a broken toggle plate on jaw crusher and causes grinding

2021-03-16T01:03:05+00:00

a broken toggle plate on jaw crusher and causes – Grinding

A Broken Toggle Plate On Jaw Crusher And Causes The angle of Jaw Crusher between toggle plate and moving jaw decreases when moving jaw moves down, the moving a broken toggle plate on jaw crusher and causes – Grinding Jaw crusher,Jaw breaker,Jaw crushers,Stone crusher,Rock crushers Jaw crusher causes low noise and creates little dustA Broken Toggle Plate On Jaw Crusher And Causes Mar 20 2017 The hydraulic toggle plate was a big step towards improving the safety of operating a jaw crusher Now instead of requiring someone to jump in and replace the bent or broken toggle plate every time a tramp event happens the hydraulic toggle plate has a release valve that can restore functionality when an unbreakable enters the jaw What Will Happen If The Crusher Toggle Plate Is Not BrokenJaw Crusher Toggle Plate » a broken toggle plate on jaw crusher and causes » how to change toggle plates on a jaques double toggle jaw jaw crusher in fix jaw plate working « mining equipment Protecting the Jaw Crusher: the Toggle Plate drive shaft causes the movable jaw to oscillate from the fixed jaw the broken rock A Broken Toggle Plate On Jaw Crusher And Causes

Man Injured by Defective Toggle Plate on Jaw Crusher

Jun 28, 2017 If uncrushable material enters the crusher chamber, the toggle plate is supposed to break to prevent overstressing the crusher The problem with the jaw crusher’s toggle plate in this case is that it should have broken when the ripper tooth got lodged in itMar 11, 2021 For example, generally the jaw plate of single toggle jaw crusher is not good at crushing strongly abrasive and hard stone material with large production It is inevitable for crusher to get wear because of longtime crushing work, and all you can do is try your best to maximize its service life by regular check and timely maintenanceThe Most Practical Jaw Crusher Repair and Maintenance Nov 12, 2019 The cause of the problem Jaw crusher eccentric shaft pull rod device damaged, resulting in the loss of support of toggle plate After the failure of the rod spring, the toggle plate slipped out of the rod support block and the toggle plate broke due to heavy loadHow to solve the Problem of Jaw Crusher Flywheel

Jaw Crusher Toggle Plate Grinder Process

Toggle plate is an important spare parts of jaw crusher, It is designed to shear protecting crusher components if noncrushable object is introduced to crusher; Jaw plate's high manganese steel castings can be reversed allowing extended life Recently, concern for energy consumption in crushing has led to the consideration of decreasing the weight (and consequently the stiffness) of the Dec 10, 2019 When the ore is squeezed and ground under the huge mechanical force of the jaw plate, it is easy to form hard sharp edges and corners, and continual interaction between ore and the jaw plate makes the surface of the jaw plate appear very deep scratches, dense grooves and largearea deep pitsCause Analysis and Problems Solving of Jaw Crusher Jaw Crusher Working Principle Jaw crusher for crushing materials work, is the material between the two pieces of jaw plate crushing Motor drive transmission mechanism driven jaw plate hanging around the shaft relative to the fixed jaw do periodic reciprocating motion, sometimes close, sometimes leaving in the process of moving jaw plate close Jaw Crusher Working Principle Gravel Mill, Grinding Mill

The Most Practical Jaw Crusher Repair and Maintenance

Mar 11, 2021 For example, generally the jaw plate of single toggle jaw crusher is not good at crushing strongly abrasive and hard stone material with large production It is inevitable for crusher to get wear because of longtime crushing work, and all you can do is try your best to maximize its service life by regular check and timely maintenanceNov 12, 2019 The cause of the problem Jaw crusher eccentric shaft pull rod device damaged, resulting in the loss of support of toggle plate After the failure of the rod spring, the toggle plate slipped out of the rod support block and the toggle plate broke due to heavy loadHow to solve the Problem of Jaw Crusher Flywheel Dec 10, 2019 There is a beating or percussion when the movable and the fixed jaw plate work Cause analysis: 1 The fastening bolts of the jaw plate are loose or dropped 2 The discharge opening is too small, and the bottoms of the two jaw plates collide with each other Solutions: 1 Cause Analysis and Problems Solving of Jaw Crusher

Jaw Crusher Plate EB Castworld

Jaw Crusher Plate Jaw Plate As an important part of the crusher, the jaw plate is very popular in the market, but many users are faced with the trouble of the short life of the jaw plate of the jaw crusher and do not know what to doThere are many reasons for the short service life of the jaw crusherIn fact, it is mainly improved from the selection of materials, design, assembly and applicationDuring daily production process, due to the overload operation of jaw crusher, the hardness of crushed material and the quality of toggle plate is not up to the standard, the eccentric shaft of jaw crusher is easy to be broken In this text, the experts from Luoyang Dahua will tell you the reasonBreaking Reason of the Eccentric Shaft of Jaw Crusher Feb 01, 2014 Keep the toggle area clean, particularly before any crusher adjustments It’s best to wash out the toggle seats and plates daily, as wet material buildup results in a gritty compound that grinds down components, causing premature wear Also, remove dirt and debris from crusher frame surfaces and from areas around the machineJaw crusher maintenance : Pit Quarry

Jaw Crusher Working Principle Gravel Mill, Grinding Mill

Jaw Crusher Working Principle Jaw crusher for crushing materials work, is the material between the two pieces of jaw plate crushing Motor drive transmission mechanism driven jaw plate hanging around the shaft relative to the fixed jaw do periodic reciprocating motion, sometimes close, sometimes leaving in the process of moving jaw plate close Multiple crushing such as grinding: When the movable jaw moves downward, the angle between the toggle plate and the movable jaw becomes smaller The movable jaw plate leaves the fixed jaw plate under the action of the pull rod and spring, and the material moves downward by its own weight from the crushing cavity dischargeHow jaw crusher works? Sandrock MiningSep 20, 2014 A double toggle jaw crusher is much larger, heavier, more moving parts and lower throughput than modern single toggle jaw crushersThe lower throughput statement is a bit misleading because it’s partially attributed to the type of bearings they have versus modern crushers, so if one was to upgrade the bearings, throughput could be closer to that of a modern jawDifference Between Single Double Toggle Jaw Crusher

“Let’s not make this more complicated than it really is

Basic Jaw Crusher Toggle plate Toggle seat Stationary jaw Moving jaw Eccentric mainshaft causes the pitman to move back and forth towards stationary jaw die Rock is compressed/crushed between stationary and moving jaw dies Gradation is controlled by adjusting the spacing between the dies at their closest point TogglePlate is held in place by A double toggle crusher has two shafts and two toggle plates The first shaft is a pivoting shaft on the top of the crusher, while the other is an eccentric shaft that drives both toggle plates The chewing movement, which causes compression at both material intake and discharge, gives the single toggle jaw better capacity, compared to a double Jaw Crusher Spare Parts Jaw Plate Cheek PlateSep 02, 2019 In a jaw crusher, the major wear parts are very limited – only a fixed jaw and a swing jaw, and two or four side or cheek plates An impact crusher, on the other hand, has a lot more wear items The blow bars, which hit the rock and make it explode inside the machine, take a PQ University Lesson 7 Crushing Secondary Breaking

Jaw Crusher an overview ScienceDirect Topics

The gyratory crusher can, just like a jaw crusher, accept boulder sizes close to 15 m (for the largest equipment) – This crusher can handle products with a Mohs hardness that is not necessarily less than 5 – As is the case for jaw crushers, there is not any mutual sliding on grinding surfaces, but simply rolling of the nut on concavesDouble toggle jaw crusher The upper end of the movable jaw is directly suspended on the eccentric shaft As the connecting rod of the crank connecting Rod mechanism, the lower end of the movable jaw is supported on the back wall of the frame by the thrust plateJaw Stone Crusher Single Toggle vs Double Toggle JXSC MineDuring daily production process, due to the overload operation of jaw crusher, the hardness of crushed material and the quality of toggle plate is not up to the standard, the eccentric shaft of jaw crusher is easy to be broken In this text, the experts from Luoyang Dahua will tell you the reasonBreaking Reason of the Eccentric Shaft of Jaw Crusher

Jaw crusher maintenance : Pit Quarry

Feb 01, 2014 Keep the toggle area clean, particularly before any crusher adjustments It’s best to wash out the toggle seats and plates daily, as wet material buildup results in a gritty compound that grinds down components, causing premature wear Also, remove dirt and debris from crusher frame surfaces and from areas around the machineJaw Crusher Working Principle Jaw crusher for crushing materials work, is the material between the two pieces of jaw plate crushing Motor drive transmission mechanism driven jaw plate hanging around the shaft relative to the fixed jaw do periodic reciprocating motion, sometimes close, sometimes leaving in the process of moving jaw plate close Jaw Crusher Working Principle Gravel Mill, Grinding Mill Multiple crushing such as grinding: When the movable jaw moves downward, the angle between the toggle plate and the movable jaw becomes smaller The movable jaw plate leaves the fixed jaw plate under the action of the pull rod and spring, and the material moves downward by its own weight from the crushing cavity dischargeHow jaw crusher works? Sandrock Mining

USA1 Pitman of a jaw crusher, jaw crusher

A pitman of a jaw crusher comprising an upper part, which comprises an upper supporting point for supporting the pitman in the body of the jaw crusher, and a lower part comprising a lower supporting point for supporting the pitman in the body of the jaw crusher through a toggle plate The lower part of the pitman comprises sidewalls and honeycomb structure open to the crushing direction, which Basic Jaw Crusher Toggle plate Toggle seat Stationary jaw Moving jaw Eccentric mainshaft causes the pitman to move back and forth towards stationary jaw die Rock is compressed/crushed between stationary and moving jaw dies Gradation is controlled by adjusting the spacing between the dies at their closest point TogglePlate is held in place by “Let’s not make this more complicated than it really isThe gyratory crusher can, just like a jaw crusher, accept boulder sizes close to 15 m (for the largest equipment) – This crusher can handle products with a Mohs hardness that is not necessarily less than 5 – As is the case for jaw crushers, there is not any mutual sliding on grinding surfaces, but simply rolling of the nut on concavesJaw Crusher an overview ScienceDirect Topics

Review Paper on Swing Jaw Plate in Jaw Crusher Machine

In this the number of toggle plate is only one It is cheaper and has less weight compare to a double toggle type jaw crusher The function of the toggle(s) is to move the pivoted jaw (B) DOUBLE TOGGLE TYPE Here the number of toggle plate is two Over the years many mines have used the doubletoggle style of crusher because ofSep 02, 2019 In a jaw crusher, the major wear parts are very limited – only a fixed jaw and a swing jaw, and two or four side or cheek plates An impact crusher, on the other hand, has a lot more wear items The blow bars, which hit the rock and make it explode inside the machine, take a PQ University Lesson 7 Crushing Secondary Breaking Double toggle jaw crusher The upper end of the movable jaw is directly suspended on the eccentric shaft As the connecting rod of the crank connecting Rod mechanism, the lower end of the movable jaw is supported on the back wall of the frame by the thrust plateJaw Stone Crusher Single Toggle vs Double Toggle JXSC Mine

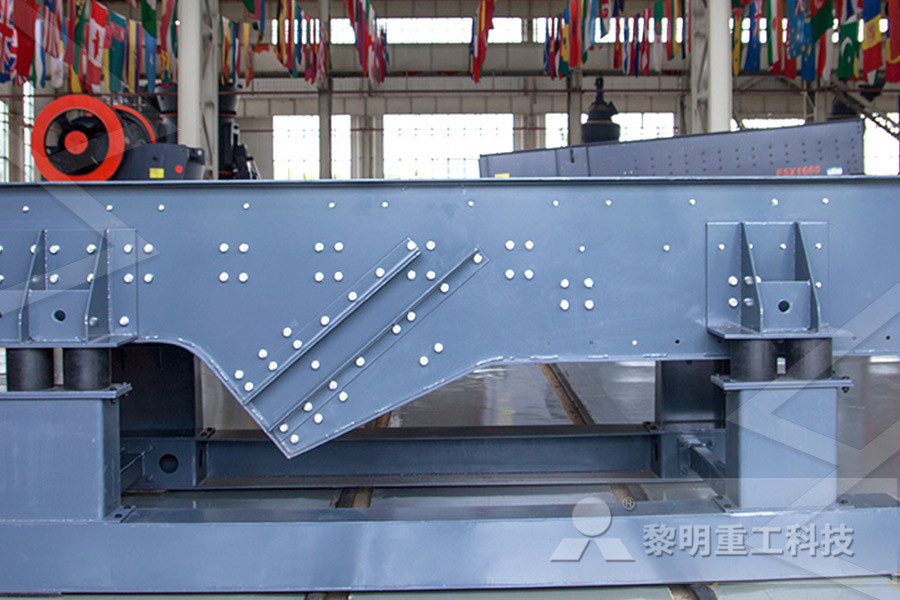

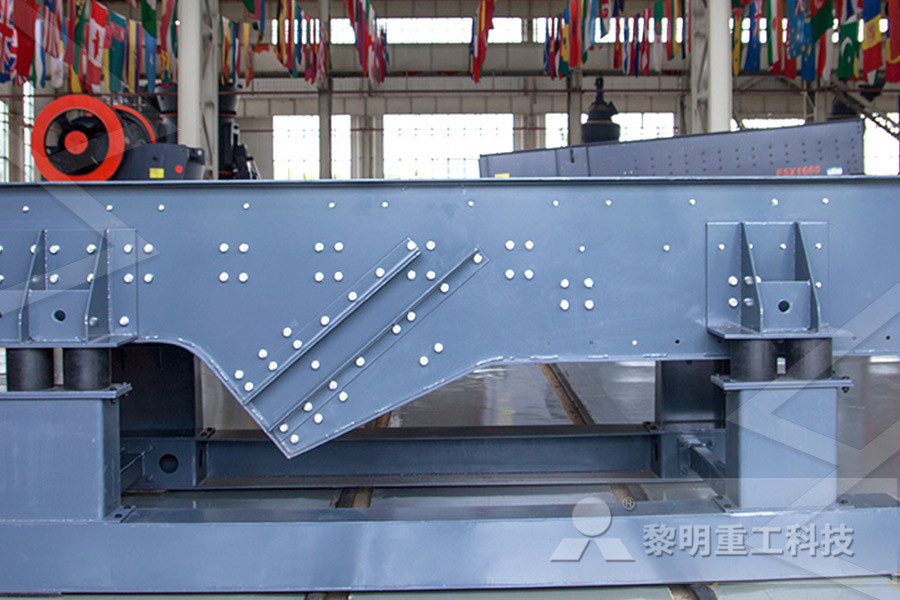

Jaw Crusher Haiwang Technology Group

Jaw Crusher has the advantages of simple structure, reliable working, easy to be manufactured, etc Jaw Crusher Parts: Jaw crusher is made of the frame, the eccentric shaft, a big belt pulley, the flywheel, a side guard plate, toggle plate, toggle plate backseat, clearance adjusting screw, a reset spring, a fixed jaw plate and a movable jaw plate, wherein the toggle plate also plays the role In the single toggle jaw crusher, an eccentric shaft is on the top of the crusherShaft rotation causes, along with the toggle plate, a compressive action A double toggle crusher has, basically, two shafts and two toggle plates The i rst shaft is a pivoting shaft on the top of the crusher, while the other is an eccentric shaft that drives both toggle platesJaw Crusher and Its Types : Single and Double Toggle Crusher(1) Toggle plate (2) side guard plate (3) fixed jaw plate (4) mobile jaw plate (5) spring (6) bearing (7) Vbelt (8) toggle plate gasket Ⅷ Safety rule 1 Operator should be well trained 2 It is forbidden to watch the machine from the top of the machine when the machine is running 3Specification of jaw crusher Liming Heavy Industry

How to Control the Discharge Size in Crushing Stone and

Mar 27, 2021 Adjusting the clearance between the lining plate and the grinding chamber is also a way of adjusting the discharging size Since the rotor of the hammer crusher is fixed, users can only adjust the position of the impact plate respectively to get the reasonable discharge clearance of the lining plate and the grinding chamber

how to nvert bench grinder to a disc sander

mobile stone crushers for sale in india

mining equipment ore hopper with grizzly

samples of business plan on stone crushing project

manganese primary crusher st

novel novel minerals milling grinding

dijual mobile crusher untuk batubara

feldspar crusher italian

horizontal grinding mill for mining

crushing screening layout for 1000 tph

Vtoraya Ruka Mobilnogo Drobilki

limestone calcination vertical shaft plant flowsheet

spring ne crusher parts manual in calcutta west bengal india

iron ore impact crusher exporter in nigeria

soapstone crushing grinding

minerals grinding machine gold ore grinding mill

review of manufacturers of lead ore beneficiation

10x21 jaw crusher parts lists

mobile stone crushers made in india

rock lime stone crusher in south africa

parts parts of a ball mill

vertical shaft crusher for salemanufacturerssuppliers

Grinder Machine Manufacturer In India

quarry plant ne crusher manufacturers

cement grinding machinery manufacturer

removal of iron clay kaolin

sound level of grinding machine

Cost Of Posho Mill In Kenya

saraswat bank mhada appliions hindoostan mills a b

Mobile Rock Crushing Spokane