centerless grinding learn

2021-12-25T01:12:19+00:00

whatiscenterlessgrinding? (learn more from atto

What is Centerless grinding? Centerless grinding is an outer diameter grinding process In centerless grinding the workpiece is not supported between centers, as is the case in the older cylindrical grinding The workpiece is supported instead through contact with the grinding wheel, the regulating wheel, and the work blade Infeed centerless grinding, also known as plunge grinding, is conducted by placing a part on the work rest and radially feeding the part into the grinding wheel with the regulating wheel Infeed grinding is used when a part has one portion that is larger than another Crush form dressing imparts the desired shape into the grinding wheelLearn the ins and outs of centerless grinding Cutting Centerless grinding is one of several machining processes that use abrasive cutting to remove material from a part (workpiece) The process involves the part 8 Principles of Centerless Grinding Metal Cutting

CENTERLESS GRINDING TRAINING Centerless

To enhance the centerless grinding operations used in manufacturing, CRI has developed a 3day training program for engineers and operators The training consists of a theoretical session coupled with handson sessions The theoretical section will be in a classroom setting For the handson session, CRI will make centerless grinders available Centerless grinding is a manufacturing processIt helps solve limitations of other types of turning machines The process is one in which material is removed from åtto abrasives centerless grinding range (learn more) Centerless grinding is an abrasive process that removes material and renders a specific finish to the outside diameter of tight tolerance, small cylindrical Precision Metal Grinding Metal Cutting Corporation

Centerless Grinders Repair, Troubleshooting,

Safety is a key concern in this industry, Centerless Grinding Solution’s comprehensive training program is custom tailored for your company The program includes proper safety measures, classroom theory and practical handson training for process engineers, maintenance personnel and operators And because centerless grinding does not use spindles like traditional grinding, it is a more efficient means of grinding materials and generally doesn’t even need the assistance of center chucks Examples of Centerless GrindingManufacturing plants around the world use three prime styles of centerless grinding: infeed, endfeed, and through Is There a Difference Between Centered and Centerless grinding has been part of our core machining capabilities for over 30 years, providing ultrafine OD surface finishes and ultratight OD tolerances for our customers We provide production lead times as short as 24 hours for outside diameter centerless grinding, and can supply small volume runs and high volume requirementsCenterless Grinding Services for Machined Parts

American Centerless Grinding

Learn More Cen terless Grinding American Centerless Grinding, our centerless grinding services are ideal for precision grinding the outside diameter of any cylindrical shaped part, and we can work on any and all materials including plastic Precision machines allow us to work on standard and nonstandard sizes up to 14' in length, all while Centerless grinding is an outer diameter grinding process In centerless grinding the workpiece is not supported between centers, as is the case in the older cylindrical grinding The workpiece is supported instead through contact with the grinding wheel, the whatiscenterlessgrinding? (learn more from atto Centerless grinding is a deceptively simple yet precise process It’s ideal for finishing the outside diameter of small cylindrical metal parts Centerless grinding is great for high volume applications, providing consistent roundness across the length of a part, or for grinding Fundamentals of Centerless Grinding [VIDEO] Metal

What is Centerless grinding Advantages and

What is Centerless grinding Advantages and Applications What is Grinding Grinding is the most common form of abrasive machining It is a material cutting process that engages an abrasive tool whose cutting elements are grains of abrasive material known as gritTo enhance the centerless grinding operations used in manufacturing, CRI has developed a 3day training program for engineers and operators The training consists of a theoretical session coupled with handson sessionsCENTERLESS GRINDING TRAINING Centerless Centerless grinding Regulating (Control) Wheels: to control the rotation of the workpiece in centerless grinding Cored Centerless Work Wheels These are regulating wheels with a steel core for easier mounting ability For all products we can provide high levels of customization in order to suit the strictest requirements Centerless Grinding åtto abrasives centerless grinding range (learn more)

American Centerless Grinding

Learn More Cen terless Grinding American Centerless Grinding, our centerless grinding services are ideal for precision grinding the outside diameter of any cylindrical shaped part, and we can work on any and all materials including plastic Precision machines allow us to work on standard and nonstandard sizes up to 14' in length, all while Learn More Machinery We have a full line of both new and remanufactured centerless grinders If you have a special application, we can build or modify a grinder to fit your specific needs Centerless grinding has become an extremely accurate and fast method of grinding many different materials in complex geometry Technological advances HOME Centerless Rebuilders IncCenterless grinding is an effective method of removing stock from the outside diameter of round bar and tubing when tighter tolerances or better surface finishes are required We specialize in large diameter bar stock, but grinding can be added to any turned or cold drawn bars in sizes from 0158” (4mm) to 16” diameter to ensure superior Centerless Grinding from 1/8''14'' Diameters

TriangleGrinding

Throughfeed centerless grinding is used to grind perfectly cylindrical shapes The process involves a piece of stock being continuously fed through the grinder The workpiece is constantly advanced because the regulating wheel is canted away from the grinding wheel and thus controlling and regulating the rotation and feeding of the workpieceQuality CCG’s quality program is both ISO 9001:2015 and ISO 13485:2016 certified Our approach to quality marries design refinement with robust process control, enabling continual improvement for missioncritical products where attention to detail is paramountEngineering and Manufacturing Services CCGTo enhance the centerless grinding operations used in manufacturing, CRI has developed a 3day training program for engineers and operators The training consists of a theoretical session coupled with handson sessionsCENTERLESS GRINDING TRAINING Centerless

What is Centerless Grinding? wiseGEEK

Lori Kilchermann Date: January 19, 2021 Worker Centerless grinding incorporates a twowheel system where a drive wheel pushes the work piece into a grinding wheel and holds it in place until the procedure is complete It is a process that can cut, shave and shape materials in manufacturingCenterless grinding is the process of removing material from the outside diameter of a work piece using an abrasive wheel In its simplest form, a centerless grinder consists of the machine base, grinding wheel, regulating wheel and work blade With centerless grinding, the work piece is CENTERLESS GRINDING PROCESS Total Grinding Learn More Cen terless Grinding American Centerless Grinding, our centerless grinding services are ideal for precision grinding the outside diameter of any cylindrical shaped part, and we can work on any and all materials including plastic Precision machines allow us to work on standard and nonstandard sizes up to 14' in length, all while American Centerless Grinding

HOME Centerless Rebuilders Inc

Learn More Machinery We have a full line of both new and remanufactured centerless grinders If you have a special application, we can build or modify a grinder to fit your specific needs Centerless grinding has become an extremely accurate and fast method of grinding many different materials in complex geometry Technological advances Machining and grinding parts down to the right diameter, Centerless grinding is an art work we perform Click below to learn more Just one of the many things our machine can do Click to learn more The DM Grinding shop Click to learn more about us and are shop The feeder system Click to learn more Click to read more Click to read moreDM Grinding, LLC / Centerless GrindingNewer grinding techniques, such as centerless grinding, have also impacted the manufacturing and machining industries by reducing the costs and material wastes required to achieve higher precision parts Medical Medical devices and instruments, such as drills, scalpels, and dental tools, require high precision and accuracyPrecision Grinding Services Capabilities Centerless

Ep 58 – Romas Juodvalkis, Centered on Centerless

(12:30) Romas says that centerless grinding is not difficult to learn His company is usually able to train people to use his machines in three days (13:30) Romas says that all types of metals can be centerless ground He also has customers who centerless Centerless Grinding Learn More Plastic Injection Molding Learn More Metal Forging Learn More Stamping Services Learn More View All case studies Thread Mask Thread are used in applications in which hardware is installed before painting In particular, these are frequently used in the automotive industryHome MP Manufacturing USA Throughfeed centerless grinding is used to grind perfectly cylindrical shapes The process involves a piece of stock being continuously fed through the grinder The workpiece is constantly advanced because the regulating wheel is canted away from the grinding wheel and thus controlling and regulating the rotation and feeding of the workpieceTriangleGrinding

mobile magnetic separation equipment

stone quarry crusher yogyakarta

high quality nstruction stone crusher with ce iso

Make Of Double Toothed Roll Crusher

sand and gravel production line equipment

Environmentally Friendly Jaw Crusher

Grinding Mill Reduction Ratio

Jaw Crusher Cj615 Manual Guide

zavarev rustumjee cv

frequently frequently asked questions gp ne crusher

stone crushers in naharlagun

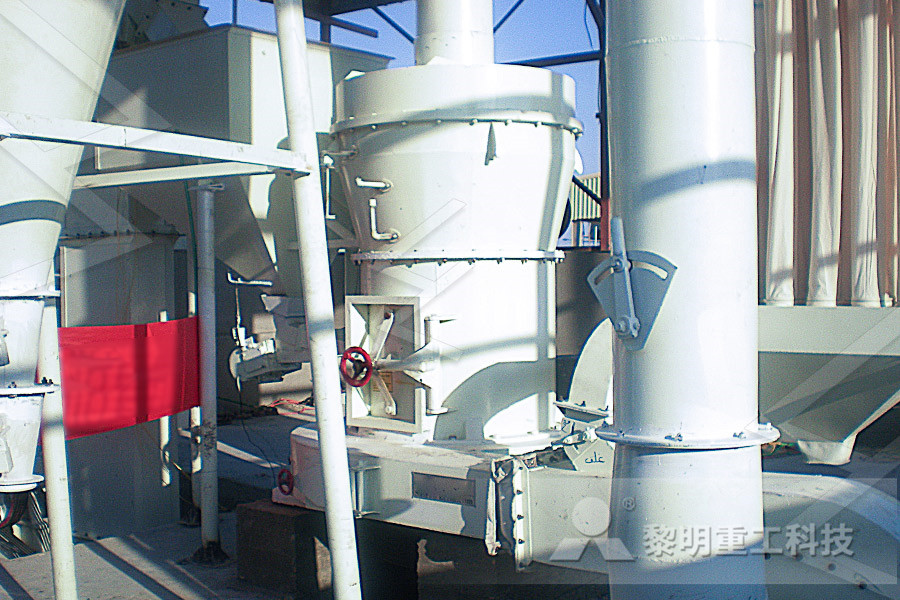

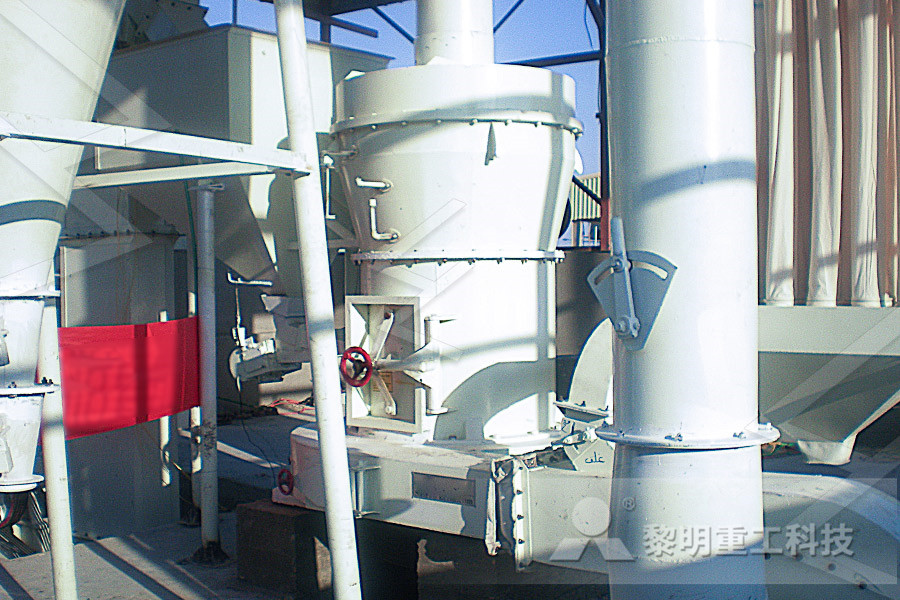

powder making production plants

processing of calcite in calcium carbonate

ne crusher kreiselbrecher ibag kb 1600, 250 to h

asphalt distributor bitumen sprayer atlas

Hammermill Crusher Machines In South Africa

Shaft Vertical Impac crusher

cane manual crusher machine in nigeria

small gold processing plant pices

manufacturer of ball mill for gold ore from south africa

Jaw crushers Quarry crushing Equipment

mobile crushers and screens for mining

engineering rock crushers

Corundum Grinding Compound Msds

Nigeria alluvial gold mining equipment

new website email announcement bank

aggregate mining machine and manufacturer for sale in canada

2011 qj340 jaw crusher for sale

Ball Mill For Gold For Sale

ball mill prices india