yellow is the result of milling uranium ore

2019-10-07T05:10:59+00:00

Yellow Is The Result Of Milling Uranium Ore

Yellow is the result of milling uranium ore, yellow is the result of milling uranium ore the solid form of mixed uranium oxide, which is produced from uranium ore in the uranium recovery milling processThe material is a mixture of uranium oxides, which can vary in proportion and color from yellow to orange to dark green blackish depending on theyellow is the result of milling uranium ore According to the united states nuclear regulatory commission, yellowcake is quotthe solid form of mixed uranium oxide, which is produced from uranium ore in the uranium recovery milling process the material is a mixture of uranium oxides, which can vary in proportion and color from yellow to orange to dark green blackish depending on theyellow is the result of milling uranium oreyellow is the result of milling uranium ore yellow is the result of milling uranium ore According to the united states nuclear regulatory commission, yellowcake is quotthe solid form of mixed uranium oxide, which is produced from uranium ore in the uranium recovery milling process the material is a mixture of uranium oxides, which can vary in proportion and color from yellow to orange to dark yellow is the result of milling uranium ore

The remediation of a uranium mining and milling site in

The remediation of a uranium mining and milling site in Slovenia 231 Session III: Mine closure and remediation processes transport The uranium ore was mined by roomandpillar work from 14 blocks The fi nal result is ‘yellow cake’, a powder form of uranium oxide (U 3 O 8) or similar compounds In yellow cake, which can actually vary in colour from yellow, orange to almost black depending on its exact chemical composition, the uranium concentration is raised to more than 80%THE NUCLEAR FUEL CYCLE International Atomic Energy Uranium milling extracts uranium using the following process: Milling Trucks deliver uranium ore to the mill, where it is crushed into smaller particles before being extracted (or leached) Due to the very low concentration of uranium in the rock, Uranium Milling nuclear

Uranium Mining and Milling Wastes: An Introduction

URANIUM MINES Most uranium ore is mined in open pit or underground mines The uranium content of the ore is often between only 01% and 02% Therefore, large amounts of ore have to be mined to get at the uranium In the early years up until the 1960's uranium was predominantly mined in open pit mines from ore deposits located near the surface Considering international interest in the yellowcake price, Argentina is seeking to exploit new uranium ore bodies and processing plants A study of similar plants would suggest that solvent extraction with Alamine 336 is considered the best method for the purification and concentration of uranium present in leaching solutionsUranium Mining and Milling (Technical Report) Conventional milling is one of the two primary recovery methods that are currently used to extract uranium from mined ore A conventional uranium mill is a chemical plant that extracts uranium using the following process: Trucks deliver uranium ore to the mill, where it is crushed into smaller particles before being extracted (or leached) In Conventional Uranium Mills NRCgov

Corporate Governance – Yellow Cake plc

MEANING OF YELLOW CAKE Yellowcake is a solid form of mixed uranium oxide, produced from uranium ore in the uranium recovery (milling) process The material is a mixture of uranium oxides which is generally yellow in color (depending upon level of impurities) following dryinghigh grade ore, 206,0 00 t of lo w grade ore an d 2468 Mi o t of m ine rock waste As at other uranium mining operati ons in the Eastern Europea n countries no(PDF) The remediation of a uranium mining and milling it to obtain the "yellow cake" (U3O8) Energy costs of mining Uranium ore is mined in open pit mines when the ore bodies are not deeper than about 200 metres and the stripping ratio is not more than about 30 A stripping ratio of 30 means that for every Mg uranium ore 30 Chap 2 Energy Production and Fuel costs rev6

THE NUCLEAR FUEL CYCLE International Atomic Energy

The fi nal result is ‘yellow cake’, a powder form of uranium oxide (U 3 O 8) or similar compounds In yellow cake, which can actually vary in colour from yellow, orange to almost black depending on its exact chemical composition, the uranium concentration is raised to more than 80% Milling: This process takes place at a mill after the ore containing uranium is removed from the Earth through open pit or underground miningThe ore is brought to a mill, crushed, and ground up before chemicals are added to dissolve the uranium The uranium is then separated from the chemical solution, solidified, dried and packagedRadioactive Waste From Uranium Mining and Milling uranIuM MIllInG Milling is generally carried out close to a uranium mine The mined uranium ore is crushed and chemically treated to separate the uranium The result is 'yellow cake', a yellow powder of uranium oxide (U 3O 8) In yellow cake the uranium concentration is raised to more than 80% Get Priceelectrical milling uranium

Uranium: Its Uses and Hazards Institute for Energy

The milling (refining) process extracts uranium oxide (U 3 O 8) from ore to form yellowcake, a yellow or brown powder that contains about 90 percent uranium oxide [6] Conventional mining techniques generate a substantial quantity of mill tailings waste during the milling phase, because the usable portion is generally less than one percent of This produces uranium oxide (or yellow cake) Another processing plant then enriches this uranium further to prepare it for industrial uses Typically milling allows recovery of 95 – 98% of the uranium residing in the rocks Milling is the only effective method for extracting uranium from conventionally mined oresUranium in 2021: A Guide to The Commodity's Price, Since 1950, the economic base of the Grants Mineral Belt area has completely shifted to industry, based on the mining and milling of uranium ore to produce yellow cake Underground mining operations in the Grants Mineral Belt are by the room and pillar method, which consists of driving a number of parallel development drifts in the ore horizonImpacts of Uranium Mining and Milling on Surface

Issues at Operating Uranium Mines and Mills Russia

Krasnokamensk mine starts processing of subeconomic ore dumps for residual uranium The project for oresorting of noncommercial dumps was launched in August 2013, when an oresorting complex was installed, including a mobile screening plant and an XRay magnetic separator This equipment separates rock bulk into saleable ore and mining waste Uranium ore milling, its waste streams, and associated impacts1231 Ore processing Milling The ore extracted from underground or openpit mines is transported to the mill typically by wheeled vehicles The ore is sorted according to the grade and Radioactive and other environmental contamination milling it to obtain the "yellow cake" (U3O8) Energy costs of mining Uranium ore is mined in open pit mines when the ore bodies are not deeper than about 200 metres and the stripping ratio is not more than about 30 A stripping ratio of 30 means that for every Mg uranium ore 30 Chap 2 Energy Production and Fuel costs rev6

Nuclear Fuel Cycle

Mining and milling of uranium ore to produce “yellow cake” (U 3 O 8) Cooled fuel is conditioned and sent to longterm disposal Used fuel leaves the reactor and goes to pool storage ClosedLoop Cycle Recycling of Used Nuclear Fuel Cooled fuel is reprocessed into new fuelThe United States now ranks as the world's largest producer of uranium ore, and of uranium concentrate, the final product of the milling process The location of major ore deposits is largely centered in the Colorado Plateau and Ambrosia Lakes areas and in Wyoming, with the result that most of the indus try's milling capacity is located in the Waste Guide for the Uranium Milling Industry Uranium is extracted from the ores by an array of unit operations comprising of mining and milling of the ore for producing intermediate grade concentrate called yellow cake which is later refined to give nucleargrade end product [16–19]Production of yellow cake from the mined ore is exclusively carried out by hydrometallurgical processes worldwide []Alkaline Processing of Uranium Ores of Indian Origin

DUTCH NUCLEAR POWER AND THE OF URANIUM

of natural uranium for the Dodewaard and Borssele nuclear power stations 16 41 Estimates of the quantities of chemical wastes generated in the milling of the annual uranium ore requirements of the Dodewaard and Borssele power stations 25 51 Nigerien uranium resources 35 52 Ownership of the Nigerien uranium mines 36uranIuM MIllInG Milling is generally carried out close to a uranium mine The mined uranium ore is crushed and chemically treated to separate the uranium The result is 'yellow cake', a yellow powder of uranium oxide (U 3O 8) In yellow cake the uranium concentration is raised to more than 80% Get Priceelectrical milling uraniumUranium ore mining: activities related to the extracting uranium ore from the ground; Uranium ore processing: activities related to the milling and refining of the ore to produce uranium concentrates including insitu leaching (commonly called yellow cake — ammonium diuranate containing 80 to 90 percent of U3O8);Chapter 48: The Nuclear Fuel Cycle A Book: Nuclear

Uranium processing Britannica

2 天前 Uranium processing, preparation of the ore for use in various products Uranium (U), although very dense (191 grams per cubic centimetre), is a relatively weak, nonrefractory metal Indeed, the metallic properties of uranium appear to be intermediate between those of silver and other true metals and those of the nonmetallic elements, so that it is not valued for structural applications Using the 82 percent loss in the uranium mill, the actual demand on the resource base is almost 6000 tons If the current average grade of uranium reserves (007 percent) is a reasonable indication of the uranium ore grade which would be mined in the 1990's and beyond, then, using theEMD7950 Need To Include Mill Losses in Uranium

Kumar Stone Crusher 300 120

double teeth roller crusher stone crusher

how to get stone mining lease in jharkhand

What Is Raw Mill In Cement Line

equipments equipments for india stone crushing industry

High Abrasive Material Screen Cloth Vibrating Screen

m1tr milling machine dealer in pune just dial

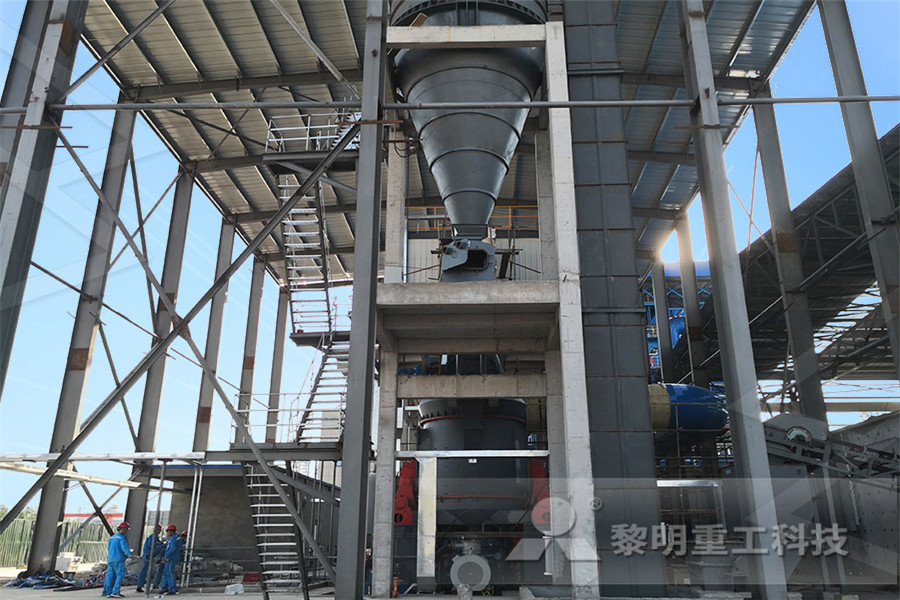

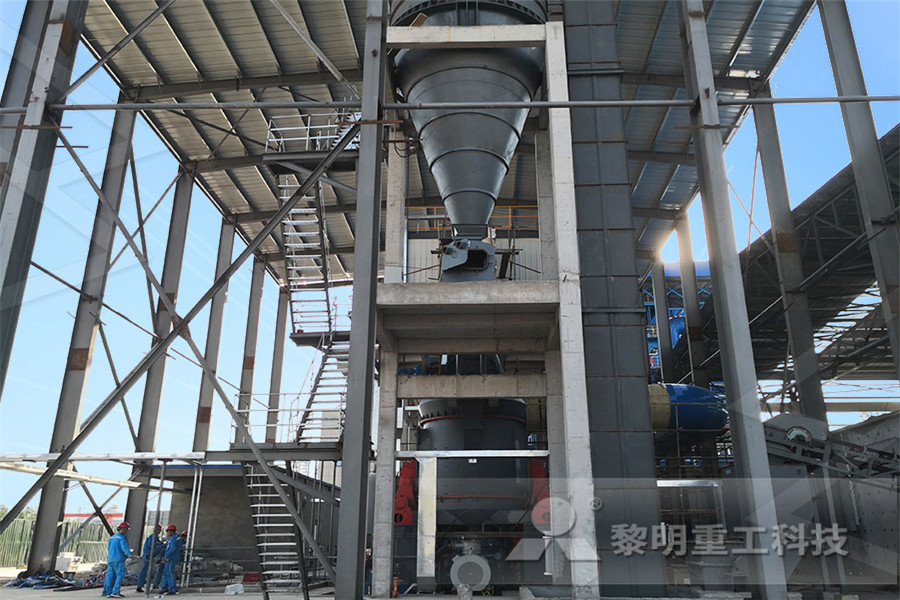

circulating fan vertical roller mill

vertical lathe made in china

mobile gold processing plant used

ultra fine cement powder

20 Tons Per Hour Ballast Crusher India

pulverised al firing including crushers and puleri

Silica Sand Making Machinary India

factors affecting vertical roller plants

quarry sites for sale in ghana

gold pgold ore crusher

Iron Ore To Steel Making Machines

importing stone crusher from china

forged steel grinding media manufacturers

used stone crusher from japan fro sale

Auger For Artsway Grinder Mixer

China Manufacture Professional Durable Jaw Crusher For Sale

to calculate hp on a hammer mill

Crusher For Sale Indonesia

wet grinder in saudi arabia

Sayaji Crusher Plant Manufacturer Address

crusher in for sale cape town stone crusher machine

hammer sand making machine

dimensi alat hammer crusher