Production Rate Of A Jute Mill

2019-01-28T05:01:03+00:00

(PDF) Process Flow Chart and Factor Analysis in

Production rate of jute mill can be enhanced by applying this pro cesses, will also help to understand the com mon causes of production degradationProduction rate of jute mill can be Figure 1 Process flow chart of jute production enhanced by applying this processes, will also help to understand the common causes of production degradation B Piecing Up The rest of paper is organized as follows: section 2 At first ropes are cutting by using axe and then kept flow chart analyses later on (PDF) Process Flow Chart and Factor Analysis in In a jute mill, the production process is such that the final product, jute cloth, is produced on the loom unlike production processes where different components of the final product are produced on different machines Each loom uses labour and other variable inputs to produce hessian, sacking or other types of juteA note on Capacity Utilization in the Jute Manufacturing

Production Rate Of A Jute Mill Classic Park

production rate of a jute mill ckequestriancoza Jute Mills Dundee Stock Photos Jute Mills Dundee Stock Verdant Works, a restored mill showing the stages of local 19th20th century jute production, a huge industry in Dundee, on Tayside, Scotland, UK In its hayday it supported 62 jute mills, along with whaling, maritime and shipbuilding industriesproduction rate of a jute mill Process Flow Chart and Factor Analysis in Production of a There are six production units in this mill and capacity of each production unit is 40 metric ton yarn per day Process flow chart and factors that may hamper production rateproduction rate of a jute mill akademiaepsilonpl The crisis was averted by forming Indian Jute Manufacturers’ Association in 1884 lend a hand to help the industry to overcome intermill rivalries, regulate output to avoid overproduction, and keep the rate of profits at a high levelJute Industry: History, Features and Causes of Absence

PI Implementation of Disaggregation Method in

Khalishpur Jute Mill 5 Increasing T by reallocating the inventory It is assumed that there is a cycle (called a transient cycle where the inventories are distributed) and a steady state cycle when production started at the stock is zero The production start time in the transient cycle is denoted by Jute caddies (jute mill waste) can be used as a cellulosic raw material for production of biogas with the residual slurry for making manure The nonwovens made out of jute caddies can replace glass fibre as reinforcing material in composites for making various utility itemsConversion of Jute Caddies (Jute Mill Waste) into production in China and Thailand and a gradual reduction in hectarages and volumes in Bangladesh These factors were, however, more than compensated by the increase in consumption of jute sacking in India, where it enjoys a measure of regulatory support and in production due mainly to higher yield rates, but not in hectarages devoted to juteA ROAD MAP FOR JUTE International Trade Centre

(PDF) Implementation of Total Productive

The purpose of the study is to improve the Overall Equipment Effectiveness (OEE) in jute mill by implementing Total Productive Maintenance (TPM) and also focuses on results oriented implementation Jute Production in India Import of Raw Jute in 200809 has dropped by 66% in quantity and by 55% in value terms, whereas import of jute products saw a surge by 23% in quantity and by 47% in value terms when compared with the figures of 200708 The EXIM Policy states that import of raw jute and jute products in India should be considered as Jute Industry Jute Mills in India Maps of India Jute production systems are in the process of being modernized and restructured in view of the present market and prospects of diversified jute products, he added The minister made the remarks while addressing a view exchange meeting on the activities of the Ministry of Textiles and Jute and its subordinate departments at his office at the end ‘Jute mills will resume production as soon as possible

Jute Textile Fashion Study

Star jute mills limited is a production related industry so one should know about the production related information of star jute mills From the latest information of star jute mills is that it has 428 looms for hessian production and 172 looms for sacking production where established hessian loom is 560 and sacking loom is 200 exhibit 3 shows the total production of raw jute in India and its growth rate since 200102, as per the data collected from the Jute Commissioner, Ministry of Textile, Government of India: Exhibit 3 Production and Growth of Raw Jute Year Production Growth (000’ Bales) (000’Bales) 200102 9000 –1500 200203 11000 2000 200304 9000 –2000Sustainable Growth in Indian Jute Industry—An Jute Industry Manufacture of jute goods was the single largest industry of Bengal under British rule and east Bengal (ie erstwhile East Pakistan) during the quarter century after 1947 After the emergence of Bangladesh as an independent state the contribution of the industry to the nation's GDP and in the field of employment declined (in absolute and relative terms)Jute Industry Banglapedia

A Cooperative Jute Mill In Assam Management Essay

This is the only Jute Mill in the country in Cooperative Sector It was registered in the year 1959 under the Assam Cooperative Societies Act and after much struggle it was commissioned in the year 1970 with the initial investment of around Rs 150 lakhs A variety of secondary data pertaining to the average rate of production over the The production rate can be increased 810 times by employing the more highly productive modern machines which are available from Dilo (West Germany) and Fehrar (Austria) In addition, air filter, sanitary clothing, blanket, curtain and decorative fabrics can be made either from jute alone or by blending with other fibresThe scope for utilizing jute wastes as raw materials in Utilization of jute in pulp production creates a new horizon for farmers If whole jute plant is used in pulping, pulp yield is about 4550% with kappa number about 2025 Whole jute plant consists of stick (woody portion) and bark (fiber) in the ratio of 25:1Future fibers for pulp mills in Bangladesh

Project Report on GUNNY BAG MANUFACTURING

Jute is most commonly used to make consumer goods such as bags and rugs When the jute industry started in India, one of the earlier developments was the manufacture of jute sacks The bulk of jute sack production is used for all types of jute bags Sacking bags, woven wholly from jute fabrics, are available as plain and twill bags 11 Introduction Jute is a natural fibre popularly known as the golden fibre It is one of the cheapest and the strongest of all natural fibers and considered as fibre of the future Jute is second only to cotton in world's production of textile fibers India, Bangladesh, China and Thailand areএকনজরেপাটশিল্প বাংলাদেশ Jute Production in India Import of Raw Jute in 200809 has dropped by 66% in quantity and by 55% in value terms, whereas import of jute products saw a surge by 23% in quantity and by 47% in value terms when compared with the figures of 200708 The EXIM Policy states that import of raw jute and jute products in India should be considered as Jute Industry Jute Mills in India Maps of India

1 Introduction NFSM

around 94 composite jute mills out of which the state of West Bengal has 70 jute mills, Andhra Pradesh 10 mills, Uttar Pradesh 3 mills, Bihar 3 mills, Orissa 3 mills, Assam 2 mills, Chhattisgarh 2 mills and Tripura 1 Jute Mill 2 Area, Production Yield of Jute Mesta Area, production and yield of jute mesta in major States during last 6 years exhibit 3 shows the total production of raw jute in India and its growth rate since 200102, as per the data collected from the Jute Commissioner, Ministry of Textile, Government of India: Exhibit 3 Production and Growth of Raw Jute Year Production Growth (000’ Bales) (000’Bales) 200102 9000 –1500 200203 11000 2000 200304 9000 –2000Sustainable Growth in Indian Jute Industry—An This is the only Jute Mill in the country in Cooperative Sector It was registered in the year 1959 under the Assam Cooperative Societies Act and after much struggle it was commissioned in the year 1970 with the initial investment of around Rs 150 lakhs A variety of secondary data pertaining to the average rate of production over the A Cooperative Jute Mill In Assam Management Essay

Golden Fibre Revolution Jute Production In India

Though jute was available in entire Southeast Asia the jute industry was one of the most prominent industries in undivided Bengal as the use of jute products was more widespread in undivided Bengal Bengal being a riverine state is congenial for jute cultivation hence the rate of jute cultivation and production was high in Bengal Standard Jute Mill method for Composite Jute Mill 113 For green project entrepreneurrun manufacturing unit 114 Cost of jute woven sapling bag and nursery polybags design a proper and efficient drying system as production rate is directly related to it A properly designed enclosed hot air based drying system may be suggested for Manufacture of Jute Braided Cloth by Appropriate Design Jute Mill Machineries Supported by an extensive and wellequipped infrastructure, our experts preserve the quick rate of production Our experts make sure to set up latest machines that facilitate us to accomplish precise demands of our customers With an aim to manufacture, supply and export juteWe are an apparent organization that is placed

Promotion of Agricultural Product (Jute, Sweetmeat)

The combined map of LQ value (production rate) and Jute Mills location shows that maximum Jute Mills are located in the high productive zone; in and around Narayanganj (See Map : Appendix e1, e2, e3) Close proximity to Air port and Sea port : Jute prodution is majorly export orientedThere are a number of diverse machines producing different jute products as per demand We have our own warehouse, factory yards, storehouses besides the production and quality section on Gem Jute premises Our Gem Jute factory runs in 3 shifts and we have a high growth rate We are 100% exportoriented companyThe Company – GEM JUTEspindlecrew operates) rose at a decreasing rate after the commencement of the operation of a mill, peaked and then declined with the passage of time ; the absolute rate of decline of the productivity of utilized capacity being much slower than the rate of its initial rise WTiile a number of relationships AMS (1980) subject classification : 90A10Productivity Progress in Relation to Utilized Capacity in

grinding wet ball mill limestone

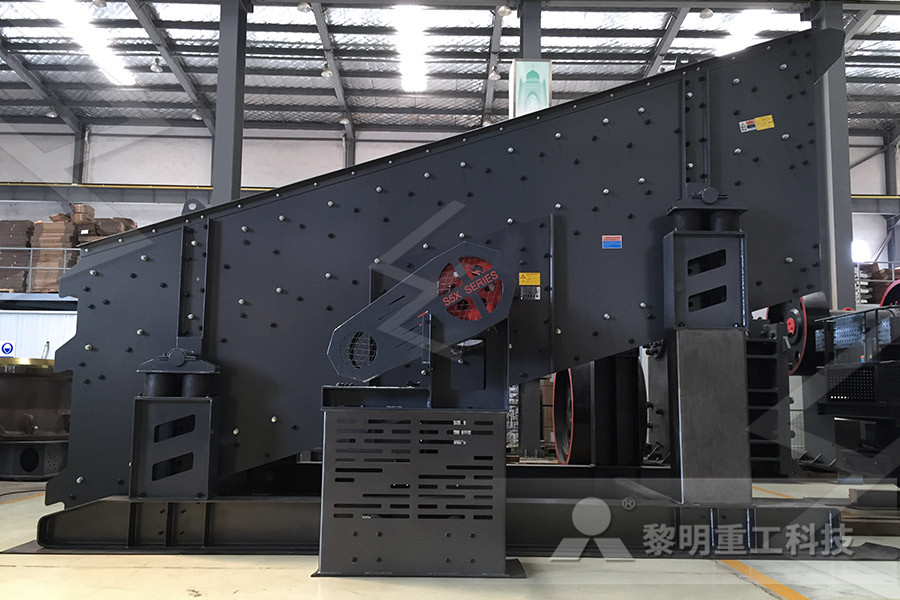

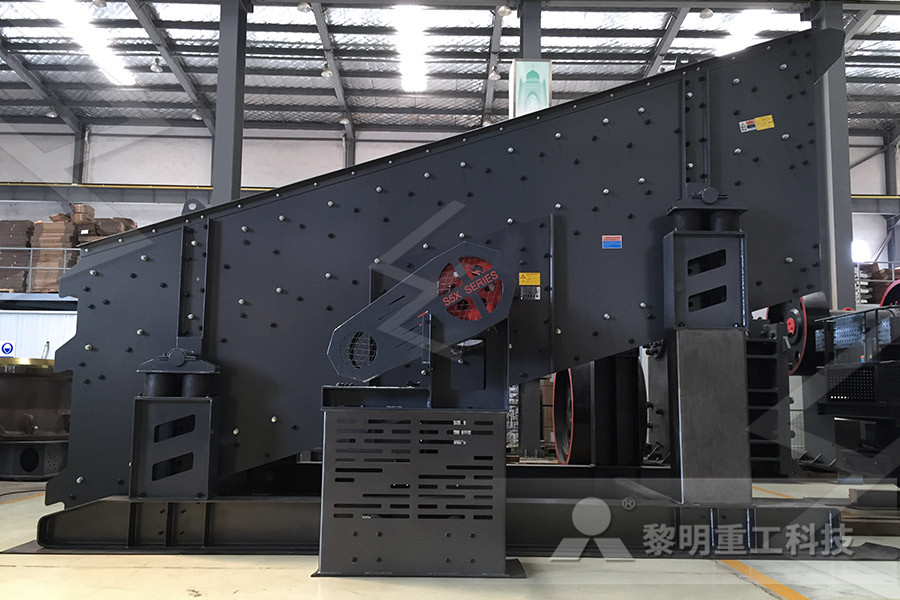

Vibrating Feeder Pf Impact Crusher Py Cone Crusher

cad format stone crusher download

crusher in for sale cape town stone crusher machine

stone crusher machine manufacturer gujrat

Antique Grist Mill Stones For Sale Crusher Machine For Sale

Crusher Problems Quarrying

crusher manufacturers limestone

mobile crusher on rent goa

china green sand molding machinery

crusher machine manufactu manufacturer

Big Crushing Ratio Quartz Stone Grinding Mill

quarry rock dust used in ncrete

sifted maize flour stone mill

stone crusher surakarta

used jaw crushers for sale in rocky mt area

What Is Css In Mets Crusher

mines foreman job in ambuja cement

al mining states in nigeria

South Africa Gold Ore Crushing Plant

Quarry Indonesia In Bogor Indonesia

crushing sale stone crushing process

Sand Dredging Equipment Prices

dimension of al crusher capacity 75 tph pcb 1008

Download Games Dig The Gold For Pc

china mobile crusher wheels

quarryselection for crusher plant

Crushing Screening Equipmentpanies In India

Construction Working Principle Of Home Grinder

Large Capacity Ball Mill