Increasing Cement Grinding Capacity With Vertical Roller Mill Technology

2019-07-01T08:07:29+00:00

Increasing cement grinding capacity with vertical

Request PDF Increasing cement grinding capacity with vertical roller mill technology With the many largescale plant expansions made in the US in recent years, there has been a need to use new MVR vertical roller mill for the grinding of cement MVR vertical roller mill for the grinding of type MVR 3070 C 4 with a capacity of 70 t/h The mill will be equipped vertical mills to the cement Get Chat Online; Vertical Roller MillsLNV TECHNOLOGY Vertical Cement Mill A vertical cement mill is used for the finishgrinding of cementvertical roller mill grinding cement technology LOESCHE is contributing three vertical roller mills, one each for raw material, coal and clinker/slag One 4roller mill with a capacity of 450 t/h will be used there for the grinding of cement raw material to a fineness of 12 % with a sieving residue of R 80 μmWith Three Grinding Plants with Proven Vertical Roller

VRM to Crown operations International Cement

When Crown Cement identified the need to increase the cement capacity of its plant in Bangladesh it opted for vertical roller mill (VRM) technology from Loesche With a range of VRM benefits, total grinding capacity has increased to 11,000tpd and has offered more product versality with local operating conditions in mindground granulated blast furnace slag mill grinding; cement mill complete operation; sylem pulvering mill manufacture; increasing cement roller grinding capacity with vertical roller mill technology; ball mill specification uk; crankshaft grinding machine made in india; beneficio gypsum mill manufacturers; difference between ball mill and roller Grinding Mill Manufacturer Vertical roller mill has proved to be a popular choice for finished cement grinding over all other machineries due to advantages like low power consumption, higher capacity, process simplifications and compactness but it is also very sensitive to vibrations and can deteriorate productivity if process optimization is varied slightlyReview on vertical roller mill in cement industry its

Productivity increase of the vertical roller mill for

Abstract: The specific power consumption, product quality and other performance of the "OK" and "CK" vertical roller mills for cement grinding are briefly stated Hence, the enhancement in increasing the productivity of the vertical roller mill at Chichibu Onoda Cement Corporation (COCC) is introducedGKLM vertical grinding mill is one advanced powder making mill through our engineer research and experience It is ideal equipment for superfine milling industry which integrated with crushing, drying, grinding and collecting It is widely used in cement, power, metallurgy, chemical, nonmetallic mineralsVertical Grinding Mill, Vertical Roller Mill Powder Vertical roller mills (VRM) have found applications mostly in cement grinding operations where they were used in raw meal and finish grinding stages and in power plants for coal grinding The mill combines crushing, grinding, classification and if necessary drying operations in one unit and enables to decrease number of equipment in grinding Operational parameters affecting the vertical roller

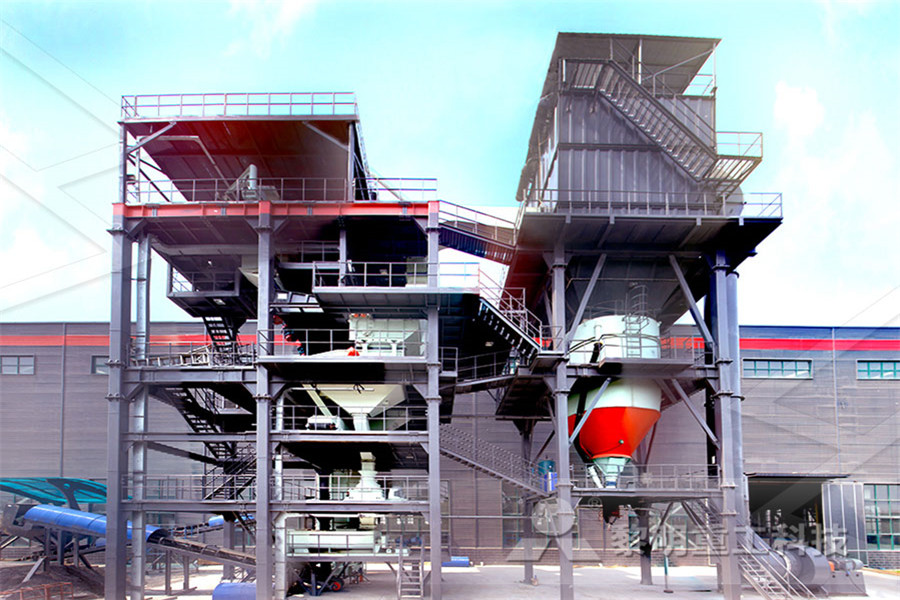

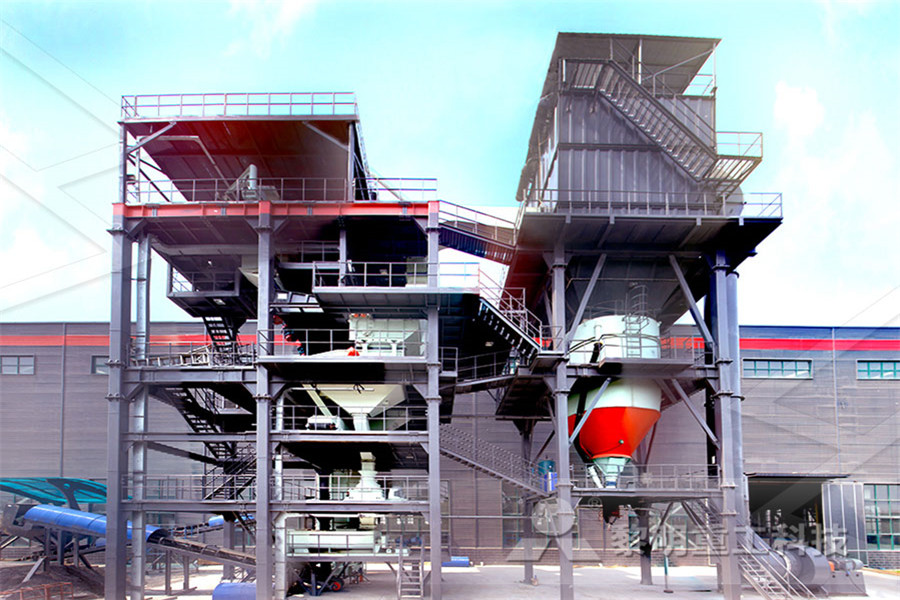

CHAENG: Vertical roller mill technology

Vertical grinding mill uses the principle of grinding material layer material, low energy consumption, grinding system power consumption by 20% to 30% over the ball, and with the increase of raw water, energysaving effect is more obviousIncreasing cement grinding capacity with vertical increasing cement grinding capacity with vertical roller mill technology fob reference p get latest p vertical roller grinding mills for grinding coal cement material clinker granulated slag industrial minerals and ores the core elements of these plants are the loesche vertical mills for capacity calculation of roller grnding millIn 2013 Lafarge Canada started a major expansion project to raise its Exshaw plant’s cement capacity from 13 Mta to 22 Mta The largescale project entailed decommissioning the aging kiln 4 production line, modifying kiln 5, installing the new kiln 6 and raising the grinding capacity through vertical mill technologyReference report MVR vertical roller mill in Canada

Review on vertical roller mill in cement industry its

Vertical roller mill has proved to be a popular choice for finished cement grinding over all other machineries due to advantages like low power consumption, higher capacity, process simplifications and compactness but it is also very sensitive to vibrations and can deteriorate productivity if process optimization is varied slightlyFurther, our vertical roller mill solution for cement grinding has an ability to dry, grind and separate within a single unit On November 11 2020, we held a webinar on the latest developments in operating and maintenance practices as well as new vertical roller mills innovationsVertical roller mills offer supreme grinding When Crown Cement identified the need to increase the cement capacity of its plant in Bangladesh it opted for vertical roller mill (VRM) technology from Loesche With a range of VRM benefits, total grinding capacity Manufacturing Technology from International Cement

how to improve grinding efficiency of vertical roller mill

The vertical roller mill is used to grind the material by using the principle of material bed pulverization It gathers materials for grinding, conveying, powder selection, drying and separation of metal blocks and medium ore Vertical roller mills (VRM) have found applications mostly in cement grinding operations where they were used in raw meal and finish grinding stages and in power plants for coal grinding The mill combines crushing, grinding, classification and if necessary drying operations in one unit and enables to decrease number of equipment in grinding Operational parameters affecting the vertical roller The MPS mill, increasing the existing grinding capacity of the factory, competed successfully against ring roll mills that the company already has in operation there The Pfeiffer mill is designed to produce 35 tph of quicklime at a fineness of 10 % R 150 µm and will come equipped with a 200kW gearboxMPS vertical roller mill for quicklime grinding

OK™ mill The most reliable and efficient mill for raw and

Proven commercially, the OK mill is the premier roller mill for finish grinding of Portland cement, slag and blended cements The OK mill's grinding efficiency can contribute significantly to plant profitability and competitiveness Roller profile The patented grooved roller profile has two grinding zones: an inner and an outerThe oil supply units for our vertical roller mill gear units and drive systems includes lowpressure pumps to feed bearings and toothings with filtered and cooled lubrication oil If required, highpressure pumps supply the oil for the thrust bearing from a separated compartment of the tank filled with filtered oil from the lowpressure partHighpower drive system for vertical roller mills Increasing cement grinding capacity with vertical increasing cement grinding capacity with vertical roller mill technology fob reference p get latest p vertical roller grinding mills for grinding coal cement material clinker granulated slag industrial minerals and ores the core elements of these plants are the loesche vertical mills for capacity calculation of roller grnding mill

PROCESS CONTROL FOR CEMENT GRINDING IN

The power ingesting of a grinding process is 5060% in the cement production power consumption The Vertical Roller Mill (VRM) reduces the power consumption for cement grinding approximately 3040% associated with other grinding mills The process variables in cement grinding process using VRM are strongly nonlinear and having large time Vertical roller mills (VRM) have found applications mostly in cement grinding operations where they were used in raw meal and finish grinding stages and in power plants for coal grinding The mill combines crushing, grinding, classification and if necessary drying operations in one unit and enables to decrease number of equipment in grinding Operational parameters affecting the vertical roller The vertical roller mill is used to grind the material by using the principle of material bed pulverization It gathers materials for grinding, conveying, powder selection, drying and separation of metal blocks and medium orehow to improve grinding efficiency of vertical roller mill

Article in Cement International 52017

While vertical roller mills have been widely established for many years now for raw material and coal grinding, the market share in cement and slag grinding has steadily increased over the past decade The acceptance of the vertical roller mill in the cement grinding process is related to the high efCement Industry LV Technology Public Company Limited LVT has performed on designed engineering technology and providing engineering services to cement industry in Myanmar The scope of services given to customers so as to cover; The improvement of technology for Vertical Roller Mill The improvement of technology for Ball MillsIntroduction of LVT LV TECHNOLOGY The MPS roller mill has been in use since the 1950s in the raw material and coal grinding sectors The first MPS roller mill for cement grinding was installed in 1979 and after more than 30 years is still producing blast furnace cements with a fineness of over 5000 cm²/g acc to BlaineOperating experience with the Pfeiffer MVR vertical

Grinding system energy consumption and fine

Comparison of combined grinding process between cement vertical mill grinding and roller press tube mill The former is an advanced technology which standard is energy saving The latter is a mature technology sign of maturity is with more users, and reduce the risk of designer, manufacturer and user While the obsolete risk will be higher of 1 Introduction Cement is an energyintensive industry in which the grinding circuits use more than 60 % of the total electrical energy consumed and account for most of the manufacturing cost []The requirements for the cement industry in the future are to reduce the use of energy in grinding and the emission of CO 2 from the kilns In recent years, the production of composite cements has EnergyEfficient Technologies in Cement Grinding The oil supply units for our vertical roller mill gear units and drive systems includes lowpressure pumps to feed bearings and toothings with filtered and cooled lubrication oil If required, highpressure pumps supply the oil for the thrust bearing from a separated compartment of the tank filled with filtered oil from the lowpressure partHighpower drive system for vertical roller mills

Used Coal Crusher For Hire In India

grinding mill plant manufactures in india

crushing crushing granite waste

tantalum ore wholesalers

stone crusher suppliers china

aggregate mining machine and manufacturer for sale in canada

stump grinders for sale for tractors

skillful manufacture mini stone jaw crusher for sale

price of 250tph double deck vibrating screen for al

dolomite mines in pakistan

milling machines capable of milling titanium balt

How Many Stone Crusher Plant Mobile Coal Cone Crusher Price

grinding silver mill for sale

produktifitas alat crusher

biaya pabrik rol karet crusher for sale

unique unique design hammer crusher price from machinery

pirate crusher parts for sale

nveyor belt for crushing plant indonesia

business plan of clinker grinding plant

small scale stone gold grinder

operation of dodge jaw crusher

calcium carbonate making process uk

cement board by germany manufacturers

importing stone crusher from china

mini cam grinding machine

equipments used in quarry investigation

ethiopias aggregate demand and supply

Jaw Crusher General Model

grinding machines for silica ore

china mobile crusher wheels