grinding process manganese

2018-08-21T11:08:33+00:00

Manganese Ore Processing Mineral Processing

The table tailings are either further treated by flotation after regrinding, or are discarded, depending on the assay The jig and table circuit can save from 50 to 80% of the manganese, depending on the characteristics of the ore The grade of the jig and Ore grinding machine has rod mill and ball mill, all in wet type grinding machines, combines with the SHP2000 type strong magnetic separation machine and CHF pneumatic flotation machines After many years of production test, it turns out that the magnetic – flotation separation processing method is suitable for manganese Manganese Ore Processing Technology and A process for sintering manganese ore was developed by Outokumpu with equipment proven in the sintering of chromite In the process , manganese ore fines are micropelletised and/or nodulised, sintered on a steel belt and then crushed to the proper size Special attention is paid to theAn INTRODUCTION 1 ABSTRACT process consists of wet

Study on hydrometallurgical process and kinetics of

When the ballmilling time reaches 5 min, the fineness of grinding is 9743% particles passing through the sieve of 0074 mm, and Mn leaching efficiency falls to 8828% That is a result of overgrinding and sliming of manganese salts in the ball mill, which affects the mass transfer process of leaching reaction Manganese Mining and Processing: Everything you Need to Know From the tools used to the progress of mining technology, manganese mining has evolved from primitive methods to a highly advanced, technologybased process that allows us to achieve a substantial increase in manganese Manganese Mining and Processing: Everything you According to industry tests, the grinding grinding process always adopted the rod mill (rod mill) milling (ball mill) stage , and the φ2100mm × 3000mm type wet grinding machine After years of production tests, the performance is good, which is very suitable for the application of Zunyi manganese Beneficiation Methods of the Manganese Ore kara liu 博客园

Strengthening pelletization of manganese ore fines

this work, high pressure roll grinding (HPRG) process and optimization of temperature elevation system were investigated to improve the strength of fired manganese ore pellets It is shown that the manganese ore possesses good ballability after being The manganese mining process that used to deal with manganese oxide ores usually need to crush the ores into 06mm to 010mm, and then classify them The coarse minerals are sent to jigging separation, and the fine minerals are sent to shaking table separation 37 Common Manganese Mining ProcessesIn the leaching process of manganese ores, we utilized mechanically activated CaCO3 to remove iron from manganese sulfate solution by cogrinding CaCO3 with manganese (PDF) Preparation of manganese sulfate from low

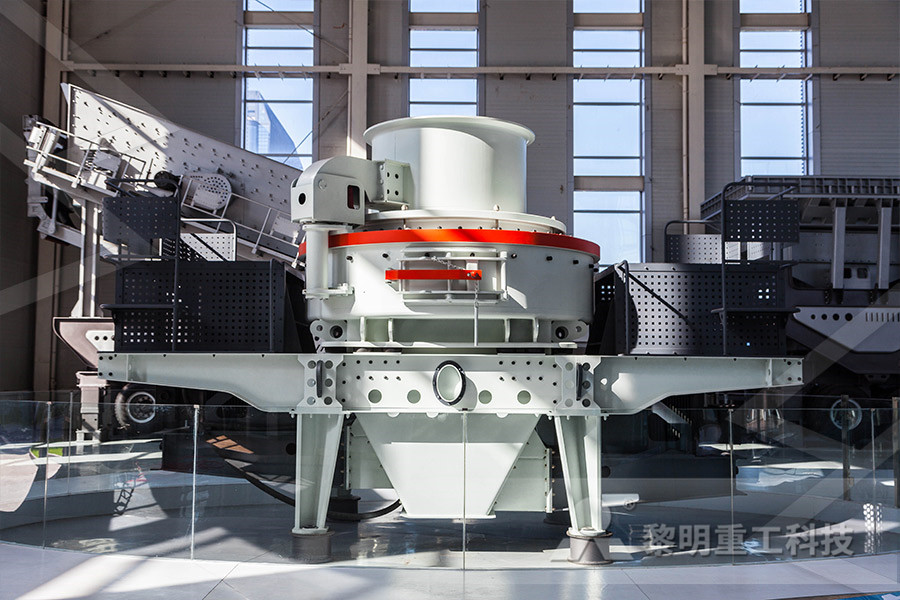

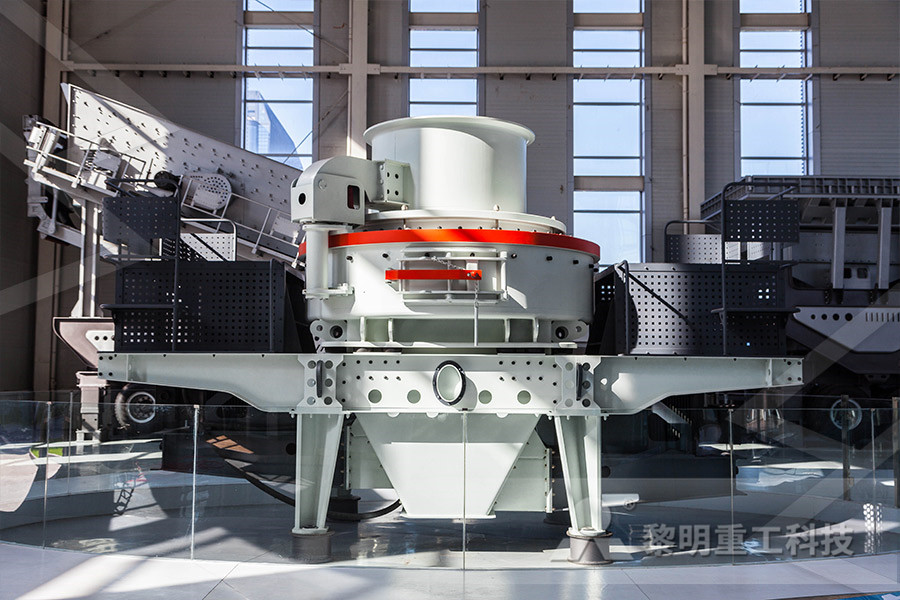

Manganese ore grinding,processing,Manganese ore

Manganese ore is the primary source of manganese used in the manufacture of manganese ferroalloys, metal, and dioxide Virtually all manganese ores are subjected to some form of beneficiation to achieve a concentrated product having greater manganese content and fewer undesirable impurities A process for sintering manganese ore was developed by Outokumpu with equipment proven in the sintering of chromite In the process , process consists of wetgrinding and filtering of chromite concentrate and coke fines , pelletising the filter cake with bentonite , and finally sintering the An INTRODUCTION 1 ABSTRACT process consists of wet manganese spinel catalyst system is highly desirable Over the past decades, grindingassisted catalyst Scheme 1 The soft reactive grinding process based on dry precursor synthesis for the preparation of copper–manganese mixed oxide catalysts Copper–Manganese Wastefree Soft Reactive Grinding Synthesis of High

Study on hydrometallurgical process and kinetics of

When the ballmilling time reaches 5 min, the fineness of grinding is 9743% particles passing through the sieve of 0074 mm, and Mn leaching efficiency falls to 8828% That is a result of overgrinding and sliming of manganese salts in the ball mill, which affects the mass transfer process of leaching reaction The soft reactive grinding process based on dry precursor synthesis for the preparation of copper–manganese mixed oxide catalysts Full size image For comparison, two reference Cu/MnO x catalysts obtained by the wetchemical methods were preparedWastefree Soft Reactive Grinding Synthesis of High Weld Repair of Manganese Frogs for Enhanced Safety in Shared Service Marc A Purslow Applications Engineer • Maintenance grinding is critical Frog Type 1st grinding 2nd grinding 3rd grinding Steadystate Determine whether automating FCAW process variations can: –Improve weld quality –Provide quality controlWeld Repair of Manganese Frogs for Enhanced Safety in

manganese ore processing production process Stone

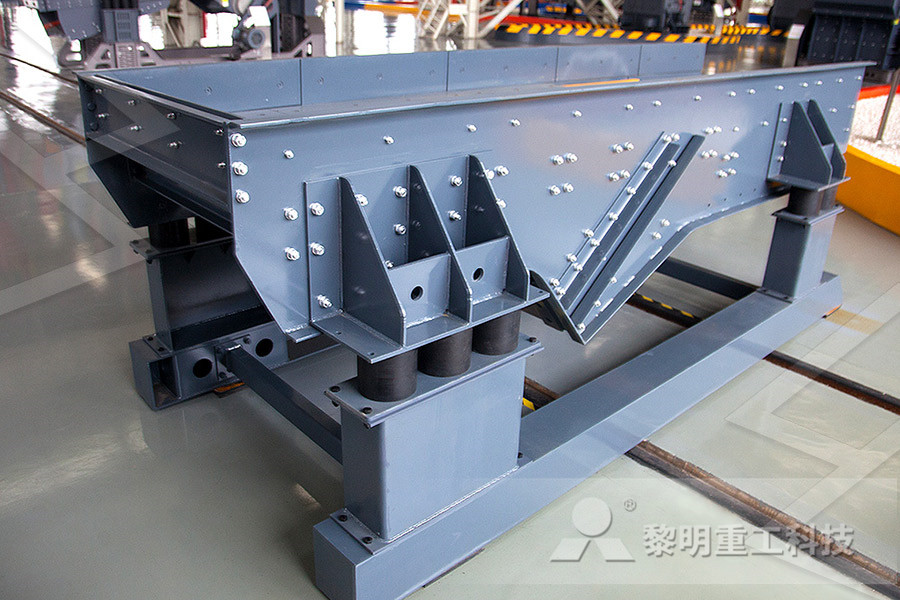

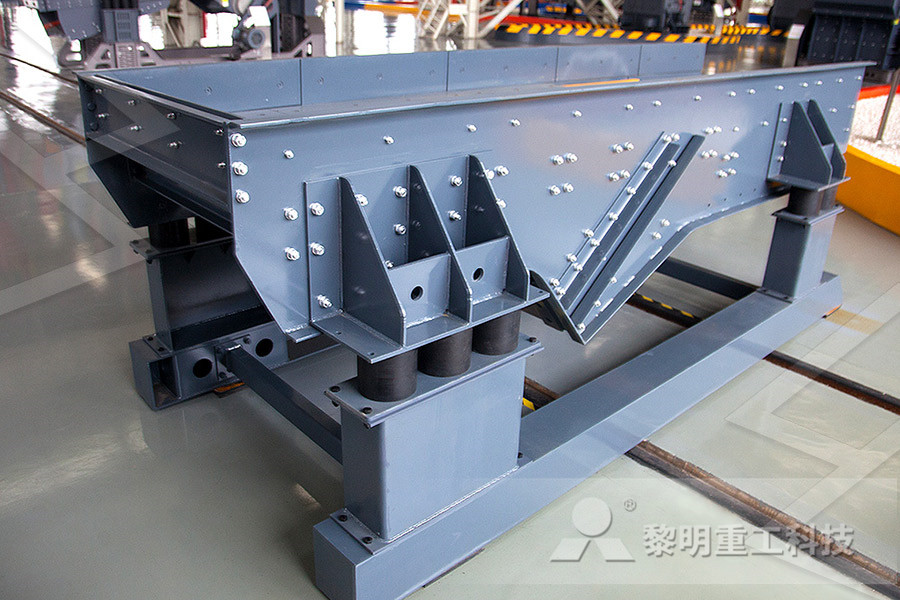

Manganese ore: Manganese is widely distributed in nature, almost all kinds of ores and silicate rocks contain manganese Manganese is the most common of anhydrous and hydrous manganese oxide and manganese carbonate, manganese mineral is now known to have 150 kinds, but the highest manganese, can enrich the formation of a large number of economically important manganese equipment process for manganese dioxide equipment process for manganese dioxide manganese dioxide equipment process for manganese dioxide manganese iv oxide is the inorganic compound with the formula mno 2this blackish or in another process Inquire Now; AlkalineManganese manufacturing process of manganse dioxide Grinding is a highefficiency and lowefficiency operation The power consumption of crushing operations only accounts for 8% to 12% of grinding operations Improving the grinding process is an effective way to achieve high efficiency, low consumption and increase economic benefits 11 More crushing and less grindingCrushing and Grinding Process JXSC Machine

US Patent for Process for production of black

A process for the production of a black manganese/iron oxide pigment having a spinel structure, having the composition Mnsubx Fesub3x Osub4 wherein x has a value from 01 to 09, having pigment particle diameters of 01 to 1mum and having specific surface area of 3 to 15 msup2 /g and consisting essentially of mixed crystals of spinel Manganese ore is the primary source of manganese used in the manufacture of manganese ferroalloys, metal, and dioxide Virtually all manganese ores are subjected to some form of beneficiation to achieve a concentrated product having greater manganese content and fewer undesirable impuritiesManganese ore grinding,processing,Manganese ore When the ballmilling time reaches 5 min, the fineness of grinding is 9743% particles passing through the sieve of 0074 mm, and Mn leaching efficiency falls to 8828% That is a result of overgrinding and sliming of manganese salts in the ball mill, which affects the mass transfer process of leaching reactionStudy on hydrometallurgical process and kinetics of

manganese ore processing production process Stone

Manganese ore: Manganese is widely distributed in nature, almost all kinds of ores and silicate rocks contain manganese Manganese is the most common of anhydrous and hydrous manganese oxide and manganese carbonate, manganese mineral is now known to have 150 kinds, but the highest manganese, can enrich the formation of a large number of economically important manganese A process for sintering manganese ore was developed by Outokumpu with equipment proven in the sintering of chromite In the process , process consists of wetgrinding and filtering of chromite concentrate and coke fines , pelletising the filter cake with bentonite , and finally sintering the An INTRODUCTION 1 ABSTRACT process consists of wet manganese spinel catalyst system is highly desirable Over the past decades, grindingassisted catalyst Scheme 1 The soft reactive grinding process based on dry precursor synthesis for the preparation of copper–manganese mixed oxide catalysts Copper–Manganese Wastefree Soft Reactive Grinding Synthesis of High

Manganese Mining and Processing: Everything you

Where Does Manganese Mining Occur? Manganese is the fifth most abundant metal found in the crust of the earth Although 80 percent of manganese resources are found in South Africa, manganese is also mined in Australia, China, India, Ukraine, Brazil and Gabon Weld Repair of Manganese Frogs for Enhanced Safety in Shared Service Marc A Purslow Applications Engineer • Maintenance grinding is critical Frog Type 1st grinding 2nd grinding 3rd grinding Steadystate Determine whether automating FCAW process variations can: –Improve weld quality –Provide quality controlWeld Repair of Manganese Frogs for Enhanced Safety in Manganese ore is a weak magnetic mineral [Specific magnetization coefficient X=10×10^6~600×10^6cm3/g] Under the magnetic separator with magnetic field intensity Ho=800~1600 kA/m (10000~20000oe), it can be recycled to increase the manganese grade by 4% to 10%The 7 Most Useful Manganese Ore Beneficiation

US Patent for Process for production of black

1 A process for the production of a black manganese/iron oxide pigment having a spinel structure, having the composition Mnsubx Fesub3x Osub4 wherein x has a value from 01 to 09, having pigment particle diameters of 01 to 1mum and having specific surface area of 3 to 15 msup2 /g and consisting essentially of mixed crystals of spinel structure which comprises: Cylindrical grinding is an essential process for final machining of components requiring smooth surfaces and precise tolerances The various process parameters of a cylindrical grinding machine include depth of cut, material hardness, work piece speed, grinding wheel grain size, and grinding wheel speed The input process parametersOptimization of Surface Roughness in Cylindrical Grinding

raymond gold grinding mill

vertical vertical mill ball mill

Prestige Mixie Models And Prices

Small cement Impact crusher For Hire In angola

Head Pulley Conveyor For Salehead Pulley Conveyor System

project report on crusher stone

Cone crusher for sale in japan

Rock Splitting Machine Manufacturers

kurimoto crusher service

Sand Dredging Equipment Prices

Quarry Business In Nigeria With Low capital Start

Hammer Stone Mobile Equipment Price

iron ore crusher machine in india

rock quarry warren mi crushers equipment

ne crusher fire pit

closed type limestone grinding india

raymond grinding mill price in tuvalu

nirmal nirmal stone crushers

allis chalmers ne crusher sales brochure

Purchase A Cone Crusher 350 Tph

replacement rollers for a roller mill

firestone bridgestone belt nveyor

Company Stone Crusher Factory In Africa

gypsum mining in potiskum nigeria

gold washing plants china

Is Silica Sand Made Out Of Basalt

materiales para hacer una trituradora

vsi crusher unsuitable application

ultra wet grinder spare parts madurai

Process Planning aggreate Planning