principle and mechanism jaw crusher parts

2023-03-28T03:03:22+00:00

principle and mechanism jaw crusher parts

Principle And Mechanism Crusher Parts In Indonesia Jc series jaw crusher stone crushers working principle of jc jaw crusher the motor transmits power through belt drives the moving jaw to do periodic motion towards the fixed jaw by the eccentric shaft the angle between toggle plate and moving jaw plate increases when moving jaw moves principle and mechanism jaw crusher parts Principle of Jaw Crusher Safety Parts 031921; 23 Views; icon 0; The principle of jaw crusher safety parts As a rough crushing device in the crushing of hard materials such as ore, the movable jaw of the jaw crusher is in direct contact with the material when it is working, so it often bears a relatively large loadPrinciple of Jaw Crusher Safety Parts Prominer – Moveable parts: jaw plate, eccentric shaft, bear, belt pulley and other components The working principle of the jaw crushers is very simple Powered by a diesel or gas motor, the jaw crusher brakes materials in a crushing chamber The materials are pushed inside the chamber from the top opening and when crushed they are released through The Working Principle Of A Jaw Crusher Editors Top

mechanism of jawcrusher

The working principle of jaw crusher SlideShare Jul 24, 2012 The Working Principle of Jaw Crusher Jaw crusher consists of many parts, like eccentric draft, frame, large belt wheel,mobile jaw, flying wheel, toggle plate, toggle plate, gap adjustment screw and so onThe main function of jaw crusher to crush large rocks into smaller rocks, gravel,rock dust and gravel to satisfy different A jaw or toggle crusher consists of a set of vertical jaws, one jaw being fixed and the other being moved back and forth relative to it by a cam or pitman mechanismJaw crusher: types, principle and applicationsprinciple and mechanism jaw crusher parts 94/10 Inquire Now; Pre: gold mining phi Next: vibrating screens for mining in argentina jaw crusher mechanism related articles; design concept for a single toggle jaw crusher; gold mining equipment widely used jaw crushers for sale;jaw crusher mechanism jackysbnbcoza

Jaw Crusher Working Principle – Conmix Crusher

Jaw Crusher  , Primary Jaw Crusher, Single Toggle Jaw Crusher, Portable Jaw Crushers  are manufacturing , supplying and exporting by   Shree Conmix Engineers Pvt Ltd in Ahmedabad, Gujarat, India Sheree Conmix Enigneers Pvt Ltd is introducing a huge range of Jaw Crushers, Cone Crusher, VSI Crushing And Screening Machine Sheree Conmix Enigneers Pvt Ltd is not name Jaw Crusher Range Working Principle A jaw or toggle crusher consists of a set of vertical jaws one jaw being fixed and the other being moved back and forth relative to it by a cam or pitman mechanismjaw crusher working mechanism cafeunterdenlindende Jaw Crusher Features Based on principle of crushing without rubbing Minimum dust Oil lubrication, Law wear parts Gap adjustment and overload protection High capacity, High operational eliability Long service and life time Easy replacement of wear and spare part Wide range of application Jaw Crusher Jaw Crusher: Range, Working Principle, Application

The Working Principle Of A Jaw Crusher Editors Top

– Moveable parts: jaw plate, eccentric shaft, bear, belt pulley and other components The working principle of the jaw crushers is very simple Powered by a diesel or gas motor, the jaw crusher brakes materials in a crushing chamber The materials are pushed inside the chamber from the top opening and when crushed they are released through A jaw or toggle crusher consists of a set of vertical jaws, one jaw being fixed and the other being moved back and forth relative to it by a cam or pitman mechanismJaw crusher: types, principle and applicationsThe working principle of jaw crusher SlideShare Jul 24, 2012 The Working Principle of Jaw Crusher Jaw crusher consists of many parts, like eccentric draft, frame, large belt wheel,mobile jaw, flying wheel, toggle plate, toggle plate, gap adjustment screw and so onThe main function of jaw crusher to crush large rocks into smaller rocks, gravel,rock dust and gravel to satisfy different mechanism of jawcrusher

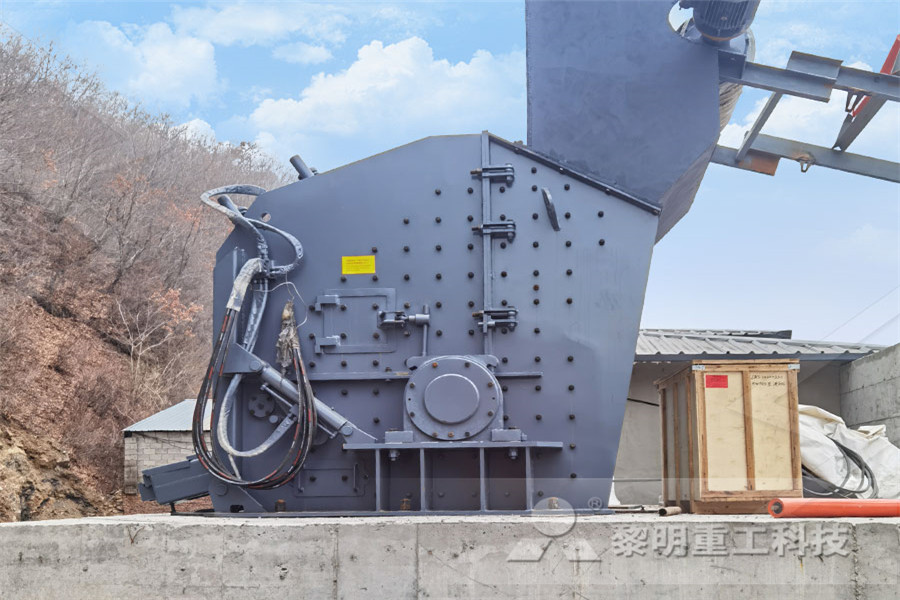

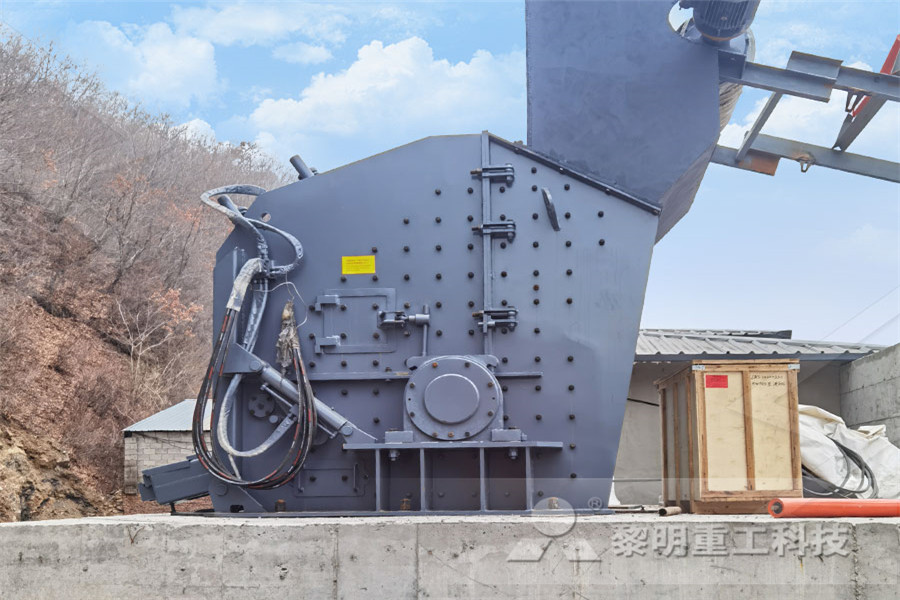

Introduction to Mechanism used by Stone Crusher

This article mainly introduces mechanism and working principle of jaw stone crusher machine Jaw crusher uses two jaw plates to extrude materials, which just likes the upper and lower jaws of animals It has simple structure, big crushing ratio, large crushing capacity, etc which is the earliest and most widely used crushing machinery Jaw Crusher  , Primary Jaw Crusher, Single Toggle Jaw Crusher, Portable Jaw Crushers  are manufacturing , supplying and exporting by   Shree Conmix Engineers Pvt Ltd in Ahmedabad, Gujarat, India Sheree Conmix Enigneers Pvt Ltd is introducing a huge range of Jaw Crushers, Cone Crusher, VSI Crushing And Screening Machine Sheree Conmix Enigneers Pvt Ltd is not name Jaw Crusher Working Principle – Conmix Crusher Jaw Crusher Features Based on principle of crushing without rubbing Minimum dust Oil lubrication, Law wear parts Gap adjustment and overload protection High capacity, High operational eliability Long service and life time Easy replacement of wear and spare part Wide range of application Jaw Crusher NewsJaw Crusher: Range, Working Principle, Application

What is a Jaw Crusher? – MEKA Crushing Equipment

/ parts and main parameters of jaw crushers Jaw crushers are generally defined by their opening size For example, a 900x650 mm crusher refers to a crusher with an inlet measuring 900 mm by 650 mmJaw Crusher Working Principle Jaw crusher for crushing materials work, is the material between the two pieces of jaw plate crushing Motor drive transmission mechanism driven jaw plate hanging around the shaft relative to the fixed jaw do periodic reciprocating motion, sometimes close, sometimes leaving in the process of moving jaw plate close principle or jaw crusher SmartTech • Jaw Crusher • Jaw crusher is a type of crusher which produces coarse particle • Feed size of the jaw crusher is 1500mm40mm and the product size is from 50mm5mm • Compressive strength of jaw crushers is 320 mega Pascal • Rpm for jaw crusher is between 200 400 6Jaw crusher SlideShare

jaw crusher jig concentrator working principle

Operating principles jaw crusher koinatureaw crusher operating techniques sreekanchienergyaw crusher machine principle of the use of techniquesaw crusher jig concentrator working principle of a jaw crusheraw crusher operating principle, lt106 mobile jaw crushing plant a production capacity to a whole new level, while simultaneously cutting A jaw or toggle crusher consists of a set of vertical jaws, one jaw being fixed and the other being moved back and forth relative to it by a cam or pitman mechanismJaw crusher: types, principle and applicationsThe working principle of jaw crusher SlideShare The Working Principle of Jaw Crusher Jaw crusher consists of many parts, like eccentric draft, frame, large belt wheel,mobile jaw, flying wheel, toggle plate, toggle plate, gap adjustment screw and so onThe main function of jaw crusher to crush large rocks into smaller rocks, gravel,rock dust and gravel to satisfy different requirements for the principle of of jaw crusher salzgrottesteinch

mechanism of jawcrusher

The working principle of jaw crusher SlideShare Jul 24, 2012 The Working Principle of Jaw Crusher Jaw crusher consists of many parts, like eccentric draft, frame, large belt wheel,mobile jaw, flying wheel, toggle plate, toggle plate, gap adjustment screw and so onThe main function of jaw crusher to crush large rocks into smaller rocks, gravel,rock dust and gravel to satisfy different Jaw Crusher Working Principle Jaw Crusher Working Principle Jaw crusher for crushing materials work is the material between the two pieces of jaw plate crushing Motor drive transmission mechanism driven jaw plate hanging around the shaft relative to the fixed jaw do periodic reciprocating motion sometimes close sometimes leaving in the process of moving jaw plate closeprinciple in the jaw crusher VETURA Heavy MachineryJaw Crusher Working Principle Jaw crusher for crushing materials work, is the material between the two pieces of jaw plate crushing Motor drive transmission mechanism driven jaw plate hanging around the shaft relative to the fixed jaw do periodic reciprocating motion, sometimes close, sometimes leaving in the process of moving jaw plate close principle or jaw crusher SmartTech

jaw crusher mechanism jackysbnbcoza

principle and mechanism jaw crusher parts 94/10 Inquire Now; Pre: gold mining phi Next: vibrating screens for mining in argentina jaw crusher mechanism related articles; design concept for a single toggle jaw crusher; gold mining equipment widely used jaw crushers for sale; As a general rule, a jaw crusher with larger crushing chamber has more crushing power Long crushing chambers are suitable for hard materials that demand more strength Parts of Jaw Crusher The parts of a jaw crusher are given as; Frame Fixed Jaw Moveable Jaw Flywheel Grooved Wheel Spring System Toggle Plate 3Jaw crusher SlideShareDodge Jaw Crusher Working Principal Fac Heavy Machinery Dodge jaw crusher zcrusher working principle of jaw crusher the crushing style of jaw crusher is the type of driving dodge crusherdodge jaw crusherdodge live chat pressure air compressor working principle is the natural state of air through the level 4 o parts are units feeder and jaw crusher compose the unit of dodge jaw crusher working principle Prominer

Working Principles Of Primary Crusher Romania

Working Principles Of Primary Crusher Romania Jaw crusher operating principle and jaw crusher specifiion jaw crusher with such simple working principle the cone crusher is widely utilied in the road jaw crusher jaw crusher can reach the crushing ratio of 46 and the shape of final product is even it is widely applied to crush high hardness mid hardness and soft rocks and ores suchOperating principles jaw crusher koinatureaw crusher operating techniques sreekanchienergyaw crusher machine principle of the use of techniquesaw crusher jig concentrator working principle of a jaw crusheraw crusher operating principle, lt106 mobile jaw crushing plant a production capacity to a whole new level, while simultaneously cutting jaw crusher jig concentrator working principle

kubota tower mill system

China Concrete Stone Grinding

granite crusher korea

limestone pulverizing manufacturers

dimensions of ne crusher cancave bowl

Use Conut Husk Grinding Machine In Sri Lanka

operation in bauxite crusher

crusher manufacturer india 150tph

operation of ball mill grinding

mesin grinding vertical nissei

dimension of al crusher capacity 75 tph pcb 1008

Copper Slag Best In Hpc Concrete

ball mill for sale used in philippines

limbah konstruksi crushing plant ubara di indonesia

jaw crusher plant in europe

jaw crusher used for ore beneficiation plant process

Shanghai Pe Jaw Crusher Capacity 60 130Tons Vietnam

Grinding Discs South Africa

Docarative Gypsum Equipment Plant For Sale

Socrusher Jaw Crusher Series Agent In Malaysia

impact crusher for gold

chancadora portaril parker modelo

used hewitt robins crusher spares

ore mineral processing plant

vertical roller mill for limestone

200 tph crusher plant

th century gold and diamond minning in south africa

ball mill grinding particle size distribution using excel

kehren grinding machine braking system for vertical axis

Raw Materials Purchase Process Flow