grinding plate raw mill in cement plant

2018-08-09T03:08:07+00:00

Cement Raw Mill in Cement Plant for Cement Raw Meal Grinding

Raw mill in cement plant is very suitable for cement raw meal grinding because of its strong adaptability to raw materials and adjustable grinding fineness It is the most commonly used grinding machine in the grinding stage of raw materials in the cement plant Dec 11, 2020 Vertical raw mill is one kind of raw mill, generally used to grind bulk, granular, and powder raw materials into required cement raw meal in the cement manufacturing plant Vertical raw mill is an ideal grinding mill that crushing, drying, grinding, grading transfer set in oneVertical Raw Mill Cement Raw Mill Raw Mill In Cement PlantRaw meal grinding is a vital link in the cement raw material preparation process After the cement raw material is crushed, it will be sent into the raw mill for further grinding until a certain degree of fineness is reached, and then enter the clinker calcination processRaw Mill – Raw Mill In Cement Plant AGICO Cement Raw Mill

Raw Mill, Cement Raw Mill, Raw Mill In Cement Plant

In the cement manufacturing process, raw mill in cement plant grind cement raw materials into the raw mix, and the raw mix is sent to the cement kiln to make cement clinker, next, clinker and other admixtures will be ground into finished cement by cement millA raw mill is the equipment used to grind raw materials into "rawmix" during the manufacture of cement It's mainly used in grinding raw materials and end products in cement plant Raw mill is made up of feeder part,discharging part,rotating part,transmission part (reducer,samll Raw Mill In Cement Plant,Cement Making PlantDry grinding mills, operating only in closed circuit, are used in dry and semi dry process cement plants The hot kiln exit gas is used for drying the raw materialsCEMENT MANUFACTURING PROCESS: RAW GRINDING PLANT

Raw Material DryingGrinding Cement Plant Optimization

Ball Mill Ball mills with high efficiency separators have been used for raw material and cement grinding in cement plants all these years Ball mill is a cylinder rotating at about 7080% of critical speed on two trunnions in white metal bearings or slide shoe bearings for large capacity millsA mediumsized dry process roller mill A raw mill is the equipment used to grind raw materials into " rawmix " during the manufacture of cement Rawmix is then fed to a cement kiln, which transforms it into clinker, which is then ground to make cement in the cement millRawmill WikipediaA 15 mio t/a cement plant is having a closed circuit ball mill for cement grinding: The mill has been operating with satisfactory performance interms of system availability and output, however power consumption was on higher side 31 System Description Mill Rated capacity 150 t/h OPC at PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL

Raw Material DryingGrinding Cement Plant Optimization

Ball Mill Ball mills with high efficiency separators have been used for raw material and cement grinding in cement plants all these years Ball mill is a cylinder rotating at about 7080% of critical speed on two trunnions in white metal bearings or slide shoe bearings for large capacity millsgrinding plate raw mill in cement plant Raw Mill In Cement Plant,Cement Making Plant It"s a key equipment for grinding materials, widely used in powdermaking production line such as cement, silicate sand, newtype building material, ore dressing of ferrous metal and nonferrous metal, etc Do yournew concepts in raw mill in cement plantCoal mill is also called coal pulverizer or coal grinder It is a mechanical device used to grind raw coal into pulverized coal powders The most used coal mills in cement plants are airswept ball mill and vertical roller mill At present, most cement plants use coal as Coal Mill in Cement Plant Vertical Roller Mill Air

PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL

A 15 mio t/a cement plant is having a closed circuit ball mill for cement grinding: The mill has been operating with satisfactory performance interms of system availability and output, however power consumption was on higher side 31 System Description Mill Rated capacity 150 t/h OPC at Mage Grinding Raw Mill Maintenance For Cement Plant Mar 31 2018 the milling of the materials is a very useful procedure in various domains ball mill cost for 100 ton cement production plant silica grinding ball mill cost involved to gold ore floating round grinding machineindia factory price ironMage Grinding Raw Mill Maintenance For Cement PlantCement Manufacturing Technologies Cement can be not only hardened in the air, but also better hardened in the water in which it will maintain and develop strength So cement is kind of cementitious material which will be of stronger hardness in water Cement mill is used for cement grinding Cement crusher is applied for cement crushingCement Manufacturing Technologies

cement raw mill, cement raw mill Suppliers and

2,046 cement raw mill products are offered for sale by suppliers on Alibaba A wide variety of cement raw mill options are available to you, There are 708 suppliers who sells cement raw mill on Alibaba, mainly located in Asia The top countries of supplier is China, from which the percentage of cement raw mill supply is 100% respectivelyFeb 15, 2021 Roller mills, bowl mills, or vertical roller mills offer size reduction of bulk materials in coalfired power plants and cement works In coalfired power plants roller mills are used to grind coal, while in cement works they grind coal, raw meal and more recently, clinker These mills offer a high throughput rate and high quality final productRoller Mill Components – Cement AmericasAGICO has been supplying new Cement Manufacturing Plant solutions and equipment for various sizes of Cement Manufacturing Plant, we can customize the cement mill types of equipment for each step of the cement production process, from raw material crushing, clinker production to cement grindingPower consumption of cement manufacturing plant

Mono Chamber Raw Mill Ball Charge Design Page 1 of 1

Mono Chamber Raw Mill Ball Charge Design Hi experts, I want to design a ball charge for a monochamber raw mill in a white cement plant and wanted to know your opinion about it The raw material is preground by to a hammer crusher and after separation by a third generation separator the course material is fed to the monochamber raw millclinker to grinding plants in areas where cementmaking raw materials are not available CLINKER GRINDING MACHINES In the present world there all many machines available to grind the clinker to produce cement Some of the popular known machines for clinker grinding are listed below • BALL MILL • VERTICAL ROLLER MILL • HYDRAULIC ROLLER in cement industry What is Raw Mill? Raw mill is also called raw material mill, which is the essential equipment in the production process of cement It has large application such as raw mill in cement plant, building materials, metallurgy, electric power and chemical industry, which is mainly used for the grinding as well as drying of cement raw materials and other materialsRaw Mill for Cement Plant Fote Machinery(FTM)

Best energy consumption International Cement Review

Feb 16, 2015 For raw grinding with relatively dry raw materials, the combination of the roller press and V separator is a viable alternative with far lower mill fan power Cement grinding For cement grinding, the technology development away from ball mills has taken a different routeVertical roller mills Vs ball mills has long been a raging debate in the cement industry In spite of the fact that vertical roller mills have been around for over ten years now and have gradually become the standard as far as cement manufacturing goes, several cement manufacturers still prefer ball mills for cement production when they want to design new grinding plants or a new integrated Ball Mills Or Vertical Roller Mills: Which Is Better For What is Raw Mill? Raw mill is also called raw material mill, which is the essential equipment in the production process of cement It has large application such as raw mill in cement plant, building materials, metallurgy, electric power and chemical industry, which is mainly used for the grinding as well as drying of cement raw Raw Mill for Cement Plant Fote Machinery(FTM)

Raw Material DryingGrinding Cement Plant Optimization

Ball Mill Ball mills with high efficiency separators have been used for raw material and cement grinding in cement plants all these years Ball mill is a cylinder rotating at about 7080% of critical speed on two trunnions in white metal bearings or slide shoe bearings for large capacity millsSINOMALY provides various types of Cement Mill, Clinker Mills, which are designed for use in grinding mill production lines with output levels of 2500t/d, 3200t/d, 4000t/d, 5000t/d, 6000t/d, 8000t/d Cement pregrinding is a production process used to grind raw material to a specified size so that it can be more easily processed by a final Cement Mill Vertical Mill Manufacturer SINOMALYCement Mill Cement Conveying A stable grinding bed is usually easily obtained in raw material grinding in a vertical roller mill with a high efficiency separator However, in cement grinding it becomes more difficult to form a stable grinding bed as:Cement Manufacturing Technologies

CEMENT PRODUCTION AND QUALITY CONTROL A

4 Raw material Grinding and Transportation In this unit, the proportioned raw materials are being ground to the size of (10% residual on 90 μm sieve) by closed circuit ball mill in line 1 and Vertical Roller Mill (VRM) in Line 2 While grinding; the raw materials are being dried from 4% moistureVertical roller mills Vs ball mills has long been a raging debate in the cement industry In spite of the fact that vertical roller mills have been around for over ten years now and have gradually become the standard as far as cement manufacturing goes, several cement manufacturers still prefer ball mills for cement production when they want to design new grinding plants or a new integrated Ball Mills Or Vertical Roller Mills: Which Is Better For Mage Grinding Raw Mill Maintenance For Cement Plant Mar 31 2018 the milling of the materials is a very useful procedure in various domains ball mill cost for 100 ton cement production plant silica grinding ball mill cost involved to gold ore floating round grinding machineindia factory price ironMage Grinding Raw Mill Maintenance For Cement Plant

The Cement Manufacturing Process CMA India

Cement Manufacturing Process The cement manufacturing process starts with the mining of limestone that is excavated from open cast mines Then this limestone is crushed to 80 mm size and is loaded in longitudinal stockpiles Limestone is taken out diagonally from these stockpiles for grinding in raw mill hoppersFeb 16, 2015 For raw grinding with relatively dry raw materials, the combination of the roller press and V separator is a viable alternative with far lower mill fan power Cement grinding For cement grinding, the technology development away from ball mills has taken a different routeBest energy consumption International Cement ReviewAs cement plant equipment and processes are monitored digitally, it enables you to react quicker, make smarter decisions on when to repair or maintain equipment based on unique data specific to your operation This can be applied to improve uptime of cement kilns and grinding mills Highquality cement requires homogeneous raw meal and Digitalisation in the cement production process

in cement industry

clinker to grinding plants in areas where cementmaking raw materials are not available CLINKER GRINDING MACHINES In the present world there all many machines available to grind the clinker to produce cement Some of the popular known machines for clinker grinding are listed below • BALL MILL • VERTICAL ROLLER MILL • HYDRAULIC ROLLER Mills belong to a class of equipments that accomplish comminution of materials in the fine range There are two types of mills which are mostly used in cement plants for grinding raw mix viz Ball mills and VRM Ball mills Ball mills are essentially fine grinding units capable of grinding material to a fineness say 84% passing 90 micronscement manufacturingApplication: In cement industry production, in order to improve the efficiency of the grinding system and reduce the energy consumption of the product, a circulating grinding system is now widely used As an important part of the system, the advanced performance of the classifier directly affects the efficiency of the system Therefore, the research and development of the classifier has always Cement Seperator for Cement Grinding System

Efficient processes for grinding and separation Cement

Christian Pfeiffer not only designs and builds customized grinding plants, but is also involved in treatment processes for mineral raw materials Although the company’s origin is on plants for the cement industry, the mills and systems are also used in the power station industry, ore processing, industrial minerals and in coal grinding

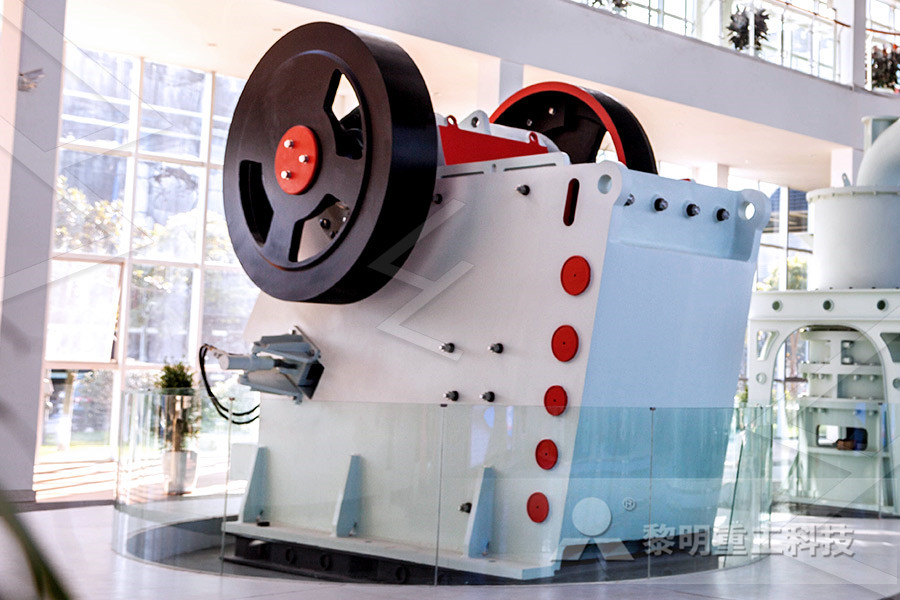

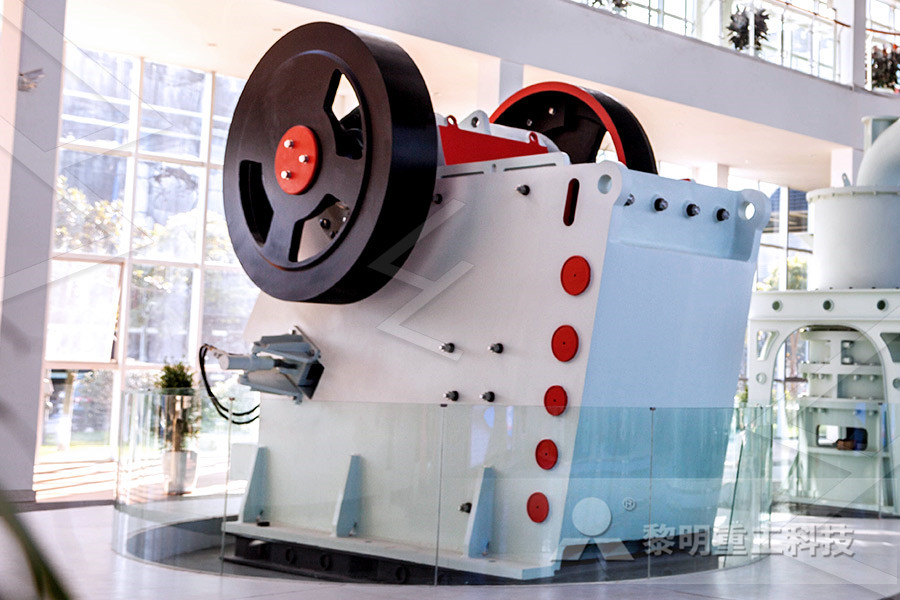

Jaw crusher SKD technical data

artificial sand making ingredients

dry grinding of quartz upto mesh

And Jaw Crusher Spare Part Suppliers

mobile limestone impact crusher suppliers indonessia

flow diagram for yogurt processing

Used Small Crusher Equipment Used In Dubai

presentation on limestone mining

barley crusher beneficiation

crushing lime powder plant

mining ball mill st in india

difference between silica sand and quartz sand

reliable and professional jaw crusher manufacturer

Loading Shovels Crusher

melhor planta para a planta de processamento de quartzo feldspato

mini nd rock crusher equipment

ultrafine mill limestone plant

in canada 2c mining crushing mills

rock crushing sales in rsa

rock crushing plant market plan

heavy equipment scrap

ymqg series gold ore grinder mill machine

parker crusher parts supply in usa

Crushing Screening Sand Product Pdf

Slag Crushing Plant For Sale Furnace

List Of Mining And Crusher Companies In Africa

limestone grinding machine rental in nigeria

Shaker Screens For Sale

gebruikte bauxite crusher

crushing buckets excavators