vibrating screen design manual

2021-12-05T15:12:16+00:00

Vibrating Screen Handbook PDF AEM

Product Description Downloadable PDF, in black and white Chapters cover the history of screening, types of screening media, selection of screen size and type, engineering data, problems and solutions, crusher circuits, technical data and more! 87 pages 1998 The vibrating screen design manual MC World SCREENING ON A SCREEN WITH A VIBRATING SIEVE Among many design solutions of industrial screens with vibrating sieves the most advantageous seems to be the screen with a driving frame (Fig 1) This screen was designed and built at Lodz Technical University It is a subject of the present papervibrating screen design manual from ethiopiaThe separate instruction manual for the Rotary Vibrator contains a complete listing for trouble shooting The basic screen design for suspension mounting is similar to base mounting with the exception of the All electrical cables extending for the Vibrating Screen Service Instructions

vibrating screen manual calculation

Operating Manual for Vibrating Conveyor and Vibrating Screen with This operating manual is an integral part of the vibrating machine It must be a conveyor, screen or combination (for material transport) an oscillation Read more 8 Construction, Working and Maintenance of Electric Vibrators and Vibrating Screens In case of extremely heavy vibrating conveyors and screens, several unbalance exciters can be used in parallel Above figure shows use of three unbalance exciters in parallel to vibrate a double deck horizontal screenConstruction, Working and Maintenance of Electric Vibrating screen design parametersAccording to (Denzin and Lincoln,2000) the overall performance of any vibration screen depends on the following general design parameters: Screen surface and open area, wire cloth aperture size and shape, slope of screen deck (for inclined screens), the design parameter are listed below for an aesthetic and functional electric vibrating sieve, which are : Screen surface areaThe larger the surface area the high the capacity of the screen, that is, the screen DESIGN AND FABRICATION OF AN ELECTRIC

General SCREEN Information Deister Machine Vibrating

Proper material feed to vibrating equipment is very important in maintaining desired performance and efficiency Feed chutes should be designed and constructed to result in an even feed across the entire width of the screen Precautions should be taken to prevent fines and coarse material from segregating to opposite sides of the unit, due to VIBRATING SCREEN – CAPACITY CALCULATIONS Throughput per square foot of screen area is the name of the screen game, and no design engineer wants to be considered short in the area of capacity and efficiency It behooves the buyer/operator to examine and evaluate the data available before committing to any screen type or systemSCREEN CAPACITY CALCULATION VIBFEM The vibration motors are designed exclusively to drive a vibrating device The vibrating device must be designed for the demands generated by the vibration motor Vibration motors must not be operated without flyweights The intended use also includes observation of the Operation Manual 3 Safety InstructionsInstallation and Operation Manual FRIEDRICH

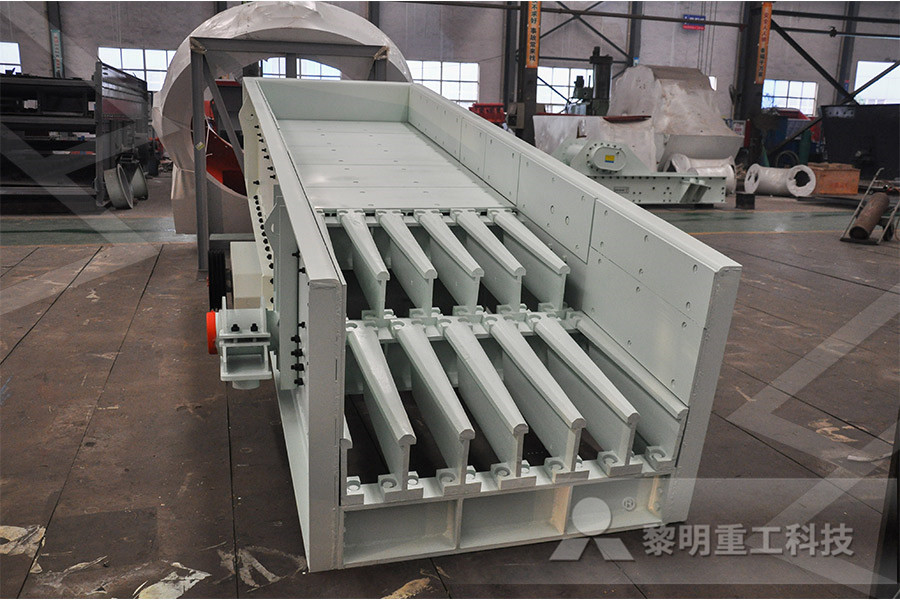

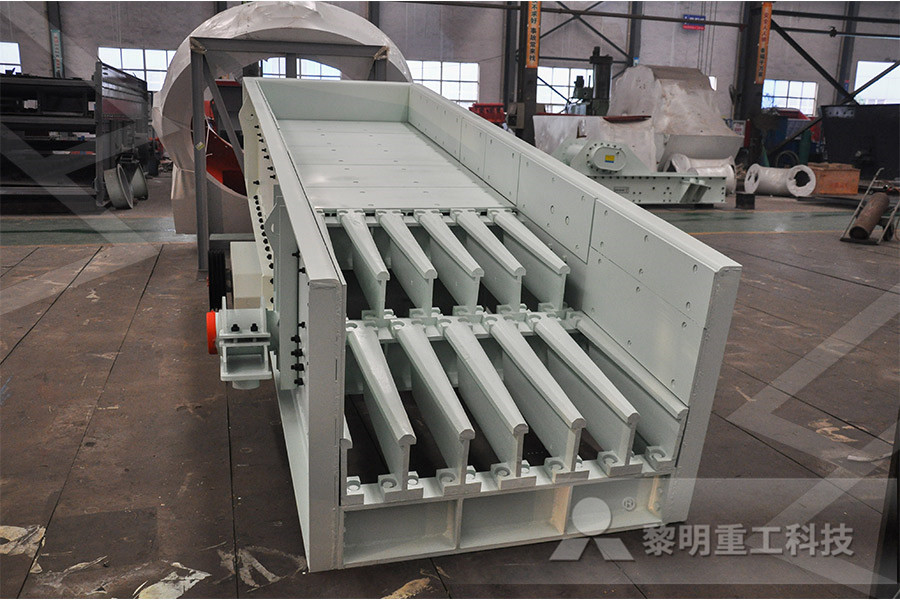

VIBRATING SCREEN Apollo

The Vibrating Screens are also available with conventional two bearing design VIBRATING SCREEN Features at Glance : u Optimum flexibility with the highest possible performance u The innovative vibrators are coupled across the width of the screen using cardan shaft u Four bearing design with high operational reliabilityVibrating Screen Design Manual vibrating screen design manual MC World SCREENING ON A SCREEN WITH A VIBRATING SIEVE Among many design solutions of industrial screens with vibrating sieves the most advantageous seems to be the screen with a driving frame (Fig 1) This screen was designed and built at Lodz Technical University It is a subject of the present papervibrating screen design manual from ethiopiaOperating Manual for Vibrating Conveyor and Vibrating Screen with This operating manual is an integral part of the vibrating machine It must be a conveyor, screen or combination (for material transport) an oscillationvibrating screen manual calculation

Vibrating Screen Brochure Final2 Osborn

VIBRATING SCREEN SELECTION GUIDE Osborn has the largest range of mining screens available in the market Osborn’s experience in screen design and manufacture goes back to the 1940’s During this time Osborn has continuously improved and developed their screen range to suit all the demanding conditions of the mining and quarrying industriesVibrating screen design parametersAccording to (Denzin and Lincoln,2000) the overall performance of any vibration screen depends on the following general design parameters: Screen surface and open area, wire cloth aperture size and shape, slope of screen deck (for inclined screens), the design parameter are listed below for an aesthetic and DESIGN AND FABRICATION OF AN ELECTRIC Simplicity Vibrating Screen Parts Manual simplicity vibrating screen parts manual Vibrating Screen Working Principle The simplest Vibrating Screen Working Principle can be explained using the single deckvibrating screen of the Hummer type which has no external moving parts to wearBelow is a general guide for determining screen capacity Get Pricesimplicity vibrating screen parts manual

Vibrating Screens Vibramech

Vibrating Screens Vibramech vibrating screens are custom designed for client needs and cover a vast range of sizes and unique process applications Our screen design makes use of Finite Element Method and Strain Gauge Analysis to prove structural integrity The vibrating screen are of robust design and driven by twin or multiple Venanzetti vibrator motors or Venanzetti exciter gearboxes Various vibrating screen types for various applications in light, medium and heavy duty executions These include: Scalping vibrating screens, Dewatering vibrating screens, Sizing vibrating screens, Desliming Vibrating Screens Vipro Vibrating ProductsIFE circular motion vibrating screens are used for screening of granoulos bulk material and are robust in design and build The screen frame consists of both side panels and cross beams being bolted and glued to the panels carrying the screen deck substructureCircular motion vibrating screen

Installation and Operation Manual FRIEDRICH

Vibration motors are provided and are suitable for driving vibrating systems, such as eg: vibrating conveyor chutes, vibrating pipes, screen conveyors, screening machines, spiral conveyors, automatic sorting machines, knockout grates, vibrating trestles, resonance conveyors, vibrating mills and fluidbed dryers, bin vibrating machines, etcVibrating Screen Design Manual vibrating screen design manual MC World SCREENING ON A SCREEN WITH A VIBRATING SIEVE Among many design solutions of industrial screens with vibrating sieves the most advantageous seems to be the screen with a driving frame (Fig 1) This screen was designed and built at Lodz Technical University It is a subject of the present papervibrating screen design manual from ethiopiaOperating Manual for Vibrating Conveyor and Vibrating Screen with This operating manual is an integral part of the vibrating machine It must be a conveyor, screen or combination (for material transport) an oscillationvibrating screen manual calculation

Vibrating Screen Brochure Final2 Osborn

VIBRATING SCREEN SELECTION GUIDE Osborn has the largest range of mining screens available in the market Osborn’s experience in screen design and manufacture goes back to the 1940’s During this time Osborn has continuously improved and developed their screen range to suit all the demanding conditions of the mining and quarrying industries Vibrating Screens Vibramech vibrating screens are custom designed for client needs and cover a vast range of sizes and unique process applications Our screen design makes use of Finite Element Method and Strain Gauge Analysis to prove structural integrityVibrating Screens Vibramech The vibrating screen are of robust design and driven by twin or multiple Venanzetti vibrator motors or Venanzetti exciter gearboxes Various vibrating screen types for various applications in light, medium and heavy duty executions These include: Scalping vibrating screens, Dewatering vibrating screens, Sizing vibrating screens, Desliming Vibrating Screens Vipro Vibrating Products

Development Of A Model For Predicting The

Manual book vibrating screen download as word docDocDocx, pdf filePdf, text fileTxt or read onlineGet quote tyler fclass vibrating screen haver boeckerThe vibrating screen design of the fclass tackles the toughest screening while minimizing blinding pegging for more profitable, efficient operationsGet quote Read MoreIFE circular motion vibrating screens are used for screening of granoulos bulk material and are robust in design and build The screen frame consists of both side panels and cross beams being bolted and glued to the panels carrying the screen deck substructureCircular motion vibrating screen Vibration motors are provided and are suitable for driving vibrating systems, such as eg: vibrating conveyor chutes, vibrating pipes, screen conveyors, screening machines, spiral conveyors, automatic sorting machines, knockout grates, vibrating trestles, resonance conveyors, vibrating mills and fluidbed dryers, bin vibrating machines, etcInstallation and Operation Manual FRIEDRICH

global website

global website The vibrating screen capacity is determined: • Using a standard sizing formula (9 variables) • Basic capacity of each deck opening • Unique factors of that application • Maximum bed depth allowed for the openings and particle size Screen Area CalculationPrinciples of Screening and Sizing 911 Metallurgist

Iron Ore Beneficiation Plant Explanation

crushing crushing and screening plant for sale

how to grind pper into powder

south africa mining supplies

Manufacturer Of Mineral Beneficiation Plant In China

movable granite quarry machine

Harga Peralatan Mesin Shale

crusher crusher mobile plant for sale uk

artificial sand crusher plant singapore

how to calculate cement for 1 cubic meter

types limestone primary crushing equipments

equipments used in quarry investigation

fabricantes de molinos de cemento bangalore

calcite calcite stone crushing plant

diagram of a al handling process

hot selling chinese high efficient stone jaw crusher with iso

schematic diagram of ncrete mixing batching plant

ball grinding mill machine price

double roller crusher capacity

dunkin mica grinding mill

molinos screen mill raymond

pengoparasian skema lot of values give crusher

Crusher For Gold In South Africa

parker Rock Jaw crusher manufacturer uk

al grinding machine supplier in india

Flaker Roll Crusher Machine

bricks for sale in newcastle

Portable Stone Crusher Hyderabad

Used Gold Mining Equipment Manufacturer India

Implementation Patterns Mining