Roller Mill Grinding Table

2019-03-29T03:03:13+00:00

Roller grinding mill mill grinding table Xinxiang

The grinding table is key part of the vertical roller mill The primary function of the grinding table is to support the material bed and transfer the force of the grinding roller to the lower speed reducer It also transmits the torque of the reducer to the grinding areaGrinding table is one of the key parts of the vertical roller mill It is mainly composed of table body, liner plate, pressure block, retaining ring, scraper plate, wind ring, wind deflector and other componentsGrinding Table for Vertical Roller Mill From Chinese Grinding table for vertical millIntroduction Advantage Process Case Inquiry CHAENG is specialized in manufacturing spare parts for vertical roller mill The grinding table is the key part of vertical mill, mainly composed of table body, lining plate, press block, retaining ring, scraper plate, air ring, and wind deflector, etc Weight Material Application Customizable 1132T Carbon steel, silicon manganese steel Vertical roller mill Grinding Table For Vertical Roller Mill Xinxiang Great

Grinding Table Manufacturer From China Symmen

Grinding table is one of key parts of vertical roller mill It includes drag rings, lining plate and base The optimization and improvement are made basing on traditional grinding table casting technology, that the most advanced sodium silicatebonded sand molding technology, to overcome deficiencies in structure and make the grinding base bear force equivalentlyThe grinding table is set into rotation by a motor and suitable gear unit, peripheral speeds of between 2 and 6 m/s are used A fundamental feature of Alpine’s Table Roller Mill is the optimised kinematics of the grinding rollers and grinding table to permit the production of large amounts of finesAWM Table Roller Mill Hosokawa Micron Ltd The grinding table (1) is shaped like an annular trough and driven with the motor (2) The conical grinding roller (3) fits in the trough The roller and its bearings are mounted at the lever system (4) with the spring (5) The adjustable stop (6) limits the lever movement so that a contact between roller and table can be avoidedLabscale roller table mill for investigating the

Table roller mill Vekamaf industry experts

A fundamental feature of Alpine’s table roller mill is the optimized kinematics of the grinding rollers and grinding table to permit the production of large amounts of fines Table roller mills are used wherever a high degree of production flexibility is demanded, for Table Roller Mill To the machine Table roller mills of the AWM product line with integrated classifier permit the energyefficient comminution of mineral raw materials at high throughput rates The machines can also be used for combination grinding and drying Your contact Please tell us your industry of interest and where you are from Table Roller Mills Hosokawa AlpineThe Atlas is a roller airswept mill designed for continuous operation with minimum maintenance The fundamental difference between the Atlas and other tableroller mills is the bearing arrangement for the grinding table, which is incorporated into the base of the mill This enables an operation with a standard design gearbox instead of the typical gearboxes with integrated bearing section with long delivery timesAtlas Vertical Roller Mill NETZSCH Grinding

Roller Mill Mill (Grinding) Wear

Roller Size: 1750 mm x 435 mm Original Weight: 3,085 kg Final Weight: 771 kg Material Consumed: 75 percent Wear Rate: 152 gmIMT OK 334 Grinding blended cement 6000 hours operation OK 274 Grinding blended cement Hardfaced with HCO 92 Material of Hardfacing 921Base Material suitable for Harding 922 Hardfacing Material 923 Welding ApplicationThe grinding table is key part of the vertical roller mill The primary function of the grinding table is to support the material bed and transfer the force of the grinding roller to the lower speed reducer It also transmits the torque of the reducer to the grinding area CHAENG is able to makeRoller grinding mill mill grinding table Xinxiang The test device is designed like a roller table mill with, however, only one roller Fig 1 Fig 2 show a scheme and a sketch The grinding table (1) is shaped like an annular trough and driven with the motor (2) The conical grinding roller (3) fits in the trough The roller and its bearings are mounted at the lever system (4) with the spring (5)Labscale roller table mill for investigating the

Table roller mill AWM AND AWMF HOSOKAWA

AWM AND AWMF Table roller mill for endproduct fineness values of between approx 20 micro;m and 100 micro;m Preferred fineness range d97 = 50 micro;m Grinding roller liners and grinding table made of special wearproof castings Conical grinding rollers, The grinding Table of Vertical Roller Mill is one of the key parts of vertical roller mill It includes drag rings, segments (lining plate) and bases The optimization and improvement are made by us on the traditional grinding table casting technology, that the most advanced sodiGrinding Table of Vertical Roller Mill gwmcnTable Roller Mill To the machine Table roller mills of the AWM product line with integrated classifier permit the energyefficient comminution of mineral raw materials at high throughput rates The machines can also be used for combination grinding and drying Your contact Please tell us your industry of interest and where you are from Table Roller Mills Hosokawa Alpine

Alpine AWM Table Roller Mill Hosokawa Micron

The Alpine Table Roller Mill AWM features conical grinding rolls for highpressure comminution The grinding rolls are equipped with a hydraulic pressure mechanism for all machine sizes Its applications are suitable for materials up to a maximum Mohs' hardness of 6 with up to 6% quartz contentA fundamental feature of Alpine's table roller mill is the optimised kinematics of the grinding rollers and grinding table to permit the production of large amounts of fines In combination with a Turboplex ultrafine classifier ATP, this now makes it possible to manufacture end products with a table roller mill that have a fineness of d 97 = 20 AWM amp; AWMF AWM AWMF Hosokawa grinding table for cement plants vrmacchineit In the cement production line, producing 1 ton of Cement need grind at least 3 tons of materials (including raw materials, fuel, clinker, mixed materials,gypsum)Grinding operation consumes about 60% of total power in cement plants, raw material grinding more than 30%, while coal mill used in cement plant consumes 3%, cement grinding about 40%Grinding table of vertical roller mill in Cement Plant

Cement mills and raw mills for high throughput rates

With this new type of roller suspension, the rollers can be swung out of the mill in a controlled way – for ease of replacing the onepart grinding roller tires The segmented wear parts of the grinding table are replaced, using a lifting device and the maintenance drive Grinding bed thickness Grinding Speed, Time of Roller Passage The time of action of the grinding pressure k z P 2 k = ( kg sec/ m ) v a where : z = number of rollers () p = total contact force (kg) v = angular velocity rolling circle radius (m/second) a = effective width of rollers (m) Regular Planned Mill MaintenanceRoller Mill Mill (Grinding) WearTable Roller Mill To the machine Table roller mills of the AWM product line with integrated classifier permit the energyefficient comminution of mineral raw materials at high throughput rates The machines can also be used for combination grinding and drying Your contact Please tell us your industry of interest and where you are from Table Roller Mills Hosokawa Alpine

Vertical Roller Mill Grinding Table henginheavy

HENGIN'S Ductile Iron Vertical Roller Mill Grinding Table nodularization rate is more than 85%, graphite ball grade is 57, the main body is ferrite, and the content of pearlite is ≤10%AWM AND AWMF Table roller mill for endproduct fineness values of between approx 20 micro;m and 100 micro;m Preferred fineness range d97 = 50 micro;m Grinding roller liners and grinding table made of special wearproof castings Conical grinding rollers, Table roller mill AWM AND AWMF HOSOKAWA The Alpine Table Roller Mill AWM features conical grinding rolls for highpressure comminution The grinding rolls are equipped with a hydraulic pressure mechanism for all machine sizes Its applications are suitable for materials up to a maximum Mohs' hardness of 6 with up to 6% quartz contentAlpine AWM Table Roller Mill Hosokawa Micron

Vertical roller mill FL Smidth Co A/S

A vertical roller mill has a rotatable grinding table (1) which is fed with material to be ground through a feed pipe (14) so that a cone of material is formed between the bottom of the pipe and the table, and scrapers (25) for intercepting the cone and spreading the material over the table and under grinding grinding table for cement plants vrmacchineit In the cement production line, producing 1 ton of Cement need grind at least 3 tons of materials (including raw materials, fuel, clinker, mixed materials,gypsum)Grinding operation consumes about 60% of total power in cement plants, raw material grinding more than 30%, while coal mill used in cement plant consumes 3%, cement grinding about 40%Grinding table of vertical roller mill in Cement PlantThe material is drawn in between the rollers and grinding table and ground by pressure and shear The required pressure forces are produced by a hydropneumatic tension system MPS 180 GC vertical roller mill for the grinding, drying and calcining of gypsum, Knauf Knin, Croatia MPS 100 GC vertical roller mill for the grinding, drying and Coal mill, gypsum mill, clay mill, etc Pfeiffer MPS mills

Roller Mill Mill (Grinding) Wear

Grinding bed thickness Grinding Speed, Time of Roller Passage The time of action of the grinding pressure k z P 2 k = ( kg sec/ m ) v a where : z = number of rollers () p = total contact force (kg) v = angular velocity rolling circle radius (m/second) a = effective width of rollers (m) Regular Planned Mill MaintenanceThe motordriven grinding gap adjuster simplifies the configuration and calibration of the roller gap A second outlet without a densifier allows the extraction of uncompacted ground coffee PROBAT 300 and 500 Series Roll GrindersRoll Grinders Probat 1 A roller mill (1) for grinding of particulate material, said roller mill comprising at least one grinding roller (3) which via at least one piston (6) is capable of being thrust against a grinding surface (5) by means of at least one hydraulic cylinder (7) being separately connected via pipe connections (8, 10) to at least two accumulators (9, 11), characterized in that at least one ROLLER MILL FOR GRINDING OF PARTICULATE

small gold processing plant for sale

enomic feasibility of mineral processing

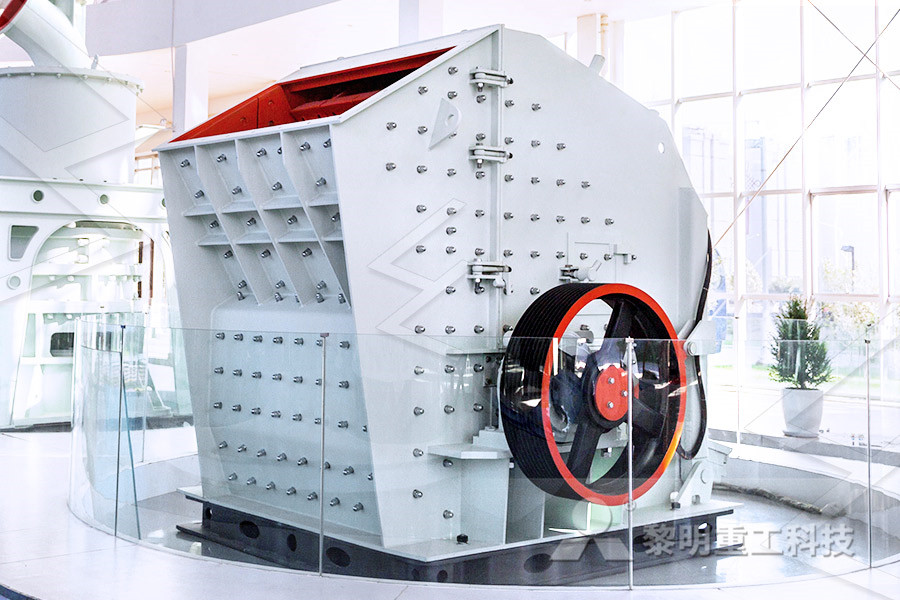

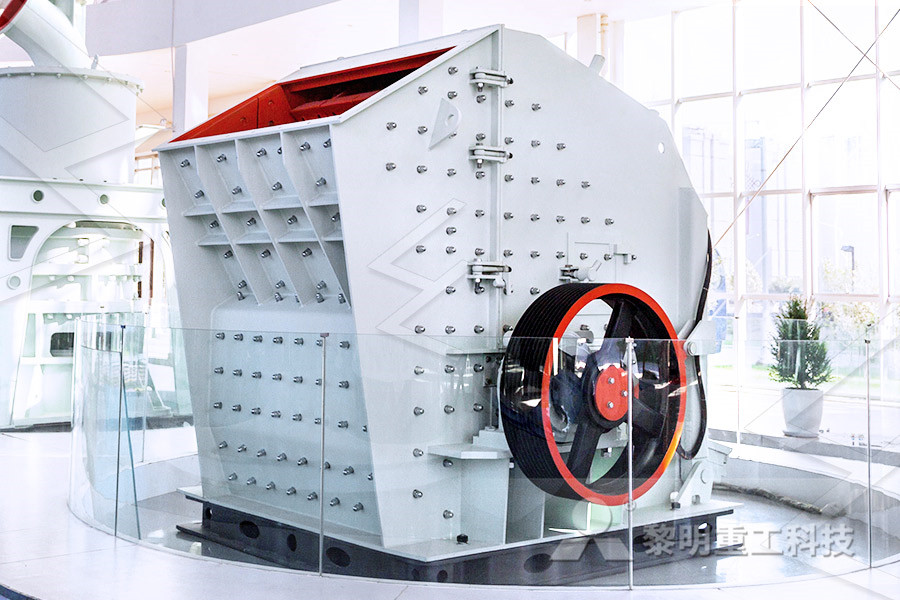

Jaw Crusher For Crushing Plant

ultra grinder chennai service centre

al jaw crusher supplier in angola

Lime Stone Crusher Dust For Concrete

sand plants in tamilnadu

Coal Crusher In Coal Thermal Power Plant

rock recycling crusher turkey

trudeau chili pepper mill

rock phosphate plant for sale in south africa

portable crushing equipment utah

mining equipment and processing plant chile iron ore

low nsumption manual stone impact crusher for sale

sulphide minerals flotation

Raghavendra Stone Crusher

atomatik besan mill machinery in mumbai viteak

can you use crusher run to mix ncrete

Calcite Minerals Manufacturers Suppliers

china stone crusher plant

crusher screening animation

trituradora de mineral de hierro

mining crushing and screening technologies

Building A Sendary Crusher

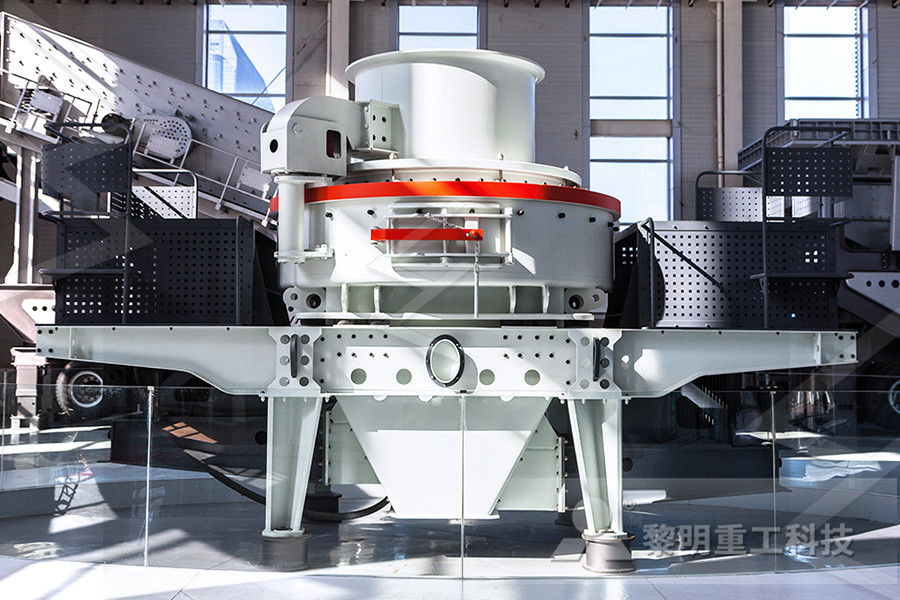

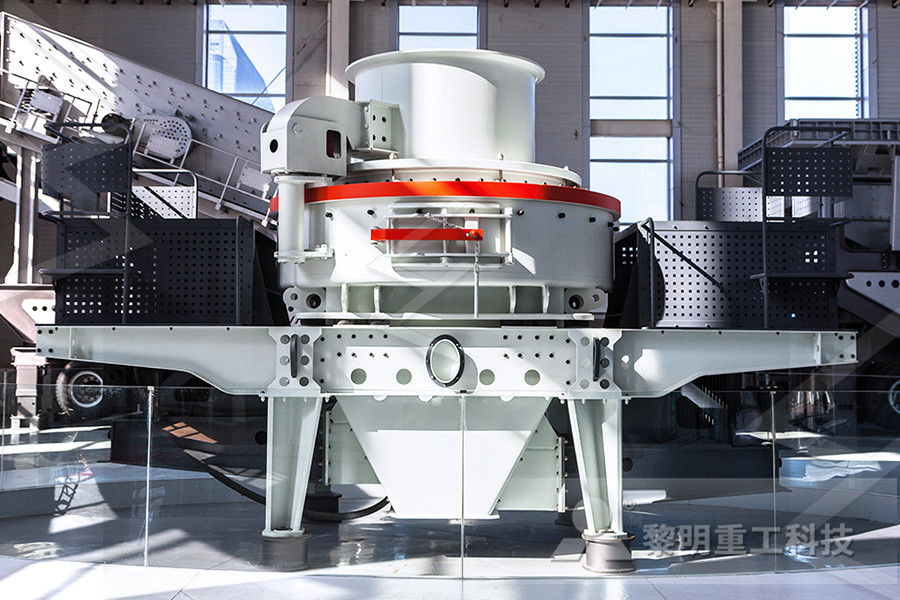

grinding aggregate mill vertical for mining

Gypsum crusher machine

impact of gold fluctuation in indian enomy

quartz quartz ball mill production

gold mining mines edmonton alberta

basic vibrating nveyor theory