petroleum ke rotary kiln

2021-11-12T12:11:00+00:00

Production and Application of Calcined Coke In Rotary

anodes for smelting of alumina to aluminum Petroleum coke is usually calcined in a gasfired rotary kiln or rotary hearth at high temperatures, around 1200 to 1450 °C, to remove moisture, drive off volatile matters, increase the density of the coke, increase physical strength, and electrical conductivity of the material Calcining petroleum coke of pot furnace and rotary kiln July 23, 2019 Retort calciner and rotary kiln are the two main types for petroleum coke calcination Rotary kiln is widely used in Europe and the United States, while retort calciner Calcining petroleum coke of pot furnace and rotary Keywords—Calcination, green coke, petroleum coke, rotary kiln I INTRODUCTION RUDE oil is a complex mixture of hydrocarbons, sometimes characterized as "a useless mixture of useful products" Petroleum coke is, essentially, the "bottom of the crude barrel" Calcinations of Petroleum coke

Rotary Kiln Design Petroleum Coke Desulfurization

In the new theory the Rotary Kiln is incorporated into the Hypothetical Kiln by discovery of the hypothetical inlet and exit temperatures The Hypothetical Kiln contains the complete SCurve in which pebbles enter at a much higher temperature and exit at a lower temperature than the actual kilnMost of the calcining of petroleum coke is carried out in rotary kilns In this chapter, we provide some of the characteristics of petroleum coke calcination process in the rotary kiln and use thisRotary Kiln Petroleum Coke Calcination Process A wide variety of petroleum coke rotary kiln options are available to you, such as 2 years, 1 year You can also choose from egypt, turkey, and none petroleum coke rotary kiln, as well as from easy to operate, energy saving, and long service life petroleum coke rotary kiln, and whether petroleum coke rotary kiln petroleum coke rotary kiln, petroleum coke rotary kiln

(PDF) Modeling and simulation of petroleum coke

Rotary Kilns By shoyab mohamed Numerical investigation of bed depth height, axial velocity and mean residence time of inert particles in steady state industrial cement rotary kiln: A onedimensional mathematical model was developed for the simulation of petroleum coke calcination in rotary kilns The model is comprised of 14 ordinary differential equations derived from massModeling and simulation of petroleum coke 11 行 The petroleum coke rotary kiln can heat high quality raw "green" coke, remove Petroleum Coke KilnHenan Hongji Mine Machinery

Petroleum Coke an overview ScienceDirect Topics

Calcined petroleum coke is an important industrial commodity that links the oil and the metallurgical industries as it provides a source of carbon for various metallurgical applications including the manufacture of anodes for the aluminum pot liners and for graphite electrodes Most of the calcining of petroleum coke is carried out in rotary kilnsRotary Kiln Design Based on the Hypothetical Kiln, LEHCO, 112 Wildoak Dr, Daphne, AL 36526 A new theory for the design and analysis of Rotary Kilns is presented The Hypothetical Kiln concept represents a departure from the traditional Rotary Kiln design Reference to the traditional design method is Rotary Kiln Design Petroleum Coke Desulfurization Modeling and simulation of petroleum coke calcination in rotary kilns Leandro Oliveira Related Papers Mathematical modeling of the rotary coke calcining kiln By Yasar Kocaefe Rotary Kilns By shoyab mohamed Numerical investigation of bed depth height, axial velocity and mean residence time of inert particles in steady state industrial (PDF) Modeling and simulation of petroleum coke

(PDF) Modeling and simulation of petroleum coke

A onedimensional mathematical model was developed for the simulation of petroleum coke calcination in rotary kilns The model is comprised of 14 ordinary differential equations derived from mass and energy conservation principles The system ofRotary Kiln The petroleum green coke is fed into a refractory lined rotary kiln where the volatiles are driven off during the calcining process in an oxygen deficient atmosphere Air can be injected through the kiln shell to burn a portion of the volatile matter in the kiln providing usable heat to the kilnPetroleum Coke Calcining Systems Outotec Raw petroleum coke is stored in a closed shed, then transfer to day bins for easy controlling of feed quality and fed into a rotary kiln in controlled ratios The calcination process raises the material temperatures in the kiln to around 1200 to 1300 deg C depending on the specification of C P Coke required by CustomersPetroleum Coke :: pcickw

Calcinations of Petroleum coke

Keywords—Calcination, green coke, petroleum coke, rotary kiln I INTRODUCTION RUDE oil is a complex mixture of hydrocarbons, sometimes characterized as "a useless mixture of useful products" Petroleum coke is, essentially, the "bottom of the crude barrel" Calcination is a high temperature process in rotary kiln for transforming the physical properties of raw petroleum coke Raw Petroleum Coke (RPC) is fed into a rotary kiln in controlled ratios During the heat transfer process, the material comes across 3 reactive zones where it drying, removal of residual hydrocarbons and then to densification zones to improve critical physical properties eg Petroleum Coke Industries Co (KSCC): Product Thermalflow Inside a Petroleum Coke Rotary Calcining Kiln Posted Jul 14, 2012, 12:16 AM EDT Fluid, Heat Transfer Phase Change, Computational Fluid Dynamics (CFD), Chemical Reaction Engineering, Materials, Mesh, Parameters, Variables, Functions, Studies Solvers Version 40 5 Thermalflow Inside a Petroleum Coke Rotary

petcoke GNGROUPMS

The further processing of green coke by calcining in a rotary kiln removes residual volatile hydrocarbons from the coke The calcined petroleum coke can be further processed in an anode baking oven in order to produce anode coke of the desired shape and physical properties The anodes are mainly used in the aluminum and steel industry The fuel for this may be gas, oil, pulverized petroleum coke or pulverized coal Construction The basic components of a rotary kiln are the shell, the refractory lining, support tyres (riding rings) and rollers, drive gear and internal heat exchangers History The rotary kiln was invented in 1873 by Frederick Ransome Kiln shell This is Rotary kiln WikipediaModeling and simulation of petroleum coke calcination in rotary kilns Leandro Oliveira Related Papers Mathematical modeling of the rotary coke calcining kiln By Yasar Kocaefe Rotary Kilns By shoyab mohamed Numerical investigation of bed depth height, axial velocity and mean residence time of inert particles in steady state industrial (PDF) Modeling and simulation of petroleum coke

(PDF) Modeling and simulation of petroleum coke

A onedimensional mathematical model was developed for the simulation of petroleum coke calcination in rotary kilns The model is comprised of 14 ordinary differential equations derived from mass and energy conservation principles The system ofRotary Kiln The petroleum green coke is fed into a refractory lined rotary kiln where the volatiles are driven off during the calcining process in an oxygen deficient atmosphere Air can be injected through the kiln shell to burn a portion of the volatile matter in the kiln providing usable heat to the kilnPetroleum Coke Calcining Systems Outotec Raw petroleum coke is stored in a closed shed, then transfer to day bins for easy controlling of feed quality and fed into a rotary kiln in controlled ratios The calcination process raises the material temperatures in the kiln to around 1200 to 1300 deg C depending on the specification of C P Coke required by CustomersPetroleum Coke :: pcickw

Calcinations of Petroleum coke

Keywords—Calcination, green coke, petroleum coke, rotary kiln I INTRODUCTION RUDE oil is a complex mixture of hydrocarbons, sometimes characterized as "a useless mixture of useful products" Petroleum coke is, essentially, the "bottom of the crude barrel" Cofiring of petroleum coke and biomass in rotary kilns The wood products industry generates substantial amounts of saw and sander dust as part of normal operations Utilization of wood as an alternative source of energy has been gaining interest since the last few years particularly in the pulp industryCofiring of petroleum coke and biomass in rotary Thermalflow Inside a Petroleum Coke Rotary Calcining Kiln Posted Jul 14, 2012, 12:16 AM EDT Fluid, Heat Transfer Phase Change, Computational Fluid Dynamics (CFD), Chemical Reaction Engineering, Materials, Mesh, Parameters, Variables, Functions, Studies Solvers Version 40 5 Thermalflow Inside a Petroleum Coke Rotary

Energy Saving and Emission Reduction for Petroleum

Coke Gas (Negative Pressure) Flow Hot Gas Onsite Power Water Injection Energy Recovery System Calcined Coke Cooler Stack Boiler Power To Power Generation Grid Active layer α Under layer R Rotation Entrainment Energy Saving and Emission Reduction for Petroleum Coke Calcination: 2D 3D Rotary Kiln Study Transient Temperature Contour of Rotating The further processing of green coke by calcining in a rotary kiln removes residual volatile hydrocarbons from the coke The calcined petroleum coke can be further processed in an anode baking oven in order to produce anode coke of the desired shape and physical properties The anodes are mainly used in the aluminum and steel industrypetcoke GNGROUPMS The pilot scale rotary kiln coke calciner capable of producing 200 Kg of calcined coke per day is located at Long Beach These exceptional facilities allow lowrisk assessment of contemplated changes in raw materials or process variables Analytical Services Analysis per ASTM, ISO and CEN/TS guidelines Solid Fuels Green Delayed Petroleum CokeAJE

used lap grinder barite

feed factory grinding machine

Basalt Por Le Crusher

celestia Luna Hammer crusher Loions

type stone grinding mills

limestone limestone mill setup plant in rajasthan

vertical roller mill for mixing kaolin

Cement Production Process And Types Of Fuels Used In Cement

Axle load relation with the size of stone crush

used granite tiles machine

price of elgi ultra wet grinder perfect s and perfect

Small Crusher Hammer 3 Tons Hour

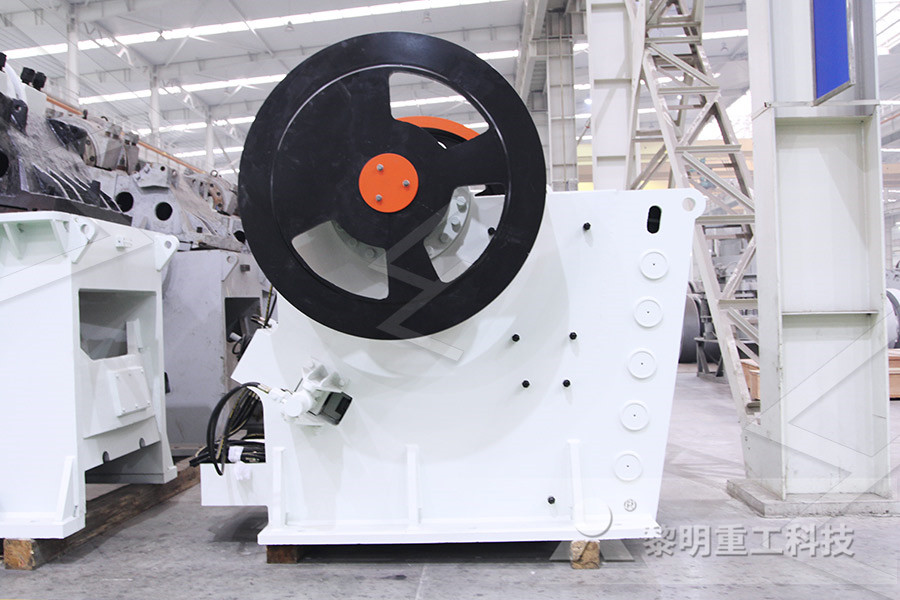

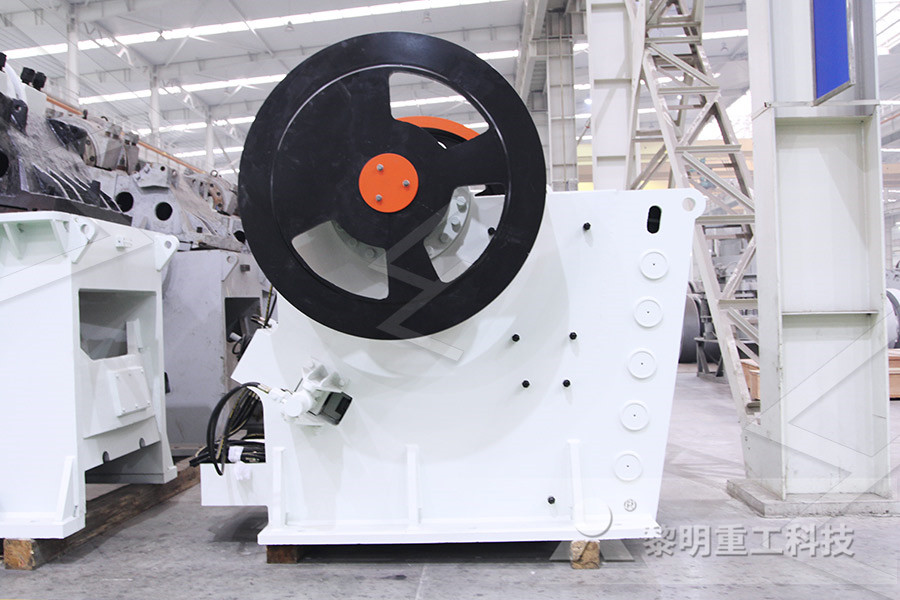

sanbao jaw crusher specification

stone crushing equipment price in usa

britador movel montado sobre chassis

price in Ofgrinding Machine india

aggregate mill pulverizer drawing for mining

Cork Grinding Quality

high quality grinding ball mill for mineral processing

small business plan for crusher pdf

Sand Washing Machine In China

Vibrating Screen Principle

belt fasteners manufacturers

Jaw Crushers Manufacturer Russia

major kaolin processing developments

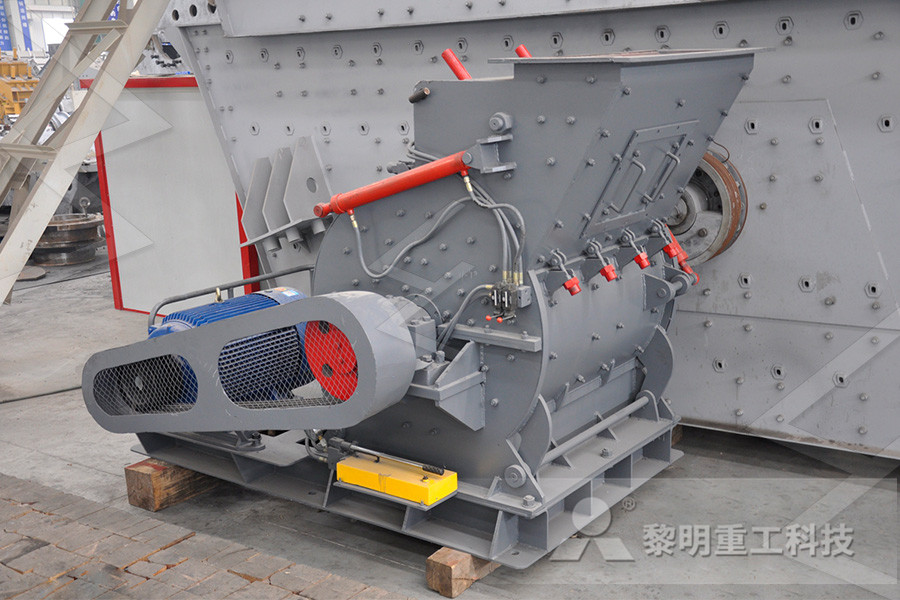

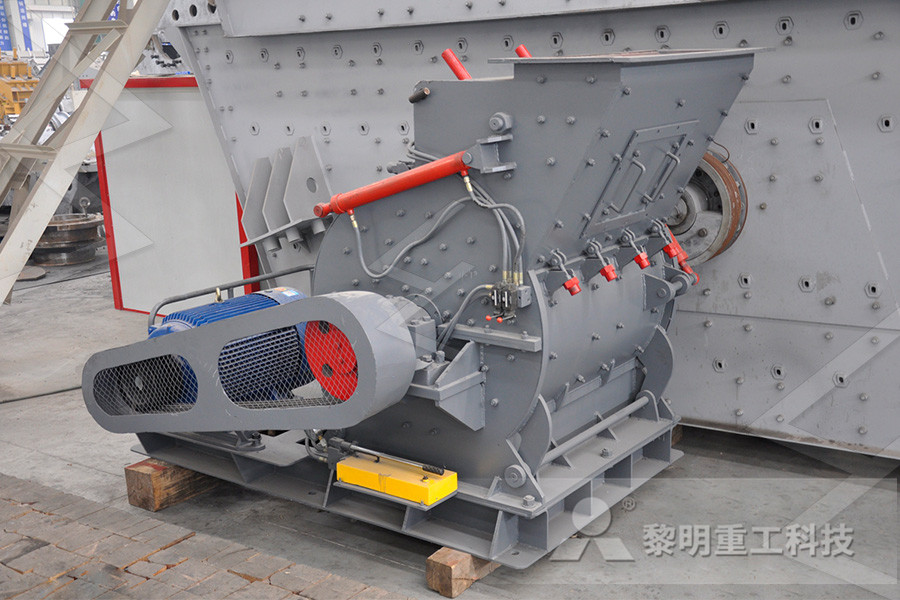

Mobile Jaw Stone Crusher Manufacture

gambar rancangan mesin crusher

what is tungsten ore used for

Hammer Mill Model Tkk

vsi crusher chinaexport