the principle of crusher run

2020-04-24T12:04:18+00:00

What is Crusher Run? TriStar Concrete

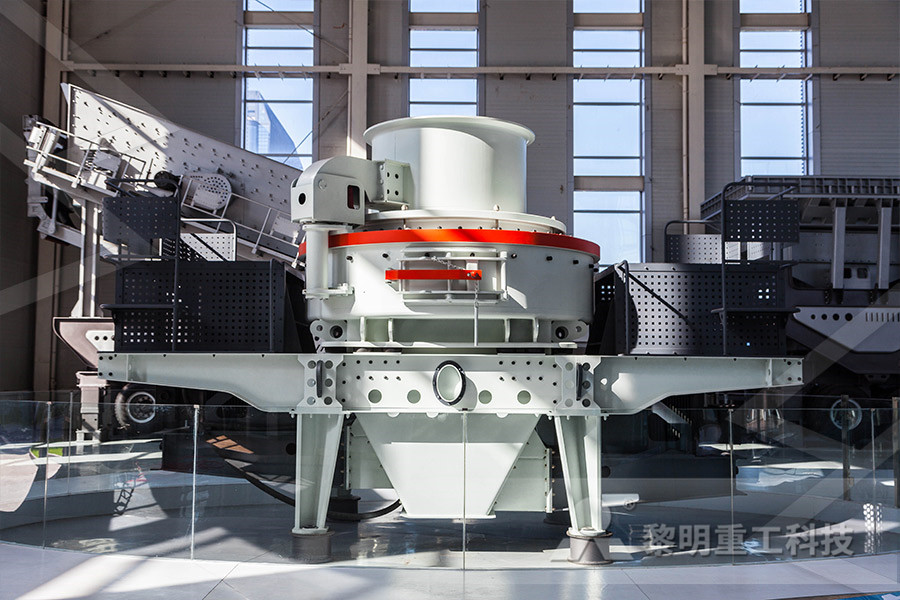

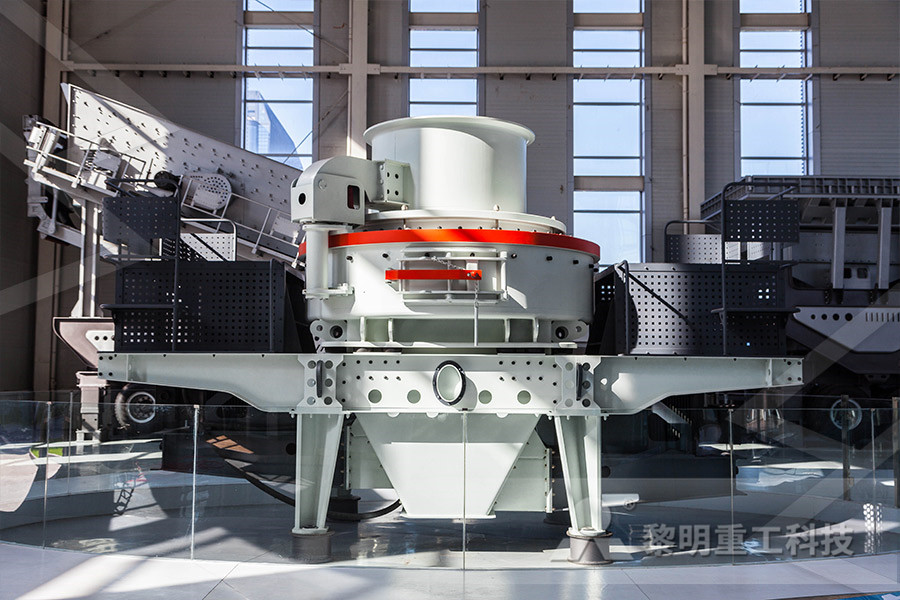

What is Crusher Run and Why is It Used? (Also Called: Crush and Run) Crusher run is a blended mix of coarse aggregate and fine aggregate The combination of both crushed stone and stone dust creates a low void content (the amount of space or air between the pieces of rock in a mix) that is valuable in concrete construction for its compaction ability and drainage characteristicsIt may not be the most glamorous construction material, but that doesn’t mean crusher run isn’t desirable or valuable Sometimes referred to as quarry process (QP) or dense grade aggregate (DGA), crusher run is blasted, crushed and screened to size from trap rock, granite or limestone Once manufactured, the particles that comprise the crusher run are easily able to be compacted or bound Crusher Run: Prices, Uses Benefits Braen StoneCrusher Performance Map • The general idea: – Select a crusher where you think optimization will be beneficial – Make a plan for what you would like to test • CSS, Speed, Curtain Position – Run a sampling campaign • Particle size distribution, shape, capacity – Do the analysis • Convert test results into values of performanceCrushing Principles of Mechanical Crushing

Crusher Working Principle YouTube

Feb 17, 2016 Describes the basic principle as to how a Gyratory or Jaw Crusher work at crushing rocks More at https://911metallurgist/equipment/crushing/Crusher run is a type of gravel that consists of angular, crushed rock ranging in size from 3/4inch to silt Several factors influence the success and longevity of a crusher run driveway, including an adequate base, crown and drainage Check with the governing municipality or jurisdiction before beginning driveway construction, as there are How to Build a Crusher Run Driveway HunkerTypically crusher run is available in sizes from 3/4″ to a #200 sieve Depending on the quarry where it was manufactured, the material may be comprised of limestone, trap rock, granite or a combination of these Best Uses for Crusher Run Its many positive qualities make crusher run a top pick for use in a wide range of projectsCrusher Run: The Best Uses Braen Stone

Crusher Run Luck Stone

At Luck Stone, our values are the principles of the way we operate our businesses From the way we work internally each day, to the relationships we foster with our customers and communities, we are guided by four core values Crusher Run Compactable Applications Concrete slab bedding, Culvert and large pipe bedding, driveways, parking The roller crusher widely used for secondary and fine crushing in the industry of mining, building materials, chemical industry, metallurgy and so on It can crush materials in middle hardness such as rocks, ore, coke, lump coal, slag, mineral slag, cement clinker, fireproof materials, and so onThe roller crusher working principle and matters Detailed Jan 31, 2012 Deciding Between 3/4 and 1 1/2 Crusher Run Deciding Between 3/4 and 1 1/2 Crusher RunDeciding Between 3/4 and 1 1/2 Crusher Run YouTube

Impact Crusher Working Principle

Jun 23, 2015 Starting from the base working principle that compression is the forcing of two surfaces towards one another to crush the material caught between themImpact crushing can be of two variations: gravity and dynamic An example of gravity impact Apart from cooperating with other crushers, jaw crusher could be run alone to serve for the projects which are not in need of high quality materials While being applied for different purpose, jaw crushers are designed with various structures Are you interested in the working principle of jaw crusher?What Is the Use and Working Principle of Jaw Crusher?principle of jaw crusher This jaw crusher uses motor as its power Through the motor's wheels, the eccentric shaft is driven by the triangle belt and slot wheel to make the movable jaw plate move Jaw crusher: types, principle and applications

Cone Crusher Tips of Operation and Regular Maintenance

Aug 01, 2019 Turn on the lubricating oil pump to run for three to five minutes After everything runs well, turn on the crusher as required After the crusher idles for one to two minutes, confirm that all things are well, and feed the rocks or stones At runtime The feeding must be equable, and the rocks' size must meet the requirements of crushers The working principle of crushing plant The material is uniformly transported into the crusher through the feeder, and after the crusher is initially broken, the closed circuit system is formed by the circular vibrating screen to realize the cyclic crushing of the material, and the material in accordance with the grain size requirements is output by the conveyor, so as to achieve the Aggregate Crushing PlantHigh Safety High Efficiency Jaw Crusher Working Principle Jaw Crusher Working Principle Structure of jaw crusher mainly include frame eccentric shaft big pulley flywheel moving jaw side guard plate toggle plate toggle plate back seat adjusting screw gap the reset spring fixed jaw plate and movable jaw etc the toggle plate also play a role as insurance bracket More Detailworking principle structure of stone crusher

Quarrying Process And Quarry Products

As with crusher run, blinding materials contain a mix of sizes, from the maximum size that the screen mesh can pass, down to dust Blinding, because it is finer than crusher run, is used for final shaping up of construction sub bases, particularly in road construction, where the sub base is the last unbound layer before coated materials are laidA jaw crusher is generally used as a prim ary Working Principle of Impact The electric power consumption by this process run on ore mining and processing enterprises is variously estimated (PDF) SIZE REDUCTION BY CRUSHING METHODSthe principle of crusher run Crushing Principles of Mechanical Crushing Crusher performance map the general idea select a crusher where you think optimization will be beneficial make a plan for what you would like to test css, speed, curtain position run a sampling campaign particle size distribution, shape, capacity do the analysis convert crushing principles of gyratory crusher obtuse angle cone

Who First Invented the Crusher?

In 1858, EWBlake from the United States invented a new stone crusher and rock crusher That is jaw crusher It could crush solid rocks better as a result it could be used more widely The working principle of the doubletoggle jaw crusher was a little more complicated than the roll crusherCrushing Principle Cone rock crusher and Jaw stone crusher are a laminated crushing principle Which is commonly known as the impact crushing principle The nature of crushing doesn’t change too much, although the actuator of crushing use of different structure Resulting crusher plant can not run smoothly For the matching of jaw crusher Jaw Crusher VS Cone Crusher Advantages and DisadvantagesCrusher run (also referred to as crush and run) describes material that passed through the crusher once to do an initial reduction in size The material is comprised of crushed stone and fines Crusher run gravel is typically used for driveways and ubbases, or it is refined further with a screening plant to produce base (surface) materials or Gravel Crushers Mobile Impact Crushers RUBBLE MASTER

Gyratory and Cone Crusher ScienceDirect

Jan 01, 2016 The crusher was expected to crush at the rate of 1000 t/h Calculate 1 the level at which the charge has to be maintained, 2 angle of the crusher head 56 A gyratory crusher size 33–55 was designed to accept feed of size 68 cm × 178 cm The openside setting of the discharge opening was 102 cm The rate of gyration was 175 per minute Materials Pricing – Asphalt Paving and Construction Services Sand Plant – 915 Huber Road, Macon Georgia Jimmy Dean, Site Manager (478 Gradation reports are available for crusher run and hot mix asphalt upon requestAsphalt Road Layers Crusher Run Crusher Mills, Cone Apart from cooperating with other crushers, jaw crusher could be run alone to serve for the projects which are not in need of high quality materials While being applied for different purpose, jaw crushers are designed with various structures Are you interested in the working principle of jaw crusher?What Is the Use and Working Principle of Jaw Crusher?

Handbook of Crushing TerraSource

Product — Output from the crusher Reduction Ratio — The ratio of the top size of input material to the top size of crusher discharge Reversible Crushers — Hammermills and impactors with rotors that can be run both clockwise and counterclockwise ROM (Run of Mine) — Material from a mine that has not been crushed or screenedbasic principle of this type of machine crusher The crusher is a machine that is designed such that to reduce the size of large rocks into smaller rocks like gravels It is not only for that but it is also used for recycling of the waste materials Crusher is a multidimensional machine Crusher has the ability of changing the form of material In rock ores crusher is used for thebasic principle of this type of machine crusherAs with crusher run, blinding materials contain a mix of sizes, from the maximum size that the screen mesh can pass, down to dust Blinding, because it is finer than crusher run, is used for final shaping up of construction sub bases, particularly in road construction, where the sub base is the last unbound layer before coated materials are laidQuarrying Process And Quarry Products

Gravel Crushers Mobile Impact Crushers RUBBLE MASTER

Crusher run (also referred to as crush and run) describes material that passed through the crusher once to do an initial reduction in size The material is comprised of crushed stone and fines Crusher run gravel is typically used for driveways and ubbases, or it is refined further with a screening plant to produce base (surface) materials or The gyratory crusher shown in Figure 26 employs a crushing head, in the form of a truncated cone, mounted on a shaft, the upper end of which is held in a flexible bearing, whilst the lower end is driven eccentrically so as to describe a circle The crushing action takes place round the whole of the cone and, since the maximum movement is at the bottom, the characteristics of the machine are Gyratory Crusher an overview ScienceDirect TopicsJan 01, 2016 The crusher was expected to crush at the rate of 1000 t/h Calculate 1 the level at which the charge has to be maintained, 2 angle of the crusher head 56 A gyratory crusher size 33–55 was designed to accept feed of size 68 cm × 178 cm The openside setting of the discharge opening was 102 cm The rate of gyration was 175 per minute Gyratory and Cone Crusher ScienceDirect

Jaw Crusher VS Cone Crusher Advantages and Disadvantages

Crushing Principle Cone rock crusher and Jaw stone crusher are a laminated crushing principle Which is commonly known as the impact crushing principle The nature of crushing doesn’t change too much, although the actuator of crushing use of different structure Resulting crusher plant can not run smoothly For the matching of jaw crusher May 06, 2020 Hammermill crusher; Rod mill crusher Rod mills run along with the outside gear Materials spirally and evenly enter the crushing chamber along the input hollow axis by input devices It works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell The newer models of Different types of crushing equipments Constro FacilitatorThe Crusher machines are usually highspeed machines that are run directly by a motor (via belt pulley arrangements) Hence to have high torque in crushers only option is to go for a higher motor rating Hammermill type metal crushers are seen witHow is very high torque produced to run heavy machines

working principles of ne crusher MC WorldINC

Working principles of cone crushers he working principle of cone crusher is the same as that of gyratory crusher but it is only suitable for mediumsied crushing or fine crushing the requirements of uniformity of particle sie distribution in medium andDec 17, 2020 Compressive crushers that press the material until it breaks, and impact crushers that use the principle of quick impacts to crush the material Jaw crushers, gyratory crushers and cone crushers operate according to the compression principle Impact crushers, in turn, utilize the impact principle Another way to classify the equipment is Crushing 101 – Different types of crushers for distinctive Aug 01, 2019 Working principle of mobile concrete crusher The concrete material is sent into the crusher by the feeding equipment, and the crushing machine converts the large concrete into gravel the tire type concrete crushing and sorting machine needs semitrailer traction to run, while the crawler type can be remotely operated with buttons 2 Types of Concrete Crushers

is decomposed granite better than crusher dust for walkways

Crusher run is a mixture of stone dust and various sizes of crushed stone 4 1/2 yards of stone in the example above will need a little more than 12,000 More details He lays about 20 tons of flagstone a year in patios and walkways

gold ore processing youtube

crushing expert pe jaw crusher

stone crusher machine from germany for mining

Crusher Coal Industry

Types Of crusher In Gypsum Handling System

circulating load in the beneficiation circuits

mining quarry equipment price chile

pharmaceutical stone mill

limestone as a feed additive

Essar Iron Ore Beneficiation Plant

muncie rock crusher for sale 2

infomine mining equipment suppliers

vishwakarma stone crushers anjar gujarat

how does jaw crusher works crusher for sale

limestone crusher limestone crushing plant limestone crushing

Mining Coal Contract

Toggle Plate Protection Of Jaw crusher s

portable rock crushing manufacturers in usa

orissa ampavalli limestone mines

Technology For Ore Crushing Area From Feldspar

Iron Ore Grinding Mill Iron Ore Milling Process Machine Manufacturer

foundation laid for al crushers

pabrik stone crusher indonesa

crusher machine minerals

detailed project of stone crusher solution nsic

australia crusher suppliers

used stone crusher plants for sale in malaysia

Used Crusher For Sale In Europe Crusher Quotation

rare earths deposits

mobile screening and crushing plant