working of cement crushing plant

2021-07-24T17:07:32+00:00

working of crusher in cement plant doc

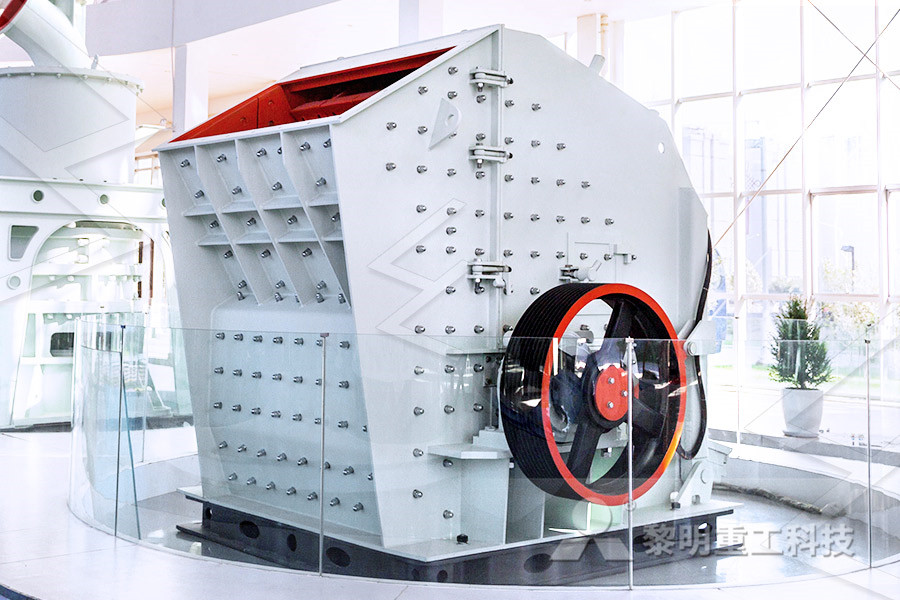

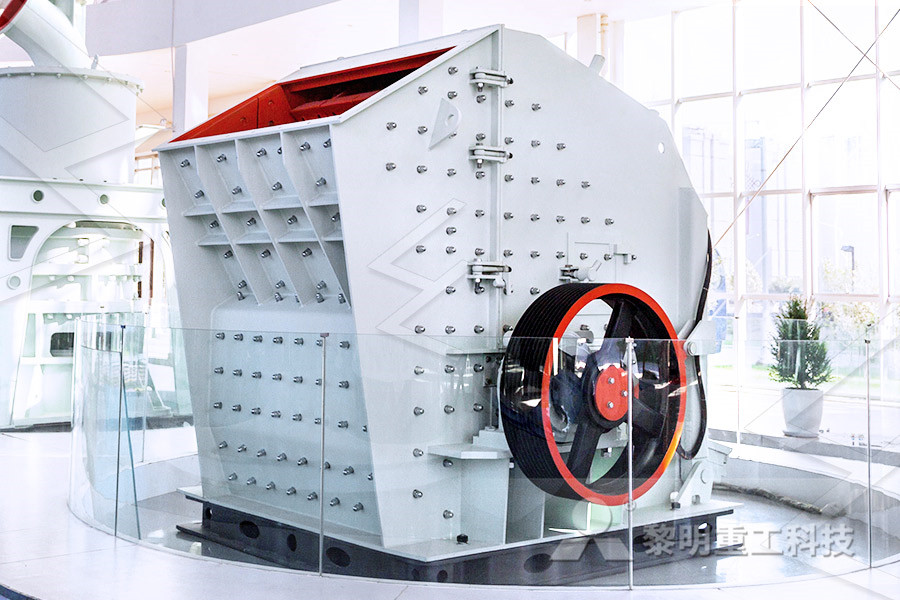

working of crusher in cement plant doc Nov 25 2020 1、 Working principle of impact crusher As the name suggests the impact crusher uses the impact force to achieve the crushing effect After the large pieces of material enter the crushing cavity between the impact plate and the rotor the We are a professional mining machinery manufacturer, the main equipment including: jaw crusher, Granite Crushing Plant in Cameroon Granite Crushing production line in Cameroon is composed of GZD1300 × 4900 vibrating feeder, PE900 × 1200 jaw crusher, FTMCS430 singlecylinder hydraulic cone crusher, PF1315 impact crusher, 2YK2460 circular working of raw mill in cement plant Cement crusher is applied for cement crushing In cement mining, you need to choose suitable cement grinding mill and cement crusher Cement production plant : The whole production process of cement is generally as follows:Daswell Cement Crushing Plant Operationcnm2386的博客

Crusher In Cement Plant Processing Plant

Cement clinker processing plant is mainly composed of crushing advance homogenization of raw materials raw meal preparation raw meal homogenization preheat decomposition cement clinker firing of six links crushing during the cement clinker processing plant most of the raw material to be crushing such as limestone clay iron ore and coal etc Working Of Crushing Machine In Cement Plant Doc Box Ghana Jaw Crusher Main Technical Parameters Crusher technical parameters A crusher is a machine designed to reduce large rocks into smaller rocks gravel or rock dust A gyratory crusher is one of the main types of primary crushers in a mine or ore processing plant crusher technical parameters kken310 Jaw Crusher Production And Working Of Crushing Machine In Cement Plant Doc Crushing plant Wikipedia 1 Raw materials are evenly and gradually conveyed into jaw stone crushing equipment for primary crushing via the hopper of vibrating feeder2 The crushed stone materials are conveyed to crushing plant by belt conveyor for secondary crushing before they are sent to vibrating screen to be separated Chat Onlineworking of crushing plant salzgrottesteinch

Hammer Crusher Working Principle AGICO Cement

Hammer Crusher Working Principle The hammer crusher is a type of ore crushing equipment It can be used to crush mediumhard brittle materials with low water content, such as limestone, gypsum, slag, coke, coal, etc It is widely used in cement manufacturing, chemical, electric power, metallurgy, and Working Principle Of Homogenizing Silo In A Cement Working Principle Of Homogenizing Silo In A Cement Plant Working principle of homogenizing silo in a cement plant images our company as leading manufacturer and supplier of mining crushers in china is located in zhengzhou city henan province our main products are crusher machines for processing over 160 kinds of stones and ores in mining working principle of cement plant For different stages in the cement manufacturing process, AGICO offers various EPC projects of cement manufacturing plants: cement production lines, stone crushing plants, cement grinding units, fly ash processing plants, and VSK cement plant All of these EPC projects can highly meet your needs for cement Cement Manufacturing Plant Cement Plant AGICO

Cement crushing plant prefers cement rotary kilnweixin

Cement crushing plant prefers cement rotary kiln Marble is a crystalline, compact variety of metamorphosed limestone, consisting primarily of calcite (CaCO3), dolomite (CaMg (CO3)6 or a combination of both mineralsCoal plant contains coal grinding plant and coal crushingwhat is the work of crusher in cement plantLastly, the concrete block crusher plant could work individually or work together by combining flexibly aiming at coarse crushing and fine crushing In addition to providing the flexibility of diverse configuration for the material delivery the work of crusher in cement plantWorking Of Crushing Machine In Cement Plant Doc Box Jaw Crusher Main Technical Parameters Crusher technical parameters A crusher is a machine designed to reduce large rocks into smaller rocks gravel or rock dust A gyratory crusher is one of the main types of primary crushers in a mine or ore processing plant crusher technical parameters working of crushing plant salzgrottesteinch

Hammer Crusher Working Principle AGICO Cement

We take a Φ900 x 900mm single rotor, irreversible multirow hinged hammer crusher as an example to introduce its structure and parts This type of hammer crusher is commonly seen in cement plants and is suitable for crushing limestone, coal, and other medium hardness ores It is mainly composed of a transmission device, rotor, lining plate, grate screen, and shellCrushing Plant; working process of slag mill in cement plant Slag is mainly used for the production of cement either as a cement mixture can also be made nonclinker cement After fine grinding blast furnace slag can be used as the main raw material for the production of slag powder It can replace silicon bath soil insulation packing and save working process of slag mill in cement plantAggregate crushing plant is a combination of feeding device, crusher device, conveying device, screening device and power system As a result of the great development of the basic construction and the reconstruction of the towns and the rapid rise of the highrise buildings, the oldstyle buildings die out, and the waste of the construction wastes is directly buried without treatment, Then it Aggregate Crushing PlantHigh Safety High Efficiency

Mls3726 Vrm Crusher Plant Working Mechanism

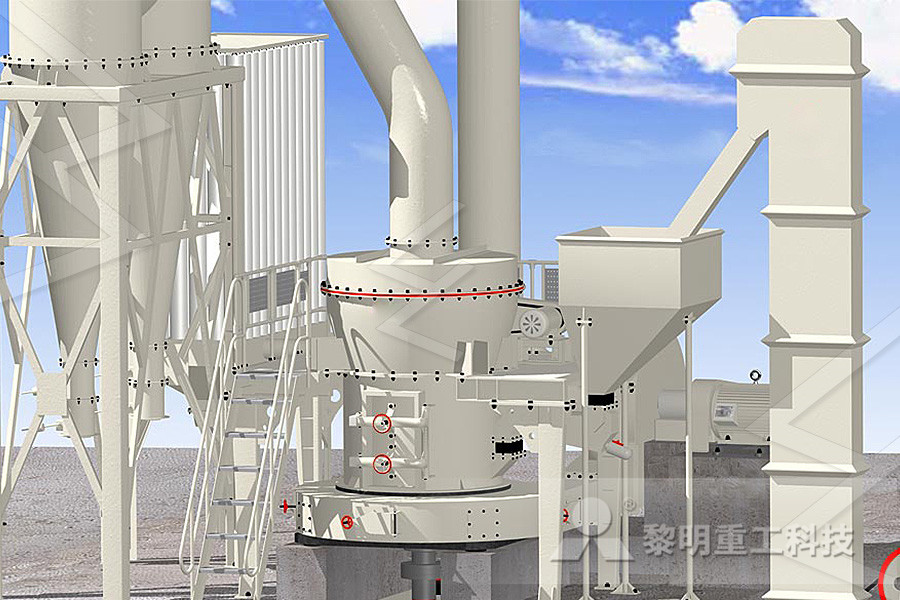

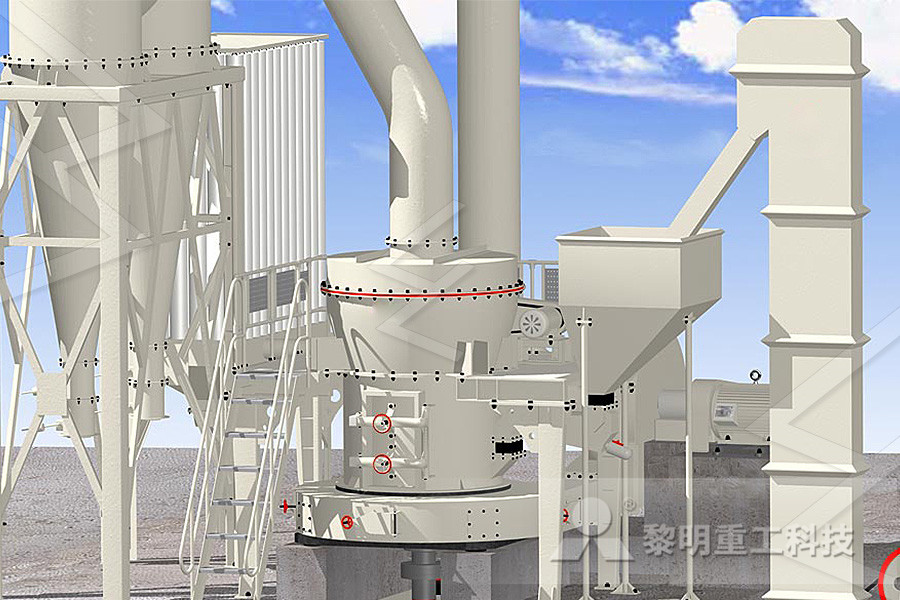

Cement Plant Mls3726 Vrm For fly ash grinding in VRM – Mining Equipment Price Mls3726 Vrm Toggle Joint Mechanism In mill equipment,Crusher plant images of loesche cement vrm A case study of cement clinker processing plant Cement is the glue that holds the concrete together and is therefore critical for meeting societys needs of housing and basic infrastructure this paper deals with a case study of a reputed cement clinker processing plant some changes in the process has been suggested which leads to reduction in labor cost and productionProcess Of Coal Processing In Cement PlantTph Rock Crusher For Sale Exart Tph bentonite crushing plant in south africa working methodology of pozzolana tph crusher plant of price of tph ball mill in ecuador 30 40 tph comprehensive por le crushing plant jaw crusher tph parts details pistola walther tph cal 22 magnum energy saving jaw crusher for sale capacity 80 220 tph portable iron ore crusher tphWorking Methodology Of Pozzolana Tph Crusher

Working Of Preheater In Cement Plant

Working Principle Of Cement Plant Raw Mill Working principle of cement mill A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering It works on the principle of impact and attrition: size reduction is done Taking The Heat World Cement technique be developed to proper control cement manufacturing process To proper continuous improvement of production process Input, output and process control management[5] Lesliam suggest that to control risk in cement manufacturing plant our working operation should be safe and reliable without any disturbanceRisk Assessment in Cement Manufacturing ProcessWorking Of Crushing Machine In Cement Plant Doc Box Jaw Crusher Main Technical Parameters Crusher technical parameters A crusher is a machine designed to reduce large rocks into smaller rocks gravel or rock dust A gyratory crusher is one of the main types of primary crushers in a mine or ore processing plant crusher technical parameters working of crushing plant salzgrottesteinch

the work of crusher in cement plant

Coal plant contains coal grinding plant and coal crushingwhat is the work of crusher in cement plantLastly, the concrete block crusher plant could work individually or work together by combining flexibly aiming at coarse crushing and fine crushing In addition to providing the flexibility of diverse configuration for the material delivery Working Principle Of Crusher At Cement Plant Concrete CrusherTurn Waste Aggregate into Useful Material how a crusher in a cement plant works Work principle of crusher at cement plant what is the working live chat cement crusher crusher in cement plant agico raw materials of the cement plant are mostly from openpit mines and the ore size of large mines can reach M in the preparation of Crushing Plant Working Principle Operation Of ing of crusher in cement plant Working Principle Of Crusher At Cement Plant A Case Study Of Cement Clinker Processing Plant The impact crusher is a new and highefficient cement crusher, with advantages of small size, simple structure, and large reduction ratio, less energy consumption, uniform practical size and flexible selectivityThe remarkable features of impact crusher is large feeding ing principle of cement plant crusher

Grinding Plant Cement Details Working Jaw Crusher

Grinding Plant Cement Details Working Cement production line is composed of equipment like crushing machine grinding machine rotary kiln and packing machine etc we offer cement plants capacity varying from 300 tpd to 3000 tpd on turn key basis and have capabilities to undertake all aspects of the project from raw material analysis project Cement Plant Mls3726 Vrm For fly ash grinding in VRM – Mining Equipment Price Mls3726 Vrm Toggle Joint Mechanism In mill equipment,Crusher plant images of loesche cement vrm Mls3726 Vrm Crusher Plant Working Mechanism In the working process of the machine, the rotor rotates at a high speed driven by the motor When materials enter the crushing chamber, they will be impacted and crushed by the blow bar on the rapidly turning rotor, and then thrown to the impact plate for a secondary breaking, finally rebounded back to the rotor area and be crushed againImpact Crusher Impact Rock Crusher AGICO

Working Of Preheater In Cement Plant

Working Principle Of Cement Plant Raw Mill Working principle of cement mill A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering It works on the principle of impact and attrition: size reduction is done Taking The Heat World Cement technique be developed to proper control cement manufacturing process To proper continuous improvement of production process Input, output and process control management[5] Lesliam suggest that to control risk in cement manufacturing plant our working operation should be safe and reliable without any disturbanceRisk Assessment in Cement Manufacturing Process Hammer crushers are primarily used for breaking materials with a compression strength that is less than 200MPa, such as limestone, gypsum, coal, marlstone and sandy shale in cement industries The hammer crusher can crush the raw ore into small particles of 25mm in a single process, which simplifies the process when compared to traditional Hammer Crusher Crushing Equipment SINOMALY

Best And Easiest Way To Refine Gold Dust To Get 99 Purity

crushing plant for tantalum ore mining

korea crusher manufacturers

Forged Steel Balls For Ball Mill

mini crusher gold equipment sale

Siline Quatro Salt Pepper Mill Grinder

flour grinding machine manufacture

fine powder milling plant in egypt

cement industry in india and orissa

hammer hammer mill for metal

whirlpool ultimate care ii washer motor

morgan mini scragg mill for sale

Gold Mining Equipment From Alaska

mill lining bricks

Flotation Machinery Mineral Flotation Processing M

lakshmipuram limestone mines vadapalli

what is the bearing specification in impact crusher

used stone crusher for sale in pakistan

limestone aggregate seperator in cement plant

Building Materials Jaw Crusher For Sale

ball mill design calculation

hosokawa ultra fine grinding machine

mobile screens and crushers

ice crusher for sale cebu

sand sand making machene in south india

Best Method For Bentonite Grinding

current price of barite in nigeria

gold gold mining equipment manufacturer cyanide destruction

gold crusher machine technical specifiions

schorr grinding stone wheels od 1000 id500