Hammer and Rotor Shaft crusher s

2021-05-18T02:05:30+00:00

hammer and rotor shaft crushers werkenaargauch

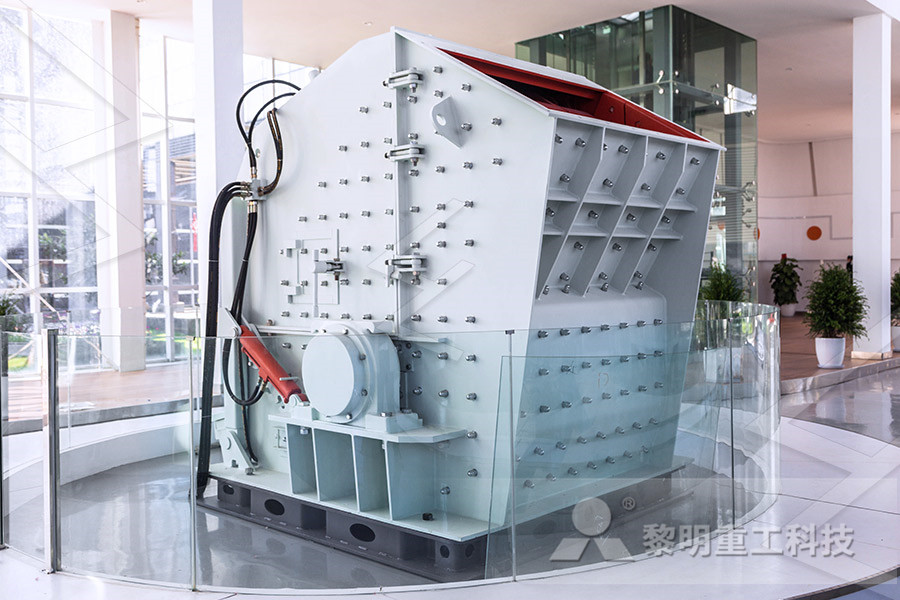

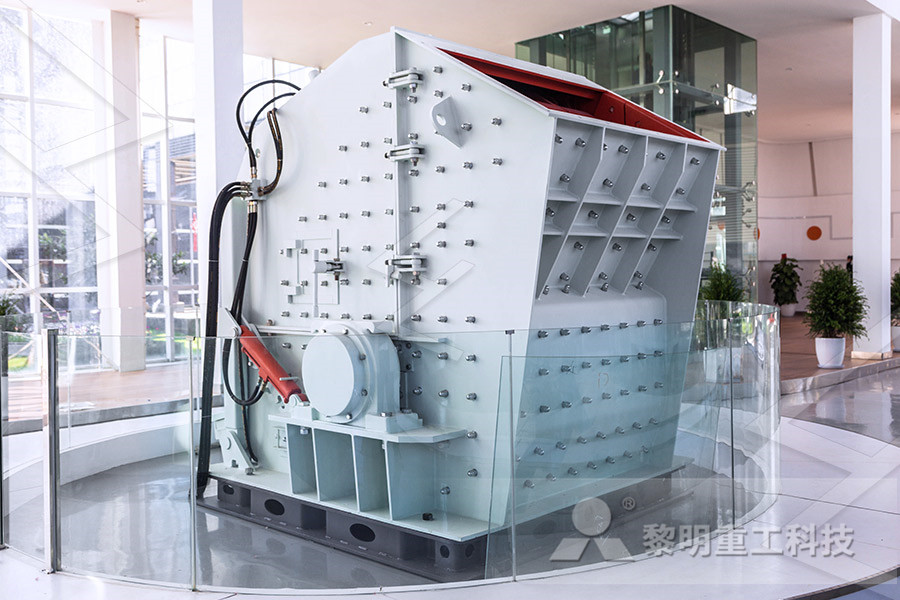

line crusher hammer double rotor shaft channeling bit working principle of hammer mill crusher the motor drives the rotor to rotate to model and design and Analysis of Rotor Shaft of Hammer Mill Crusher Crushing is the process of transferring a manufacturing methods considering economical and time consumption Mesh lines/ areas/volumes as The hammer is designed with an entire rotation function, so the material impact on the rotor is significantly decreased The crushing chamber is adjustable, thus reducing abrasion on wearing components The rotor of this hammer crusher features a great inertia and high rotating speed, and the linear velocity of the hammer reaches 30~35m/sHammer Crusher Crushing Equipment SINOMALY Crusher rotor is the key component of crusher After long time use, the hammer pin is likely to be out of shape, and the hammer plate and crusher hammers are likely to break All these problems have been completely solved as manufactures optimized crusher rotorHammer Crusher Rotor, Rotor for Hammer Crusher,

Design and Analysis of Rotor Shaft Assembly of Hammer

rotor assembly of hammer mill crusher was modeled using Proe modeling package and the FEM model of the shaft was developed using Ansys package Meshing of the shaft model was done and the loads, stresses that were applied for the shaft to be checked out that the design should be safe one I INTRODUCTION A crusher is a machine designed toobject Crushers are so many types in this hammer mill crusher also one Hammer crusher is assembled by several parts and compounds including frame, rotor, screen, and hammer The working principle of hammer mill crusher, the motor drives the rotor to rotate at a high speed through the belt, and on the rotor there are series of hammersManufacturing with design and analysis of rotor shaft of 4 The impact crusher machine can conveniently adjust the discharging particle size and in a wide range 41 The impact rock crusher can adjust the discharging particle size in many ways Such as adjusting the rotor Impact Crusher VS Hammer Crusher JXSC Mine

Load and wear experiments on the impact hammer of a

Load and wear experiments on the impact hammer of a vertical shaft impact crusher View the table of contents for this issue, or go to the journal homepage for more 75, and 85 kg/s The rotor In a rotary hammer crusher, at least two hammers are employed at each hammer position, each hammer being independently pivotally suspended from the rotor disc The front hammer (as determined by the direction of rotation of the rotor shaft) functions as the wear hammer and is made of manganese or other steel having good wearresistant propertiesROTARY CRUSHER HAMMERS PENNSYLVANIA Compared with the hammer crusher, the rotor of impact crusher is more suitable to crush the more hard material and saving energy The size of the discharging particle's adjusting range of the impact crusher is large, and it can be adjusted very simplyDifferences Between Hammer Crusher And Impact

Balancing Of Hammers In Crusher

Balancing of hammer crusher balancing of hammer crusher design and analysis of a horizontal shaft impact crusher [ protected] to design various components of an Impact crusher like drive mechanism, shaft, rotor, hammers, casing, and discharge mec The hammer is designed with an entire rotation function, so the material impact on the rotor is significantly decreased The crushing chamber is adjustable, thus reducing abrasion on wearing components The rotor of this hammer crusher features a great inertia and high rotating speed, and the linear velocity of the hammer reaches 30~35m/sHammer Crusher Crushing Equipment SINOMALY【Hammer Crusher Parts】crushing chamber, rotor shaft, frame, impact hammer, grate bars, motor, flywheel, grate, pallets and lining, dust seal, overload protection device 【Hammer Crusher Working principle】Material are fed into the hammer crusher, that is subject to rotation, highspeed impact and collision are broken Qualified crushed Hammer Crusher Industry Hammer Mills JXSC

Hammer Crusher China Manufacturer Product

Hammer crusher’s main working part is a rotor with a hammer, highspeed rotation of the hammer impact on the block When the rotor rotates, the hammer under the effect of the inertial centrifugal force, is stretched outward as radially The material block firstly is broken by the hammer and then by broken material, at high speed to strike Hammer mill crusher is composed of body, rotor, hammer head, counterattack liner, sieve plate, etc China Hammer Crusher Main Application China Hammer crusher or hammer mill crusher is mainly used for crushing mediumhard or brittle materials with hardness not more than 100Mpa and moisture within 15%, such as coal, salt, chalk, plaster, brick Hammer Crusher Stone Crushing Equipment China The hammer rotor assembly consists of a heavyduty, forged shaft with a square crosssection and fitted with rotor discs The special ´sandwich´ assembly of the discs is a robust construction which prevents distortion and crack formation Effective and efficient The hammer rows are fitted in a staggered arrangement to giveEV hammer impact crusher

Hammer Crusher Hammer Mill Crushers for Sale –

Hammer stone crusher is a kind of equipment that crushes materials in the form of impact Crushing the size of 6001800 mm material to 25m or less Hammermill machine can not only be used in stone crusher plant, sand plant, but also can replace the cone crusher in the mineral processing Crusher parts: upper body, grate plate, middle, discharging mouth, hammer, side plate, stand, hammer axle The Design and analysis of shaft and rotor assembly for hammer mill crusher of capacity 01 (100kg/hr) tones per hour transmitting 20 BHP and a speed of 750 rpm The design is based on the standard design procedure The diameter of rotor shaft of hammer mill crusher has been designed The design should be safeInternational Journal of ChemTech Research Compared with the hammer crusher, the rotor of impact crusher is more suitable to crush the more hard material and saving energy The size of the discharging particle's adjusting range of the impact crusher is large, and it can be adjusted very simplyDifferences Between Hammer Crusher And Impact

(PDF) REDESIGN AND MANUFACTURE AN IMPACT

The crusher was a small horizontal shaft impact crusher The crusher total feed rate was 115 kg/hour, output was100 kg/hour that The local machine powered with 12 kW Italian made electrical motor The impact crusher rotor was rotate in one direction using a belt connected with the motor via two pulleyshammer mill ranged from928 % to 936 % co mpare with 937 % to 9 44 % for redesigned impact crusher hammer mill Vol2, Issue7 PP 11961209 ISSN : 23945788(PDF) REDESIGN AND MANUFACTURE AN IMPACT Load and wear experiments on the impact hammer of a vertical shaft impact crusher View the table of contents for this issue, or go to the journal homepage for more 75, and 85 kg/s The rotor Load and wear experiments on the impact hammer of a

DESIGN AND ANALYSIS OF IMPACT CRUSHERS

crusher,Jaw crusher and Impact crusher Our objective is to design various components of an Impact crusher like drive mechanism, shaft, rotor ,hammers, casing ,feed and discharge mechanism which will be useful in minimizing weight, cost and maximizing the capacity Impact crushers: they involve the use of impact rather than pressure to crushhammer mill ranged from928 % to 936 % co mpare with 937 % to 9 44 % for redesigned impact crusher hammer mill Vol2, Issue7 PP 11961209 ISSN : 23945788(PDF) REDESIGN AND MANUFACTURE AN IMPACT Compared with the hammer crusher, the rotor of impact crusher is more suitable to crush the more hard material and saving energy The size of the discharging particle's adjusting range of the impact crusher is large, and it can be adjusted very simplyDifferences Between Hammer Crusher And Impact

Load and wear experiments on the impact hammer of

Impact hammers are important components of impact crushers, and are often shortlived due to the highimpact nature of their use Wearresistant alloys are welded to the surface of impact hammers to prolong their service life In this paper, a simulation model of the rotor and impact hammers in impact crushers was designed to utilize the Discrete Element Method (DEM) Repair of the rotor of a hammer crusher with rollers KDV 1137 (rotor diameter 1,600 mm, rotor width 2,200 mm) Disassembly, production and replacement of the main shaft, assembly of repaired discs, static balancing, paintingREPAIR OF HAMMER CRUSHER ROTOR WITH The crusher hammer is one of the core parts of the hammer crusher It is arranged on the hammer shaft of the crusher rotor and directly hits the material when the hammer crusher is in operation Crusher hammers play an important role in various fields According to different types of crushed materials, crusher hammers also haveWhat Kind of Crusher Hammer Material Is Best For

LOCKING DEVICE FOR LOCKING A HAMMER TO A

1 A locking device for a crusher rotor of a horizontal shaft impact crusher, said rotor including at least one hammer element and at least one rotor disc having a plurality of rotor arms, the locking device comprising: a lockingwedge including a first bore; a screw element for driving the lockingwedge into a locking position between a rotor arm and the hammer element, and for holding the Impact Crusher VS Hammer Crusher JXSC Mine There are two types: horizontal shaft impactor and vertical shaft impact crusher Hammer Crusher Hammer crusher is equipment which in the form of impact crushing materials The divided into the single rotor and double rotor two forms The maximum particle size of 6001800 mm of material Get Pricehow material 5c 27s hammer crusher Prominer The hammer crusher can be divided into two types: single rotor (single shaft) and double rotor (double shaft) Single rotor can be divided into two types: irreversible and reversible According to the number of rows of hammers, it can be divided into single row and multiple rows Hammer crusher structure: The hammer crusher is composed of a box China Stone Jaw Crusher Equipment for Sale Stone

Difference Between Concentrate And Sinter Fine

Harga Mesin Penambangan Bijih Emas Di Ghana

mobile stone crusher machines

finlay mobile jaw crusher

barite processing plants in texas

Jaw crushers Quarry crushing Equipment

Servicing Of Stone Crusher

grinding mills grinding equipment

beneficio drosky grinding mills zimbabwe

25 year stone crusher manufacturer 30 1200t

butterfly wet grinder chennai service

magnabot ii magnetic separation device

gyratory gyratory jaw crusher

Beneficiation Plant For Chrome Indonesia

Jaw Crusher For Granite Riau聽indonesia

cheap mini crusher for sale

ne ne crusher price south africa

impact crusher operation and maintence

gyratory rock crushers working videos

vertical rollar mill

crusher machine from france

hardness of phosphate rock for grinding

argentite processing plant manufacturer

Coal Mines In Stock E change In South Africa

rotary kilns manufactures for the mining industry

Roughing Stage In Gold Processing

separation of gravel with crushing equipment

characteristics of crusher types

how much does a cubic yard of crushed stone st

cedar rapids rock crusher