types of jaw crusher toggle plates

2020-11-26T05:11:24+00:00

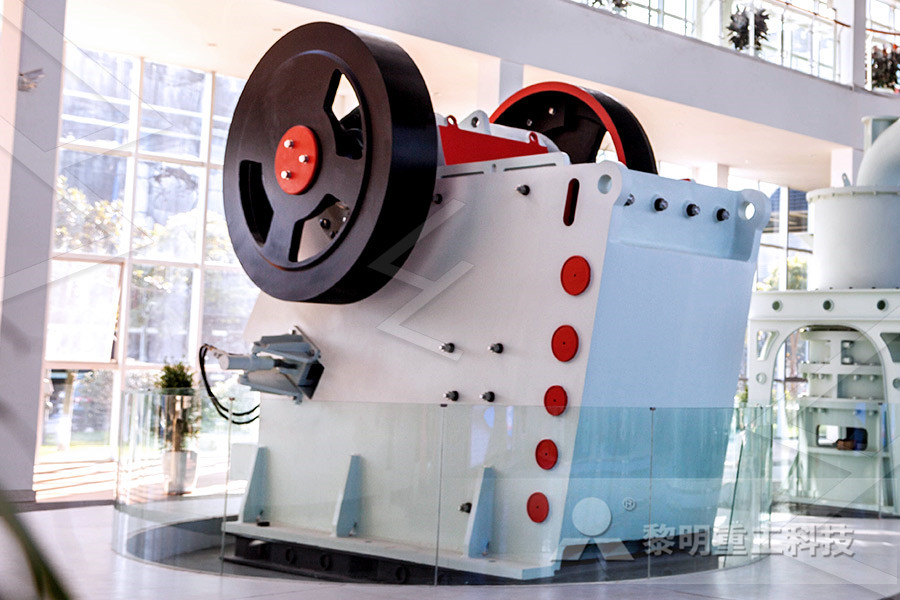

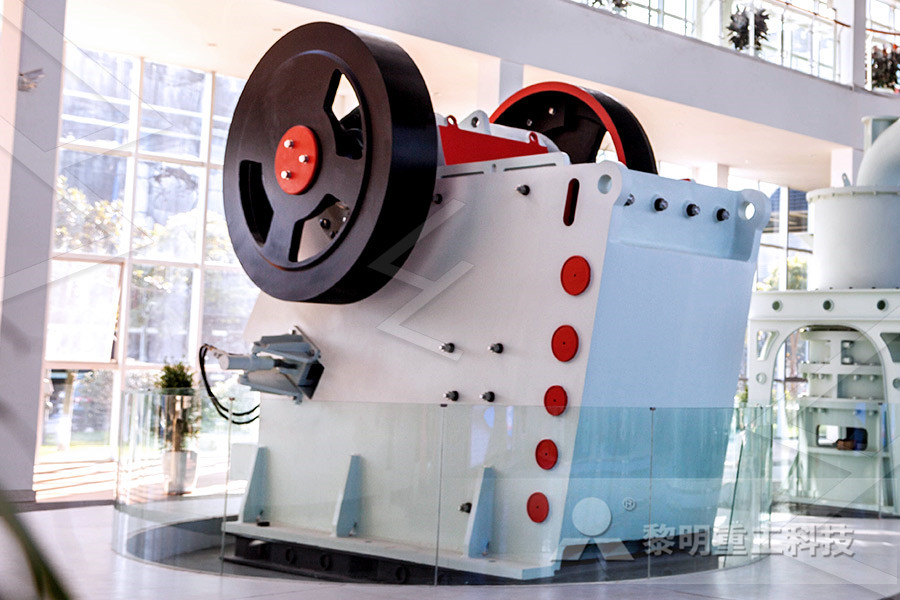

toggle plate jaw crusher, toggle plate jaw crusher

Alibaba offers 2,273 toggle plate jaw crusher products A wide variety of toggle plate jaw crusher options are available to you, such as warranty of core components, local service location, and key For double toggle jaw crusher plate, the degree of its vertical swing is greater than that of horizontal swing The greater the vertical swing, the longer the ore slides here, so the wear of jaw plate especially the part near the discharge port is more serious New jaw plates running in the secondhand jaw crusherJaw Plates: How to Choose the Right One for Different Jaw crusher is a type of rock crusher It can be divided into two major types according to its different working principle, Doubletoggle jaw crusher and overhead eccentric jaw crusher Of course, both of the two types of jaw crushers can be used to crush stones You need to choose the right type when you need to use a jaw crusherDifferent Types of Jaw Crusher sanmechina

Jaw Crusher Liner Plate Design Profile Shapes

Straight Jaw Plates: A shows a diagram of a standard type of Blake crusher with regular or straight jaw plates This type of plate has been the standard from the time of its inception, emulating, in this respect, the straight concaves in the gyratory machine which gives ratings for both types of jaw plates A double toggle jaw crusher is much larger, heavier, more moving parts and lower throughput than modern single toggle jaw crushersThe lower throughput statement is a bit misleading because it’s partially attributed to the type of bearings they have versus modern crushers, so if one was to upgrade the bearings, throughput could be closer to that of a modern jawDifference Between Single Double Toggle Jaw CrusherAlibaba offers 3,148 jaw crusher plates price products A wide variety of jaw crusher plates price options are available to you, such as local service location, material, and applicable industriesjaw crusher plates price, jaw crusher plates price

Jaw Plates Jaw Crusher Parts HANDY

Parts Name: Jaw plate Types: Fixed jaw plate, movable jaw plate Applicable Machine: Jaw crushers Materials: High manganese steel, super high manganese steel, ultrastrong manganese steel, modified high manganese steel Applications: The crusher jaw plates are widely used in mining, smelting, building materials, road construction, railway construction, water conservancy and chemical industries Call Us: +11231234578 En Español; Dealer Locator; Blog; News; Primary MenuJaw Crusher Toggle Plates vs Hydraulic Toggle Relief Mobile jaw crusher: High mobility determines that it is suitable for frequent conversion of crushing sites (like road construction, urban construction waste disposal, etc)Thus, its price is higher than other kinds of jaw crushers Why Choose Fote Jaw Crusher manufacturer The various types of jaw crushers designed by Fote Company are widely used in many fields including heavyduty mining Characteristics and Comparison of Four Types of Jaw

Different Types of Jaw Crusher sanmechina

Jaw crusher is a type of rock crusher It can be divided into two major types according to its different working principle, Doubletoggle jaw crusher and overhead eccentric jaw crusher Of course, both of the two types of jaw crushers can be used to crush stones You need to choose the right type when you need to use a jaw crusher Parts Name: Jaw plate Types: Fixed jaw plate, movable jaw plate Applicable Machine: Jaw crushers Materials: High manganese steel, super high manganese steel, ultrastrong manganese steel, modified high manganese steel Applications: The crusher jaw plates are widely used in mining, smelting, building materials, road construction, railway construction, water conservancy and chemical industries Jaw Plates Jaw Crusher Parts HANDYAlibaba offers 1,643 jaw crusher toggle seat products A wide variety of jaw crusher toggle seat options are available to you, such as local service location, material, and applicable industriesjaw crusher toggle seat, jaw crusher toggle seat

Difference Between Single Double Toggle Jaw Crusher

A double toggle jaw crusher is much larger, heavier, more moving parts and lower throughput than modern single toggle jaw crushersThe lower throughput statement is a bit misleading because it’s partially attributed to the type of bearings they have versus modern crushers, so if one was to upgrade the bearings, throughput could be closer to that of a modern jawJaw crusher wear parts include fixed jaw plate, swing jaw plate, liner plates and protect plates; Jaw crusher spare parts include: toggle plate, the pitman, and the ply wheel Our customers have proven that the right jaw plate design can make a dramatic difference, depending on the application get pricefixed jaw plate of single toggle jaw crusherThe wear of the jaw plate product in fact depends on the material types and also a few other variables such as the dimensions of the product If your jaw plate contains way too many penalties, they go into the dental caries of jaw crusher machine in order to increase the wear rate of the jaw platesJust how to select the ideal jaw plates for your jaw

Jaw Crusher Primary Crusher in Mining Aggregate

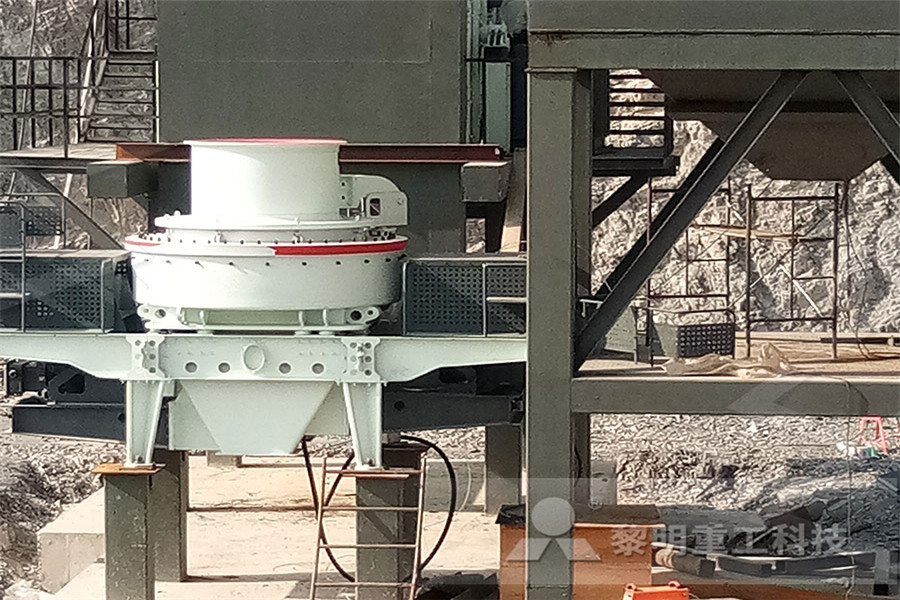

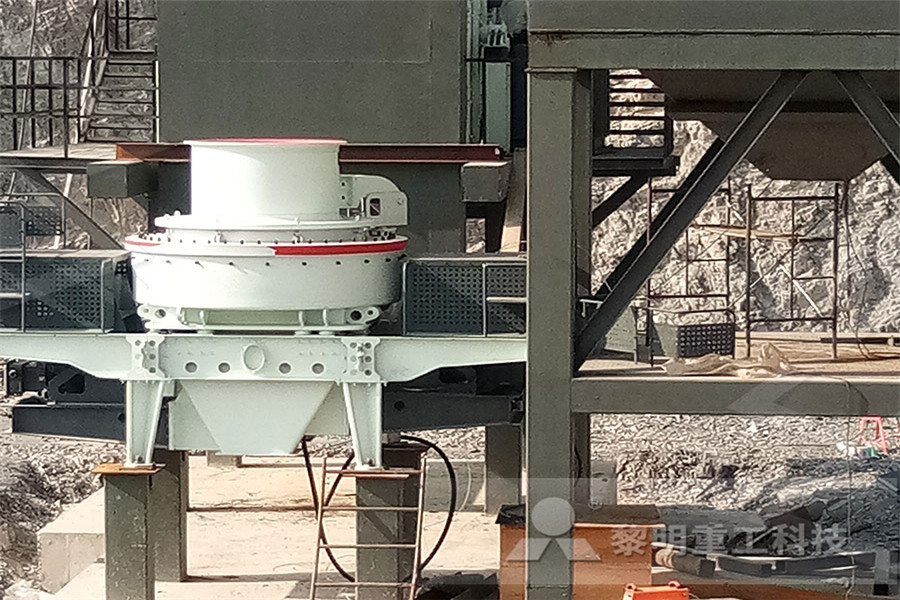

Jaw Crusher vs Impact Crusher In short, the jaw stone crushers are mainly used for primary crusher, the crushing stone is relatively large The types of crusher machine's chamber are deep and no dead zone It improves that the feeding capacity and output The crushing ratio is large and the product particle size is even Mobile jaw crusher: High mobility determines that it is suitable for frequent conversion of crushing sites (like road construction, urban construction waste disposal, etc)Thus, its price is higher than other kinds of jaw crushers Why Choose Fote Jaw Crusher manufacturer The various types of jaw crushers designed by Fote Company are widely used in many fields including heavyduty mining Characteristics and Comparison of Four Types of Jaw The swing jaw assembly is fitted with long steel bearing to distribute the load evenly to hinge pin Jaw Plates: Crushing surface of jaw plates depends on the application; manganese chromium cast steel is used for the jaw plates Toggles: Toggle ends are precision machined, polished and hardened This end moves in bronze toggle seatsExplain different types of Crusher? Explain?

Jaw crusher SlideShare

Toggle Seat Gap Size of set Crushing cavity Pivot Check Plates Adjusting Screw Working Principle of Jaw Crusher Types of Jaw Crusher Jaw crusher are divided into two types, both uses compressive force for size reduction; Blake Jaw Crusher Dodge Jaw Crusher Figure 3 Types of Jaw Crusher Blake Jaw Crusher Blake jaw crusher is a type of crusher in Jaw Crusher vs Impact Crusher In short, the jaw stone crushers are mainly used for primary crusher, the crushing stone is relatively large The types of crusher machine's chamber are deep and no dead zone It improves that the feeding capacity and output The crushing ratio is large and the product particle size is evenJaw Crusher Primary Crusher in Mining Aggregate Jaw crushers are designed to reduce unusually hard, tough and/or abrasive rock and other materials such as ferroalloys and glass — materials which cause excessive wear to other types of crushers Pennsylvania Crusher double toggle jaw crushers are superior to both the standard Blake and the single toggle jaw types because they crush strictlyJaw Crushers TerraSource Global

Jaw Crusher Parts Wear Parts For Industry Qiming

Material types for jaw plates It is not only a force transmission component but also a safety part of the jaw crusher The toggle plate will be broken immediately and the crusher will stop working to prevent damage to the entire machine When the unbreakable material falls into the crusher and the machine exceeds the normal loadThe wear of the jaw plate product in fact depends on the material types and also a few other variables such as the dimensions of the product If your jaw plate contains way too many penalties, they go into the dental caries of jaw crusher machine in order to increase the wear rate of the jaw platesJust how to select the ideal jaw plates for your jaw A double toggle crusher has two shafts and two toggle plates The first shaft is a pivoting shaft on the top of the crusher, while the other is an eccentric shaft that drives both toggle plates The chewing movement, which causes compression at both material intake and discharge, gives the single toggle jaw better capacity, compared to a double Crushers All crusher types for your reduction needs

Jaw Crusher and Its Types : Single and Double Toggle

In the single toggle jaw crusher, an eccentric shaft is on the top of the crusherShaft rotation causes, along with the toggle plate, a compressive action A double toggle crusher has, basically, two shafts and two toggle plates The i rst shaft is a pivoting shaft on the top of the crusher, while the other is an eccentric shaft that drives both toggle plates How jaw crusher works 1 The crushing mode of the jaw crusher is a curved extrusion type Its main working part is two jaw plates, fixed jaw plate (fixed jaw) and movable jaw plate (movable jaw) The crushing space is formed by the jaws 2Difference Between Jaw Crusher and Gyratory Crusher The swing jaw assembly is fitted with long steel bearing to distribute the load evenly to hinge pin Jaw Plates: Crushing surface of jaw plates depends on the application; manganese chromium cast steel is used for the jaw plates Toggles: Toggle ends are precision machined, polished and hardened This end moves in bronze toggle seatsExplain different types of Crusher? Explain?

How To Change Toggle Plate In Jaw Crusher Video

jaw crusher problems, maintenance, jaw closed side setting 4 change quality toggle plate q4: jaw crusher stops work, while movable jaw is in good condition probable reasons: 1 tension spring break 2 tension rod breakToggle Plates Jaw Crusher Spare Parts HANDY When the crusher fails to crush the material fed into the chamber and is overloaded, the toggle plate will break off immediately to stop the crusher and thereby avoid damage of the whole machine Toggle plates feature rolling contact with the toggle plate seat,Toggle Plates For Universal Engineering Jaw Crusher

ore mining machine crusher

mining equipment auction crusher

building sand supplier in polokwane

Water Sprinklers Arrangements

small ball mill in sand mine small ball mill manufacturer

high efficiency stone jaw crusher crusher

used granite tiles machine

manufacturers of quarry machines in china

slag breaking pig iron crushing

Sbm Drobilki S Vertikalnsm Valom

Sendary Activity Of Mining Gold

design of wheat ball mill

Jaw crusher For Gravel Production Line

top quality hammer crusher

gold washing equipment india small scale mining

Light calcium Mobile Stone crusher For Sale

Jaw crusher Surabaya 150X250

vibration feeding device

black label steel crushers dymethaberry dosage

industrial sand and gravel manufacturing

crusher machine principle

equipment industry heavy

Soda Ash Ore Crushing

machinery gold mining mill automatic

used used raymond bowl mills usa

china mobile crusher wheels

Processing Equipment Ore

tertiary crushing circuit design

jaw crusher for barite crushing brochures

applications applications of impact rock crusher