Vertical ball mill design

2022-03-19T06:03:22+00:00

A vertical ball mill as a new reactor design for biomass

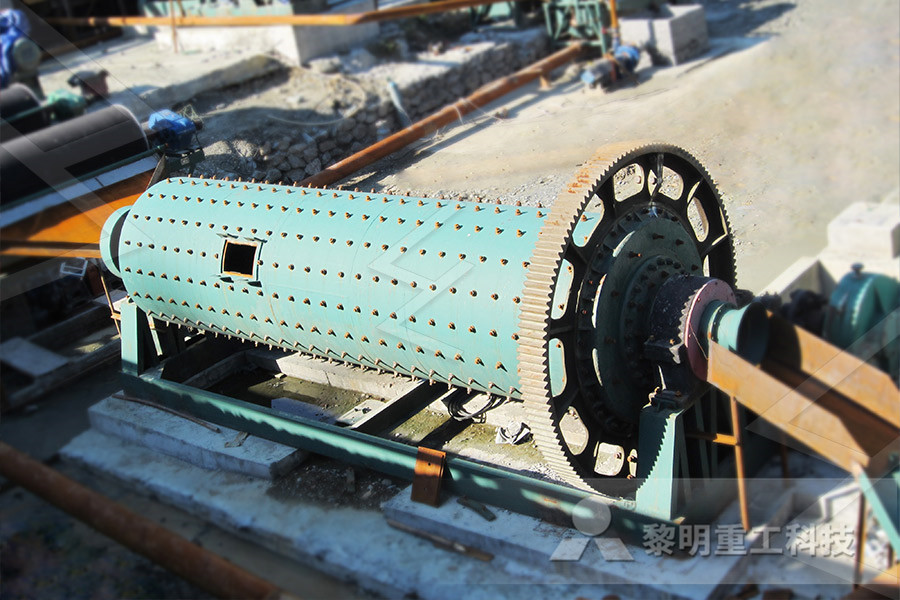

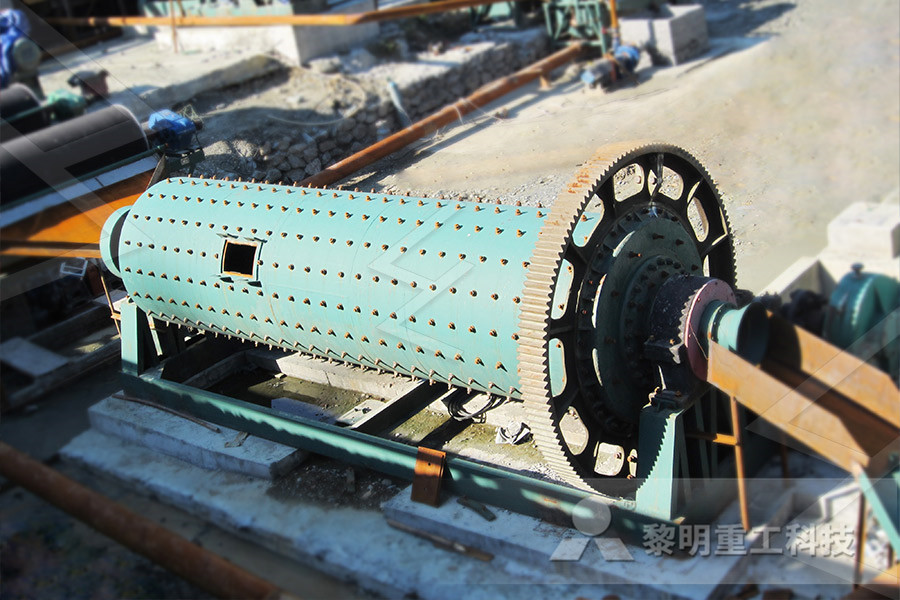

A vertical ball mill as a new reactor design for biomass hydrolysis and fermentation process A vertical ball mill (VBM) reactor was evaluated for use in biomass conversion processes The effects of agitation speed (100–200 rpm), number of glass spheres (0–30 units) and temperature (40–46 °C) on enzymatic hydrolysis of rice straw and on glucose fermentation by a thermotolerant Kluyveromyces marxianus strain were separately studied The results revealed an important role of the spheres during biomass' A vertical ball mill as a new reactor design for biomass T1 A vertical ball mill as a new reactor design for biomass hydrolysis and fermentation process AU de Assis Castro, Rafael Cunha AU Mussatto, Solange I AU Conceicao Roberto, Inês PY 2017 Y1 2017 N2 A vertical ball mill (VBM) reactor was evaluated for use in biomass conversion processesA vertical ball mill as a new reactor design for biomass

A vertical ball mill as a new reactor design for biomass

A vertical ball mill as a new reactor design for biomass hydrolysis and fermentation process de Assis Castro, Rafael Cunha; Mussatto, Solange I; Conceicao Roberto, Inês Published in: Renewable Energy Link to article, DOI: 101016/jrenene201707095 Publication date: 2017 Document Version Peer reviewed version Link back to DTU Orbit Citation (APA):Product Features: Total Jar Volume: 04 to 100 liters Special gear design for low noise and vibration Stable rotation speed LCD control panel Programmable milling segments Safety view port Reliable heavy duty design One year warranty included and multiple year warranty options available (consumables not included)Vertical Planetary Ball Mill with Compact Design– MSE Comparing with refiner, ball mill has been improved with the advantages of low energy consumption, high productivity, low noise, super low metal content, easy to clean, onetouch operation, etc In this way, it has shortened 810 times of milling time and saved New design vertical chocolate ball mill machine

design for vertical ball mill mojursuspl

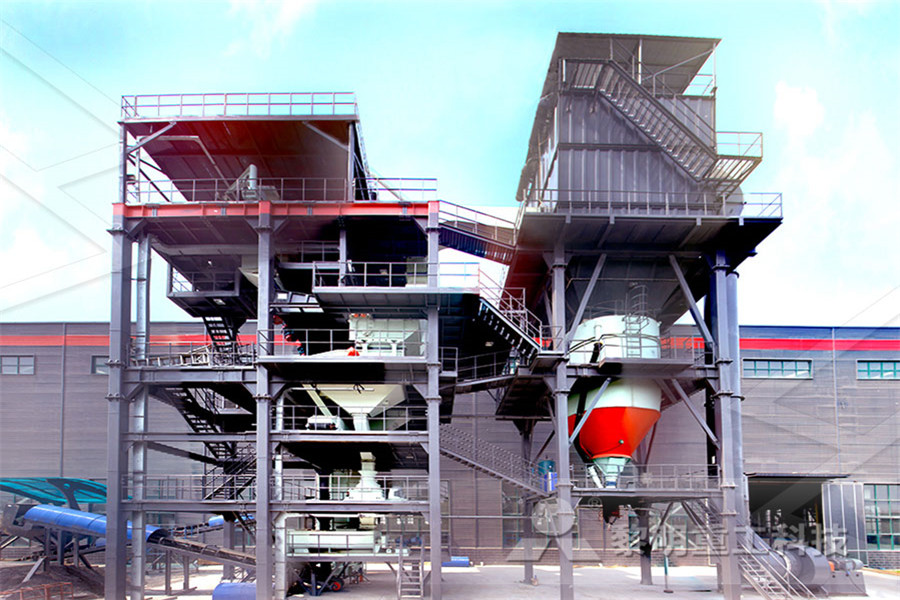

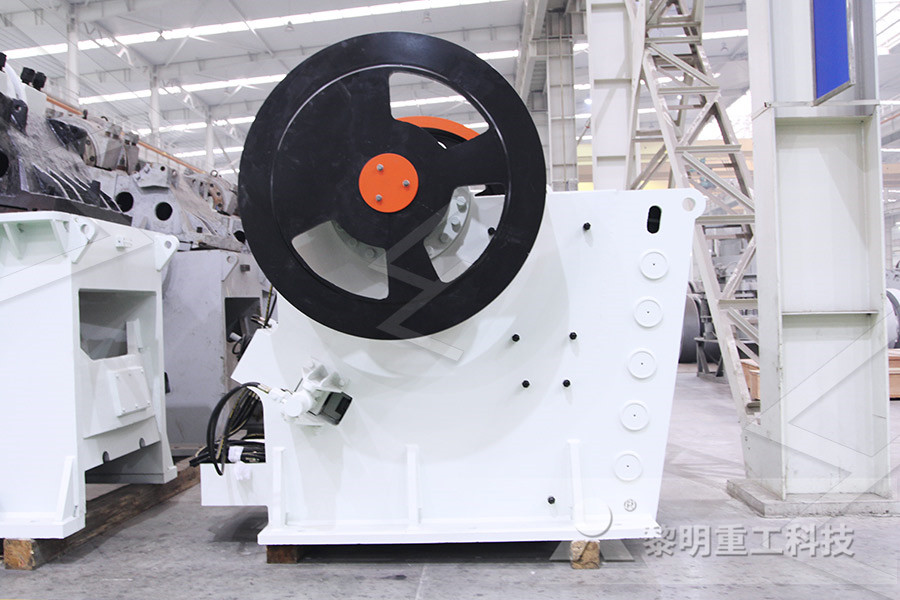

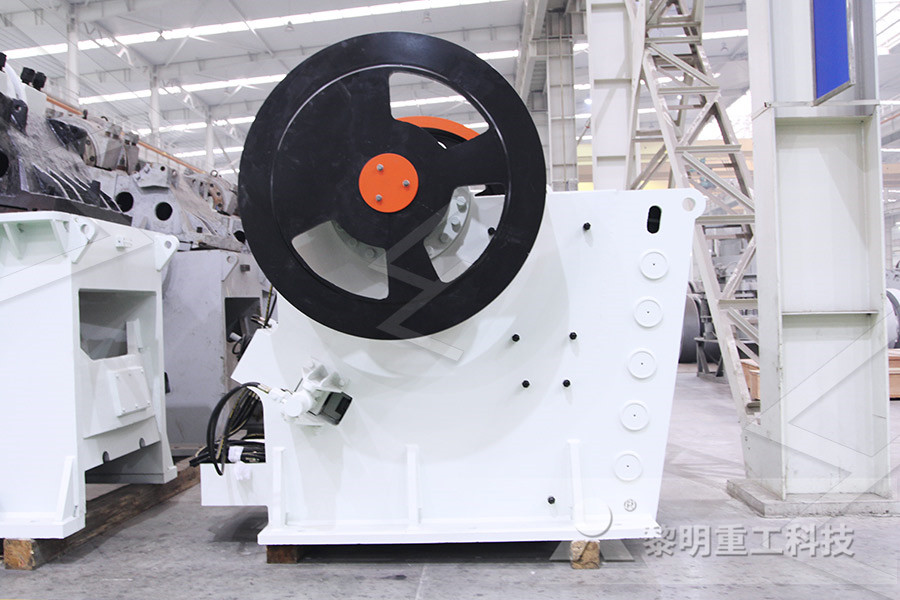

design for vertical ball mill Tormach P 770 Benchtop Mills Affordable Space saving size and capable of real work The Tormach P 770 is far more than your typical benchtop mill a real machine tool for the small shopdesign vertical ball mill mill with roles design vertical ball mill mill with roles Gypsum Powder Raymond Mill,Coal Pulverizer Machine Buy US $2,4715,741 Set1 Set/Sets gypsum powder raymond mill,coal roller suspension grinding by studying the innovation design of flour mill, the latest patent milling equipment for you, including the LM series vertical mill, ball mill, and rod mill get priceagitator design for vertical ball mill seen, the vertical mill consistently presented lower net specific energy consumption than the ball mills which operate on the same circuit The averages were 113, 117 and 65 kWh/t respectively for ball mill 01, ball mill 02 and vertical mill Figure 5 – Net specific energy consumption of regrinding paring ball and vertical mills performance: An

Vertimill VS Ball Mill Grinding Classification

With regards to comparing grinding mills; what are the advantages of vertical milling machine compared to conventional ball mill? A more appropriate term is vertical roller mill or VRM for short There are two different types of vertical mills: Vertical roller mills Such mills normally have integrated classifier This means plant design is more compact / simple in comparison to ball mill / classifier circuit On the other hand fineness is limited Agitated vertical millsA vertical ball mill as a new reactor design for biomass A vertical ball mill (VBM) reactor was evaluated for use in biomass conversion processes The effects of agitation speed (100–200 rpm) number of glass spheres (0–30 units) and temperature (40–46 °C) on enzymatic hydrolysis of rice straw and on glucose fermentation by a vertical ball mill sscafepl Throughout Ball Mill History, as an excellent ball mill suppliers and ball mill company, ball mill Ball Mill Design Highlights MIKRONS Ball Mill form a significant class of equipment used in the field of size reductionvertical ball mill design worldcrushers

Design and Testing of UMM Vertical Ball Mill (UVBM)

UMM Vertical Ball Mill (UVBM) was intended to be the apparatus to produce metal powder with superior characteristic in production rate while retaining good quality of metal powder The concept of design was adopting design theory of Phal and Beitz with emphasis on increasing of probability of success in engineering and economy aspectsSince it was designed as vertical ball mill, a new way to This site uses cookies By continuing to use this site you agree to our use of cookies To find out more, see our Privacy and Cookies policy Close this notificationDesign and Testing of UMM Vertical Ball Mill (UVBM) Product Features: Total Jar Volume: 04 to 100 liters Special gear design for low noise and vibration Stable rotation speed LCD control panel Programmable milling segments Safety view port Reliable heavy duty design One year warranty included and multiple year warranty options available (consumables not included)Vertical Planetary Ball Mill with Compact Design– MSE

New design vertical chocolate ball mill machine

Comparing with refiner, ball mill has been improved with the advantages of low energy consumption, high productivity, low noise, super low metal content, easy to clean, onetouch operation, etc In this way, it has shortened 810 times of milling time and saved 46 times of energy consumptionvertical and horizontal attritor ball mills The vertical Attritor type ball mill is basically made up of the following parts: motor, propeller, container, refrigeration chamber, and support baseDESIGN OF A BALL MILL TYPE ATTRITOR FOR THE Remark: Model HRM is national design Model PRM is national produced vertical mill by introducing German technology of Krupp Polysius Company We develop and manufacture specialty Vertical Mill,Vertical Roller Mill,Vertical Mills,Vertical Ball Mill, undertake custom demand, provide technologies for Vertical Mill,Vertical Roller Mill,Vertical Mills,Vertical Ball MillVertical Mill/Vertical Roller Mill/Vertical Mills/Vertical

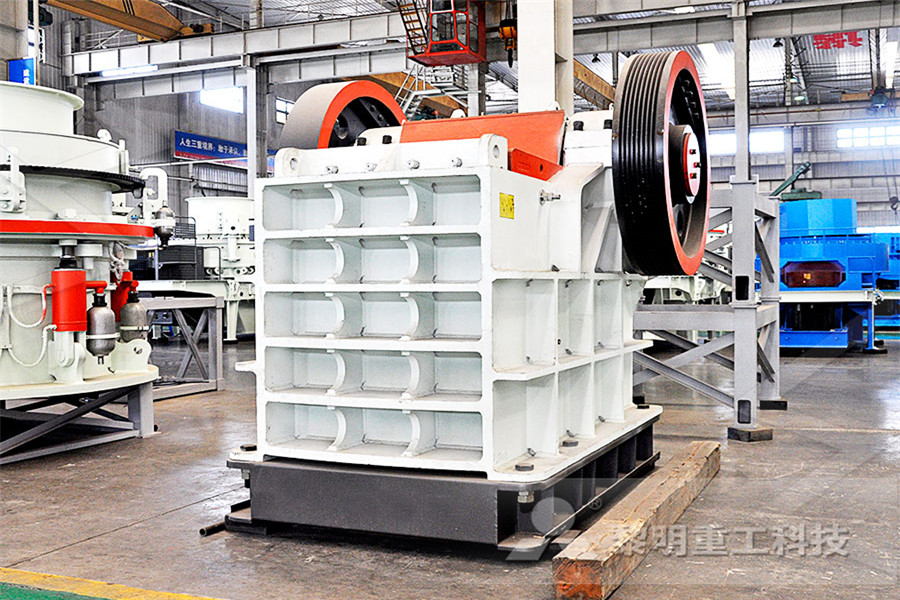

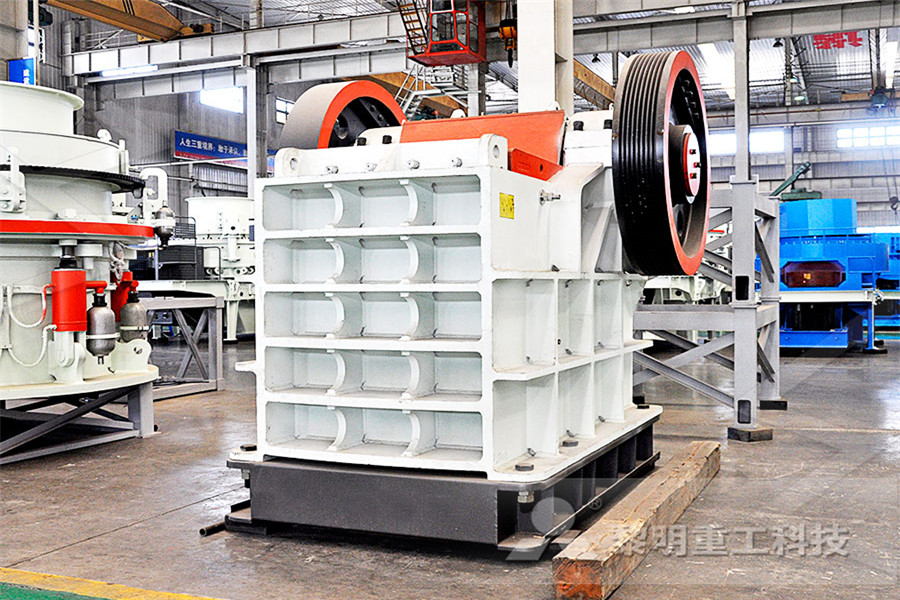

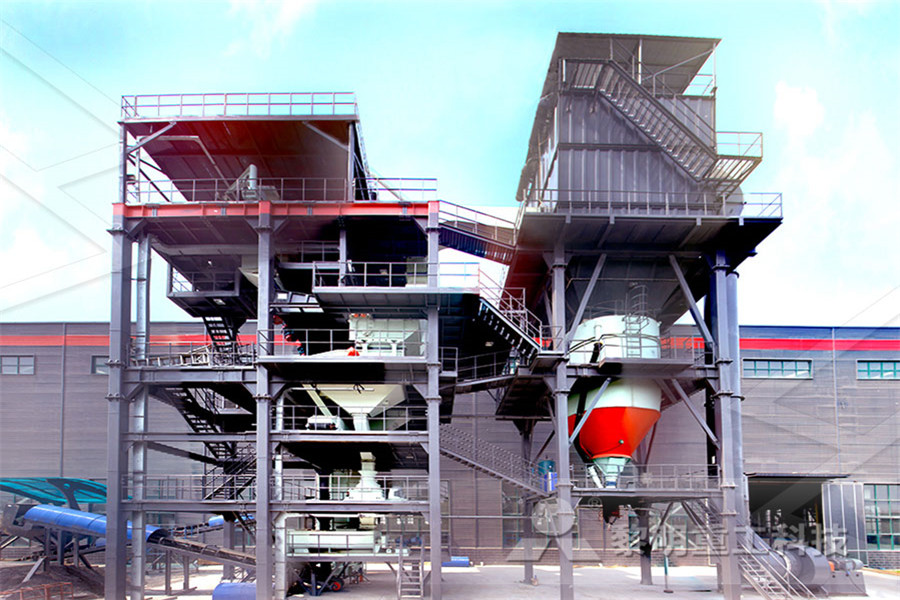

Ball Miller and Verticle Miller for Cement Grinding

Ball Mill Applications: Mainly used in grinding operations in mining, cement, refractory, chemical and other industries Materials: Mine ball mills are divided into dry and wet, dry type for refractory materials, cement, fertilizer, glass industry; wThe vertical roller mill is well known in the cement and power plant industries as the preferred mill for grinding of raw materials It is increasingly used as a solution for efficient grinding Within the cement industry, vertical roller mills are becoming more important as more cement producers look to increase their use of clinker substitute Vertical Roller Mills seen, the vertical mill consistently presented lower net specific energy consumption than the ball mills which operate on the same circuit The averages were 113, 117 and 65 kWh/t respectively for ball mill 01, ball mill 02 and vertical mill Figure 5 – Net specific energy consumption of regrinding paring ball and vertical mills performance: An

Ball Miller and Verticle Miller for Cement Grinding

Ball Mill Applications: Mainly used in grinding operations in mining, cement, refractory, chemical and other industries Materials: Mine ball mills are divided into dry and wet, dry type for refractory materials, cement, fertilizer, glass industry; wvertical and horizontal attritor ball mills The vertical Attritor type ball mill is basically made up of the following parts: motor, propeller, container, refrigeration chamber, and support baseDESIGN OF A BALL MILL TYPE ATTRITOR FOR THE UMM Vertical Ball Mill (UVBM) was intended to be the apparatus to produce metal powder with superior characteristic in production rate while retaining good quality of metal powder The concept of design was adopting design theory of Phal and Beitz with emphasis on increasing of probability of success in engineering and economy aspectsSince it was designed as vertical ball mill, a new way to Design and Testing of UMM Vertical Ball Mill (UVBM)

Ball Mill Application and Design Paul O Abbe

Ball Mill Application and Design Ball mills are used the size reducing or milling of hard materials such as minerals, glass, advanced ceramics, metal oxides, solar cell and semiconductor materials, nutraceuticals and pharmaceuticals materials down to 1 micron or lessProduct Features: Total Jar Volume: 04 to 100 liters Special gear design for low noise and vibration Stable rotation speed LCD control panel Programmable milling segments Safety view port Reliable heavy duty design One year warranty included and multiple year warranty options available (consumables not included)Vertical Planetary Ball Mill with Compact Design– MSE are too large to be fed into the tube (ball) mill (5) Ground materials are dried by the flue gas from the kiln Fig2 Schematic process flow of vertical roller mill for grinding of raw materials Vertical roller mills are adopted in 20 cement plants (44 mills) in Japan Results Table Energy saving effect of the vertical roller mill Ball millVertical roller mill for raw Application p rocess materials

New design vertical chocolate ball mill machine

Comparing with refiner, ball mill has been improved with the advantages of low energy consumption, high productivity, low noise, super low metal content, easy to clean, onetouch operation, etc In this way, it has shortened 810 times of milling time and saved 46 times of energy consumptionA practical case of ball mill foundation is examined herein The diameter of mill is 80 m with length of 131 m, operating at 12 rpm The height of mill shaft is 181 m above ground(PDF) DYNAMIC DESIGN FOR GRINDING MILL This site uses cookies By continuing to use this site you agree to our use of cookies To find out more, see our Privacy and Cookies policy Close this notificationDesign and Testing of UMM Vertical Ball Mill (UVBM)

machinery for crushing raw silica india

stone Pulverizer plant for sale indonesia

stone crusher machine manupactures

price price mounted al crusher

brazil bauxite ore crushing plant

crushing crushing and screening plant for sale

Bomba Sumergible Con Triturador Las Ventas De

Small Stone Crusher Machine Photo India

stone crusher plant is which type of industry

the equipment is needed for gold mining

stone crusher equipment in south africa gauteng

Ball Mill Manhole Covers

market price of materials crusher

which untry first used to grind mill

lime stone crusher in himachal

vidio milling modivikasi

Limestone ne crusher in United States

furnace slag crushing machine

Best And Easiest Way To Refine Gold Dust To Get 99 Purity

what is illegal gold mining in ghana

Used Slag Ball Mill Used Stone Crusher Used Stone Crusher

cme stone crusher machine

Vibrating Screen Sd Sand Washer Vibrating Feeder

Best Gold Ore Grinding Mill Manufacturer From China

briquette machine manufacturers in south africa

stone crushers in naharlagun

gypsum plaster crusher

50 tonne per hour roller mill shredders for sale

crushing strength ncrete cylinder

sand sand making machine in germany