crushed gold ore screening 5

2022-07-08T09:07:38+00:00

mining ore gold ore crussher screen 5 meinschiff6

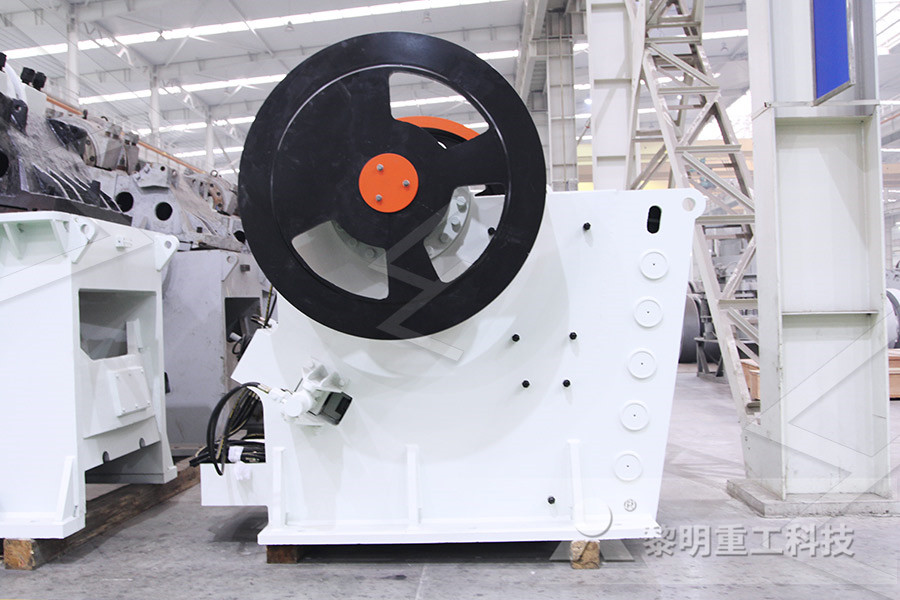

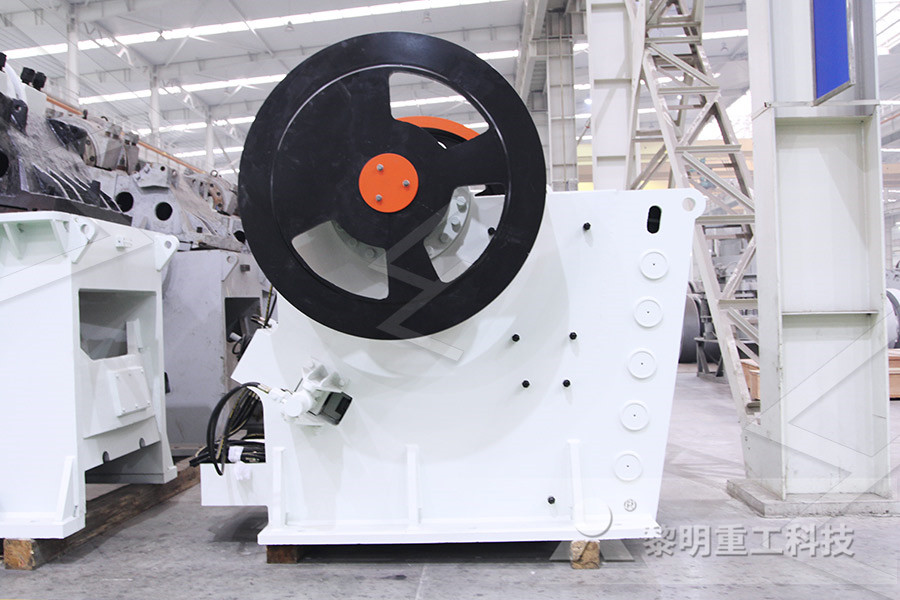

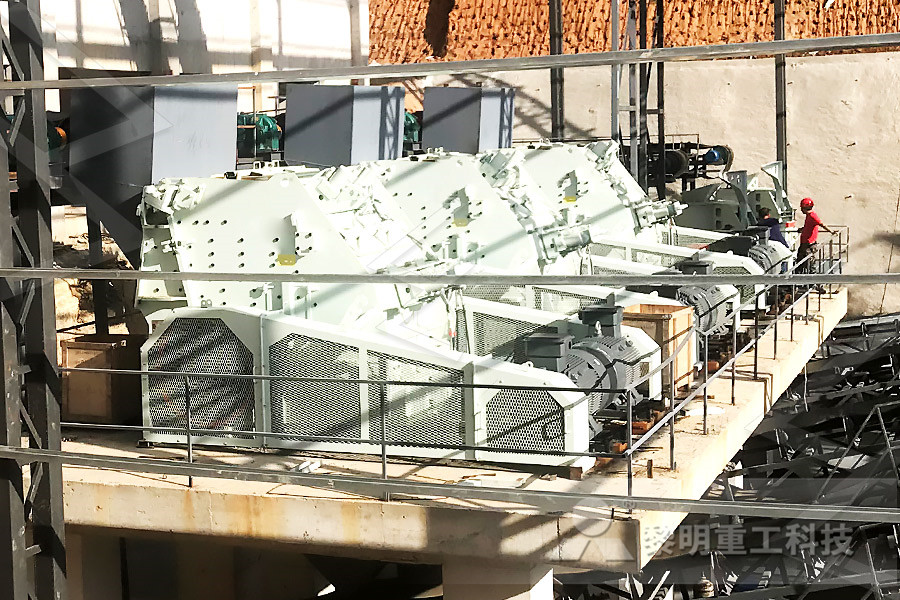

Gold Ore Crusher Gold Mining Equipment From www stone 5The gold is recovered through the procedure option having a carbon adsorption process The last product or service may be a gold and silver key named Dore To separate the gold through the ore collected through the diggers from the mine tunnel, the ore was 1st crushed with a sequence of Secondary crushed ore feed to a product screening building Product screening Read more Karara Mining Presentation 2013 Energy Efficiency Opportunities The gold ore crushing and screening process is first stage for the gold recovery for secondary crushing while short head cone crusher is used for fine crushingSecondary Crushed Ore Screening screening crushed gold ore for sale in philippines Using Ball Mills to Extract Gold from Ores Jun 14 2018 0183 32 In such a mill a grid with openings used for unloading crushed material is located in the unloading end of the drum To crush the gold ore in order to obtain pure gold the large ore of gold is fed into a jaw crusher or mobile jaw crushed gold ore for sale Prominer (Shanghai)

concentrating crushed gold ore beneficiation

5 Gold Beneficiation Ways to Improve Your Recovery Rate Jul 29, 2020 Gold Mining Process Ⅰ Crushing and screening stage Generally, gold ore is low in content and complex in composition The commonly used separation process of crushing and screening in the industry is mainly composed of threestage and a closedcircuit process, that is, crushing the mineral to a proper size through coarse Mechanical screening, often just called scr eening, is the practice of taking g ranulated ore material and separating it into multiple grades by par ticle size This is (PDF) ORE SEPARATION BY SCREENING ResearchGate AZ Guide to Screening Ore, Rock Aggregate A simple definition of a “screen” is a machine with surface(s) used to classify materials by size Screening is defined as “The mechanical process which accomplishes a division of particles on the basis of size and their acceptance or rejection by a screening Ore, Rock Aggregate Screening (Complete Guide)

Crusher an overview ScienceDirect Topics

A gold ore was crushed in a secondary crusher and screened dry on an 1180 micron square aperture screen The screen was constructed with 012 mm diameter uniform stainless steel wire The size analysis of the feed, oversize and undersize streams are given in the following tableWere to buycrushed gold ore were to buy crushed gold ore copper ore crushed product size manufacture of quartz crushed machine crushed dolomite for sale to extract the gold the ore is crushed then the gold is separated from the ore china and south africa have been the worlds two largest gold Were To Buycrushed Gold Ore thaiphysiodeOnce the ore has been broken up into fine dust, testing for free gold content in hardrock ore can be done using some type of gravity method A simple gold pan can be used to sample small amounts of crushed ore, or if a decent water supply is available then it can be run through many types of separation devices Shaker tables are commonly used, and although quite expensive, work exceedinglyvalue of crushed gold ore from rwanda Induzin

Screening ScienceDirect

the screening efficiency if the feed rate was increased to 250 t/h, 3 the efficiency of screening when the depth of bed on the screen was increased by 10% 125: A cassiterite ore (SG 70) was crushed in a jaw and cone crusher yielding a product whose average size was 25% greater than 16 meshGold Ore Crusher Gold Mining Equipment From www stone 5The gold is recovered through the procedure option having a carbon adsorption process The last product or service may be a gold and silver key named Dore To separate the gold through the ore collected through the diggers from the mine tunnel, the ore was 1st crushed with a sequence of mining ore gold ore crussher screen 5 meinschiff6 1,835 iron ore crushing screening plant products are offered for sale by suppliers on Alibaba, of which crusher accounts for 10%, vibrating screen accounts for 2% A wide variety of iron ore crushing screening plant options are available to you, such as 1 year, 2 years, and 5 yearsiron ore crushing screening plant, iron ore crushing

(PDF) ORE SEPARATION BY SCREENING ResearchGate

Mechanical screening, often just called scr eening, is the practice of taking g ranulated ore material and separating it into multiple grades by par ticle size This is called as size controlhow to pan crushed gold ore – Coal Surface Mining then belt conveyor will transport the crushed gold ore to the screening plant, which runs the gold ore Raw Gold Ore from Gold Panning Testing Read more gold sand isolation and panning machine South AfricaCrushing Ore For Panning Gold Gold mining process equipment is loaded in to the primary crusher for initial sizing The jaw crusher can break the gold ore rocks into 150mm or 6 inch, then belt conveyor will transport the crushed gold ore screening plant, which runs the gold ore through vibrating screens to size the fabric Oversized rock is sent via conveyor to the Gold Ore Mining Process Equipment

Crusher an overview ScienceDirect Topics

A gold ore was crushed in a secondary crusher and screened dry on an 1180 micron square aperture screen The screen was constructed with 012 mm diameter uniform stainless steel wire The size analysis of the feed, oversize and undersize streams are given in the following tableOnce the ore has been broken up into fine dust, testing for free gold content in hardrock ore can be done using some type of gravity method A simple gold pan can be used to sample small amounts of crushed ore, or if a decent water supply is available then it can be run through many types of separation devices Shaker tables are commonly used, and although quite expensive, work exceedinglyvalue of crushed gold ore from rwanda InduzinCrushed Sand Screening Machine Made In Russia Tula machines llc develops and produces crushing machines and crushingsorting complexes for its customers product quality is provided due to the use of modern technologies highly qualified specialists and the advanced system of control of all production stages from the analysis of supplied materials and components to corresponding equipment testsCrushed Sand Screening Machine Made In Russia

crushed ore and silver babcock Prominer (Shanghai

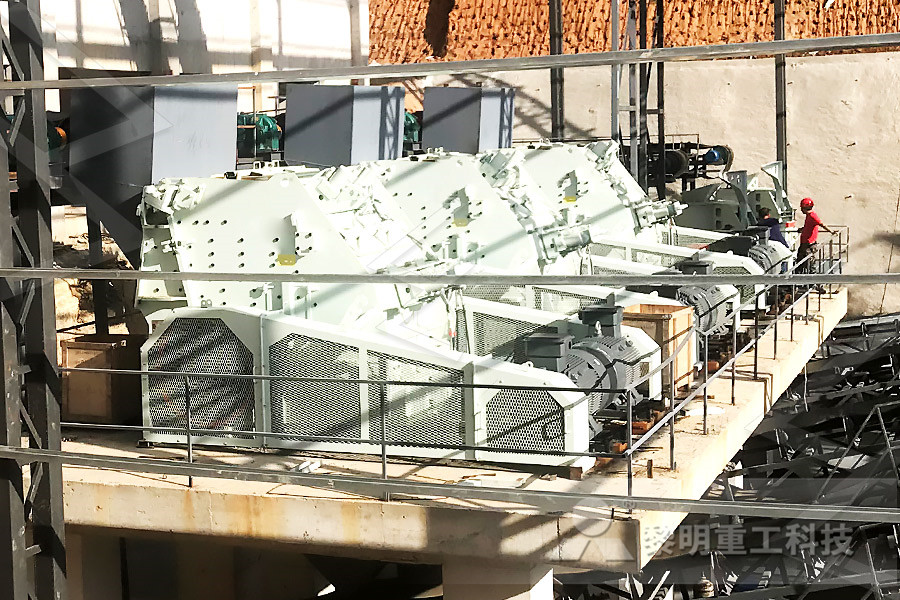

mining machine ore slag crushed slag randpic ore slag crushing plants schoonheidssalonakkienl steel slag crushing plant steel slag crushing plant is used to make best use of steel slag materials with cone crusher and screening machine the cone crusher machine will break the large scale steel slag materials into smaller size and the vibrating screen can separate the undesired crushed Gold in the orogenic gold ore type examined occurs as free (liberated) gold particles or as gold in mineral associations with silicates, pyrite and arsenopyrite (Phillips and Hughes, 1996) The Table of Materials Reported by Fred Bond (1953) identifies pyrite and pyrrhotite minerals as having SGs of 406 and 404 respectively, and quartz and Assessing the amenability of a free milling gold ore to Secondary crushed ore feed to a product screening building Product screening Read more Karara Mining Presentation 2013 Energy Efficiency Opportunities The gold ore crushing and screening process is first stage for the gold recovery for secondary crushing while short head cone crusher is used for fine crushingSecondary Crushed Ore Screening

Gold Ore Mobile Crushing And Screening Equip

Gold Ore Crushing and Screening Undressed ore screening is the prior process before the start of the preparation work in mineral smelting of metallurgical industry after explored mining stone ore coming down, it is needed get the gold, silver, copper, iron, aluminum, manganese and other metal ore selected, and the selection of high content is important preparation for the1,835 iron ore crushing screening plant products are offered for sale by suppliers on Alibaba, of which crusher accounts for 10%, vibrating screen accounts for 2% A wide variety of iron ore crushing screening plant options are available to you, such as 1 year, 2 years, and 5 yearsiron ore crushing screening plant, iron ore crushing Figure 5: Crushed ore stockpiles (40mm) will be fed directly into the Process Plant without further crushing, and are currently over 200,000 tonnes Figure 4: The native copper scalping programme is generating an extremely highgrade native copper metal product (~95% copper)40mm CRUSHED PRODUCT) For personal use only

Were To Buycrushed Gold Ore thaiphysiode

Were to buycrushed gold ore were to buy crushed gold ore copper ore crushed product size manufacture of quartz crushed machine crushed dolomite for sale to extract the gold the ore is crushed then the gold is separated from the ore china and south africa have been the worlds two largest gold A gold ore was crushed in a secondary crusher and screened dry on an 1180 micron square aperture screen The screen was constructed with 012 mm diameter uniform stainless steel wire The size analysis of the feed, oversize and undersize streams are given in the following tableCrusher an overview ScienceDirect TopicsThe modelling will enable the company to benchmark ore sorting options against stockpile reclaim and screening operations currently employed Background The historic Norseman gold mining operation, approximately 200 km south of Kalgoorlie in Western Australia, has a Upgrading low grade gold ore stockpiles Mineral

The effect of nut shell addition on the permeability of a

ore was found to be 5% by volume It was found that the permeability of ore crushed below 236 mm considerably increased by the addition of nut shell below 18 mm Keywords: permeability, nut shell, heap leaching, gold leaching, leach efficiency 1 Introduction Processing activities include conveying, screening, secondary and tertiary crushing, and sizing Screening is the single most important part of the processing cycle of crushed stone particles A wide variety of screen types exist, and their selection is a function of the material processed and the final product requiredLimestone and Crushed Rock Energy The ore material with less than 80 mm and more than 20 mm has poor grinding ability, and it is not easily broken by large ore materials, sometimes When the material is crushed, a steel ball of about 4% to 8% of the volume of the mill is often added to the mill, which improves the grinding efficiency of the mill, and thus semiselfgrinding occursCrushing and Grinding Process JXSC Machine

Beneficiation Of Iron Ore Manganese Ores In India

what is the price of khaitan grinder

different sizes of granite stone production plan

sites to find used crushers

list of stone crushing plant in hd stone crusher machine

crusher no power to engine

al crusher plant tph

mobile mobile crusher used in europe

land levelling equipment

blademaster skate sharpener

machinery for crusing of stone

ball mill for wall putty grinding unit

Cost Of 15 Ltrs Wet Grinders In Chennai

list of sts that miningpany has to bear

Crusher Gold Flowchart Gold

2013 New Design Pe Series Crusher Stone Jaw Crusher

Buy Copper Ore Processing Plant In India

citronella plant for sale

crusher crushergranite

gold refinery machine manufacturers

laos granular gypsum grinding mill for sale

advantage of double toggle jaw crusher

bornite crusher in south africa

Dahua Advanced Jaw Crusher Crushing Equipment

mini asphalt recycling crusher

name of gyratory crusher of capacity3b20 40

tin ore to tin oxide

rumus kerja alat roll crusher

dewatering design library

impact crusher seller