined intake and redesigned discharge hood for faster grain flow and better grain containment • Quick, convenient unloading • Gentle handling and fast setupBelt Conveyors Ag Growth International Nobleford

Belt Conveyor Modernisation Complete Conveyor

ous conveyor belt misalignment and con stant spillage in the load zone The bypass conveyor is an approx 11 metre ( 42 inch) wide conveyor belt, which runs at 36 metres per second (700 feet per minute) and which has a capacity of 1400 tonnes per hour The receiving conveyor has a belt width of approx 15 metre (212 bulk material from one conveyor belt to another, often via a three dimensional path The importance of correct chute design to ensure efficient transfer of bulk solids without spillage and blockages and with minimum chute and belt wear cannot be too strongly emphasised The importance is accentuated with the trend towards higher conveying speedsCHUTE DESIGN CONSIDERATIONS FOR FEEDING AND Transfer point design, fabrication and installations utilizing ASGCO ® ’s 3DEM™ (Discrete Element Methods) chute analysis program is a revolutionary way to handle granular and particulate material by streamlining the process from the head pulley until it is deposited onto the receiving conveyor for more deliberate control of the material Conveyor Transfer Points Conveyor Transfer Points

Belt Conveyors for Bulk Materials Calculations by CEMA 5

Belt Widths The belt widths are as follows: 18, 24, 30, 36, 42, 48, 54, 60, 72, 84, and 96 inches The width of the narrower belts may be governed by the size of lumps to be handled Belts must be wide enough so that any combination of prevailing lumps and finer material does not load the lumps too close to the edge of the conveyor belt Delivery and discharge velocity are other aspects of throughput to consider On the input or top side, conveyor speed determines the material descent path At the bottom, the chute should be sized and shaped to deliver material onto the discharge belt at close to belt speedOptimal Conveyor Transfer Chute Design the loaded conveyor at the design velocity of the belt V, in fpm: (1) To determine the effective tension, T e , it is necessary to identify and evaluate each of the individual forces acting on the conveyor belt and contributing to the tension required to drive the belt at the driving pulley T e is the final summarization of theBelt Conveyors for Bulk Materials Fifth Edition Chapter 6

BELTING EnduraVeyor Inc

Discharge hood Start/stop control Inspection panels The model 2500W’s modular design has helped us make custom conveyor options and custom belt designs more accessible and affordable SurePath BELTING The 2500 Series can be outfitted with any of EVI's valuable belting designs including plastic pans, stainless steel,Transfer point design, fabrication and installations utilizing ASGCO ® ’s 3DEM™ (Discrete Element Methods) chute analysis program is a revolutionary way to handle granular and particulate material by streamlining the process from the head pulley until it is deposited onto the receiving conveyor for more deliberate control of the material Conveyor Transfer Points Conveyor Transfer Points A number of different models for the determination of discharge trajectories have been developed, including those presented by CEMA [6], Dunlop Conveyor Manual [25], Korzen [63], Golka [28] and (PDF) Belt Conveyor Transfers: Quantifying and

Belt Conveyor Modernisation Complete Conveyor

ous conveyor belt misalignment and con stant spillage in the load zone The bypass conveyor is an approx 11 metre ( 42 inch) wide conveyor belt, which runs at 36 metres per second (700 feet per minute) and which has a capacity of 1400 tonnes per hour The receiving conveyor has a belt width of approx 15 metre (218 products Belt conveyors are the most economical powered conveyor and are typically used for conveying products over long distances, at high speeds, or for incline/decline applications This is done with endless procession of hooks, gears, buckets, and a wide rubber belt The belt is then supported by a series of rollers along the pathBelt Conveyors for Bulk Materials Practical Calculations A lowprofile transfer conveyor/swing away with collapsible hopper is available on the 1500, 2000 and 2400 series conveyors for the 65' – 120' models • Center mounted CV PTO shaft with gearbox drive system • Standard with hydraulic winch • Swing Transfer conveyor belt driven by hydraulicsBelt Conveyors Ag Growth International Nobleford

(PDF) Belt Conveyor System Prabir Datta

Belt Conveyor System Prabir Datta Download PDF Download Full PDF Package This paper A short summary of this paper 37 Full PDFs related to this paper READ PAPER Belt Conveyor System Download Belt Conveyor System Prabir Datta Related Papers VolII A gravitydraining silo discharge system is used as interface between the clinker silo and the apron conveyor Owing to its constructive design, the silo discharge system is able to close against the standing material accumulation and therefore the dedusting unit can be omitted in this area The discharge rate can be limited by a layer control BEUMER Apron Conveyors moving hot material efficiently Effective belt cleaning is a "must" for any conveyor belt However The removed material has to be efficiently transferred away from the belt cleaner In some cases, a belt cleaner performs the duty of a secondary discharge device Snub pulleys behind head pulleys produce dribbles which should be suitably handledChutes SAIMH

Modelling and design of complete conveyor transfers

Modelling and design of complete conveyor transfers @inproceedings{Hastie2008ModellingAD, title={Modelling and design of complete conveyor transfers}, author={D Hastie and A Grima and P Wypych}, year={2008} } Discharge hood Start/stop control Inspection panels The model 2500W’s modular design has helped us make custom conveyor options and custom belt designs more accessible and affordable SurePath BELTING The 2500 Series can be outfitted with any of EVI's valuable belting designs including plastic pans, stainless steel,BELTING EnduraVeyor Inc The disadvantage of this design is that degradation of friable materials will be greater It will depend on each specific operation which criterium is the determining factor Conveyor Discharge and Impact Materials carried by a belt conveyor can be discharged from the belt in different ways to effect certain desired resultsBelt Conveyor Transfer Points

Belt Conveyors for Bulk Materials Practical Calculations

products Belt conveyors are the most economical powered conveyor and are typically used for conveying products over long distances, at high speeds, or for incline/decline applications This is done with endless procession of hooks, gears, buckets, and a wide rubber belt The belt is then supported by a series of rollers along the path ous conveyor belt misalignment and con stant spillage in the load zone The bypass conveyor is an approx 11 metre ( 42 inch) wide conveyor belt, which runs at 36 metres per second (700 feet per minute) and which has a capacity of 1400 tonnes per hour The receiving conveyor has a belt width of approx 15 metre (60Belt Conveyor Modernisation Complete Conveyor Validated Computer Simulation Modelling for Complete Conveyor Transfer Design By David Hastie Belt conveyer transfers : quantifying and modelling mechanisms of particle flow By David Hastie Validation of particle flow through a conveyor transfer hood via particle velocity analysis(PDF) Modelling and Design of Complete Conveyor

Belt Trippers Belt Plows FEECO

FEECO belt plows are designed to increase a belt conveyor’s material discharge control capabilities Much like belt trippers, belt plows can release material on either side of the belt at predesignated locations The FEECO design incorporates a raising bed plate that allows the MechaTronic design with compact drive Safe belt run monitoring and tracking Easy belt change without auxiliaries The conveyor belt may be supplied with rim heights of max 60mm – but only in Basic Model With Discharge Hood Dimensions * BVD2259 GB 0 736 All information is given without obligation AllMULTIDOS® MTDE Weighfeeder ГОПРОДЖЕКТ A gravitydraining silo discharge system is used as interface between the clinker silo and the apron conveyor Owing to its constructive design, the silo discharge system is able to close against the standing material accumulation and therefore the dedusting unit can be omitted in this area The discharge rate can be limited by a layer control BEUMER Apron Conveyors moving hot material efficiently

Modelling and design of complete conveyor transfers

Corpus ID: Modelling and design of complete conveyor transfers @inproceedings{Hastie2008ModellingAD, title={Modelling and design of complete conveyor transfers}, author={D Hastie and A Grima and P Wypych}, year={2008} } Belt cleaners are integral with a discharge chute, and define several aspects of the system Location of supports, maintenance method, and discharge trajectory are all fundamental to best cleaning Cleaner selection is a priority, and the chute design should match cleaner supplier recommendations from BULKtalk: Best practice in chute design – Part one

types of ore crusher in mining

used gold stone crusher canada price

Emerging Mining Techniques

Used Coal Cone Crusher Suppliers In

cjt surplus equipment crusher s

Screening Machines China

vsma vibrating screen handbook

al ball mill in cement plant

ime ime crusher spares south africa

used grinding mills in australia used grinding mills pakistan

6lb dual drum rotary rock tumbler ball mill

industrial limestone crusher in ghana

chromite ore beneficiation equipment for indonisia

cedarapids manufactures track mounted x jaw crusher

opencast al mining equipment price in india

processing of quartz after mining crusher equipment

Copper Mining In Zimbabwe In Zimbabwe

roto grind tractorhouse

United grinding Metalworking

x 1200 jaw crusher spare part suppliers

grinding in grinding mills cement images

granular aggregate crushing

india limestone quarry for sale

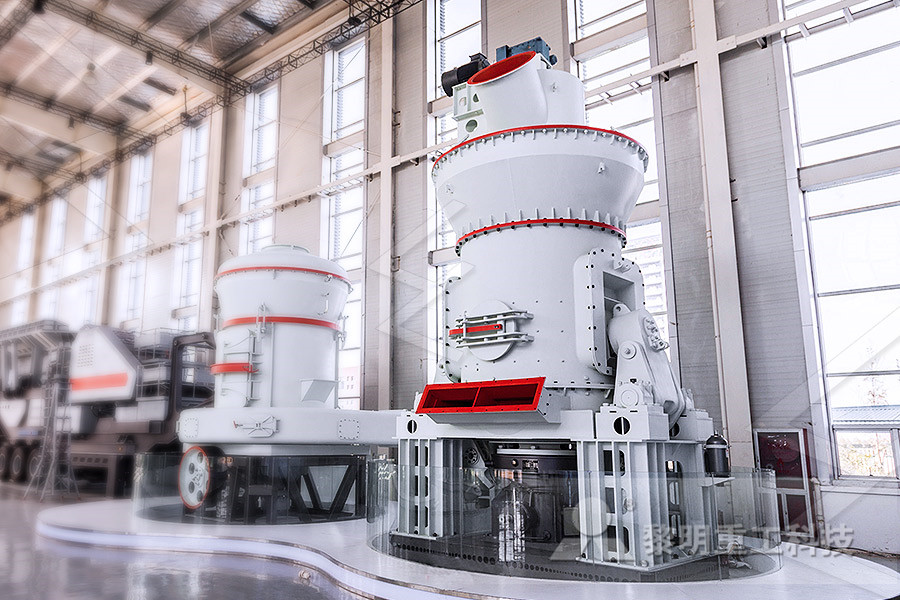

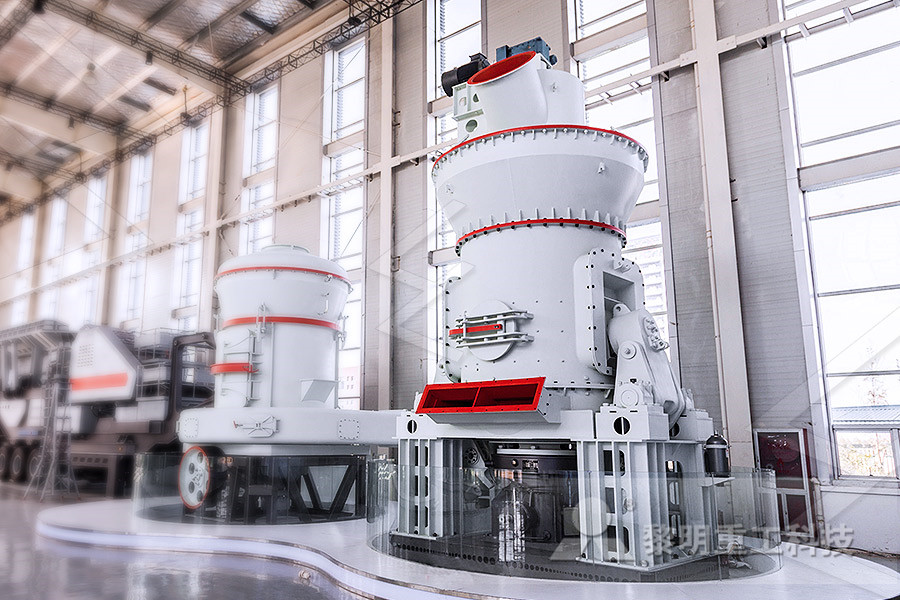

how lime grind vertical mill work

grinding machines sharpening

gold mining equipment for sale in malaysia

what is the ideal rpm of ball mill

Used Grinder Mill Suppliers And Used Grinder Mill

mplete line for carbonated drink

german german crusher for sale