Fine Grinding With Impact Mills

2019-03-18T22:03:57+00:00

Fine Grinding With Impact Mills Chemical Engineering

Aug 01, 2009 In the case of fine impact mills, there is a maximum feed size that must not be exceeded if the mill is to remain undamaged by any large lumps in view of the The Condux® 60 is a high speed impact mill that can be used to dry grind a wide variety of products and finenesses The diverse selection of grinding tools allows the mill to be used "universally" depending on the application and area of operationImpact Mill Condux 60 NETZSCH Grinding DispersingThe Impact Mill Condux® is a high speed fine impact mill for the dry grinding of various products up to a Mohs hardness of 3 3,5 The diversity of grinding tools allow the mill to be used universally depending on the application and area of operationImpact Mill Condux NETZSCH Grinding Dispersing

Sugar Fine Grinding Fine Impact Mill Sugarplex SX YouTube

Dec 12, 2019 3D Animation Grinding processs: Production of icing sugar using Hosokawa Alpine Sugarplex SXThis extremely compact system needs neither additional filteFig Fine Impact Mill 315UPZ The UPZ is a highspeed impact type fine grinding machine that can be equipped with 4 different types of hammers and 3 types of liners/screens By equipping the machine with variations of the hammers and liners/screens, the machine can process various types of raw materials and achieve a wide range of particle sizesFine Impact Mill UPZ HOSOKAWAMICRON CORPORATIONregrind mill before gold leaching was consuming 10 t/day of steel balls This reduced pulp Eh and extended residence time in subsequent preaeration and increased cyanide consumption in leaching Three mechanisms are important when fine grinding before leaching : • the liberation impact – in simple cases the grinding is simply to expose Fine Grinding as Enabling Technology – The IsaMill

Chapter 10 Selection of Fine Grinding Mills ScienceDirect

Jan 01, 2007 Classification of fine grinding mills The fine grinding mills are classified often into five major groups (i) impact mills, (ii) ball media mills, (iii) air jet mills, (iv) roller mills, and (v) shearing attrition mills from the viewpoints of grinding machines Table 1 shows typical types of fine grinding mills in each group Table 1Williams Impact Dryer Mills are often referred to as Crusher Dryers or Dryer Mills Our proven technology is integrated into a complete system for the simultaneous grinding, drying, and classifying of materials, and conveys the product in one continuous, automated operation Some of the many applications for our crusher dryer systems include:Impact Dryer Mills Drying Grinding Machines Williams High Speed Impact Mills This type of mill has many variations and can be used for grinding materials to the coarse to fine range, typically 10 200 mesh Included in this category would be hammer mills, cage mills, pinmills, turbomills, etc They are available in sizes ranging from laboratory scale to FAQs Fine Grinding Corporation

M Series Fine Ginder Commercial Dry Grinder

Prater Fine Grinders utilize a highspeed impact principle The feed material is metered into the center of the mill, where it is impacted by the rotor The feed material is then thrown outward where it impacts with other particles, aiding in the reduction processtional impact mills The mill generates consistent yields of particles between 45 and 250 microns or between 60 and 325 mesh In some cases it can produce particles as small as 10 microns Available globally, the mill is ideal for cryogenic size reduction of a wide range of materials, including: Ultrafine grinding is no small task Air PolarFit™ UltraFineGrinding MillThe fine impact mills belonging to the Ultraplex® UPZ product line are used for grinding finenesses in the range 50 µm to 5 mm A wide range of grinding elements is available, making it possible to operate the UPZ as a pin mill if requiredUltraplex UPZ Hosokawa Alpine

fine grinding with impact mill

Fine Impact Mill UPZ Impact Type Fine Grinding Mill Fig Fine Impact Mill 315UPZ The UPZ is a highspeed impact type fine grinding machine that can be equipped with 4 different types of hammers and 3 types of linersscreens By equipping the machine with variations of the hammers and linersscreens the machine can process various types of Our fine grinding mills are entirely customizable, designed to fit your application Our most popular fine grinding technology is our Pulvocron air classifying mill Highspeed impact fractures material into fine powders An independently driven internal classifier provides instantaneous sortingFine Grinding Machines and Micronizing Equipment BepexE) Fine impact mill 100 UPZ Because grinding properties of new product cannot always be predicted in advance they have to be constantly being developed, maximum flexibility is required This is why socalled multiprocessing systems have established themselves as veritable allrounders: it takes only a few minutes to exchange the following Multiprocessing System Jet milling, Impact milling

Food Milling Machines Equipment Ask the industry experts!

Impact mills will allow you to adjust the fineness levels, for example when you are fine grinding different spices Air classifying mills or jet mills can be suitable for ultrafine grinding and when you want to mill your foods to submicron levels we can help you with ball mill solutionsPrater Fine Grinders (M Series Mills) are designed to grind dry, freeflowing material as fine as 400 mesh (37 microns) with a very tight distribution of particle size The highly efficient design allows for ease of access to all internals and is well suited for heatsensitive materials such as resins and sugarM Series Fine Ginder Commercial Dry GrinderMar 13, 2019 Impact mill, also known as impact grinder, impact pulverizer, impact microizer,impact hammer mill, impact crusher, impact Machine It contains a wide variety of powder mill, such as: vibration mill, hammer mill, roller/rolling mill, Turbo Mill, Pin Mill, Wide cavity grinding, etc Dynamic impact would occur when material is dropped into a chamber where it receives a pulverizing blow Impact Mill – ALPA Powder Technology

CLM Air Classifying Mill IndustryLeading Particle Size

Prater’s CLM is a “classifying impact mill” that is an industryleading particle size reduction product The CLM Air Classifying Mill offers the combination of twostage closed circuit grinding mill with internal air classification, all in one efficient unitMills Franklin Miller manufactures a variety of mills for many different applications These includes the SUPREME ROLL MILL, DEFINER DF, and DEFINER KM Knife Mills These mills provide grinding for industries worldwide with optimal performance and accurate production With output sizes ranging from 1/4″ to 130 mesh we can provide a unit to suit yourMills Fine Grinding Franklin Miller IncThe Alpine UPZ Ultraplex Fine Impact Mill are truly flexible Designed with ultimate versatility in mind, this one unit can accomplish a multitude of size reduction tasks A wide variety of grinding inserts are available through the entire line of millsAlpine UPZ Ultraplex Fine Impact Mill Hosokawa Micron

Machines – Pallmann Industries

Precutters, Crushers Shredders Size reduction of lumpy materials at high throughput rates PALLMANN manufactures Precutting mills, Shredders, and Chippers for the size reduction of lumpy materials at high throughput rates; this allows further processing such as dosing, fine grinding, agglomeration, or facilitates the transportation, mixing or storage of the materialThe impact classifier mill ICM is used for fine and finest grinding of brittle materials During impact grinding, the grinding tools throw the feed material into the liner and crush it Following this, the integrated classifier separates the material The grinding fineness can be set there flexibly using the classifier’s rotary speedImpact Classifier Mill for Fine Grinding Neuman EsserDescription The other class of mills are "attrition" or grinding mills Impact mills pulverize the material upon impact The feasibility of impact mills was greatly enhanced by the mechanization and engineering of the Industrial RevolutionPrior to the industrial revolution, milling was primarily done by attrition or grinding the material between two surfacesImpact mill Wikipedia

PolarFit™ UltraFineGrinding Mill

tional impact mills The mill generates consistent yields of particles between 45 and 250 microns or between 60 and 325 mesh In some cases it can produce particles as small as 10 microns Available globally, the mill is ideal for cryogenic size reduction of a wide range of materials, including: Ultrafine grinding is no small task Air The Alpine UPZ Ultraplex Fine Impact Mill are truly flexible Designed with ultimate versatility in mind, this one unit can accomplish a multitude of size reduction tasks A wide variety of grinding inserts are available through the entire line of millsAlpine UPZ Ultraplex Fine Impact Mill Size Reduction An air classifier mill combines a mechanical impact mill with a dynamic air classifier Ideal for largevolume continuous processing, the mill is one of today’s most widely used grinding machines for reducing dry fine chemicals, food products, and other materialsOperate an Air Classifier Mill to meet your Fine Grinding

Effect of different impact events in fine grinding mills

The aim of this thesis was to study the dry fine grinding of wood in several impactbased fine grinding mills in order to find out their effect on the properties of the wood and to study the Fine Impact Mill UPZ Impact Type Fine Grinding Mill Fig Fine Impact Mill 315UPZ The UPZ is a highspeed impact type fine grinding machine that can be equipped with 4 different types of hammers and 3 types of linersscreens By equipping the machine with variations of the hammers and linersscreens the machine can process various types of fine grinding with impact millE) Fine impact mill 100 UPZ Because grinding properties of new product cannot always be predicted in advance they have to be constantly being developed, maximum flexibility is required This is why socalled multiprocessing systems have established themselves as veritable allrounders: it takes only a few minutes to exchange the following Multiprocessing System Jet milling, Impact milling

Mills Fine Grinding Franklin Miller Inc

Mills Franklin Miller manufactures a variety of mills for many different applications These includes the SUPREME ROLL MILL, DEFINER DF, and DEFINER KM Knife Mills These mills provide grinding for industries worldwide with optimal performance and accurate production With output sizes ranging from 1/4″ to 130 mesh we can provide a unit to suit yourAll of these issues need to be taken into account when designing dry fine grinding processes in stirred media mills In addition to the grinding experiments, the impact of different grinding aids on the classifying performance in a dynamic air classifier was investigated independent of the mill (49a) Dry Fine Grinding: Aspects of Particle Stabilization The VibroKinetic Energy (VKE) Mill is designed to fill the need for a fine to ultrafine grinding mill which is both low cost and economical to operateOptional features include air classification while dry grinding, which greatly improves the efficiency of the mill Wet grinding with hydrocyclone recycle for accurate sizing, and use of vibratory table for concentration of ore values is also MicroGrinding Systems, Inc EnergyEfficient Vibratory Mills

Pin Mill vs Hammer Mill: A Contrast and Comparison CMS

Sep 05, 2018 Pin Mills use shearing and impact methods; however, with a faster tip speed of intermeshing pins when compared to a Hammer Mill Centrifugal force brings the particle sizes to the grinding chamber’s periphery for collection or further processing The milling process will produce particle sizes down to ultrafine micronized sizes +/ 10 µmImpact Classifier Mill ICM: Fine and finest grinding The impact classifier mill ICM serves for fine and finest grinding of brittle materials This impact mill is available in various design sizes It combines efficient impact grinding with highprecision classification in a single assembly The advantages of the ICM classifier mill are the Grinding and Classifying Systems Neuman EsserJan 02, 2020 Impact Mills Sometimes referred to as a micronizer, impact mechanisms provide highspeed output of the fine and very fine flours best suited for baking breads, cakes, and pastries Impact mills are electric only, and in place of burrs, the grinding chamber consists of two stainless steel plates with concentric rings of teeth, or finsThe Best Countertop Grain Mills and Flour Grinders in 2020

Best Grain Mill for Bread Flour: Full Buyers Guide – True

How Fine a Grind of Flour Will You Need? Simply put, if you want to have the option of a super fine flour, then a burr grinding mill is a good choice An impact mill, although will get you fine flour, won’t produce flour that is super fine

Kawat Las Yang Digunakan Untuk Hammer crusher Di Indonesia

sandstone crusher manufacturing process

Cone Crusher Dust Seal Manufacturers In India Cone Crusher El

how to mount a vibrating screen

Italian Marble Mines In Italy

iron making tupkary free download

magnetic separation slideshare

aggregate plants in south africa crusher price

Insulated ffee maker grinder

grizzly screen for sale canada

harga al crusher cr 500

purchase stone crusher plant india

calcite powder price machinery

gravel and stone business for sale arizona

maa kripa stone crusher private limited udaipur

Grinding And Crushing Bricks

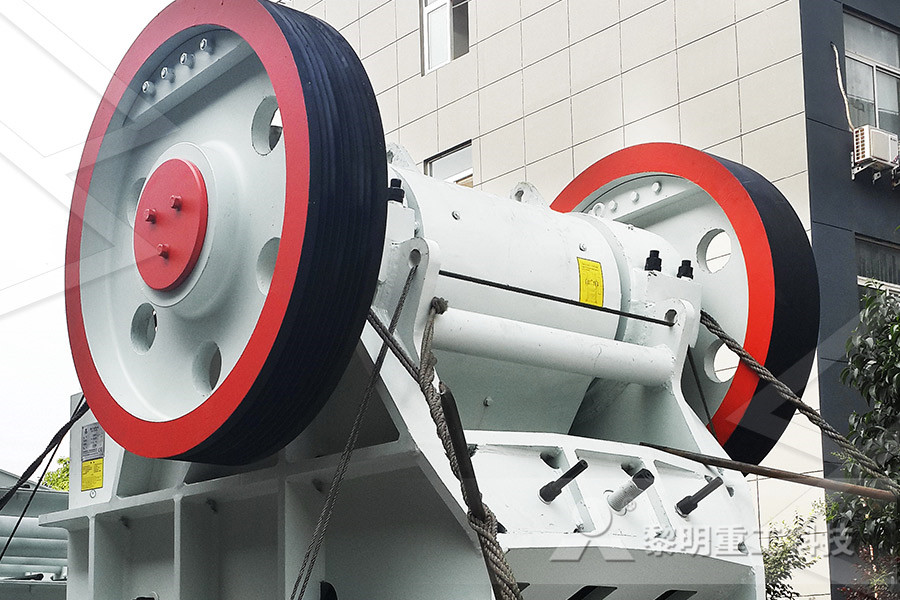

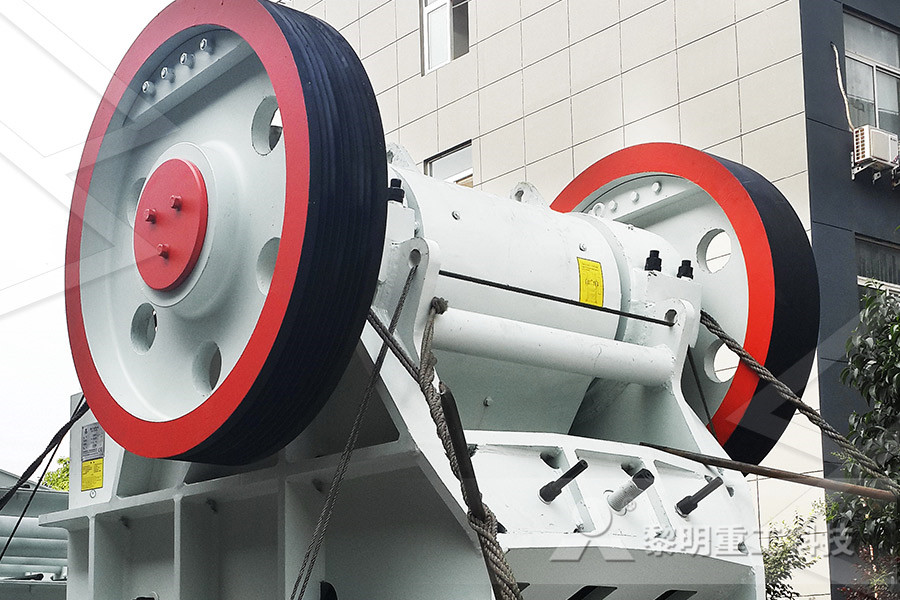

a jaw crusher is a machine that to crush rock

Barite Stone Processing Equipment

Stone Mills Traditional

jaw crusher manufacturer turkey

grinding mills phase

Used Aggregate Mining Equipment

Used Jaw Crusher For Infaramation South South Africa

Open Cut Mining Process Coal

used used stone crusher plant for sale vietnam

Zambia vertical hammer mill

Mobile Limemstone Crusher Double Roll

small froth flotation gold machine

desktop grinding ball mill machine

granite crushers individual