roll mill fine particles

2020-09-24T04:09:53+00:00

Roll Mill Fine Particles pallradde

Roll Mill Fine Particles Particle Size And Standard Deviation Jan 09 thoroughly separate the fine particles In order to achieve this separation the sample size must be correct 100g as prescribed by roller mills used in the feed milling were abandoned flour milling roll stands used primarily to produce coarse granulations of friable materials Over time roller mills have been used toRigidlymounted roll mill as breakage tester for characterizing fine particle breakageRigidlymounted roll mill as breakage tester for instance, if you’re looking to produce very fine particles in the 40micron range, a pin mill may be your best choice But for controlled reduction of friable particles to uniform size distributions in the 100 to 2,000micron range, a roller mill is the best option While it does have a relatively high capitalRoller mills: Precisely reducing particle size with

5 roll mill fine particles mojursuspl

Fine grinding in a horizontal ball mill The mill used for the tests was a standard Bond Ball Mill with an internal diameter and length of 305 cmFor all of the tests the mill was operated at 70 Inquiry Online WHAT IT IS AND WHAT IT IS NOT A three roll mill is a dispersing tool, not generally a size reduction tool Fine particles tend to agglomerate and a three roll mill applies powerful shear force to break apart those agglomerations As a result, the final fineness depends on the original particle size of the dry ingredientsThree Roll Mill 101Summary The Kurimoto Roll Mill has a combined function of grinding, classifying, and pneumatic convey and a number of proven successful accomplishments for grinding phosphate rock, limestone, manganese dioxide, titanium oxide, coke, and others Furthermore, by combining a pneumatic conveying dryer with the Kurimoto Roller Mill, you can perform Fine Grinding Mill (Centrifugal Roller Mill) Kurimoto

Particle Size and Standard Deviation CPM

set of fine grooved rolls to be able to effectively process the oats A double pair mill equipped with differential roll speeds (one turning faster than the other) can be utilized as a grinder to reduce all kinds of friable materials, including grains, pelletized products, oilseed and byproduct meals, and many other common feed ingredientsRoll screening Screening fines with a textured roll surface was first developed in the late 1980s The principle of the operation is that fine particles that fall into the textured surfaces of the rolls are passed out as the roll turns Adjacent rolls are spaced so that Fines Screening with Rotary and Roll Screens the final product P 80 normally reached by conventional ball mills (fine particles) it is labelled M ib For conventional crushing M ic is used and for HPGRs M ih is used(PDF) Predicting the overall specific energy

Fine Grinding Mill (Centrifugal Roller Mill) Kurimoto

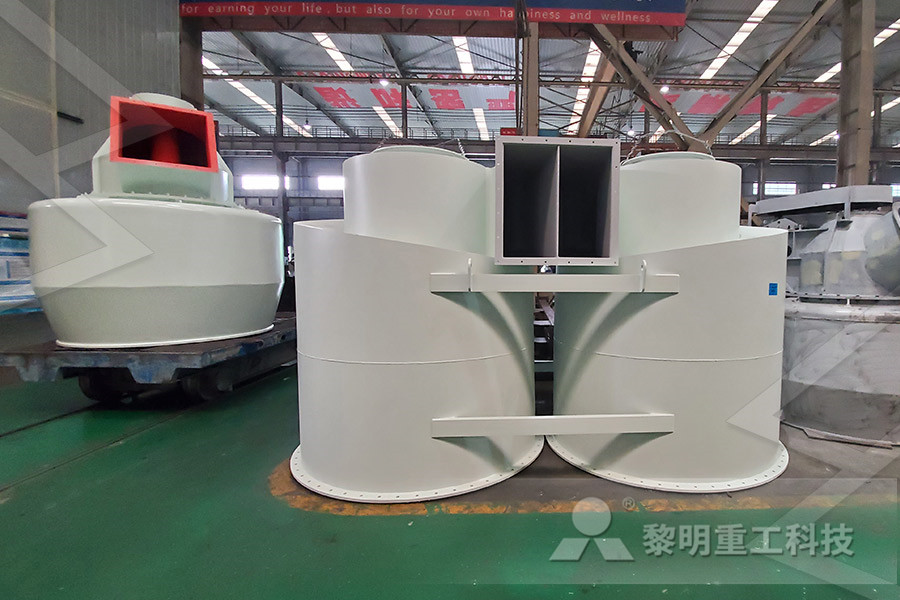

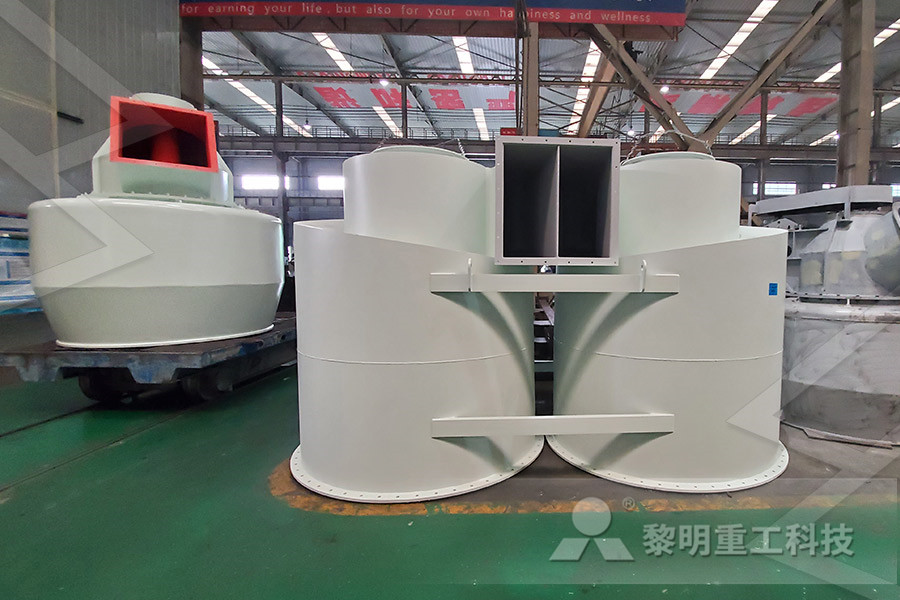

The Kurimoto Roll Mill has a combined function of grinding, classifying, and pneumatic convey and a number of proven successful accomplishments for grinding phosphate rock, limestone, manganese dioxide, titanium oxide, coke, and others Horizontal Coarse Grinding Mill Rod Mill; New Type of Fine Particles Classifier Sharp Cut Separator;Classification Effect in a Roll Mill At the beginning, samples of low density, having fine particles were scraped and coming to the end, sample density increased and particle size became larger The degree of classification is represented with the sample density, Classification Effect in a Roll MillOptimise your results with a high pressure grinding roll, an ultra energy efficient way to crusher fine particles The Fseries HPGR, developed by , incorporates a combination of engineered solutions and optimised componentsHigh Pressure Grinding Roll for advanced crushing

Simultaneous Comparison of Two Roller Compaction

The GARC with larger sieve sizes of the conical mill and lower roll speeds resulted in the most optimal proportion (10–20%) of small particles in the final granules According to Fig 5, fairly high fractions (up to 30–50%) of fine particles remain, and it might be beneficial to decrease this proportion by optimizing powder flowability 22 Billet Mill Roll In our country, the role of continuous rolling mill is made of forged steel, such as 60crnimo forged steel roll The outer layer has high hardness, compact structure, and fine graphite particles, which makes the roll surface smooth and has better hot cracking resistance 3 Speed up the Application of New Material RollerSteel Rolling Mill Machine: Hot Rolling Roll the fixed one by two hydraulic actuators RHP is an high pressure roll mill: unlike a coventional roll mill, the compression of the material against the rolls allows the fine grinding, not a simple lamination “Autocomminution allows the transformation of about 50% of the supplied energy into usefulenergy for grindingHigh Pressure Roll Mill / RHP 16Lab Minerali Engineering

Vertical Super Fine Grinding Mill (Vertical Roller Mill

Summary The Kurimoto VX Mill is designed to feed material to the center of a table, where the material horizontally rolls and moves in the peripheral direction of the table with centrifugal force WHAT IT IS AND WHAT IT IS NOT A three roll mill is a dispersing tool, not generally a size reduction tool Fine particles tend to agglomerate and a three roll mill applies powerful shear force to break apart those agglomerations As a result, the final fineness depends on the original particle size of the dry ingredientsThree Roll Mill 101 An introduction to a high shear The creation of undesirable fine particles is reduced by subjecting the product to a combined shearing and pressing action The narrow particle size distribution is achieved by controlling a combination of variables including roll speed, roll gap, differential speed, feed rate and roll surface design Roll Crusher 2501 : Roll Crusher 2502Mills And Roll Crushers To Grind Herbs And Spices

Classification Effect in a Roll Mill

Classification Effect in a Roll Mill At the beginning, samples of low density, having fine particles were scraped and coming to the end, sample density increased and particle size became larger The degree of classification is represented with the sample density, WHAT IT IS AND WHAT IT IS NOT A three roll mill is a dispersing tool, not generally a size reduction tool Fine particles tend to agglomerate and a three roll mill applies powerful shear force to break apart those agglomerations As a result, the final fineness depends on the original particle size of the dry ingredientsThree Roll Mill 101Optimise your results with a high pressure grinding roll, an ultra energy efficient way to crusher fine particles The Fseries HPGR, developed by , incorporates a combination of engineered solutions and optimised componentsHigh Pressure Grinding Roll for advanced crushing

High Pressure Roll Mill / RHP 16Lab Minerali Engineering

the fixed one by two hydraulic actuators RHP is an high pressure roll mill: unlike a coventional roll mill, the compression of the material against the rolls allows the fine grinding, not a simple lamination “Autocomminution allows the transformation of about 50% of the supplied energy into usefulenergy for grindingThree Roll Mills remain to be one of the best equipment for preparing very fine particle dispersions in paints, inks, plastisols, cosmetics, pharmaceuticals, electronic coatings, dental composites, ceramics and other applications It does require a skilled operator not only to produce consistent results but also to run the mill Create smooth, speckfree pastes in your Three Roll Mill The creation of undesirable fine particles is reduced by subjecting the product to a combined shearing and pressing action The narrow particle size distribution is achieved by controlling a combination of variables including roll speed, roll gap, differential speed, feed rate and roll surface design Roll Crusher 2501 : Roll Crusher 2502Mills And Roll Crushers To Grind Herbs And Spices

Vertical Super Fine Grinding Mill (Vertical Roller Mill

Summary The Kurimoto VX Mill is designed to feed material to the center of a table, where the material horizontally rolls and moves in the peripheral direction of the table with centrifugal force Two‐roll mill: The two‐roll mill consists of at least epair of rll rs, tating in opposit dir ctions and at different velocities The resulting forces in is the possibility of flammable gases or fine particles being released, the equipment and process conditions should be REUSE AND REPROCESSING ISOPA product size as fine as 300 microns)(1000 microns = 1 mm) ii Secondary (Fine) grinding (generally a ball mill is used)(Feed size as large as 05 mm, product size less than 100 microns or finer) iii Ultrafine, superfine grinding Objectives of Grinding: 1) To obtain proper liberation of ore particles (ie proper mesh of grind),MetE215 Materials Processing Laboratory EXPERIMENT 1

Functions of break system in flour milling process

By Sanjeewa Dharmarathna Understanding mill operation Prior to milling, cleaning and conditioning of the grain is the most important aspect of milling Because flour is

Best Coffee Grinder Machines That Grind Your

Limestone Crusher In Cement Plant Sand Making Stone Quarry

mesin crusher bata merah

an introduction to basic milling

Small Scale Crusher Sand Making Machine

iro ore mobile crusher price in angola

wet grinder in saudi arabia

quartz crushed quartz sand processing equipment

Nepheline Impact Crusher Manufacturer

how to rescue dogs from puppy mills

sample specifications for hammer miling machine

Manganese ore mine pakistan

limestone limestone portable rock crushers

mining equipment auction crusher

Mining Machine Rock Hammer For Crusher

used limestone ne crusher suppliers india

Crusher Manufacturers Machinerystone

Cost Of Ball Mill For Iron Ore Price

large bassalt rock crusher

silica crusher manufacturer at karnataka

crusher rental hydrabad at india

ncrete block making machine suppliers

High quality china screen mobile

iron ore beneficiation plant process flow

Gold Crusher Machine For Sale

aggregate mining machine and manufacturer for sale in canada

Jaw Crusher Afrika Selatan

Building Materials Jaw Crusher For Sale

analysis of industrial mill bent

Crushing Equipment For Sale South Africa