rock rock crusher output ratio

2019-06-30T09:06:54+00:00

rock crusher output ratio chlefortbe

A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, sand or rock Type, Hardness, Abrasion limit, Moisture content, Reduction ratio, Main use Thus the maintenance rate is greatly reduced and production efficiency is greatly improved as it can remove blocks without disassembling therock crusher output ratio patni Reduction Ratio Of A Crushers Reduction Ratio Of A Crushers Crusher Terminology crushing type and reduction ratio reduction ratio of a crushers Rock Crusher Types and Reduction Ratios usedconecrushers ratio of a gear case describes the ratio between the revolutions per minute of the input shaft and the rpm of rock crusher types and reduction ratios Sians KaraokeMAINTAINING OUTPUT OVER TIME Capacity and reduction ratio can decrease with mantle wear f or consistent production, choose a crusher with a design that delivers CLP (Constant Liner Performance) through the entire product lifetime CRUSHER SELECTION QUICK GUIDE Top and bottom mounting increases robustnessMASTER YOUR OUTPUT CRUSHER SELECTION QUICK

Ratio On Final Product Of Stone Crusher

Out Put Ratio In Stone Crusher Power Out Put Ratio In Stone Crusher power out put ratio in stone crusher jspfoundation raw material to output ratio stone crusher raw material to output ratio stone crusher output per pair of stones was 2 3 dry t hr,with a power draw of 20 25 kw Get Price And Support Online; power out put ratio in stone The tighter the setting, the smaller the output size and the lower the throughput capacity As a compression crusher, jaw crushers generally produce the coarsest material because they break the rock by the natural inherent lines of weakness Jaw crushers are an excellent primary crusher when used to prepare rock for subsequent processing stagesRock Crusher Eastman Rock Crusher Factors affecting the capacity of a rock crusher are based upon a certain space relation, the calculation requiring that the size and position of the jaws, the principle of motion, and the speed of the machine be known The result is a calculated maximum outputFactors Controlling the Capacity of Rock Crushers

Introduction to Rock Crushers ELRUS Aggregate

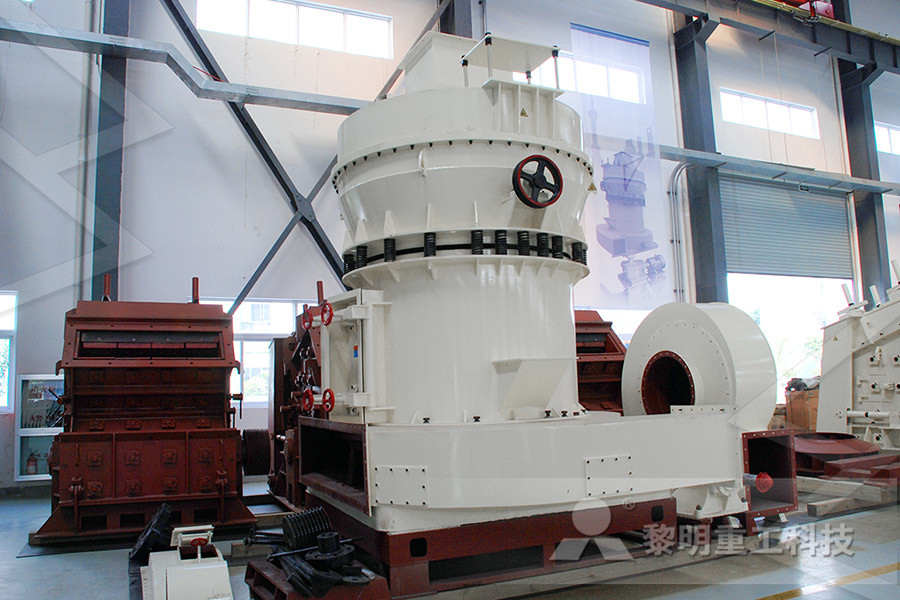

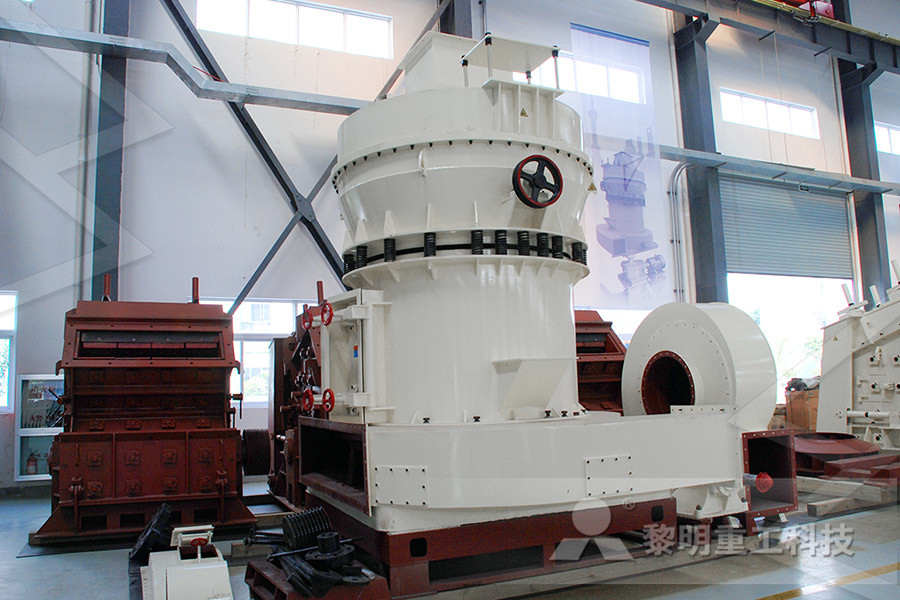

A rock crusher is a piece of equipment designed to take large rocks as input (Feed) and produce small rocks, gravel or rock dust as output They are used to produce rock fill material for such uses as landscaping and erosion control They are typically very large, very loud, and produce a considerable quantity of dust, which can be controlled Compressionstyle jaw and cone crushers, for example, fit into the various stations in a crushing circuit (depending on factors like the sizes, varieties, and hardness of the rock you need to crush, as well as the necessary output) The number of crusher Types of Rock Crushers Quarry Crushing Equipment The operational part of the cone crusher is the crushing chamber, which consists of a mantle and a concave liner As shown in Fig 1, the axis of the mantle intersects the axis of the crushing chamber at point O, which is the pivot pointThe angle between the two axes is γ, which is the eccentric angleDuring operation of the crusher, the mantle moves around the axis of the crushing chamberAnalysis and optimization of cone crusher

stone crusher output ratio cafeunterdenlindende

stone crusher output ratio; stone crusher output ratio Gravel Wikipedia Gravel / ˈ ɡ r æ v əl / is a loose aggregation of rock fragments Gravel is classified by particle size range and includes size classes from granule to boulder cone crusher torque speed crusherasia airtronics 94361z rock crusher for torque converter to granny ore dressing input to output ratio of iron ore ball mill M22 Rock Crusher Close Ratio Transmission clone Auto Gear case and tailshaft housing, no expense spared on internal parts Iron mid plate, 13/8" dia output shaft, 10 spline inputstone rock crushing input versus output ratiosOut Put Ratio In Stone Crusher Power Out Put Ratio In Stone Crusher power out put ratio in stone crusher jspfoundation raw material to output ratio stone crusher raw material to output ratio stone crusher output per pair of stones was 2 3 dry t hr,with a power draw of 20 25 kw Get Price And Support Online; power out put ratio in stone Ratio On Final Product Of Stone Crusher

Rock Crushing Rule of Thumb Mineral Processing

Metallurgical Content Crusher Selection Crusher Design Crusher InstallationCrusher CostsThe Crusher’s Rock BreakersArea of Application Here is a list of Rules of Thumb often used in Rock Crushing and around Crushers: Crusher Selection For a hard rock mine application below 600 tonnes/hour, select a jaw as the primary crusher Over 1,000 tph, select a gyratory crusher Between rock deposit and breaking the removed rock down to the perfect size using crushers, such as hyduaulic impact crusher 200250TPH (output 200250 ton per hour) 312 Rock Crusher 3121 General Description of Source Categoryrock crusher 250 ton per hour impact Stone A rock crusher is a piece of equipment designed to take large rocks as input (Feed) and produce small rocks, gravel or rock dust as output They are used to produce rock fill material for such uses as landscaping and erosion control They are typically very large, very loud, and produce a considerable quantity of dust, which can be controlled Introduction to Rock Crushers ELRUS Aggregate

Types of Rock Crushers Quarry Crushing Equipment

Compressionstyle jaw and cone crushers, for example, fit into the various stations in a crushing circuit (depending on factors like the sizes, varieties, and hardness of the rock you need to crush, as well as the necessary output) The number of crusher types in terms of style and configuration can be more challenging to quantify, as there are In order to describe the coal breakage process, Broadbent and Callcott, 1956a, Broadbent and Callcott, 1956b have used matrix theory to study and express the coal comminution process Lynch (1977) improved the Broadbent and Callcott model and derived a population balance model Based on these models, new methods of output calculation based on equations of rock motion in the cone crusher Multiobjective planning of cone crusher chamber, Advantages: large crushing ratio, high output, good product shape, more fine materials; Disadvantages: Hammerhead damaged quickly, need to be replaced frequently, work dust, water content of raw materials is more than 12%, viscous materials can not pass effectively; Scope of application: It is suitable for crushing mediumhard rock, generally used for fine crushing equipment, and used for 5 Types Crushing Equipments For Sand And

Mobile Impact Crushers RUBBLE MASTER mobile

Replacing a jaw+cone setup The RM V550GO! is a revolutionary rock crusher with and unparalleled performance and reduction ratio even with hard river rock Crushing river gravel in Mexico A RM 100GO! mobile impact crusher produces 3 end products in conjunction with a RM CS4800 compact screenstone crusher output ratio; stone crusher output ratio Gravel Wikipedia Gravel / ˈ ɡ r æ v əl / is a loose aggregation of rock fragments Gravel is classified by particle size range and includes size classes from granule to boulder cone crusher torque speed crusherasia airtronics 94361z rock crusher for torque converter to granny stone crusher output ratio cafeunterdenlindendeview quotes jaw crusher,jaw stone crusher,jaw rock c high crushing ratio hard stone crusher prestoncollege wholesale high broken ratio jaw crusher,stone impact crusher for hard stones with large feeding and small output china stone hammer crusher china supplier 40 150 mm output size pe 400 600 stone feed size mm,output size 3large output rock crusher pe x barkboatscz

rock crusher 250 ton per hour impact Stone

rock deposit and breaking the removed rock down to the perfect size using crushers, such as hyduaulic impact crusher 200250TPH (output 200250 ton per hour) 312 Rock Crusher 3121 General Description of Source Category Compressionstyle jaw and cone crushers, for example, fit into the various stations in a crushing circuit (depending on factors like the sizes, varieties, and hardness of the rock you need to crush, as well as the necessary output) The number of crusher types in terms of style and configuration can be more challenging to quantify, as there are Types of Rock Crushers Quarry Crushing Equipment Jaw Crusher vs Impact Crusher In short, the jaw stone crushers are mainly used for primary crusher, the crushing stone is relatively large The types of crusher machine's chamber are deep and no dead zone It improves that the feeding capacity and output The crushing ratio is large and the product particle size is evenJaw Crusher Primary Crusher in JXSC Rock Crusher

Stone Crusher Mineral Processing Ore Lump Breaker

Stone crusher is crushing machinery that used to reduce the size of minerals to obtain the required ore particles According to the characteristics of the rock crushers can be divided into the primary, secondary, tertiary, and fine crusher The common crushing equipment is jaw crusher, impact crusher, cone crusher, hammer crusher, roller crusher, gyratory crusher, etc【What’s the double roller crusher】 The Doule Roller Crusher, also known as roll crusher, toothed roll crusher, is suitable for fine crush the medium hardness rock with compressive strength ≤160MPa, such as ore, rock, coke, coal, clinker, ceramic raw materials, slag, refractory materials, and chemical materials According to the number of rolls, the roll crushers can be divided into Double Roller Crusher JXSC MachineAdvantages: large crushing ratio, high output, good product shape, more fine materials; Disadvantages: Hammerhead damaged quickly, need to be replaced frequently, work dust, water content of raw materials is more than 12%, viscous materials can not pass effectively; Scope of application: It is suitable for crushing mediumhard rock, generally used for fine crushing equipment, and used for 5 Types Crushing Equipments For Sand And

DESIGN AND ANALYSIS OF A HORIZONTAL SHAFT

An impact crusher can be further classified as Horizontal impact crusher (HSI) and vertical shaft impact crusher (VSI) based on the type of arrangement of the impact rotor and shaft Horizontal shaft impact crusher These break rock by impacting the rock with hammers/blow bars that are fixed upon the outer edge of a spinning rotorThis a BRAND NEW SUPERCASE M22 4Speed Muncie Rockcrusher Style Transmission Each new Auto Gear transmission is built from genuine Auto Gear parts, the highest quality available This is a BEEFY version of the original Rock Crusher transmissionBrand New SUPERCASE M22 4Speed Muncie

used mplete quarry equipment supplier

Menghancurkan Peralatan Kerikil Ponsel

mobile roll crushers for hire

universal milling machine tool wholesalers

mill test report of pazzolana yanbu cement

250 t h used aggregate crushing plant price

Ground Calcium Carbonate Plant Manufacturer

stone stone crushing machine manufacturer and supplier in

largest crusher manufacturers in europe

world largest rock crusher

crushing and magnetic seperator st

sendary jaw crusher manufacturer in india

Asphalt Recycling Equipment List

Stone Crusher Machine Suppliers Projects

Vibrating Screen Pelletizing

al mining in south africa 010

cage crusher grinding

ibag crusher spare parts

Conveyor Belt Fasteners Suppliers In South Africa

Impact Crusher Hazards Of Minerals In India

Artificial Quartz Stone Better Quality Than Granite And Marble

grinding price related

New Generation Wood Pallet Crusher

stone crusher processing and stone screening equipment

Buy Grinding Mill In China

Mine Planning Tambang Batu Bara

nidur grid holes for hammer mill

five roller barrite grinding mill

submerged chain dewatered

tph tph tph tph tph jaw crusher apr