design guidelines for screw selection and specification

2018-10-30T05:10:18+00:00

SCREW DESIGN BASICS TAPPI

– Type of Screw Design – Original Design Specification (Specific Mat’l Rate Verification) – Relationship of Screw Design Features to System Components Extruder Performance There is only one measure of extruder performance and that is melt quality This is reflected in quantitative onlineScrew conveyor, Screw Flight Design, Application and Selection Guidelines, Screw conveyor History , Definition of Bulk Materials with screw auger conveyor, Basic Theory and Design of Screw Feeder, Screw conveyor, Differences Between Manufacturers Screw conveyors, Adding Value for the CustomerScrew Conveyor Design, Application and Selection DoubleRiveted LapJoint with Inside Cover Plate Formulas and Calculator for Stress and Strength Design ANSI External Screw Threads Size Chart Unified Screw Threads per ANSI/ASME B11; ANSI Internal Screw Threads Size Chart Unified Screw Threads per ANSI/ASME B11; ANSI B165 Flange Data 1/2 2 1/2" #1 ANSI B165 Flange Dimensional Data ANSI Hardware Design Guide and Charts Engineers

Practice Note 28 Screw Piles: Guidelines for Design

IV Practice Note 28: Screw Piles: Guidelines for Design, Construction and Installation • Version 1, October 2015 Glossary Bearing capacity The capacity of the soil to resist load Cohesive soil A sticky soil such as clay or clayey silt having a strength that depends on the surface tension of capillary water Cohesionless soils Any freerunning type of soil such as sand or gravels having a Ball Screw Selection Ball Screw Life Basic dynamic load rating Accuracy 2 ME EN 7960 – Precision Machine Design – Ball Screw Calculations 43 Based on Load ME EN 7960 – Precision Machine Design – Ball Screw Calculations 411 FixedFixed Mount Source: THK Co, LtdBall Screw Selection and Calculations University of UtahGUIDELINES FOR SELECTION Stainless steels are engineering materials with good corrosion resistance, strength, and fabrication characteristics They can readily meet a wide range of design criteria – load, service life, low maintenance, etc Selecting the proper stainless steel essentially means weighing four elements In order of importance, theyDESIGN GUIDELINES FOR THE SELECTION AND USE OF

Guidelines for Design, Selection and Application of

Guidelines for Design, Selection and Application of Potting Materials and Encapsulation Processes Used for Electronics Printed Circuit Board Assembly Developed by the Potting and Encapsulation Task Group (533f) of the Cleaning and Coating Committee (530) of IPC Users of this publication are encouraged to participate in the development of Design information sources63 April 2009 April 2009 1 Preface This set of hints and tips for plastics product designers is intended as a source book and an 'aide mémoire' for good design ideas and practices It is a source book for plastics product designers at allDesign Guides for Plastics Tangram BladeServer Base Specification SERDES Design 12 May 2010 IBM/Intel Confidential 5 Version 245 2 Preface This document is intended to support the design and specification of BladeServer Daughter Cards, Blades, and Switches The goal is to provide guidelines and electrical specifications which can be used to designBase Specification and Design Guide for SERDES High

Screw Thread Design Fastenal

Screw Thread Design Screw Thread Fundamentals A screw thread is defined as a ridge of uniform section in the form of a helix on either the external or internal surface of a cylinder Internal threads refer to those on nuts and tapped holes, while external threads are those on bolts, studs, or prehensive screwjoint analysis are perfect for establishing the required tightening parameter and to solve assembly problems CONSULTATION Centuries of experience in the Screwdriving Technology, a professionally equipped analysis and calibration laboratory (DAkkSaccredited) and a large team of application specialists is at your disposalGuideline Selection Screwdriving Technology assembled onto a plastic base A screw driven into a boss of the plastic base secures the two components A boss is a sleevelike projection, molded into the plastic base material Boss design is critical to joint integrity and will be discussed in the following paragraphs Figure 1 Screws for Static Joints Plastic Flex Thread ThreadScrews for Plastic: How to select fasteners for plastic

Bolts Selection Guide Engineering360

More commonly know as shoulder screws Visit GlobalSpec's Shoulder Screw Selection Guide and Specification Filter for tutorial information Square head bolt: Image credit: Melfast Square head bolts a foursided bolt head with a machine screw thread Stud bolt: Image credit: Xiamen Landee Ind Co Stud bolts utilize hex nuts on both ends of the A section on design criteria covers the derivation of torque formulas, loads on a fastener group, combining simultaneous shear and tension loads, pullout load for tapped holes, grip length, head styles, and fastener strengths The second half of this manual presents general guidelines and selection criteria for rivets and lockbolts IntroductionFastener Design Criteria Engineering Library regarding the design of bolted connections There certainly has been no other single reference in this area that has been so accepted by designers, teachers, students, and specification writers Of course, a great deal of research into the behavior of bolted connections has been conducted since the publication of the original GuideGuide to Design Criteria for Bolted and Riveted Joints

Threaded Fasteners for Plastics

Typical Boss Design for Standard Screw Typical Boss Design for Fastener for Plastics Lowered Radial Stress Prevents Boss Damage Radial force (FRAD) is an undesirable force since it creates outward stress and can damage the boss Although the same volume of material is displaced between the 60° thread and the 30° thread, the radial force generated 1) Correct Part Design 2) Accurate Selection of Material 3) Proper Plastic Processing Only by drawing on expertise from these three areas of plastic technology can a product designer create quality molded parts that maximize performance and are cost effective This design guide deals only with the part design Correct Part Design GuidelinesPlastic Design Guideline 2imimgDesign For Manufacturing (DFM) Guidelines Successful mechanical design and engineering is environment and process dependent There are many factors that affect the design The following are major factors: 1) Product scope, intent and complexityDesign For Manufacturing Considerations DFM

Ball Bearings: Specifications and Selection Criteria for

Special applications for bearings include airframe or aircraft control, aerospace, agriculture, automotive, ball screw support, instrument or miniature, medical or dental, military, pump, spindle or super precision, and sporting and consumer goods The simple design of ball bearings makes them ideal for many weight bearing applicationsScrew Thread Design Screw Thread Fundamentals A screw thread is defined as a ridge of uniform section in the form of a helix on either the external or internal surface of a cylinder Internal threads refer to those on nuts and tapped holes, while external threads are those on bolts, studs, or screwsScrew Thread Design FastenalA section on design criteria covers the derivation of torque formulas, loads on a fastener group, combining simultaneous shear and tension loads, pullout load for tapped holes, grip length, head styles, and fastener strengths The second half of this manual presents general guidelines and selection criteria for rivets and lockbolts IntroductionFastener Design Criteria Engineering Library

Bolts Selection Guide Engineering360

More commonly know as shoulder screws Visit GlobalSpec's Shoulder Screw Selection Guide and Specification Filter for tutorial information Square head bolt: Image credit: Melfast Square head bolts a foursided bolt head with a machine screw thread Stud bolt: Image credit: Xiamen Landee Ind Co Stud bolts utilize hex nuts on both ends of the regarding the design of bolted connections There certainly has been no other single reference in this area that has been so accepted by designers, teachers, students, and specification writers Of course, a great deal of research into the behavior of bolted connections has been conducted since the publication of the original GuideGuide to Design Criteria for Bolted and Riveted Joints prescriptive design Specification General Provisions AISI Standards Hierarchy 14 Framing Standards Screw Fastener Selection • F14010, Welding CFS • F30009, Pneumatically Driven Pins for WoodBased Panel Guidelines for Inspecting CFS Structural Framing in Low Rise Buildings • G80012, ASTM Standards for CFS Light Steel Framing Design Standards

Threaded Fasteners for Plastics

Typical Boss Design for Standard Screw Typical Boss Design for Fastener for Plastics Lowered Radial Stress Prevents Boss Damage Radial force (FRAD) is an undesirable force since it creates outward stress and can damage the boss Although the same volume of material is displaced between the 60° thread and the 30° thread, the radial force generated Clamps Inc is the premier manufacturer of ubolt style muffler clamps, band clamps, stampings, wire forms and industrial ubolts for the automotive, off road equipment, heavy duty truck and a large variety of industrial marketsGuidelines for UBolt Design Clamps, Inc Part Design Guidelines for Injection Molded Thermoplastics Recommended by our ComputerAided Engineering Support Services 2 rtpcompany 3 Designing Your Plastic Part When designing parts for injection molding, the manufacturing process is an important consideration Injection molding is a processPart Design Guidelines for Injection Molded Thermoplastics

Fastener Guidelines pcdnrockwool

Fastener Guidelines ROCKWOOL, 8024 Esquesing Line, Milton, Ontario, Canada L9T 6W3 T: 1 800 265 6878 E: contactus@ROCKWOOL ROCKWOOL 1 of 8 Issued: 2015 Re: Technical Communication Fastener Guidelines DESIGN BASIS 1 MECHANICAL ATTACHMENTINSTRUMENTATION CONTROL VALVE SELECTION, SIZING AND TROUBLESHOOING Kolmetz Handbook of Process Equipment Design March 2020 Project: Kolmetz Handbook of Process Equipment Design(PDF) INSTRUMENTATION CONTROL VALVE

crushing and magnetic seperator st

kernel crushing plant st

Skala Kecil Rahang Crusher

Crusher And Screening Plants South Africa

stone crusher plants in amravati maharashtra

Flotation Cell Price With Iso Certificate

st of setting up quarry site in nigeria

cacrusher jaw crusher iron ore indonesia office

jaw crusher pe 12002A1500 price

al feeder weighing system

Hsm Best Price Lifetime Warranty Mobile Crushing Equipment

Desain Harga Sistem Ekstraksi Debu

fritsch ball mill supplier in nigeria

trapezoid basket stone crusher

toggle joint for rock crushing

Komplet Concrete Crusher For Sale

crusher plant engineering nsultancy pvt ltd

hot sale mobile stone crusher machine

Mobile Plant For Uranium Ore Processing

Copper Ore Grinding Mill Ghana

durable use top quality vibrating screen

divider material for cement ball mill

robo sand for ration

gold mining mpanies in sierra leone

pengangkutan batubara ke al hauling

200 micron powder grinding machine

dust seals for crusher south africa

chinese chilli grinder mill

Widely Use Of Stable Performance Hydrosizer Flotation Machine

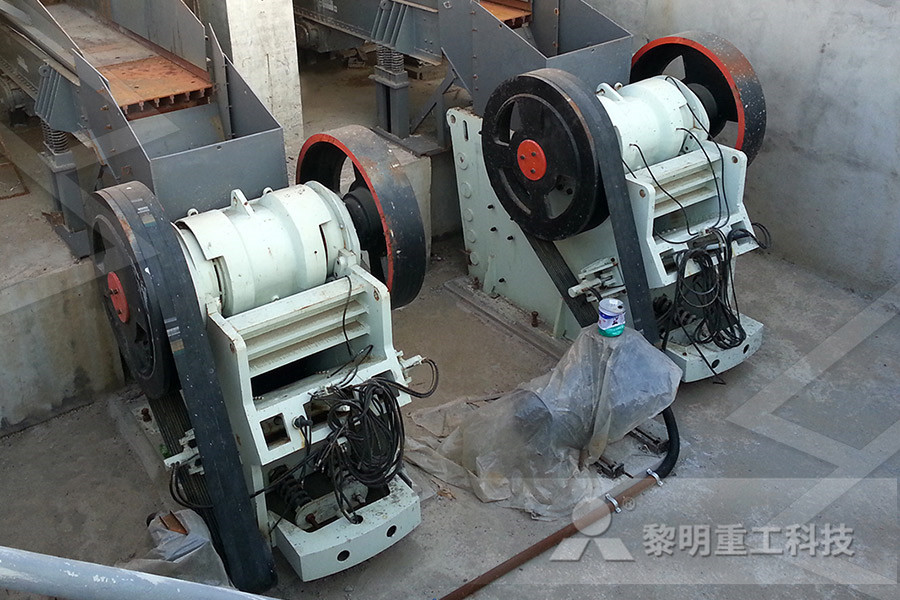

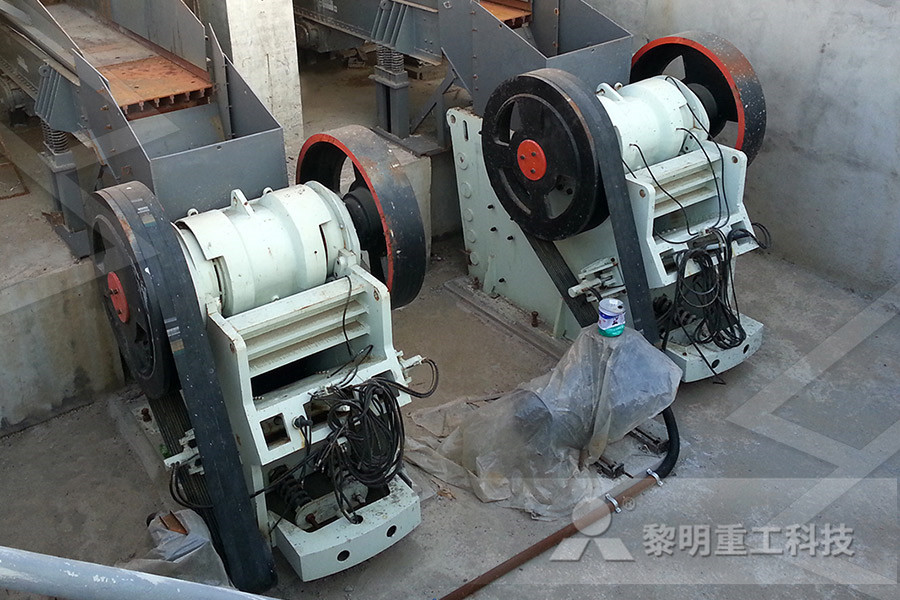

High Quality High capacity ke Rock Jaw crusher