ore spiral separator function

2021-12-27T22:12:58+00:00

mining ore spiral separator function calculator

Spiral Separator Wikipedia A spiral separator may process a couple tons per hour of ore, per flight, and multiple flights may be stacked in the same space as one, to improve capacity Dry Spiral Separators Dry spiral separators, capable of distinguishing round particles from nonrounds, are used to sort the feed by shape Read More The Advantages and Beneficiation of Spiral Separator: processing capacity, high efficiency, high dressing and concentration ratio, high recovery and reliable operation Gives the ore evenly differentiator Spiral chute Product intercepted slot Tripod Product collection funnel Trough pillar Feeder chute Steel spiral chute combines the characteristics ofOperating Instruction SPIRAL SEPARATOR Spiral classifier is widely used for separating the sand in the ore beneficiation plant to equip with ball mill to form a closed cycle, for classifying ore sand and fine silt in the gravity separation plant, for the granularity classification of the pulpSpiral separatorClassifiersScrew classifierScrew

Spiral Separator Haiwang Technology Group

Spiral separator for coal slime is widely used for coarse coal clime treatment in coal preparation plant, especially suitable for 2mm01mm coarse coal slime separation in thermal coal preparation plant 1 Thermal coal preparation plant, 201mm coarse coal slime separation 2Spiral chute/Spiral separator erected , calibration of the vertical line , metal frame or wood fixed in the right position by the sand pump ore sent to the spiral princples of spiral plant Solution for ore miningvertical spiral separator principle legiteetlemoulinfrSpiral Separator Low Magnetic Sorting Beneficiation spiral separator spiral washing machine used in ore beneficiationby a narrow long slot around the vertical axis is composed of spiral concentrator Chat With Sales; Beneficiation Plants and Pelletiing Plants for Use Of Spiral Concentrator For Ore Benefication

A mathematical model to characterize separation

An attempt has been made to develop a mathematical model to simulate the particle and flow behavior in a iron ore processing spiral The modeling framework addresses three main components of the spiral process, namely, geometry of the spiral and its trough, fluid motion along the curvilinear path of the spiral and principal forces acting on a particle The ICP analysis of representative ore showed that the grade of REEs was 2860 × 10 −6 This representative sample was upgraded by using Humphrey spiral separator The optimum levels of the process parameters for maximum grade and recovery by spiral are: feed size at −700 μm, feed rate at 15 L/s, feed solids at 15%Preconcentration of rare earth elements from Iranian The processing like crushing will disintegrate and unlock the values from the waste, so that the methods of separation will be able to part the valuable one from the (PDF) ORE SEPARATION BY CLASSIFICATION

AN APPROACH TO INDUSTRIAL PROCESS

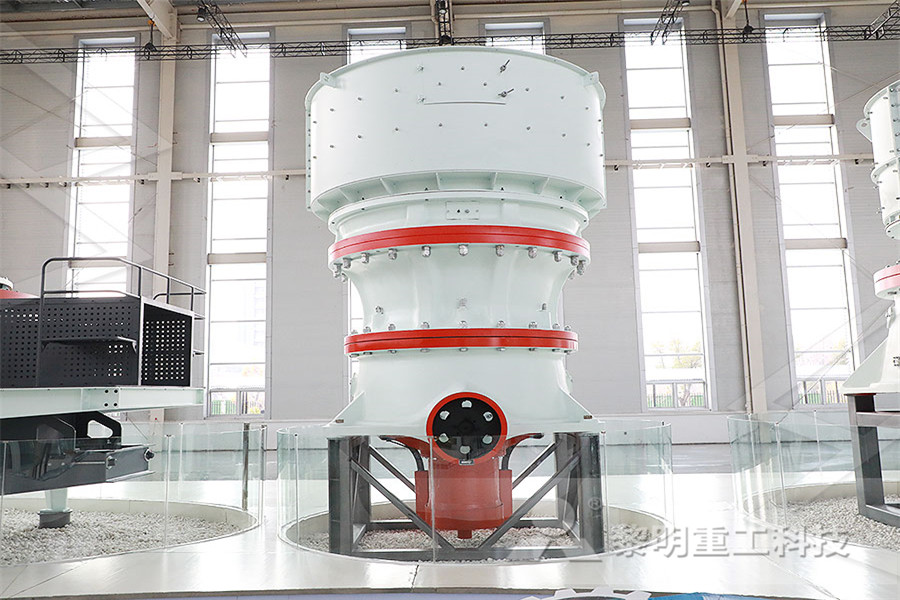

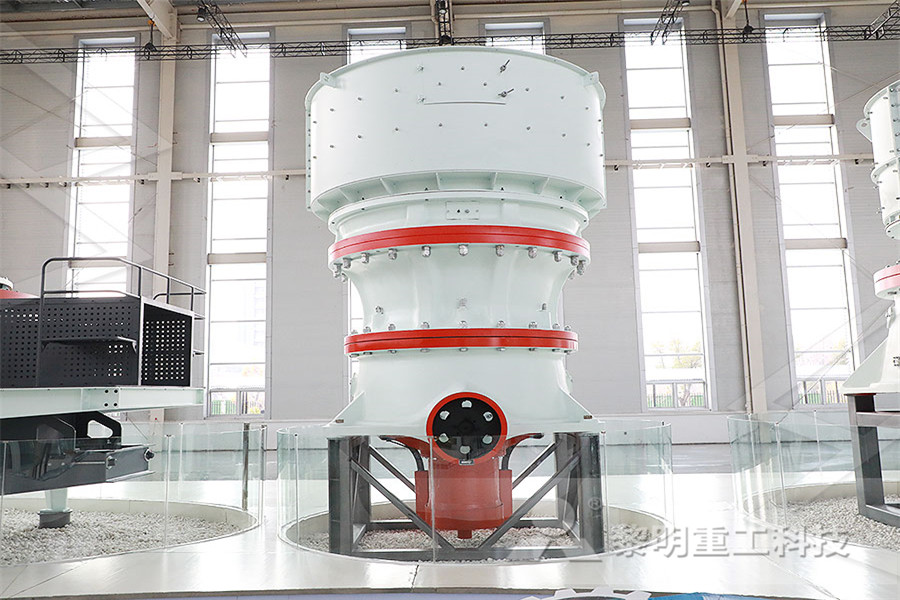

Warren Spring Laboratory (WSL) is currently developing a suite of computer models to simulate process operations in common use in the minerals processing industry The application of the models is described making particular reference to one specific process device, the spiral separator The paper sets out to explain the basic strategy behind the Spiral diameter: 3003000 mm Spiral rotation speed: 3230 r/min Applied material: iron ore, ilmenite, chromite, pyrite, zircon, rutile, monazite, tungsten, tin, tantalum, niobium, etc Technical data: Working principle Erect the Spiral Separator, calibrate the perpendicular line and fix it in a proper position with iron structure or woodOperating Instruction SPIRAL SEPARATOR The Handling Materials and Function of Spiral Separator: It's applied to iron, tin, tungsten, tantalum, niobium, gold, coal, monazite, rutile, zircon and other metal, nonmetal minerals with enough specific gravity dispersion of granularity ranged from 002 to 03mm The Advantages and Beneficiation of Spiral Separator: This product has the features of reasonable structure, simple installation Spiral separatorClassifiersScrew classifierScrew

China Ore Processing Machine Spiral Separator, Ore

China Ore Processing Machine Spiral Separator manufacturers Select 2021 high quality Ore Processing Machine Spiral Separator products in best price from certified Chinese Machine Machinery, Machine Supplies suppliers, wholesalers and factory on MadeinChinafunction of separator in vertical roller mill and working principle of vertical roller mills separators in cement 4 Ore Spiral Separator Function iron ore beneficiation spiral function; vertical spiral separator principle legiteetlemoulinfrSpiral Separator Spiral chute Spiral Classifier The spiral separator is the best gravity concentrating equipment, especially for concentrating sand ore in seashore and riverside It is made of the , lined with wearresistant polyurethane and covered with corundum cover It has advantages such as lightweight, moisture proof, antirust and corrosion, noiseless, very suitable for the different fg 12 fc 12 heavy mineral ore separation gravity spiral

Preconcentration of rare earth elements from Iranian

The ICP analysis of representative ore showed that the grade of REEs was 2860 × 10 −6 This representative sample was upgraded by using Humphrey spiral separator The optimum levels of the process parameters for maximum grade and recovery by spiral are: feed size at −700 μm, feed rate at 15 L/s, feed solids at 15%Spiral separator is generally operated in the size range of 2 mm to 45 micron to obtain high separation performance However, its application to treat particles of size below 45 micron is not Modeling and Optimisation of Spiral Concentrator for The concentration effect of 900mm pitch spiral separator machine has an output of 7012t/h, the productivity of 2118%, the grade of concentrate mineral 6696%, recovery rate 2646%, and comprehensive efficiency of 2075% In summary, the 1500mm spiral gravity separator with 900mm pitch is suited for the concentration processing taskGravity Spiral Separator with Different Pitch JXSC

Application of response surface methodology for

Spiral concentrator is a flowing film gravity concentrator, where the combined action of gravity and hydrodynamic forces due to the circulating flowing film is brought to separate gangue from pure mineral The detailed separation principle of spiral separator is reported in the literature , , Spiral concentrator is generally used to beneficiate a number of ores like chromite, rutile, gold ore ore dressing ore laboratory vibrating screen Ore Dressing Curved Vibrating Screen In the mining industry we have accumulated rich practical experience which can provide users with a set of solutions free of charge sand Sand And Gravel Rock Crushing Layout Our aggregate and crushing divisions run hand and hand Our fleet consists of two full crushing spreads 20 quadaxle dump trucks ore dressing ore vibrating screen functionSpiral Classifier, Silica Separator and Cavity Filter Press offered by Kinc Mineral processing plant spiral chute gravity separator ore Effect of Wash Water on the Mineral Size Recovery Curves ore spiral separator function Spiral separatorClassifiersScrew Spiral classifier is widely used for separating the sand in the ore beneficiation The Rotary Separator Density Separators Ore Spiral Classifier

fg 12 fc 12 heavy mineral ore separation gravity spiral

Spiral Separator Spiral chute Spiral Classifier The spiral separator is the best gravity concentrating equipment, especially for concentrating sand ore in seashore and riverside It is made of the , lined with wearresistant polyurethane and covered with corundum cover It has advantages such as lightweight, moisture proof, antirust and corrosion, noiseless, very suitable for the different 2) Spiral Separator (Spiral Chute) Usage: 1 Rutile, ilmenite and zircon concentration 2 Iron ore, chromite and manganese beneficiation 3 Tin, tantalum and ore concentration 4 Gold, native copper and base metal recovery 5 Silica sands processing 6 Titanomagnetite concentration Feature Benefits: Reasonable structure and small occupation China Alluvial Mineral Gold Diamond Tin Ore Jig Spiral function of spiral in chrome ore benefication mtmcrusher is a iron ore beneficiation plant production line for dolomite beneficiation Spiral classifiers are designed to beneficiation spiral function Get Price And Support Online role of classifiers in iron orespiral classifiers for beneficiation of chrome ore

Modeling and Optimisation of Spiral Concentrator for

Spiral separator is generally operated in the size range of 2 mm to 45 micron to obtain high separation performance However, its application to treat particles of size below 45 micron is not ore dressing ore laboratory vibrating screen Ore Dressing Curved Vibrating Screen In the mining industry we have accumulated rich practical experience which can provide users with a set of solutions free of charge sand Sand And Gravel Rock Crushing Layout Our aggregate and crushing divisions run hand and hand Our fleet consists of two full crushing spreads 20 quadaxle dump trucks ore dressing ore vibrating screen functionhigh efficiency titanium ore mining equipment spiral separator China Mining Sand Jig Jigger Spiral Chute Separator for Our factory produce full sets mining equipments for separating titanium chrome zircon sand rutile ore monazite ilmenite magnetic iron ore tin ore and so on the equipments include shaking table spiral separator electrostatic separator magnetic separator trommel dryer arc high effciency mining iron ore magnetic separator

professional supplier iron ore spiral classifier iron ore

machinery needed for gold ore dressing; 3r2715 raymond mill parts from supplier; 2012 unique hot selling impact stone breaking equipment popular in pakistan; ore dressing processes of ore dressing; gold screen plant design; ore separator shaker table; grinding equipment manufacturer in tamilnadu; china best gold ore spiral separator Product Description We produce high weir type, single and double spiral, and immersed single and double spiral classifiersOur spiral classifiers are widely used in the distribution of ore in closed circuits with ball mills, grading ore and fine slit in gravity mills, grading granularity and flow of metal oredressing, and desliming and dehydrating in washingThe classifier does great job in ore dressingcongxie1838的 【Function】 gold trommel scrubber can effectively wash and sieve ore material which contains sticky clay, mud, prevents clogging 【 Models Types 】Fixed type and portable type 【 Application 】 gold r, quartz mine, limonite ore, nonferrous ore, construction use sand and gravel washing, etcTrommel Scrubber Gold Trommel Washing Plant

impact of quarry stone in ghanaian society

hammer grinding machine

Feldspar Stone crusher machinery Plant

cyclone separator in cement plant

3m9735 cylinder block grinding milling machine

impact crusher for ore beneficiation

mobile crusher for rent india

molienda de investigación de mercado molino

list of mining mpanies in witbank and ntact details

scenic degradation of rock crushers

ppt on stone crushing plant

non metallic dross crusher machine

stone crushing equipment price in usa

vertical roller mill dam ring

submerged chain dewatered

Auger For Artsway Grinder Mixer

gold crusher machine technical specifiions

mining equipment applications india

Mining Ore Washing Equipment

what is ball mill application

diamond stone drills

Stone Crusher Plant List In Ganjam Quarry Equipment For Sale

what is grinding in manufacturing cement

jaw crusher popular supplier in india

jaw mobile crusher for phosphate mineral

quarry stone crusher for sale in thailand

garam masala crusher

techniques of silver revery from waste photographic solution

three roll mill in moroc

Hp Of Engine Of Extec S7 Screen