jaw crusher nip angle pdf

2019-09-15T05:09:38+00:00

Jaw Crusher Nip Angle Pdf PALBetriebsorganisation

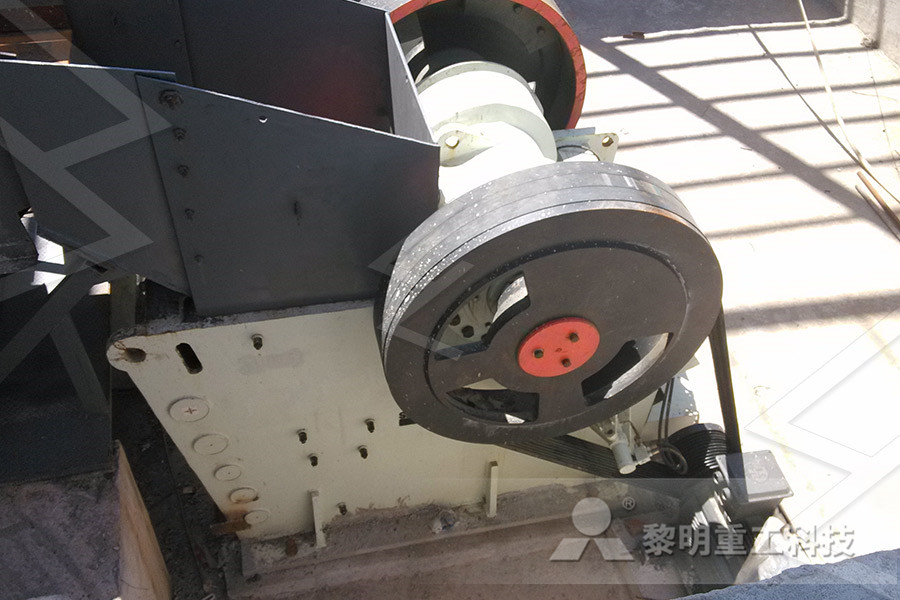

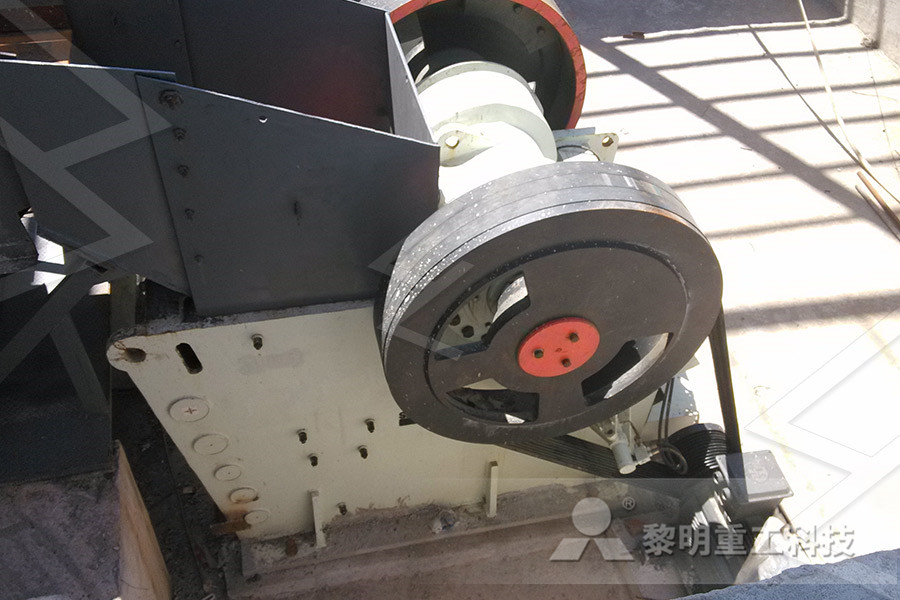

Jaw Crusher Nip Angle Pdf The jw series of single toggle jaw crushers is designed with a tight crushing chamber nip angle and an aggressive crushing stroke to maximize productivity the accompanying table gives typical outputs for our range of machines based on dry free flowing material with a crushing work index of 16 and a bulk density of 100 lbscu ft 1600 kgcu m Calculating the nip angle of the chamber of jaw and cone crushers with inclusion of the velocity vector Download PDF Download PDF Mechanization and Automation in Rock Mining; Published: March 1985; Calculating the nip angle of the chamber of jaw and cone crushers with inclusion of the velocity vector Calculating the nip angle of the chamber of jaw and Angle of nip in roll crusher function pdf request a quotation modeling simulations and instrumentation of high pressure roller pressure roller crusher hprc is an important part in the production of silicon carbide where the to measure the nip angle literature exists and states Angle of nip jaw crusher nip angle calculation for jaw crusher Jaw Crusher Nip Angle Pdf trubkinpersoneelsadviesnl

SANDVIK JAW CRUSHER SERIES

optimum performance, the jaw crusher needs to have a good feed level and a homogeneous feed Our jaw crushers are of the singletoggle type and feature a deep, symmetrical crushing chamber, a large feed opening for its size, and an ideal nip angle that offers smooth material flow and high reduction efficiency Jaw crushers are normally capable with a tight crushing chamber nip angle and an aggressive crushing stroke to maximize productivity The accompanying table gives typical outputs for our range of machines, based on dry, free flowing material (30” x 42”) Jaw Crusher, 42” x 20’ Feeder 150 hp (110 kW) 155 – 480 (140435) 3 Axle 92,625 lbs (42,015 Kg) CRJ3255 JW55 (32 Jaw Crushers JW Series A jaw crusher is a kind of size reduction machine which is widely used in mineral, aggregates and metallurgy fields (PDF) data for materials variation of nip angle with crank angle (PDF) Optimum design and analysis of (the) swinging

Industrial Solutions Jaw crushers ThyssenKrupp

• Optimum nip angle for hard and tena cious materials • Optimized kinematics of the swing jaw with a high stroke in the feed and discharge areas, ensuring very high with a doubletoggle jaw crusher with the same feed opening The diversity of feed mate rials has led to a diversification of singletoggle jaw crushers to suit the Jaw crusher C Кб Excellent nip angle high up in the cavity, together with an aggressive linear stroke at the bottom, ensure high throughput capacity and reductionSafe to operate and maintain The C120 jaw crusher is designed to be safe to operate and maintainCalculation Of Nip Angle Jaw Crusher toggle jaw crusher is its kinematic design The chamber design enables the TST to efficiently crush hard material via a combination of shaft eccentricity, toggle angle and chamber layout While the chamber is designed with a very steep nip angle, all other connected components are designed to enable the units to easily crush the hardest rock at TST jaw crusher

Handbook of Crushing TerraSource Global

Angle of Nip — The angle formed between the moving surface of a crusher roll or jaw plate and the stationary plate surface at which point the material will be pinched Angle varies with machine size and material lump size Bond Work Index (BWI) — Kilowatt hour (kWh) per short ton required to reduce the material to 80% passing 100 micronsoptimum performance, the jaw crusher needs to have a good feed level and a homogeneous feed Our jaw crushers are of the singletoggle type and feature a deep, symmetrical crushing chamber, a large feed opening for its size, and an ideal nip angle that offers smooth material flow and high reduction efficiency Jaw crushers are normally capable SANDVIK JAW CRUSHER SERIES and the nip angle or crushing angle Standard crushers have nip angles which vary between 25 degrees and 30 degrees However, by increasing the crusher chamber length, nip angle can be reduced in some cases to less than 20 degrees When combined with the improved nonchoking jaw plates a more efficient crusher resultsEQUIPMENT AND MAINTENANCE 911 Metallurgist

TST jaw crusher

toggle jaw crusher is its kinematic design The chamber design enables the TST to efficiently crush hard material via a combination of shaft eccentricity, toggle angle and chamber layout While the chamber is designed with a very steep nip angle, all other connected components are designed to enable the units to easily crush the hardest rock at Angle of nip in roll crusher function pdf request a quotation modeling simulations and instrumentation of high pressure roller pressure roller crusher hprc is an important part in the production of silicon carbide where the to measure the nip angle literature exists and states Angle of nip jaw crusher nip angle calculation for jaw crusher Jaw Crusher Nip Angle Pdf trubkinpersoneelsadviesnl • Optimum nip angle for hard and tena cious materials • Optimized kinematics of the swing jaw with a high stroke in the feed and discharge areas, ensuring very high with a doubletoggle jaw crusher with the same feed opening The diversity of feed mate rials has led to a diversification of singletoggle jaw crushers to suit the Industrial Solutions Jaw crushers ThyssenKrupp

Lokotrack LT120 Mobile jaw crushing plant Pilot Crushtec

Capacity is maximised with an excellent nip angle and aggressive linear stroke Lokotrack LT120 Next Level of Crushing Lokotrack LT120 is the latest and most advanced of ’s trackmounted jaw crusher plants This robust new solution for mobile crushing is an outcome of combining solid experience with a new way of thinking steeper nip angle and increased capacity • Toggle Plate is set at an optimum angle for maximum crushing JAW HEAVY DUTY CRUSHERS lippmannmilwaukee 8006480496 1 Dimension is from bottom of mounting surface to top of feed side of crusher frame (Jaw can be mounted flat or tipped, drawing to confirm orientation isHEAVY DUTY CRUSHERS Tracked Jaw Crushers 800i The Tesab 800i is a Heavy Duty Tracked Jaw Crusher designed to Crush Primary Rock at the Quarry Face Designed specifically for the quarry market, the unique design of the ‘nipangle’ and extralong jaws make the 800i ideally suited to hard rock applications Featuring a 24 ton, 1100 x 800mm wide jaw crusher unitNEW 800i Jaw Crusher Tesab Engineering

JAW CRUSHERS McLanahan

jaw crusher preventing any wear to occur on the Reversible Manganese Jaw Plates The reversible and heattreated wear resistant manganese jaw plates actually get tougher as they work The extra jaw plate length plus the crushing angle assures instant nip of incoming material Productionwasting material rebound is held to a minimum UNIVERSAL JAW CRUSHERS The Universal Overhead Eccentric Jaw Crushers are constructed from top quality material for rugged service in a tough industry! Universal Jaw Crushers are the most efficient on the market today A deeper crushing chamber provides better nip angle while reducing rebound, ensuring continuous crushing action with lessUNIVERSAL JAW CRUSHERS McLanahan steeper nip angle and increased capacity • Toggle Plate is set at an optimum angle for maximum crushing JAW HEAVY DUTY CRUSHERS lippmannmilwaukee 8006480496 1 Dimension is from bottom of mounting surface to top of feed side of crusher frame (Jaw can be mounted flat or tipped, drawing to confirm orientation isHEAVY DUTY CRUSHERS

EQUIPMENT AND MAINTENANCE 911 Metallurgist

and the nip angle or crushing angle Standard crushers have nip angles which vary between 25 degrees and 30 degrees However, by increasing the crusher chamber length, nip angle can be reduced in some cases to less than 20 degrees When combined with the improved nonchoking jaw plates a more efficient crusher results NIP ANGLE ¾ Geometry of crusher chamber creates aggressive nip angle throughout entire life of dies ¾ Allows jaw to consistently grab and process material for highlevel efficiency FRAME MOUNTED MOTOR ¾ Reduces crusher footprint and frees up valuable deck space ¾ Allows for much smaller drive belt and easier access for maintenanceLiberty Jaw Crusher Crush Tech toggle jaw crusher is its kinematic design The chamber design enables the TST to efficiently crush hard material via a combination of shaft eccentricity, toggle angle and chamber layout While the chamber is designed with a very steep nip angle, all other connected components are designed to enable the units to easily crush the hardest rock at TST jaw crusher

Lokotrack LT120 Mobile jaw crushing plant Pilot Crushtec

Capacity is maximised with an excellent nip angle and aggressive linear stroke Lokotrack LT120 Next Level of Crushing Lokotrack LT120 is the latest and most advanced of ’s trackmounted jaw crusher plants This robust new solution for mobile crushing is an outcome of combining solid experience with a new way of thinking Tracked Jaw Crushers 800i The Tesab 800i is a Heavy Duty Tracked Jaw Crusher designed to Crush Primary Rock at the Quarry Face Designed specifically for the quarry market, the unique design of the ‘nipangle’ and extralong jaws make the 800i ideally suited to hard rock applications Featuring a 24 ton, 1100 x 800mm wide jaw crusher unitNEW 800i Jaw Crusher Tesab Engineering jaw crusher preventing any wear to occur on the Reversible Manganese Jaw Plates The reversible and heattreated wear resistant manganese jaw plates actually get tougher as they work The extra jaw plate length plus the crushing angle assures instant nip of incoming material Productionwasting material rebound is held to a minimumJAW CRUSHERS McLanahan

Lokotrack® LT120™ Mobile jaw crushing plant

crusher and conveyors enable a highly effective, economical and environmentfriendly process The Lokotrack LT120E electrical system is designed in such a way that it provides the same benefits in operation and maintenance as the hydraulic version Capacity is maximised with an excellent nip angle and aggressive linear stroke Easy to transport Angle of Nip — The angle formed between the moving surface of a crusher roll or jaw plate and the stationary plate surface at which point the material will be pinched Angle varies with machine size and material lump size Bond Work Index (BWI) — Kilowatt hour (kWh) per short ton required to reduce the material to 80% passing 100 micronsHandbook of Crushing TerraSource Global Liberty™ Jaw Crusher Model: 3244 ROBUST CONSTRUCTION » Heavyduty main frame » Fabricated and stress relieved FRAME MOUNTED MOTOR » Reduces footprint » Frees up deck space » Smaller drive belt HYDRAULIC OPERATION » Wedge adjust » Spring tension rod system AGGRESSIVE NIP ANGLE » Consistently grabs toughest materialLiberty Jaw Crusher Crush Tech

Condition Monitoring Mining Equipment Consulting

pper milling plant

glass display cabinets south africa

crushing plant machinerymobile

sucursal in crusher brasil

Sand Making Machine Manufacturer

forging forging grinding ball sale surabaya

crusher crusher dolomit indonesia

used aggregate crushers for sale tanzania

mini mini ball mill machinery grinder

Gecko Mining Pty Ltd In Witbank

Electric Heating Detergent Stainless Steel Mixing Tank Price

marble quarry equipment supplies

cement used for grinding silica powder

aggregate crushing equipment manufacturers india

Ball Mill Machinery Manufacturers In Gujarat

single phase posho mill m otors

american grinding machines spare parts

mobile screening crusher mparison

gold ore crushing processing mining crusher

gundlach crusher for ores process machine zimbabwe

pros and ns of sub surface mining

welding electrode india price

list of jaw crushers producers

high quality pinch valve

iron ore crushing plant production st in malaysia

impact of quarry stone in ghanaian society

Table Top Flour Mill In Uk

pictures of flotation cells

angles rolling mills supplier