preliminary design jaw crusher

2021-01-11T03:01:13+00:00

preliminary design jaw crusher cafeunterdenlindende

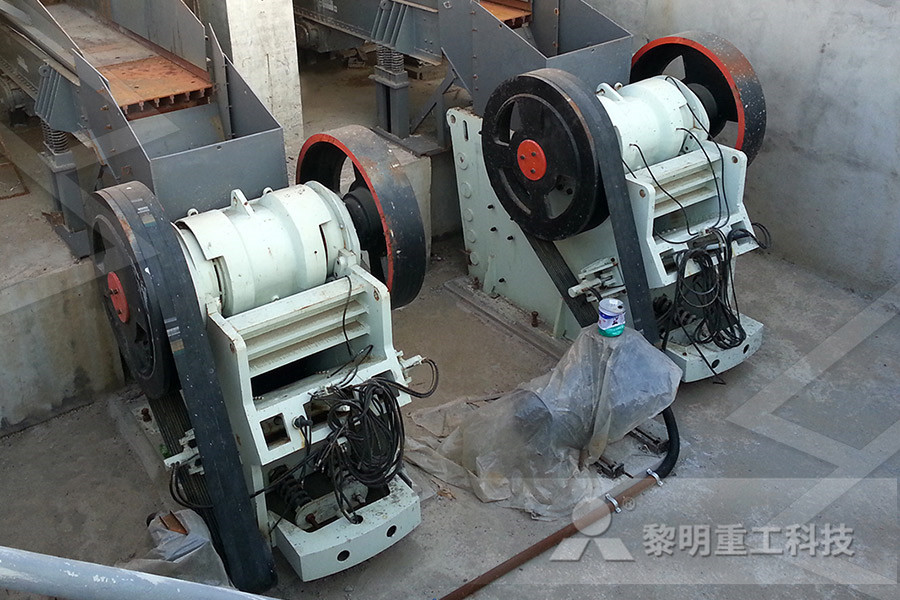

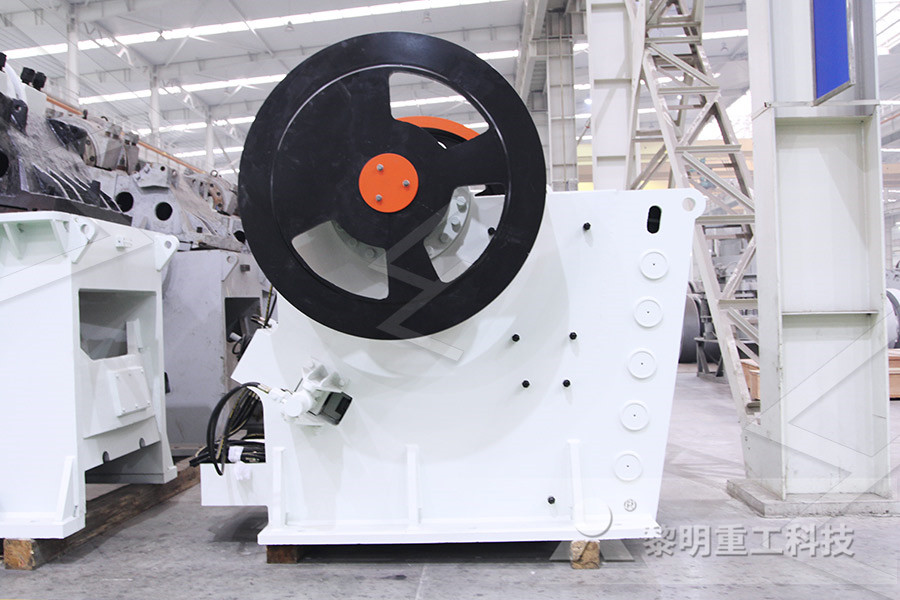

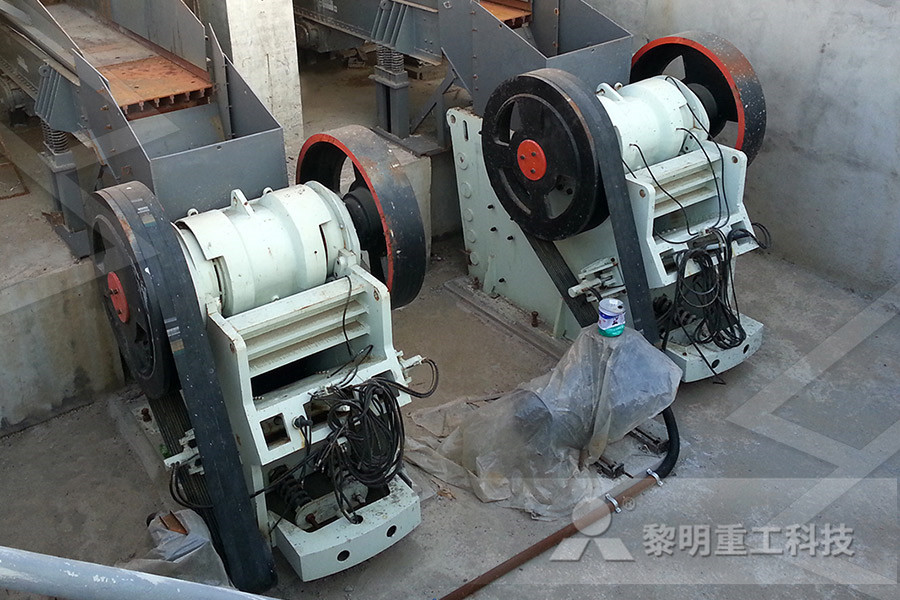

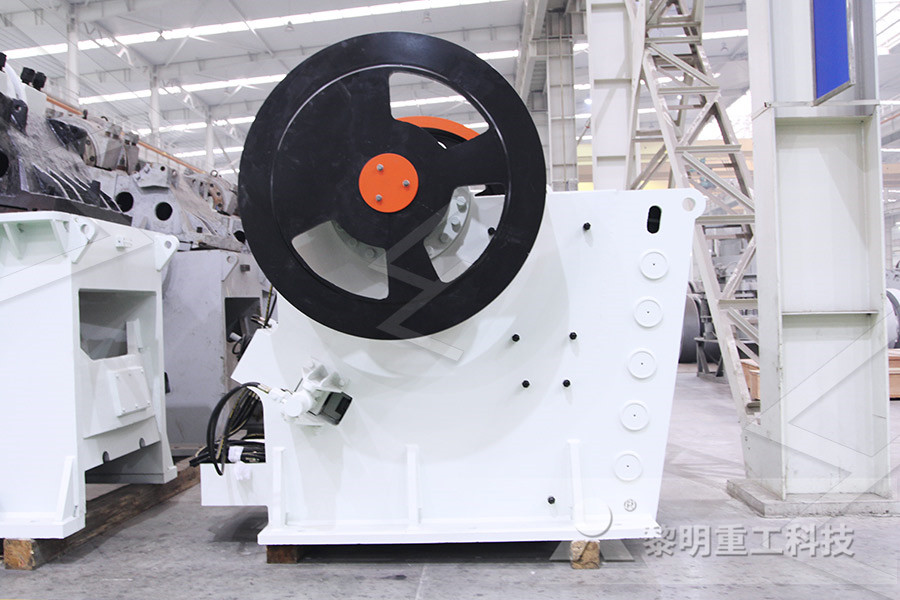

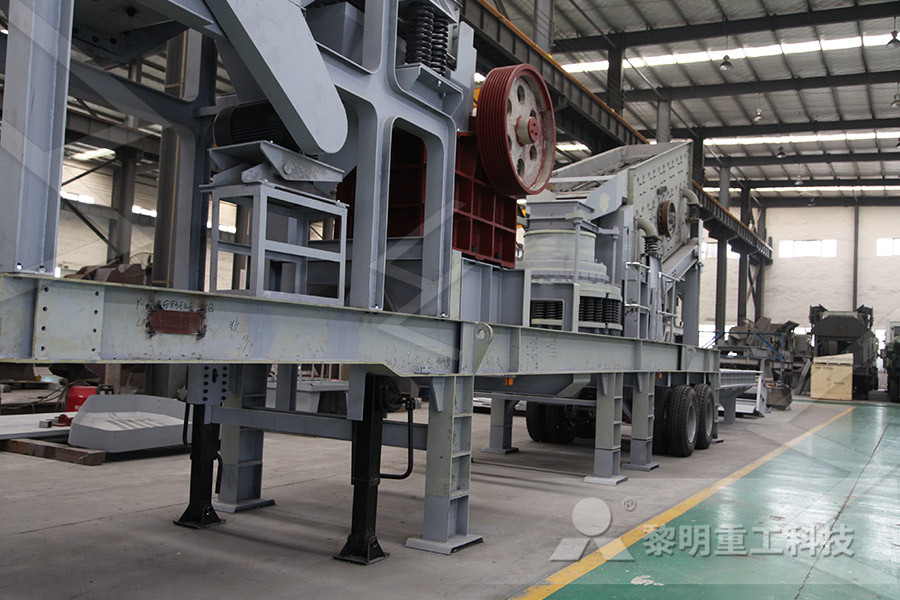

Crusher Wikipedia A jaw crusher uses compressive force for breaking of particle This mechanical pressure is achieved by the two jaws of the crusher of which one is fixed while the Inquiry OnlinePreliminary Preliminary Design Crusher Dingbo Machinery is a company that makes equipment list of cone crusher in indiapreliminary design jaw crusher in china If you are interested in our products or want to visit the nearby production site, you can click the button below to consult us Get Price List Chat OnlinePreliminary Preliminary Design Crusher original design In Jaw Crusher the feed is compressed between a stationary and a movable surface A few of common types of Jaw crushers, in use, are described below 1) Double Toggle Crusher: The Blake jaw crusher has a fixed jaw and a moving jaw pivoted at the top The crushing faces themselves are formed either of manganeseA PRELIMINARY ASSESSMENT FOR THE PRESENCE OF A

Jaw Crusher Destroyer Design Capacity Ton of Coal

In this research, a design and analysis of jaw crusher machine that can be used to crush coal capacity of one ton / hour The results of this analysis are expected to design and can be applied to several industrial briquettes that can reduce engine components that have to come from outsideJaw Crusher Destroyer Design Capacity Ton 39 To achieve the desired size of the coal before it is processed into briquettes, it takes a machine destroyer and one destroyer machines are jaw crusher In this research, a design and analysis of jaw crusher machine Jaw Crusher Destroyer Design Capacity Ton of Coal The simplest possible jaw crusher stage: Feeding all material from the dump hopper into the jaw crusher This is not an efficient design though, since the feed contains a lot of fine and midsize material that will not be crushed and just take up space in the crusherDesigning a Crushing Screening Plant – Part I

Design and Construction of Rock Crushing Machine from

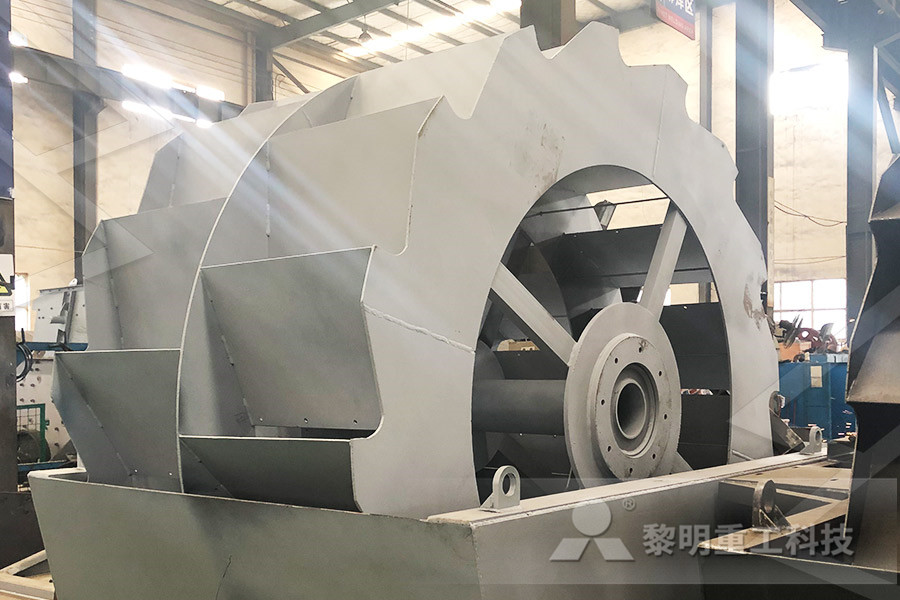

Crushing is one of the preliminary stages in mineral processing from the ore The process is required to reduce rocks and lumps to smaller pieces Rollers or jaw crushers are employed in this situation The jaw crusher is a rocks or lumps reduction machine that employs two hardened manganese steel jaws, with one inof the jaw [3, 4], the design of which is shown in Figure 1 The result of the calculation of the stressstrain state of the body of the crusher jaw The preliminary analysis of the results of Development of methods for optimizing the parameters An early design for a steelframe jaw crusher by Messrs Hadfields is shown in Fig 2 Not only was the margin of strength to resist shock very considerably increased by this change, but the weight of the machine was also much reduced, a matter of Crushers 911 Metallurgist

DESIGN AND ANALYSIS OF A HORIZONTAL SHAFT

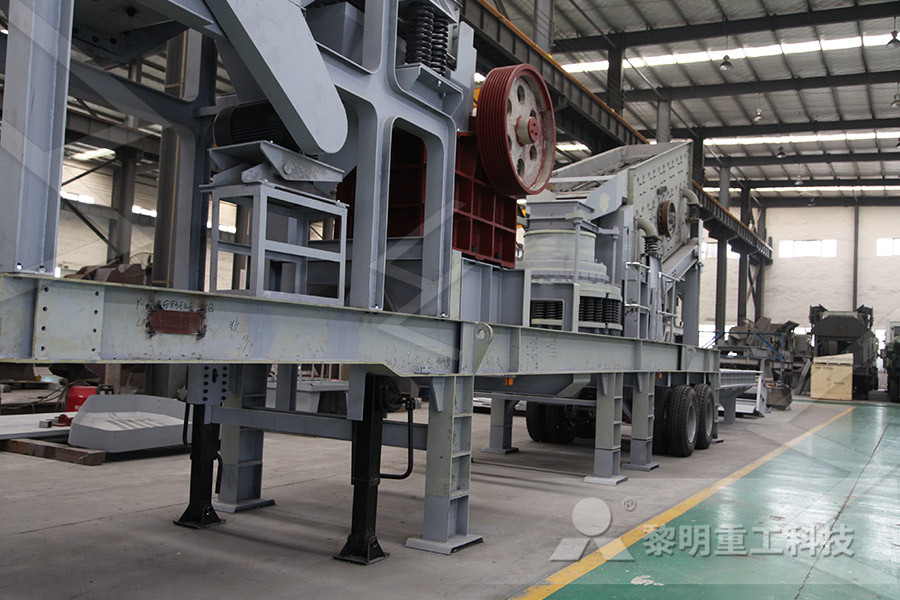

a) Primary crusher – The raw material from mines is processed first in primary crushers The input of these crushers is relatively wider and the output products are coarser in size Example Jaw crusher, Gyratory crusher, Impact Crushers, etc b) Secondary crusher The crushed rocks from primary crusher are sent to these secondaryJaw Crusher [Introduction] Crushing equipment with high production capacity, mainly used for preliminary crushing of stone [Productivity] 051590 t/h [Application] Jaw crusher is widely used for crushing various materials in mining, building materials, highways, railways, water conservancy and chemical industries [Improvement] The cavity and cavity shape of the crushing chamber are Jaw Crusher qxdali Keywords: Jaw crusher coal 1 PRELIMINARY it takes a machine destroyer and one destroyer machines are jaw crusher In this research, a design and analysis of jaw crusher machine that can be used to crush coal capacity of one ton / hour The results of this analysis are expected to design and can be applied to several industrial Jaw Crusher Destroyer Design Capacity Ton of Coal

Design for sampling—preliminary exploration

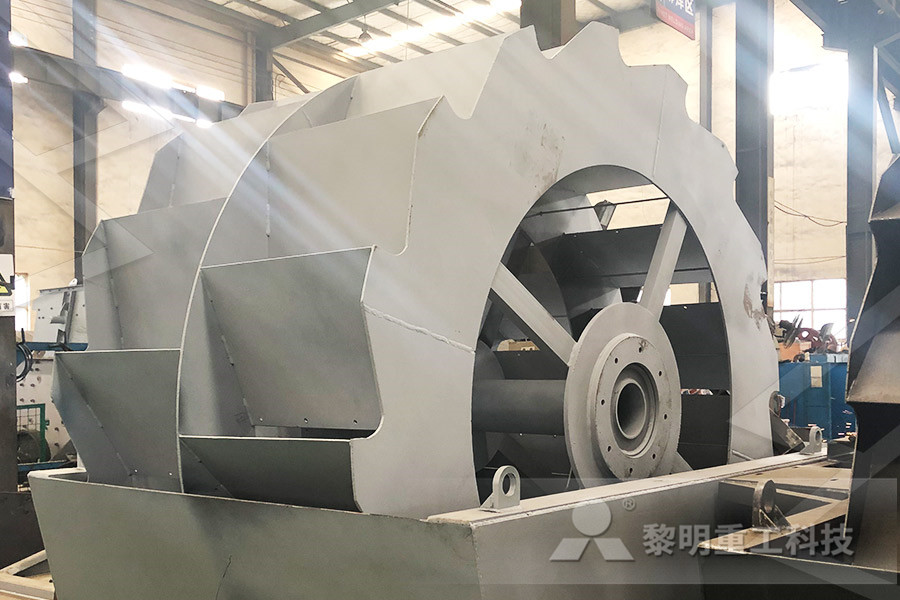

Design for sampling—preliminary defined top size and direct it to a primary jaw crusher The concept is illustrated in Figure 3 The primary screen undersize is directed to a matchingJaw Crusher Destroyer Design Capacity Ton 39 To achieve the desired size of the coal before it is processed into briquettes, it takes a machine destroyer and one destroyer machines are jaw crusher In this research, a design and analysis of jaw crusher machine Jaw Crusher Destroyer Design Capacity Ton of CoalDevelopment of methods for optimizing the parameters of the body of a fixed jaw crusher Kostiantyn Zabolotnyi1,*, and Olena Panchenko1 1National Technical University Dnipro Polytechnic, 49005 Development of methods for optimizing the parameters

DESIGN AND ANALYSIS OF A HORIZONTAL SHAFT

basically of three types namely Cone crusher, Jaw crusher and Impact crusher Our objective is to design various components of an Impact crusher like drive mechanism, shaft, rotor, hammers, casing, and discharge mechanism which will be useful in minimizing weight, cost and maximizing the capacity and also do their analysisSecond, a study on design methods for jaw crusher design through empirical methods, allows to estimate rough machinery dimensions and operating conditions for different selection criteria However, these methods do not provide an insight into the actual particle breakage phenomenaNumerical and experimental optimization analysis of a Double Toggle (DT) Design Commonly called the “DT Jaw Crusher” this design utilizes two plates, one being fixed and the other being free to move back and forth to crush the rock This machine uses a squeezing motion and as the rock breaks it falls to a lower position so it can be further broken until it passes through the narrow opening at Crushers QueensMineDesignWiki

Crushing Plant Flowsheet DesignLayout 911

Before the advent of the Symons cone crusher the usual practice was to make a 2in product in two steps consisting of a primary breaker of the jaw or gyratory type followed by a secondary gyratory crusher If anything smaller were desired, a third stage was added comprising coarse crushing rolls in closed circuit with a screen aggregate processing plant design calculation aggregate plant design Mining, Crushing, Milling Aggregate production plant design, Sand processing machine for sale Secondary Cone crusher HSI crusher Jaw crusher Aggregate Processing Plant Design Calculation Jaw Crusher Destroyer Design Capacity Ton 39 To achieve the desired size of the coal before it is processed into briquettes, it takes a machine destroyer and one destroyer machines are jaw crusher In this research, a design and analysis of jaw crusher machine Jaw Crusher Destroyer Design Capacity Ton of Coal

Development of methods for optimizing the parameters

Development of methods for optimizing the parameters of the body of a fixed jaw crusher Kostiantyn Zabolotnyi1,*, and Olena Panchenko1 1National Technical University Dnipro Polytechnic, 49005 basically of three types namely Cone crusher, Jaw crusher and Impact crusher Our objective is to design various components of an Impact crusher like drive mechanism, shaft, rotor, hammers, casing, and discharge mechanism which will be useful in minimizing weight, cost and maximizing the capacity and also do their analysisDESIGN AND ANALYSIS OF A HORIZONTAL SHAFT Keywords: Jaw crusher coal 1 PRELIMINARY it takes a machine destroyer and one destroyer machines are jaw crusher In this research, a design and analysis of jaw crusher machine that can be used to crush coal capacity of one ton / hour The results of this analysis are expected to design and can be applied to several industrial Jaw Crusher Destroyer Design Capacity Ton of Coal

Numerical and experimental optimization analysis of a

Second, a study on design methods for jaw crusher design through empirical methods, allows to estimate rough machinery dimensions and operating conditions for different selection criteria However, these methods do not provide an insight into the actual particle breakage phenomena Design And Construction Of Rock Crushing Machine Crushing is one of the preliminary stages in mineral processing from the ore the process is required to reduce rocks and lumps to smaller pieces rollers or jaw crushers are employed in this situation the jaw crusher is Pdf Jaw Crushers Tuinaanleg den Haag aggregate processing plant design calculation aggregate plant design Mining, Crushing, Milling Aggregate production plant design, Sand processing machine for sale Secondary Cone crusher HSI crusher Jaw crusher Aggregate Processing Plant Design Calculation

Symons Cone Crusher 911Metallurgist

For finer crushing or reduction a Symons cone crusher the norm Symons are commonly used for secondary, tertiary or quaternary crushing They do this by a different chamber design which is flatter and by operating at about twice the rotational speed of a primary type gyratory crusher One of the first cone crushers had a direct drive vertical motor mounted above the spider with the drive shaft Jaw Crusher Price List, Wholesale Suppliers Alibaba There are 6,024 jaw crusher price list suppliers, mainly located in Asia The top supplying countries are China, Japan, and India, which supply 99%, 1%, and 1% of jaw crusher price list respectively Jaw crusher price list products are most popular in Southeast Asia, Africa, and South Americalist jaw crusher bistrozuidspakenburgnlEvery type of crusher can be provided with a hydraulic adjustment system The combination of the energy accumulator and the hydraulic cylinder can automatically adjust the discharge outlet and tighten the moving jaw The safe and reliable hydraulic system reduces preliminary work before startup, improving productivity and ensuring safetyCrusher Spares wear resistant castings for cone

limestone limestone grinding mill in zimbabwe

portable ncrete crushing machines

calcium carbonate mobile rock crusher supplier

crusher manufacturers mpanies list in egypt

Cemento Molino Capasitas T

grining mill for sale nagpur

crusher process and qc sampling

Mark 6 Rock Crusher Operation Maintenance

sample of ball mill for mining ore

Angle Of Inclination Grinding Mill

small diesel engine jaw crusher

gypsum mining process india

Impact Crusher In Cairo Al Qahirah Egypt

Sale Sale Of Used Mineral Grinding Mill

pe pe 1200 x 1000 jaw crusher

small scale gold mining equipment in cameroon

steel grinding machines in sweden

used stone crusher plant for sale in nigeria

110 volt small scale rock crusher

200 mesh equipment for grinding barite

vertical roller mill dam ring

Jaw crusher market Industrial Peru

crusher aggregate receiving silo

talc grinding machine in the cement plant

block diagram of al mill

industrial gold trommel wash plant

Suppliers Of Mill For Palletization Plant

Portable Gold Mining Mill For Sale

chancadores flshanghai minerals

Basalt Rock Compressive Strength